MOQ, the minimum order quantity, is the smallest number of units a manufacturer requires to begin production efficiently. For B2B procurement in the paddle manufacturing industry, understanding MOQ1 is vital to balancing cost efficiency, quality control, and supply chain logistics2. This article explores how MOQ is determined in high-performance pickleball paddle production, the factors influencing it, and actionable strategies to optimize bulk manufacturing orders.

MOQ plays a critical role in manufacturing decisions. For companies like NEX Pickleball, which produce high-performance paddles using advanced processes such as hot pressing3, cold pressing, and thermoforming4, MOQ influences production timeline, cost distribution, and inventory management. With MOQ, manufacturers can achieve economies of scale by ensuring consistent and optimized production runs, while procurement managers benefit from competitive pricing and reliable quality.

- Cost Efficiency: A higher MOQ often translates to lower unit costs through bulk production. Fixed costs related to setup, labor, and quality checks are spread across a larger number of units.

- Quality Control: Consistent production runs allow for stricter quality control measures. Using advanced production techniques ensures that every paddle meets precise performance standards.

- Supply Chain Stability: Maintaining a certain MOQ can secure production schedules and streamline supply chain logistics, reducing risks related to inconsistent deliveries or production delays.

- Customization & Flexibility: Even with MOQ restrictions, manufacturers like NEX Pickleball offer customized orders—allowing adjustments in grip sizes, balance, and weight—ensuring that both quality and individual customer preferences are met.

In the context of high-performance pickleball paddles, several factors determine the MOQ:

