Transparent and printed packaging each offer distinct advantages for pickleball paddle bags, and selecting the right option depends on your priorities for branding, product protection, and cost. In this article, we compare both options in detail to help you make an informed procurement1 decision.

When choosing packaging for pickleball paddle bags, B2B buyers must consider multiple factors—brand exposure, material quality, production cost, and end-user protection. Transparent packaging offers a clear view of the product, enhancing consumer trust through visibility and simplicity. In contrast, printed packaging elevates brand identity, allowing you to incorporate custom graphics, logos, and detailed product information that reinforces your marketing strategy.

Selecting the ideal packaging solution is not merely a design choice; it is a strategic decision that impacts product perception and overall market success. Read on to understand the various aspects you should consider:

-

Transparent Packaging:

-

Advantages:

• Provides clear visibility of the product, which can instill trust and allow the consumer to appreciate quality at first glance.

• Reduces printing costs and production complexity, making it a more cost-effective option for some projects.

• Ideal for companies with established brand recognition that do not require heavy branding on the packaging. -

Disadvantages:

• Limited space for branding or marketing messages as the package is largely see-through.

• Less customization might leave less room for storytelling and emotional appeal.

-

-

Printed Packaging:

-

Advantages:

• Creates a powerful branding opportunity by allowing customized designs and vibrant colors.

• Enhances product presentation and provides additional marketing space to communicate product benefits and brand values.

• Offers private labeling2 options that can be tailored for team branding or retail distribution. -

Disadvantages:

• Potentially higher production costs due to printing processes and design requirements.

• May reduce the immediate product visibility if not designed effectively, potentially affecting buyer confidence.

-

-

Transparent Packaging:

- Typically made using high-quality plastic materials that ensure protection during transport and display.

- Can be engineered to offer excellent shock absorption and resistance against wear and tear.

-

Printed Packaging:

- Often constructed from coated cardboard or laminated materials that provide robust protection against external impacts.

- The printing process may include protective coatings that enhance durability and resistance to moisture and abrasion.

