Pickleball paddle selection for intermediate players requires a careful balance between performance, durability, and cost. In short, the ideal paddle for this market combines advanced materials—such as Carbon Fiber1 and Fiberglass2—with proven production techniques such as hot pressing, cold pressing, or thermoforming to deliver both power and control at a competitive price point.

When evaluating puddingball paddles for intermediate players, B2B buyers must navigate a maze of material choices, production methods, and design considerations. Retail managers, sports club procurement specialists, and distribution executives are tasked with differentiating between products that cater to recreational users and those that deliver competitive performance enhancements.

Intermediate players require paddles that achieve a middle ground: they must offer enough power for dynamic play while ensuring control and reduced vibrations. It is not only about the raw strength of a paddle but also its ability to maintain a consistent performance over extended use. This is why understanding the nuanced differences in manufacturing processes and materials is crucial for making bulk purchasing or distribution decisions.

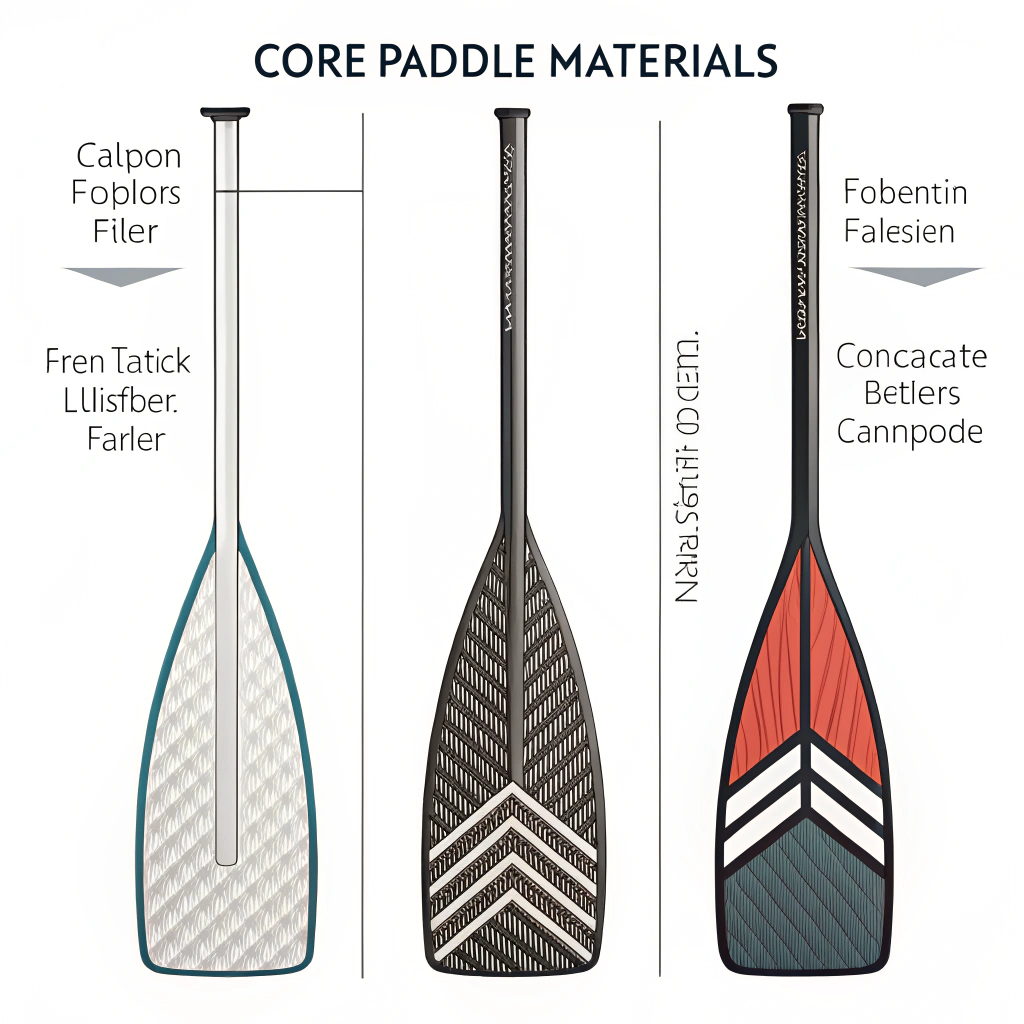

Core Material Differences: Carbon Fiber, Fiberglass, and Composite Materials3

For intermediate paddle performance, the core materials and structural components take center stage. Each material offers unique characteristics that affect weight, vibration absorption, rebound energy, and overall durability. Below, we explore the primary material options:

Carbon Fiber1 is a premium material used in high-performance paddles. It includes several variants:

- 3K Carbon Fiber: Provides excellent strength and flexibility, which increases power without compromising on control. Its lower density helps reduce paddle weight.

