Pickleball paddle design can be optimized for a larger sweet spot by carefully selecting materials and production processes that balance power, control, and durability. In this article, we compare key paddle materials and manufacturing techniques to help B2B buyers make informed decisions about high-performance sports equipment.

Pickleball paddles must meet strict performance criteria in today’s competitive market. B2B buyers and product managers are often challenged with choosing paddles that not only perform well on the court but also offer enhanced features like an enlarged sweet spot. This sweet spot, the area on the paddle face that produces optimal results on impact, is critical for achieving both power and control. In this piece, we analyze various production techniques and material compositions to explain how they influence paddle performance and overall quality.

The sweet spot is crucial for pickleball paddles as it affects hitting accuracy, ball control, and overall gameplay consistency. A larger sweet spot reduces the risk of mishits, increases forgiveness on off-center hits, and ultimately enhances player confidence. The challenge lies in balancing material properties, weight distribution, and manufacturing processes to achieve this ideal performance characteristic.

For B2B sports retail and procurement specialists, knowing how different materials and processes contribute to enlarging the sweet spot is essential. It acts as a guide for selecting paddles that provide competitive advantages for end users while ensuring product longevity and quality.

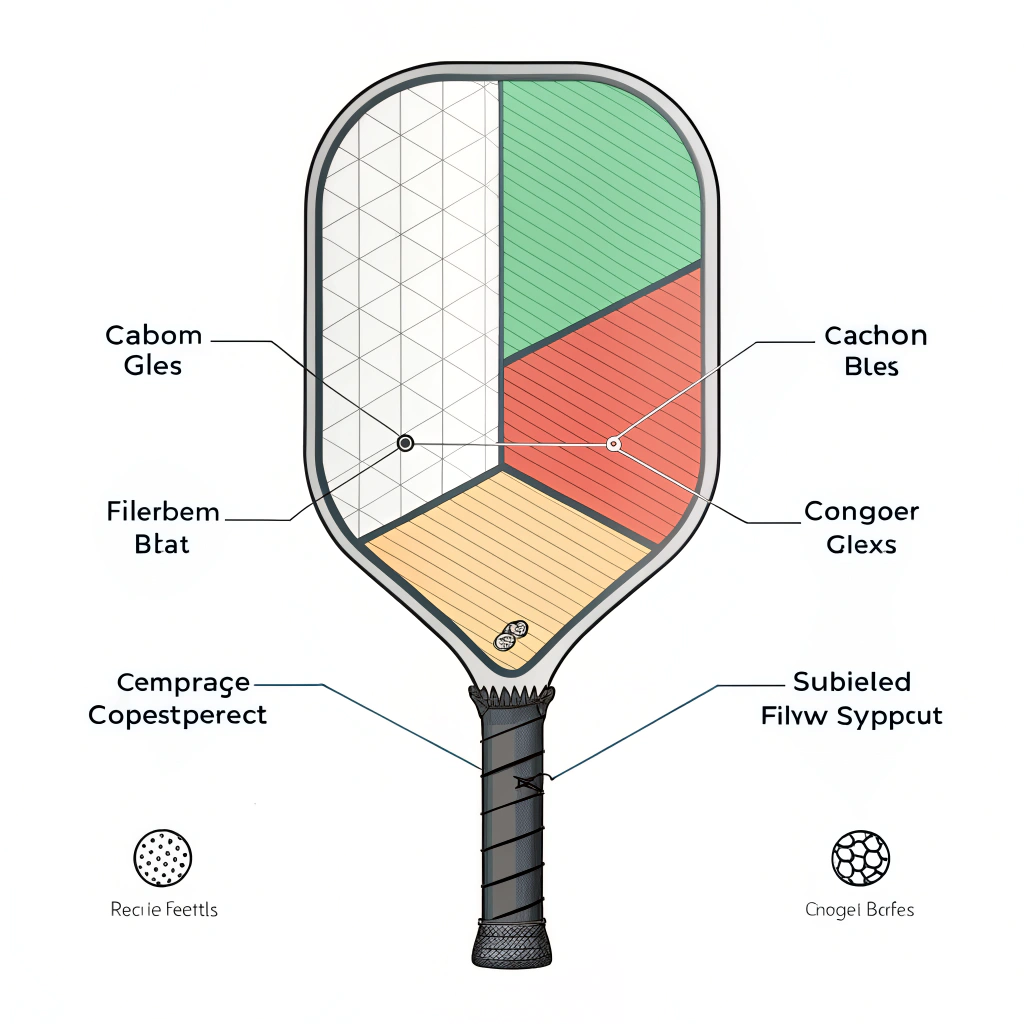

Different materials influence both tactile feel and the performance of paddle surfaces during play. Below is a detailed overview:

-

Carbon Fiber1 Paddles:

- 3K Carbon Fiber: Offers strength and flexibility. It optimizes rebound force, reducing vibrations while maintaining durability.

