High-performance power pickleball paddles are essential for competitive play, combining advanced materials and manufacturing techniques to deliver unmatched power and precision. In this article, we offer an in-depth technical comparison of today’s top power pickleball paddles, detailing material choices, production processes, and performance characteristics to help B2B purchasing managers and distributors make informed decisions.

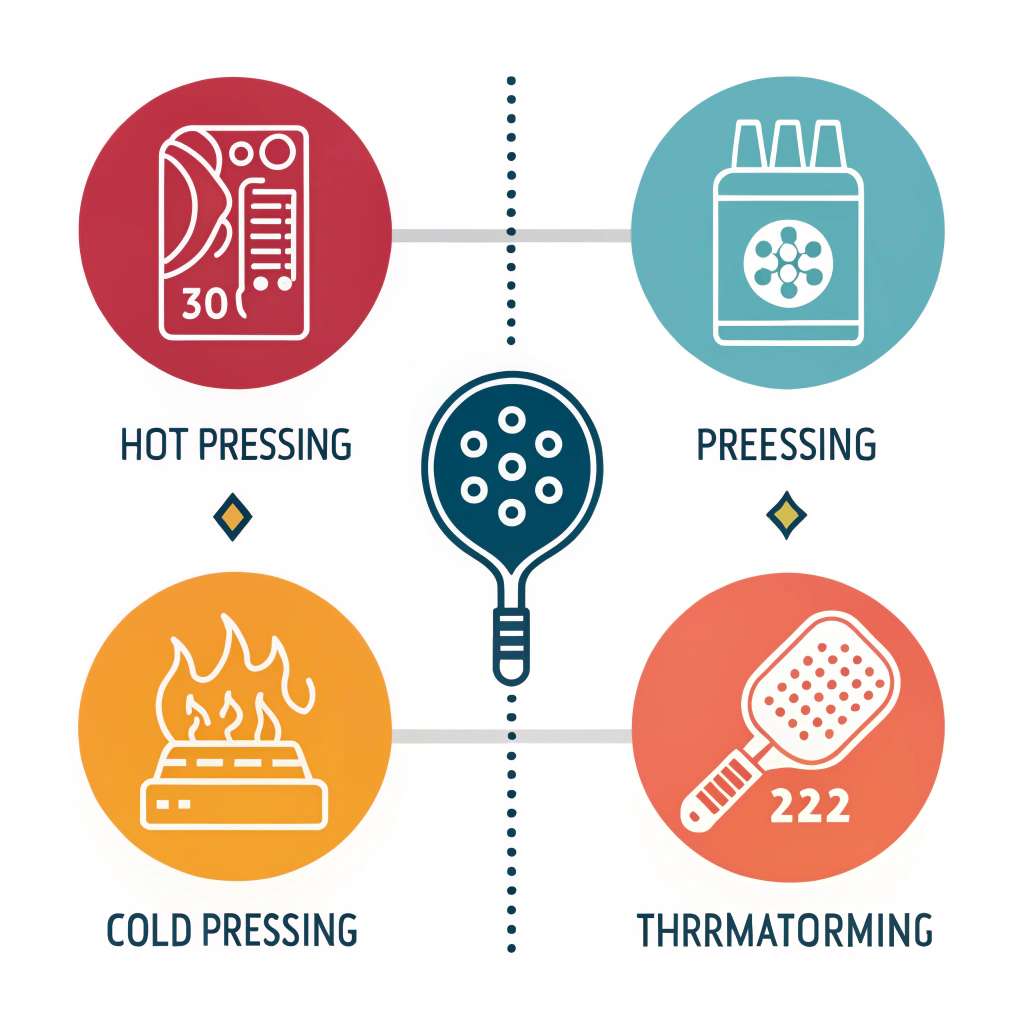

High-performance pickleball paddles must balance strength, lightness, durability, and optimal ball control. Manufacturers use advanced production techniques1 such as hot pressing, cold pressing2 and thermoforming3, each influencing the paddle’s performance in unique ways. For B2B buyers, understanding these methods is crucial as they determine not only the paddle’s quality but also its competitive edge in the market.

Our approach at NEX Pickleball focuses on producing paddles that maximize power without compromising on control. For instance, our emphasis on premium materials like carbon fiber4, fiberglass, and various composite components delivers products that meet the rigorous demands of modern pickleball competitions.

The performance and durability of a power pickleball paddle are heavily influenced by the materials used. Below, we compare the main material groups in terms of their benefits and applications:

-

3K Carbon Fiber:

- Prominent for its flexibility and strength.

- Excellent rebound forces with reduced vibrations.

- Ideal for paddles requiring high power with balanced control.

-

12K Carbon Fiber:

- Denser weave offers a smoother surface and greater hardness.

- Enhanced impact resistance which suits competitive play.

- Offers durability under heavy-duty usage.

-

T300 Carbon Fiber:

- Noted for outstanding tensile strength.

- Strikes a balance between weight and power, making it perfect for paddles that require a precise mix of speed and stability.

- Known for providing a wider sweet spot.

- Offers elasticity and excellent ball control.