- 12K Carbon Fiber: Known for its smoother surface and superior hardness, it can withstand repeated impacts. This makes it ideal for players who demand impact resistance.

- T300 Carbon Fiber: Offers a balanced profile of tensile strength and light weight, delivering reliable performance for intermediate play.

Fiberglass2 is prized for its balance between power and control:

- E-Glass Fiberglass: Provides great elasticity and tensile strength. It offers a wider sweet spot and improved ball control, making it a popular choice for players who prioritize precision.

Composite Materials3 options create a hybrid balance by combining the benefits of different materials:

- Carbon Fiber and Fiberglass Composite: Merges the rigidity of carbon fiber with the flexibility of fiberglass, ensuring paddles are both powerful and easy to control.

- Bamboo Core Composite: Favours a lightweight design with high impact resistance. Its clear hitting feel can enhance shot accuracy.

- Honeycomb Core: Made from high-density polymers or pulp, this structure is optimal for shock absorption, ensuring durability while minimizing vibration.

Each of these materials contributes to the paddle’s final performance characteristics. For intermediate players, the choice usually depends on whether they need a slight boost in power, more control, or better shock absorption.

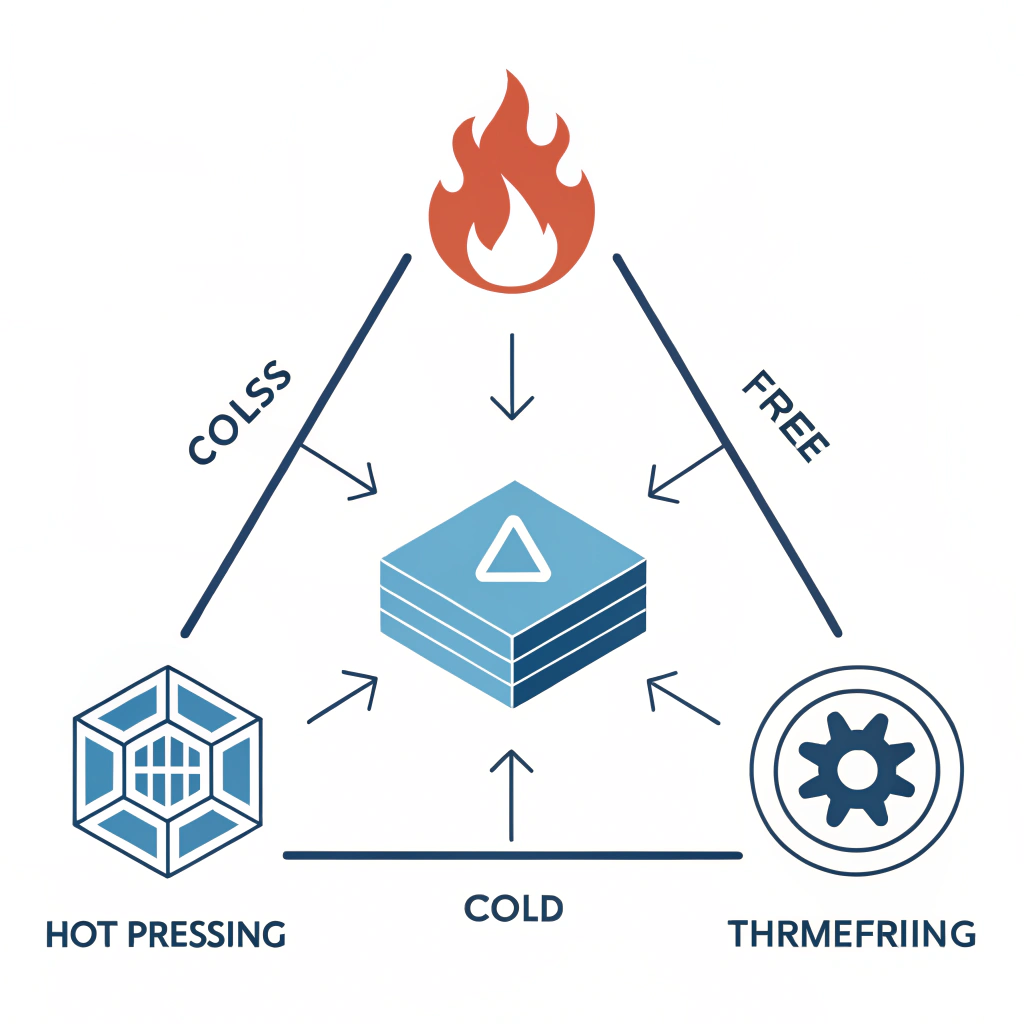

Manufacturing Processes: Hot Pressing, Cold Pressing, and Thermoforming4

The production process of a pickleball paddle is just as critical as the ingredients that make it up. At NEX Pickleball, three primary manufacturing methods are widely used to achieve optimal product performance. Understanding these processes helps elucidate why some paddles consistently outperform others in real-world play.

This process involves heating the components and applying force to ensure a strong bond between layers.

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Produces paddles with excellent impact resistance and structural integrity.

Disadvantages:

- May slightly alter the intrinsic feel of materials.

- Involves significant upfront investment in specialized equipment.

Unlike hot pressing, cold pressing shapes the paddle without heat, thereby maintaining the material's original properties.

Advantages:

- Provides precise control over the paddle’s thickness and overall structure.

- Maintains excellent ball feel and responsiveness due to preserved material integrity.

Disadvantages:

- Slower production cycles may limit volume.

- Highly dependent on precise pressure calibration to achieve consistency.

Thermoforming4 heats materials to a pliable state and forms them using custom molds.

Advantages:

- Excellent for producing paddles with complex designs and customized thickness profiles.

- Enhances material distribution for improved stability and performance.

Disadvantages:

- Longer production times and higher equipment costs.

- Typically used for premium or custom-made paddles.

The table below summarizes key differences:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | Efficient for mass production; high impact resistance | Can alter material feel; high equipment investment |

| Cold Pressing | Precise control; maintains original material properties | Slower production cycle; equipment precision required |