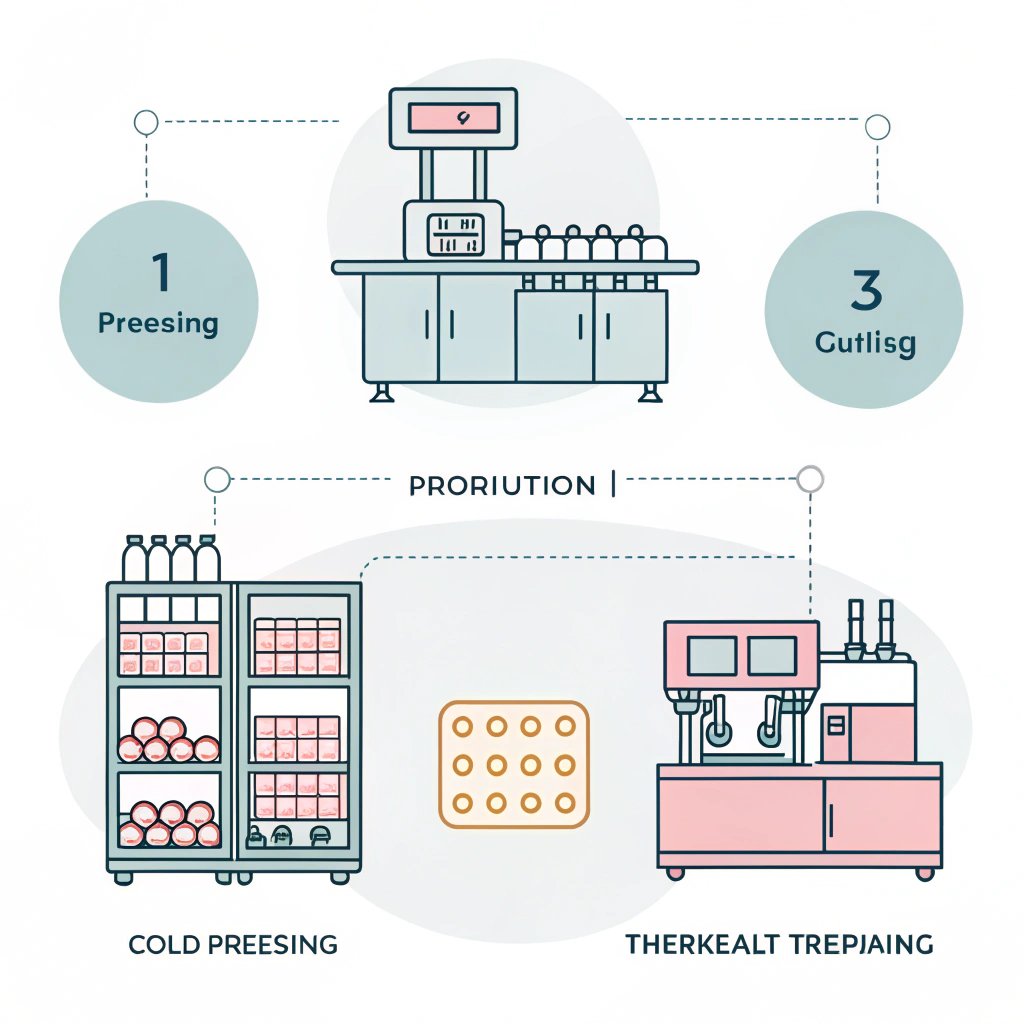

Manufacturers like NEX Pickleball, known for their robust production processes such as hot pressing3, cold pressing4, and thermoforming5, tailor product packaging to ensure both aesthetic appeal and product safety. These processes are crucial in maintaining the structural integrity of both transparent and printed packaging options.

-

Transparent Packaging:

- Lower production costs due to minimal processing and design work.

- Faster manufacturing cycle time since there is no need for complex printing setups.

-

Printed Packaging:

- Higher upfront production costs because of design, printing, and potential material waste.

- The cost may be offset by the added value of brand reinforcement and enhanced shelf impact.

-

Transparent Packaging:

- Limited customization since the material is naturally see-through.

- Best suited for products where the physical look of the paddle bag itself is a selling point, particularly when paired with distinctive paddle designs.

-

Printed Packaging:

- Highly customizable, allowing for detailed artwork, barcode placement, product information, and even use of eco-friendly inks.

- Ideal for companies that want to create a holistic promotional experience.

A side-by-side look at core differentiators helps illustrate these points more clearly.

| Feature | Transparent Packaging | Printed Packaging |

|---|---|---|

| Brand Visibility | High – Product is visible, builds trust | Moderate – Branding relies on design and print quality |

| Design Impact | Clean and minimalistic | Detailed and customizable for strong branding |

| Material and Durability | High-quality transparent plastics provide robust protection | Coated cardboards or laminates offer impact resistance and moisture protection |

| Production Cost | Lower overall cost with faster production cycles | Higher cost due to printing setup and design work |

| Customization Options | Limited – Focuses on the product inside | Extensive – Custom prints, logos, and marketing messages |

| User Perception | Enhances perceived product quality by showcasing the item | Strengthens brand identity through visual storytelling |

| Environmental Impact | Depends on plastic quality; recycling options vary | Often uses recycled materials and eco-friendly coatings |

Both packaging types benefit from advances in production methodologies. For example, companies like NEX Pickleball utilize advanced manufacturing techniques. Understanding their production processes can provide additional insights:

-

Application: Frequently used in high-volume production to ensure durability and strength.

-

Pros:

• High production efficiency

• Great impact resistance and consistent product quality -

Cons:

• Potential changes in material properties

• Requires significant investment in high-end equipment

-

Application: Ideal for designs that require precise control over package thickness and texture.

-

Pros:

• Maintains natural material properties

• Offers excellent control and customized feel -

Cons:

• Longer production cycles

• Demands precise equipment which can increase operational complexity

-

Application: Best suited for packaging with complex shapes and tailored thickness.

-

Pros:

• Enables intricate design and precise material distribution

• Maintains overall package stability -

Cons:

• Longer production cycles

• Higher production costs, usually reserved for premium product lines

Understanding these production techniques allows you to choose the packaging that not only meets branding requirements but also ensures robust product protection during the distribution cycle.