- E-Glass Fiberglass provides a balanced mix of power and flexibility, making it suitable for recreational players as well as competitive athletes.

Combining different materials yields unique advantages:

-

Carbon Fiber and Fiberglass Composite:

- Merges the benefits of both materials to offer a good balance of strength, lightness, and flexibility.

- Provides an enhanced hitting feel critical for fast-paced matches.

-

Bamboo Core Composite:

- Offers lightweight characteristics with high impact resistance.

- Ideal for long-lasting play, it gives a distinct hitting feel that many players prefer.

-

Honeycomb Core (Nomex, Aluminum, Polymer):

- Nomex Honeycomb Core5: Provides excellent shock absorption and durability.

- Aluminum Honeycomb Core: Offers balanced weight and excellent control.

- Polymer Honeycomb Core: Reduces vibrations, giving a softer hitting experience while maintaining playability.

| Material Type | Key Advantages | Typical Applications |

|---|---|---|

| 3K Carbon Fiber | Flexibility, high rebound, vibration reduction | High-power paddles, balanced control models |

| 12K Carbon Fiber | Smooth finish, enhanced hardness, durability | Competitive paddles requiring maximum impact |

| T300 Carbon Fiber | Tensile strength, balanced performance | Precision paddles needing power and light weight |

| E-Glass Fiberglass | Wider sweet spot, good ball control | Recreational to competitive players |

| Composite (Carbon Fiber & Fiberglass) | Combined strength and flexibility | High-performance paddles with dual benefits |

| Bamboo Core Composite | Lightweight, high impact resistance | Long-lasting, cost-effective paddle solutions |

| Nomex Honeycomb Core | Superior shock absorption, durability | Durable paddles for high-impact play |

| Aluminum Honeycomb Core | Balanced weight, power and control | Paddles needing precise balance |

| Polymer Honeycomb Core | Reduced vibration, excellent elasticity | Recreational to intermediate performance paddles |

Such detailed material selection is critical when deciding which paddle best meets your retailer or club’s requirements, particularly if power and performance are top priorities.

The production methods used in manufacturing pickleball paddles play a significant role in determining overall quality. Below, we analyze three primary processes:

-

Process Overview:

The paddle material is heated and pressed under high pressure in a mold. This creates a strong, durable product. -

Advantages:

- High production efficiency ideal for large-scale manufacturing.

- Robust construction offering superior impact resistance.

- Ensures structural integrity for competitive, high-energy gameplay.

-

Disadvantages:

- High temperatures can sometimes alter the material’s natural properties, impacting the paddle’s feel.

- Requires a larger investment in advanced equipment.

-

Process Overview:

Materials are shaped at room temperature using mechanical pressure. This method retains the original material properties, ensuring precise control over the paddle thickness and structure. -

Advantages:

- Maintains material integrity, favoring enhanced sensitivity and control.

- Allows for a more precise manufacturing process.

- Results in a paddle with excellent ball feedback and overall responsiveness.

-

Disadvantages:

- Longer production cycles which may reduce efficiency.

- Demands high-quality equipment for consistent pressure control.

-

Process Overview:

Material is heated until it becomes malleable, then formed into a shape using a mold. This process is suited for paddles with complex designs. -

Advantages:

- Enables intricate paddle designs and precise material distribution.

- Helps in maintaining the paddle’s stability, which is critical for power shots.

- Suitable for high-performance materials, leading to premium product lines.

-

Disadvantages:

- Requires longer production times.

- Higher manufacturing costs limit its use to premium or custom products.

| Production Process | Key Advantages | Main Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency, structural integrity, durability | Material properties may change; higher cost | Large-scale, high-performance production |

| Cold Pressing | Precise control, better material feel, flexibility | Slower production, equipment sensitive | Specialty designs needing fine control |

| Thermoforming | Intricate designs, even material distribution | Longer production time, premium cost | Custom paddles and high-end products |

Through this comparative analysis, B2B decision-makers gain clarity on which process aligns with their quality and production volume requirements. If your distribution strategy prioritizes consistent high-quality and premium performance, choosing paddles manufactured via the thermoforming process might be optimal. For cost-effective yet reliable production, cold pressing offers a balance between craftsmanship and efficiency.

When comparing power pickleball paddles for competitive play, several technical attributes matter:

- Importance: A well-balanced paddle minimizes fatigue and improves maneuverability.

- Considerations:

Paddles with carbon fiber and aluminum honeycomb cores typically offer a more balanced weight distribution essential for quick power swings.

- Importance: Reduced vibrations lead to better control and comfort during rapid play.

- Considerations:

Materials like Tensile T300 carbon fiber and polymer honeycomb cores are engineered to dampen shock, providing a smoother hitting experience.

- Importance: An enhanced grip is critical for controlled shots and spin generation.

- Considerations:

Ergonomic design combined with surface treatments can dramatically increase the paddle’s performance, especially when used for power-intensive play.

- Importance: Long-lasting paddles reduce replacement frequency, providing better ROI for retailers.