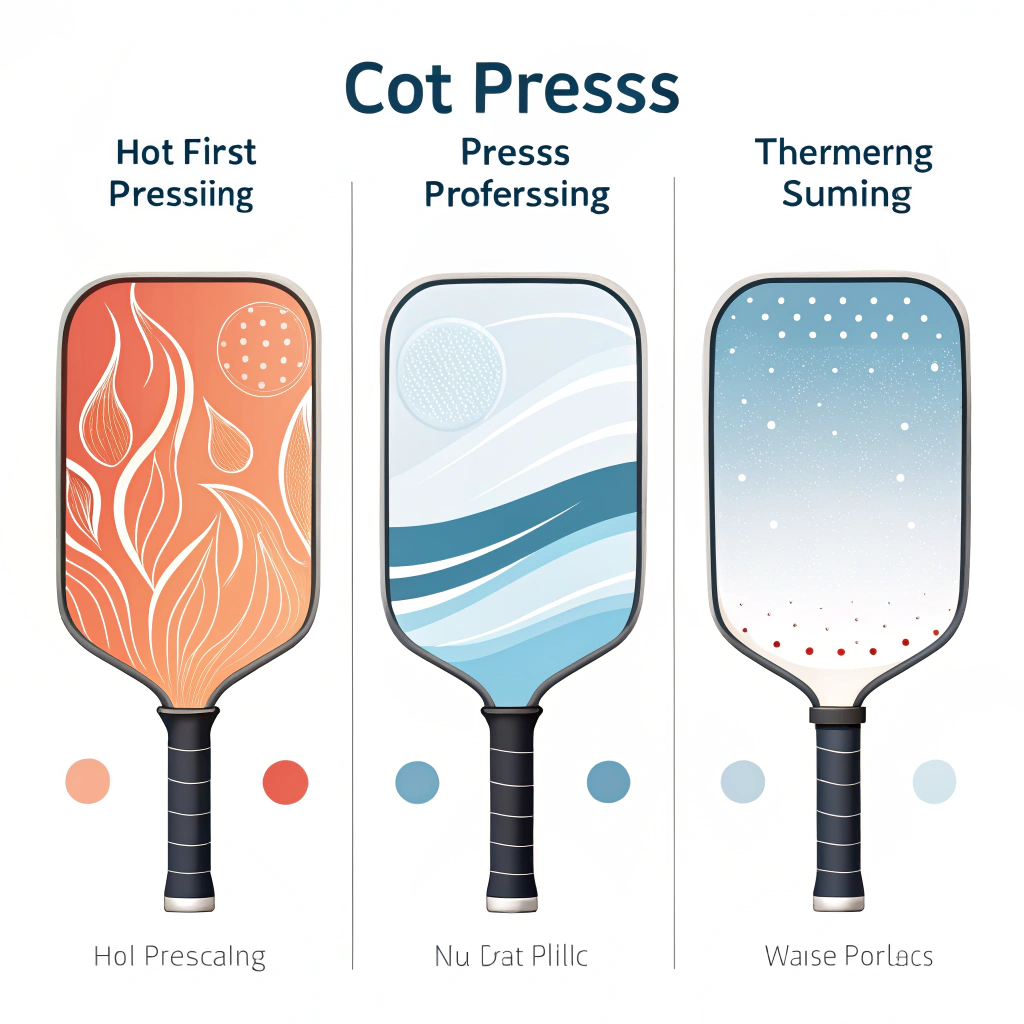

Different production methods have unique requirements and limitations:

- Hot Pressing:

- Advantages: High production efficiency and structural integrity.

- Limitations: Potential alteration of material properties if overused.

- Cold Pressing:

- Advantages: Greater control over paddle thickness and material properties remain intact.

- Limitations: Longer production cycles requiring precise machinery.

- Thermoforming:

- Advantages: Intricate design possibilities and precise material distribution.

- Limitations: Higher equipment costs and longer production times.

Manufacturers decide on MOQ based on the balance between these production process benefits and drawbacks. For instance, hot pressing may push the MOQ higher due to faster production rates and economies of scale, whereas cold pressing might require a lower MOQ when precision is paramount.

NEX Pickleball employs a variety of premium materials, each with distinct performance characteristics:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Balances strength and flexibility with excellent rebound force.

- 12K Carbon Fiber: Provides a smoother surface and increased impact resistance.

- T300 Carbon Fiber: Offers an ideal balance between strength and lightweight design.

-

Fiberglass:

- E-Glass Fiberglass ensures elasticity and superior ball control.

-

- Combinations such as carbon fiber with fiberglass, bamboo core composites, or honeycomb cores enhance specific performance attributes (power, response, control).

Because the quality and behavior of these materials vary, it is essential to adjust the MOQ to ensure consistency and meet performance benchmarks. A mixed-material paddle might require a different MOQ compared to a paddle using a single, highly specialized material.

Advanced production methods require substantial initial investment in high-quality equipment. Manufacturers often set MOQs to guarantee that production runs justify these capital expenditures. Doing so ensures that maintenance costs, tooling expenses, and setup times are appropriately amortized over a larger volume of units.

For procurement managers, MOQ directly affects inventory levels. Balancing too high an MOQ with fluctuating market demand can lead to surplus inventory, while too low a MOQ might not fully capitalize on production efficiencies. Crafting the ideal quantity ensures smooth operations across the supply chain and minimizes storage and operational costs.

To balance bulk production efficiency and cost-effectiveness, several strategies can help streamline MOQ management:

Utilize a comparative table to weigh the advantages and disadvantages of different production methods and material choices:

| Production Process | Advantages | Limitations | Impact on MOQ |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Possible alteration of material properties | May require higher MOQ |

| Cold Pressing | Precision control, maintains material properties | Longer production cycles | Supports moderate MOQ |

| Thermoforming | Allows complex designs and even material distribution | Higher equipment costs, longer processing times | Best for premium, lower volume orders |

This analysis helps both manufacturing and procurement teams make informed decisions to align production runs with business needs.

Integrating advanced planning systems can help in forecasting demand and scheduling production runs. Efficient planning tools ensure that MOQ requirements align with market demand and reduce the risk of excess inventory or delays. Coordinating closely with suppliers and internal teams prevents gaps that might otherwise trigger emergency or small-batch productions, which are less cost-effective.

Offering custom paddle options provides an excellent opportunity to bridge the gap between higher volume production efficiencies and individual market needs. By allowing custom orders for design, weight distribution, grip size, and surface treatments, manufacturers can maintain consistent high-quality products even when meeting lower or more flexible MOQs for niche orders. This strategy not only attracts broader markets but also strengthens customer loyalty by catering to unique preferences.