| Thermoforming | Customizable designs; optimal material distribution | Longer production time; higher costs |

Understanding these differences helps B2B buyers align product capabilities with their customer’s performance expectations. For example, retail chains focusing on premium intermediate paddles might lean towards thermoforming for its design flexibility, while distributors requiring superior durability might opt for hot pressing or cold pressing methods.

A side-by-side evaluation of materials and manufacturing techniques can further clarify which paddle aligns best with the needs of intermediate players:

| Feature | Carbon Fiber (3K/12K/T300) | Fiberglass | Composite Materials | Hot Pressing | Cold Pressing | Thermoforming |

|---|---|---|---|---|---|---|

| Weight | Light to moderate | Moderate | Variable – can be tuned | Consistent strength | Enhanced control | Customizable |

| Durability | High (especially 12K, T300) | Good; flexible | High impact resistance (Honeycomb) | Strong and durable | Maintains original feel | Optimal structural control |

| Vibration Reduction | Excellent (with proper core) | Moderate | Superior (with honeycomb or polymer core) | Reduces vibration | Better ball feel | Consistent performance |

| Production Efficiency | Depends on process used | Depends on process used | Customizable | High volume | Lower volume | Premium quality production |

| Manufacturing Cost | Moderate to high | Lower cost compared to carbon fiber | Variable based on material mix | Equipment intensive | Requires precision | High due to customization |

This table highlights the trade-offs that must be considered. For B2B procurement, balancing cost against performance is paramount. If the application demands high durability and power, 12K Carbon Fiber with hot pressing might be ideal. Conversely, if a retailer focuses on players who prioritize ball control and precision, a composite paddle featuring Fiberglass or a polymer core produced by cold pressing can be the best match.

B2B buyers need to consider the usage scenarios of their target market. For intermediate pickleball players, factors such as paddle weight, grip comfort, and the balance between power and control are critical. Here are a few recommendations based on different scenarios:

-

For High-Durability Demands:

Paddles using 12K Carbon Fiber paired with Nomex Honeycomb Core5—ideal for venues where high-impact play is common. These provide excellent shock absorption and can withstand the rigors of competitive play. -

For Enhanced Ball Control:

Paddles featuring E-Glass Fiberglass in combination with a Polymer Honeycomb Core are perfect. These paddles offer a softer hitting surface, which reduces vibration and improves precision—ideal for intermediate players who rely on accuracy. -

For Customized Performance Solutions:

Custom paddle designs that leverage composites with Bamboo Core or a mix of Carbon and Fiberglass offer a tailored balance between power and control. These are particularly suited for sports clubs or specialty retailers that can promote innovation as a unique selling point. -

Budget Considerations:

For buyers focusing on volume and competitive pricing without sacrificing too much performance, manufacturing processes like cold pressing may yield the best balance of cost-efficiency and product excellence.