- 12K Carbon Fiber: Provides a smoother surface with improved hardness and impact resistance, ideal for competitive play.

- T300 Carbon Fiber: Known for excellent tensile strength, making it a balanced choice in terms of weight and power.

-

Fiberglass Paddles:

- E-Glass Fiberglass: Offers elasticity and excellent ball control. It provides a widened sweet spot through its flexible structure, which helps absorb shock without sacrificing control.

-

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials, balancing strength, weight, and flexibility.

- Bamboo Core Composite: Provides lightweight properties with high impact resistance, ideal for enhancing the paddle’s feel.

- Honeycomb Core: Specifically designed for shock absorption, helping the paddle maintain integrity and a larger effective hitting area.

-

Core Materials:

- Nomex Honeycomb Core3: Delivers excellent shock absorption and durability, perfect for high-intensity play.

- Aluminum Honeycomb Core: Balances weight and control, contributing to an optimal hitting surface.

- Polymer Honeycomb Core: Reduces vibrations and ensures a comfortable stroke, which is ideal for beginners and recreational players.

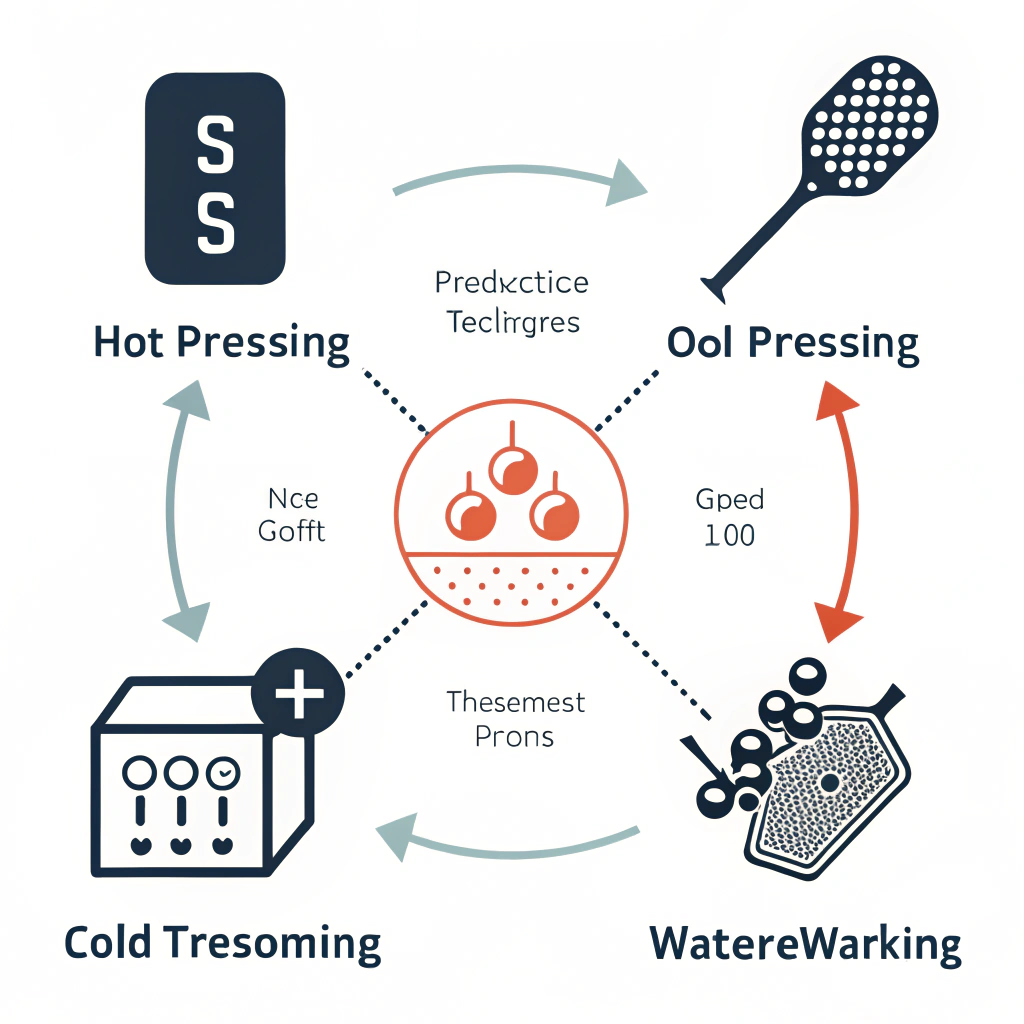

Cold Pressing4 and Thermoforming5 are key production processes alongside hot pressing. The production process plays a significant role in the final performance of a pickleball paddle. Manufacturers use various methods to mold and shape the paddle, each with its own set of advantages and limitations. Here is a table comparing the three primary techniques:

| Production Method | Advantages | Disadvantages | Impact on Sweet Spot |

|---|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; excellent structural integrity | Can alter material properties; higher equipment investments | Yields durable paddles with consistent surface hardness, potentially enlarging the effective sweet spot through uniform material distribution |

| **Cold Pressing4 | Greater precision in thickness control; preserves inherent material properties; superior ball feedback | Longer production cycles; requires precise pressure control | Improves control and precision of the paddle surface, making it easier to optimize for a larger sweet spot |

| **Thermoforming5 | Allows intricate design details; precise material allocation; ideal for premium custom products | More time-consuming; higher equipment costs | Can create finely tuned paddle surfaces, maximizing the sweet spot through careful material contouring |