Consider the context of your brand and target market when deciding between transparent and printed packaging. Here are some strategic insights based on real-world applications:

-

Enhanced Customer Trust vs. Brand Storytelling:

Transparent packaging is particularly effective in environments where product integrity is paramount. Consumers can see exactly what they are getting, which builds immediate trust. Conversely, printed packaging is an opportunity to narrate your brand’s story and highlight unique selling points, ultimately creating a memorable unboxing experience. -

Market Differentiation Through Customization:

In highly competitive B2B markets, customization can differentiate your product. Printed packaging allows you to incorporate company logos, team colors, and unique design elements that set you apart. This can be invaluable in retail settings or when targeting specific demographics. -

Cost Management and Budget Control:

For cost-sensitive procurement, transparent packaging may be the preferred choice, reducing both production expenses and lead times. However, if your brand positioning is tied to a premium experience, the higher cost of printed packaging may be justified by the perceived added value and enhanced market presence. -

Operational Efficiency:

Evaluate your current production flow. Transparent packaging generally has simpler manufacturing steps, which might align better with high-volume, rapid-turnaround orders. Printed packaging, though complex, can be run efficiently if pre-approved designs and templates are in place.

These considerations underscore the importance of aligning your packaging decision with both your operational capabilities and strategic brand objectives.

To maximize the benefits of your chosen packaging type, consider these best practices:

-

Conduct Market Research:

Understand your target audience’s preferences. Survey end users and obtain feedback on packaging design to determine which option resonates more effectively with their expectations. -

Collaborate with Manufacturing Experts:

Work closely with experienced manufacturers like NEX Pickleball who can advise on production processes and material selection. Their insights on hot pressing, cold pressing, and thermoforming can save you time and costs in the decision-making process. -

Integrate Sustainability Practices:

Consider the environmental impact of your packaging materials. Explore options that utilize recycled plastics or eco-friendly coatings, especially when opting for printed packaging. Highlighting sustainable practices can be a strong selling point in today’s market. -

Prototype and Test:

Before finalizing bulk orders, develop prototypes of your packaging. Testing for durability, user convenience, and aesthetic appeal allows you to make adjustments proactively, ensuring that the final product meets expectations in real-world conditions. -

Monitor and Evaluate:

Post-launch, continuously monitor customer feedback and return on investment. This data can help refine your packaging strategy for future orders and keep you ahead of market trends.

In summary, the choice between transparent and printed packaging for pickleball paddle bags hinges on your specific business goals.

- Transparent Packaging is ideal if you are looking for cost-effective solutions that prioritize product visibility and immediate consumer trust.

- Printed Packaging offers extensive customization opportunities, helping you build a robust brand identity and engage customers through detailed storytelling.

For procurement managers and sports equipment distributors seeking the right balance, it is crucial to align your packaging strategy with your overall marketing goals and production capabilities. Engage with your manufacturing partners early, invest in market research, and prototype extensively to ensure the optimal choice that meets both financial and branding objectives.

We invite you to leverage the expertise gained from our shared industry practices. With a clear understanding of the trade-offs and benefits provided by each packaging option, you’re well-equipped to make a strategic decision that enhances both your product protection and brand image.

Q: What pickleball bag do the pros use?

A: Professional players often use high-quality pickleball bags that offer both space and durability. For instance, the JOOLA Tour Elite Pro Pickleball Bag is recognized for accommodating all essential equipment, making it a popular choice among pros.

Q: Which material is better for pickleball paddles?

A: The choice between graphite and fiberglass depends on your performance needs. Graphite typically offers superior handling and a refined feel, while fiberglass provides more power, making it essential to evaluate your playing style and performance expectations.

Q: How do I choose a pickleball bag?

A: When selecting a pickleball bag, consider its capacity, the number and design of pockets for accessories, and overall durability. A good bag should comfortably accommodate at least two paddles and all necessary accessories, ensuring functionality and ease of transport.

-

procurement: Click here to explore how strategic sourcing and procurement practices can optimize cost management, supplier relationships, and overall supply chain efficiency. ↩ ↩

-

private labeling: Click here to learn about private labeling strategies, their benefits in market differentiation, and how they can enhance brand loyalty in competitive markets. ↩ ↩

-

hot pressing: Click here for an in-depth look at hot pressing techniques, including its role in high-volume production, material durability, and efficiency improvements in manufacturing. ↩ ↩

-

cold pressing: Click here to understand cold pressing methods, focusing on precision control in production, material property preservation, and its impact on product design. ↩ ↩

-

thermoforming: Click here to gain insights into thermoforming processes, detailing how this technique facilitates complex packaging designs and enhances product stability. ↩ ↩