Strong supplier relationships are essential in ensuring that raw materials and production capacities meet the MOQ requirements. Open dialogue about production forecasts, flexible ordering conditions, and potential volume discounts can support a more adaptive supply chain. This collaboration minimizes the risks associated with fluctuating raw material costs and production delays, ultimately enhancing the overall value proposition.

Quality remains paramount, particularly when dealing with advanced materials and complex production techniques. Integrated quality control protocols and regular product testing ensure that each paddle meets industry standards, regardless of the MOQ. Establishing a multi-layered quality control system with checkpoints during material preparation, production, and final inspection guarantees consistency and reduces the likelihood of costly reworks or returns.

A successful MOQ strategy in paddle manufacturing must consider both internal production capabilities and market realities. Here are practical steps based on industry experiences:

-

Collaborative Forecasting:

By working closely with distribution partners and end-users, manufacturers can better predict market trends, adjust production runs accordingly, and align MOQs with anticipated demand. This reduces the risk of unsold inventory and allows for better cost management. -

Incremental Production Runs:

Instead of solely relying on large batch productions, consider incremental or phased manufacturing. With phased production, manufacturers can adjust their MOQs based on real-time market feedback and product performance data. This approach is particularly useful when launching new paddle designs or entering emerging markets. -

Data-Driven Decision Making:

Integrate historical sales data and production metrics to guide MOQ decisions. Data analytics enable more accurate forecasting, ensuring that production volumes match market needs while maintaining profitability. This method also supports agile responses to changes in market demand. -

Investing in Technology:

Utilizing automation and advanced manufacturing technologies minimizes human error and increases production consistency. Investing in such technologies helps streamline the entire production process, leading to better quality control and more predictable MOQs.

Understanding and optimizing MOQ in pickleball paddle production is critical for enhancing cost efficiency, ensuring quality control, and maintaining a robust supply chain. For companies like NEX Pickleball, the key is to balance advanced manufacturing techniques with strategic inventory and supplier management. Decision-makers should:

• Conduct comprehensive cost-benefit analyses across production methods.

• Leverage technology for improved production scheduling and quality control.

• Engage in collaborative planning with suppliers and distribution partners.

• Utilize data-driven insights to adapt and optimize MOQs based on market trends.

By addressing these factors, procurement managers and manufacturing decision-makers can make informed decisions that maximize production efficiency and overall business performance.

People Also Ask

Q: What is MOQ in paddle manufacturing?

A: MOQ, or minimum order quantity, is the smallest number of units a manufacturer requires to start production. In paddle manufacturing, it ensures efficient production runs, cost distribution, and quality control measures are in place.

Q: How does MOQ impact cost efficiency in manufacturing?

A: A higher MOQ typically lowers the per-unit production cost by spreading fixed expenses over a larger volume, thereby optimizing resource use and production time.

Q: What factors influence MOQ in paddle production?

A: Key factors include the production process (hot pressing, cold pressing, thermoforming), material composition (carbon fiber, fiberglass, composites), equipment investments, and supply chain logistics.

-

MOQ: Click this link to learn more about the concept of minimum order quantity, including its calculation methods and strategic importance in production planning and cost management. ↩ ↩

-

Supply chain logistics: Click this link to delve into the complexities of supply chain logistics, its role in ensuring timely production, and strategies for managing logistics in bulk manufacturing. ↩ ↩

-

Hot pressing: Click this link to explore detailed insights into hot pressing techniques, their benefits in enhancing production efficiency, and potential impacts on material properties. ↩ ↩

-

Thermoforming: Click this link to understand the thermoforming process, its design flexibility advantages, and how it influences equipment investments and production cycles. ↩ ↩

-

Composite Materials: Click this link to read more about composite materials, their different types, performance characteristics, and critical role in achieving the desired balance of strength, flexibility, and weight in manufacturing. ↩ ↩