Each production technique offers unique benefits. For instance, hot pressing is favored in high-volume manufacturing due to its efficiency and robust paddle structure, which can enlarge the sweet spot by creating uniform pressure distribution. Conversely, cold pressing excels in optimizing material properties and thickness control, offering players a highly responsive surface area. Thermoforming, although costly, allows for custom designs that can target specific performance characteristics, such as a widened sweet spot.

When selecting pickleball paddles for retail distribution or team branding, B2B buyers need to consider several factors:

-

Material Performance:

- Consistency and Reliability: Buyers must ensure that the chosen material, be it Carbon Fiber1 or fiberglass, consistently delivers optimal performance. The choice between 3K, 12K, or T300 carbon fiber will depend on the target audience, whether recreational players or competitive athletes.

- Durability and Vibration Reduction: Materials like Nomex Honeycomb Core3 and polymer composites not only increase longevity but also reduce vibrations, contributing significantly toward a larger sweet spot.

-

Production Techniques and Precision:

- Uniformity of Surface: A uniform surface created during manufacturing is critical for enlarging the sweet spot. Techniques like Thermoforming5 allow for detailed customization that can fine-tune the paddle’s impact zone.

- Efficiency vs. Customization: Hot pressing provides fast turnaround times while Cold Pressing4 and thermoforming offer improved tactile feedback and customization potentials, respectively.

-

Ergonomic and Design Considerations:

- Weight Distribution: Significant attention is paid to balancing the paddles. A well-distributed weight increases the effective sweet spot and makes the paddle easier to maneuver.

- Ergonomic Grip and Handling: Besides the paddle face, the grip and overall design ensure that players feel comfortable during prolonged play, contributing indirectly to accuracy and performance.

Combining material innovation with advanced production processes is the key to achieving a larger sweet spot. B2B procurement specialists can look at integrated solutions offered by manufacturers who seamlessly balance these elements. For instance, a paddle using 12K carbon fiber combined with a Nomex Honeycomb Core3 and produced through a hybrid approach incorporating both Cold Pressing4 and Thermoforming5 can offer unmatched performance in terms of power and control.

Benefits of such integration include:

- Enhanced Performance: By merging the best attributes of both rigid and flexible materials, manufacturers can craft paddles that respond accurately to varied playing styles.

- Customizability: Clients can choose production methods that are best suited to their market needs. For instance, high-performance competitive paddles may benefit from the precision of cold pressing, while recreational paddles might be optimized with hot pressing for greater durability.