- Considerations:

Nomex and aluminum honeycomb cores, along with composite materials, ensure the paddle withstands heavy impacts and extended play without degrading performance over time.

| Attribute | Key Materials/Methods | Impact on Performance |

|---|---|---|

| Weight Distribution | Carbon Fiber, Aluminum Cores | Enhances maneuverability and reduces fatigue |

| Vibration Reduction | T300 Carbon Fiber, Polymer Cores | Provides a smoother, controlled hit |

| Grip and Surface Texture | Ergonomic treatments, composite surfaces | Maximizes spin and accuracy |

| Durability | Nomex, Aluminum & Composite Materials | Ensures longevity and consistent performance |

These metrics are essential when comparing various paddles in competitive markets. They provide a comprehensive framework for selecting products that not only offer power but also maintain consistent performance over time.

For B2B purchasing managers and distributors, selecting the best power pickleball paddle involves balancing technical performance with production reliability. Consider the following decision-making factors:

-

Performance Requirements:

Identify which attributes—whether it's maximum power, enhanced control, or durability—are most critical for your clientele. Competitive markets may favor premium features like advanced carbon fiber variants and thermoformed designs. -

Production Consistency:

Evaluate manufacturers based on their production processes. A company like NEX Pickleball that practices rigorous quality control with state-of-the-art methods ensures consistency, reducing risk in bulk orders. -

Customization Capabilities:

Consider whether the manufacturer offers on-demand printing or custom paddle options. This flexibility can be a significant differentiator when branding products for club teams or retail stores. -

Cost Versus Quality:

While high-performance paddles may come with a premium price tag, their durability and superior performance contribute to a higher return on investment. Draw up a cost-benefit analysis using technical specification tables to align production costs with market pricing. -

After-Sales Support and Testing:

Reliable quality assurance is vital in competitive sports equipment. A manufacturer employing multiple testing phases—including weight balance checks and durability assessments—provides a safety net for your investment.

By focusing on these criteria, you not only select products that excel in power and performance but also build long-lasting B2B relationships with manufacturers who understand market demands.

At NEX Pickleball, every paddle undergoes rigorous testing to ensure it meets the highest quality standards. Our commitment to innovation, precision engineering, and continuous improvement is evident in:

-

Quality Control Protocols:

Each paddle is scrutinized for weight distribution, vibration reduction, and impact resistance. This guarantees that every unit performs up to industry expectations. -

Custom Testing Regimes:

Our testing methodologies are designed to simulate real-match conditions, ensuring that paddle performance remains consistent regardless of usage intensity. -

Batch Consistency:

With advanced production techniques and continuous monitoring, we maintain consistent quality across large orders, making us the preferred choice for sporting goods distributors and club equipment suppliers.

Our expertise in advanced manufacturing combined with our focus on key performance metrics showcases why NEX Pickleball stands at the forefront of the power pickleball paddle market.

The competitive edge in the pickleball market hinges on the ability to supply high-performance, power-oriented paddles that blend technical artistry with advanced production techniques. By understanding the nuances of material selection, production processes, and performance metrics, B2B buyers can confidently source products that meet the high demands of today's players.

In summary:

- Advanced materials like various carbon fiber types and composite cores enhance both durability and performance.

- Production methods such as hot pressing, cold pressing, and thermoforming offer distinct advantages that can be tailored to specific market needs.

- A careful evaluation of technical attributes, including weight balance and vibration reduction, will guide you in selecting products that deliver both power and precision on the court.

For those ready to elevate their retail offerings or supply sports clubs with cutting-edge power pickleball paddles, partnering with a manufacturer who prioritizes quality, customization, and innovation is essential. Explore our product range and experience the blend of science and sport that defines our paddles.

Q1: Which pickleball paddle gives you the most power?

A1: High-performance power paddles that utilize advanced carbon fiber (such as 12K or T300) and robust composite cores are known to deliver exceptional power. Their design ensures optimal rebound force and minimal vibration, making them ideal for competitive play.

Q2: What is the #1 rated pickleball paddle?

A2: While ratings vary according to testing criteria, many top-rated paddles combine premium materials with advanced manufacturing techniques. Leading manufacturers like NEX Pickleball consistently produce paddles that meet high standards of power, balance, and durability.

Q3: What paddle do most professional pickleball players use?

A3: Professionals typically choose paddles that offer a refined combination of power, control, and durability—often incorporating advanced carbon fiber and specialized core designs. These features help maintain consistency in fast-paced competitive environments.

-

advanced production techniques: Click to learn how integrating advanced production techniques in manufacturing can boost product performance and operational efficiency. ↩ ↩

-

cold pressing: Click to understand cold pressing, a method that preserves material integrity to ensure precise craftsmanship in production. ↩ ↩

-

thermoforming: Click to explore thermoforming processes and discover how they enable intricate designs and consistent quality in complex products. ↩ ↩

-

carbon fiber: Click to learn more about carbon fiber, a premium material renowned for its superior strength-to-weight ratio and durability, crucial for high-performance products. ↩ ↩

-

Nomex Honeycomb Core: Click to understand the benefits of Nomex Honeycomb Core, a core structure offering excellent shock absorption and enhanced durability for long-lasting performance. ↩ ↩