Decisions should be guided not only by the paddle’s performance characteristics but also by the processes behind their manufacture. Cost, production speed, and design flexibility are key in ensuring that the selected products remain competitive in fast-moving retail markets.

At NEX Pickleball, stringent quality control is a core part of every production phase. Each paddle undergoes rigorous testing to ensure it meets the highest standards of strength, flexibility, and balance. Advanced production techniques—whether hot pressing, cold pressing, or thermoforming—allow us to carefully shape the paddle’s performance characteristics.

Customization Options Offered:

- Ergonomic Grip Design: Paddle handles are tailored to suit multiple grip sizes, ensuring comfort for a broad spectrum of players.

- Custom Paddle Options: Clients can specify design parameters such as weight, balance, and even graphic design, ideal for team branding or unique market needs.

- Advanced Material Selection: Buyers can choose between different core materials and surface treatments to align with their performance objectives.

Quality control measures include real-time monitoring of production parameters, regular material testing, and post-production quality checks. This systematic approach ensures that every paddle delivered is capable of performing under the demands of both recreational and competitive play. The result is a product lineup that not only meets rigorous industry standards but also advances the playing experience of every user.

In summary, when selecting intermediate pickleball paddles, B2B buyers should evaluate the following factors:

- Material Composition – Choose between Carbon Fiber, Fiberglass, and composite options based on the desired balance between power and control.

- Manufacturing Process – Consider the implications of hot pressing, cold pressing, and thermoforming in terms of production efficiency, costs, and product feel.

- Core Attributes – Focus on paddle cores such as Nomex Honeycomb, Aluminum Honeycomb, or Polymer Honeycomb to fine-tune vibration reduction and impact resistance.

- Customization and Quality Control – Verify that the manufacturing partner prioritizes quality inspection and customization options to meet market needs.

For retail managers and distribution executives, these considerations serve as actionable criteria which can guide procurement decisions through a detailed comparison of product offerings. Ensuring that a paddle matches both the usage scenario of the intermediate player and your budget will lead to higher player satisfaction, better market differentiation, and long-term success.

Organizations should request detailed product specifications, sample evaluations, and even visit manufacturing facilities to assess production quality. Understanding the technologies behind the scenes allows for a more strategic purchasing approach in a competitive market.

Convinced buyers should look for partners who not only supply high-performance equipment but also demonstrate flexibility in production and customization. NEX Pickleball’s extensive expertise in advanced production techniques positions it as a reliable partner—not only to meet current market demands but to innovate future product lines.

Q: What is the #1 rated pickleball paddle?

A: While rankings vary by source, many experts cite top models such as the JOOLA Ben Johns Perseus Pro IV for its blend of strength and tactile feedback, making it a favorite in competitive reviews.

Q: What is the best pickleball paddle for seniors?

A: For seniors, paddles crafted from lightweight materials like Fiberglass or carbon fiber are preferred. These provide a balance of control and reduced impact stress, aiding in precision and ease of play.

Q: Which pickleball paddle hits the hardest?

A: High-impact paddles, such as the JOOLA Perseus Pro IV, are renowned for their power delivery. Often, paddles that incorporate advanced carbon fiber variants excel in generating powerful hits without sacrificing control.

-

Carbon Fiber: Read the linked article to learn more about the properties, production methods, and applications of carbon fiber in advanced sporting equipment. ↩ ↩2

-

Fiberglass: Click here for an in-depth explanation of fiberglass, including its benefits in performance products and practical implementation in paddle manufacturing. ↩ ↩2

-

Composite Materials: Explore how composite materials combine different properties for enhanced performance, making them a preferred choice for tailored sports equipment solutions. ↩ ↩2

-

Thermoforming: Discover the thermoforming process, its advantages, and how it plays a crucial role in designing complex and high-performance pickleball paddles. ↩ ↩2

-

Nomex Honeycomb Core: Learn about Nomex honeycomb core technology, its unique shock absorption properties, and why it's favored for high-durability sports equipment. ↩