- Operational Efficiency: Maintaining consistent production quality, even with custom options, is vital. Advanced manufacturing techniques allow for quicker adaptation to market trends without compromising quality.

Manufacturers are adopting hybrid production methods to offer a versatile range of products suitable for various skill levels. Such strategies not only enhance the sweet spot but also ensure that every paddle is built to last, thereby supporting both short-term performance and long-term durability.

Below is a detailed breakdown of the performance factors associated with each material and production technique focused on maximizing the sweet spot:

| Key Factor | Carbon Fiber (3K, 12K, T300) | Fiberglass | Composite Materials2 | Core Materials (Nomex Honeycomb Core3, Aluminum, Polymer) |

|---|---|---|---|---|

| Sweet Spot Enlargement | Uniform surface can optimize impact zone if precision is maintained | Flexible, wider sweet area due to elasticity | Tailored combinations can target improved sweet spot | Dampens vibration and maintains structural integrity |

| Durability | High resilience and reduced vibration | Good balance of power and control but may wear faster | Superior impact resistance when well-engineered | Key to consistent performance over repeated hits |

| Manufacturing Precision | Suitable for both high-volume and custom designs | Difficulty in fine-tuning flexibility | Offers balance but relies on precise mixing and curing | Core uniformity is crucial for maintaining a large sweet spot |

This table supports decision-makers in understanding the inherent trade-offs and selecting the best combination based on their target market demands.

For businesses evaluating pickleball paddles, consider the following steps to ensure your product line meets the highest standards of performance and customer satisfaction:

- Assess your target market’s needs—whether you cater to competitive athletes or recreational players.

- Decide on the appropriate material mix and production technique. For example, if the priority is on performance with minimal vibration, investing in a paddle with a Nomex Honeycomb Core3 and Cold Pressing4 carbon fiber might offer the best results.

- Balance production efficiency with product customization. Understand that while hot pressing offers cost benefits for mass production, Cold Pressing4 and Thermoforming5 can yield superior performance characteristics ideal for specialized paddles.

- Leverage case studies and manufacturer certifications. Reliable data on production quality, testing standards, and durability ratings can be crucial in securing buyer confidence.

- Test and iterate. Consider small batch orders or pilot runs to verify that the chosen combination of materials and processes truly delivers an enlarged sweet spot and enhanced playability.

By following these steps, B2B sports equipment buyers can align their procurement strategy with industry-leading innovations and meet the evolving demands of both competitive and recreational markets.

People Also Ask

Q: What is the best pickleball paddle for 2025?

A: The best pickleball paddle for 2025 blends all-court performance with an optimized sweet spot. Look for paddles that offer a balance between power, spin, and control, such as models using advanced carbon fiber composites, innovative core materials, and precise production techniques that ensure durability and enhanced playability.

Q: Which pickleball paddle hits the hardest?

A: Paddles that hit the hardest typically incorporate advanced materials and specialized manufacturing processes to maximize impact force and energy transfer. Designs featuring a robust core (often aluminum or a composite blend) combined with high-density carbon fiber layers can deliver exceptional power without compromising control.

Q: How to make sweet spot bigger on pickleball paddle?

A: Increasing the sweet spot can be achieved by adding weight strategically, such as incorporating lead tape along the paddle’s perimeter or optimizing material distribution during production. Techniques like Thermoforming5 and Cold Pressing4 that allow precise control of material thickness and placement can enhance the effective hitting area, leading to a larger sweet spot.

-

Carbon Fiber: Click here to explore how carbon fiber technology enhances athletic equipment by providing strength, flexibility, and reduced vibration for optimized performance. ↩ ↩ ↩2

-

Composite Materials: Click here to learn about the benefits of composite materials in sports equipment, which combine different fibers and resins for a balanced performance profile. ↩ ↩ ↩2

-

Nomex Honeycomb Core: Click here to study the advantages of Nomex honeycomb cores in sports equipment, which provide superior shock absorption and durability for high-intensity play. ↩ ↩ ↩2 ↩3 ↩4 ↩5

-

Cold Pressing: Click here to understand cold pressing techniques, known for their high precision in thickness control and ability to maintain material integrity during production. ↩ ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7

-

Thermoforming: Click here for insights into thermoforming, a production process that allows for intricate design details and precise material shaping to maximize performance. ↩ ↩ ↩2 ↩3 ↩4 ↩5 ↩6