Pickleball paddles that emphasize control are crafted by combining premium materials with precise production techniques to balance ball feel, durability, and precision. In this article, we compare various materials and production methods used in high-performance control-centric paddles, giving procurement managers the insights they need to make informed purchasing decisions.

Control in pickleball is primarily about the paddle’s ability to communicate feedback to the player and allow for precise shot placement. Control-focused paddles are engineered to dampen vibration, offer a balanced distribution of weight, and maintain a consistent ball feel. For products aimed at competitive clubs and retail chains, this means not only implementing superior materials but also adopting advanced manufacturing processes.

The main factors influencing paddle control include:

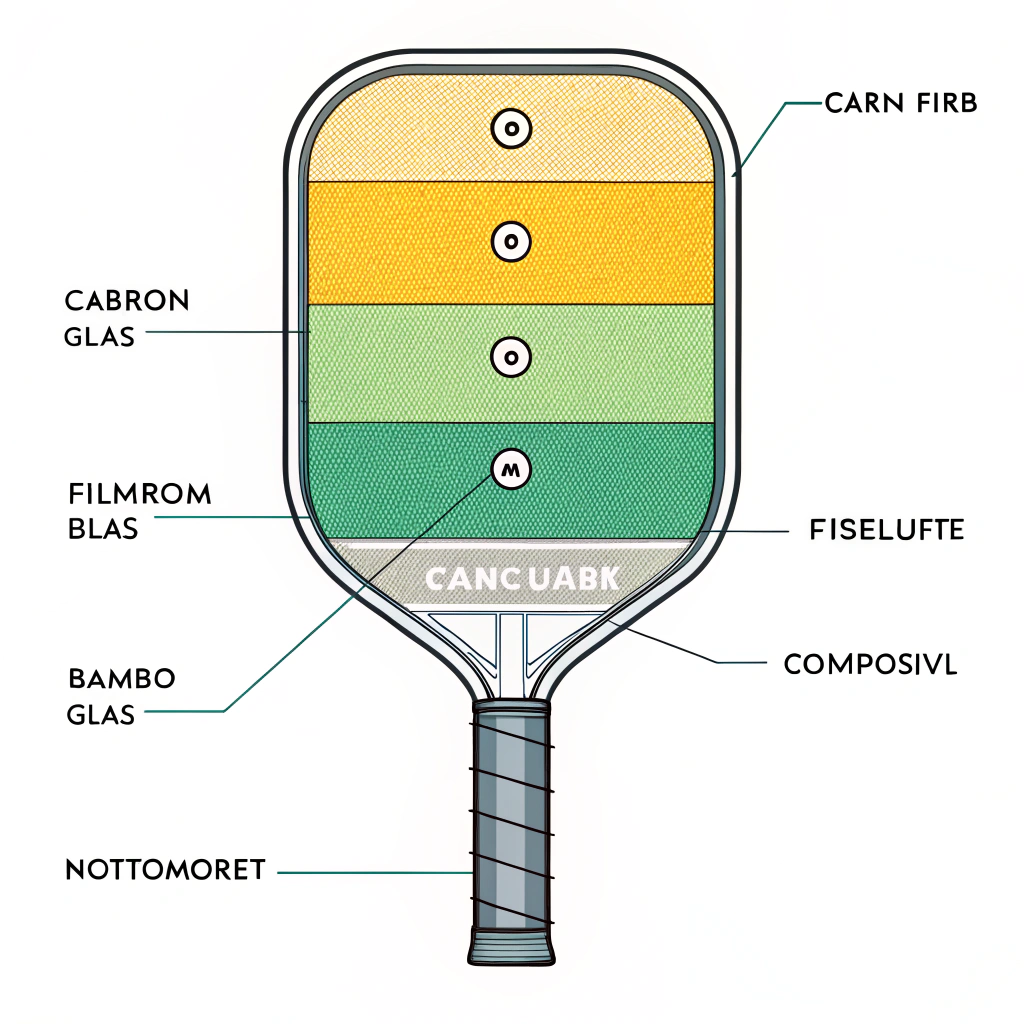

- Material Composition: The choice of carbon fiber1 (3K, 12K, T300), fiberglass, or composite materials such as bamboo core or honeycomb affects power and precision.

- Core Technology: Cores made of Nomex2, aluminum, or polymer honeycomb contribute to vibration reduction and impact resistance.

- Production Techniques: Methods like hot pressing, cold pressing, and thermoforming determine the paddle’s structural integrity and consistency.

For control-focused paddles, performance often hinges on the combination of surface and core materials. Here we compare the key materials used in paddle manufacturing:

-

Carbon Fiber Paddles:

- 3K Carbon Fiber: Excellent strength and flexibility, better for rebound and power retention while reducing vibration during play.

- 12K Carbon Fiber: Offers a smoother and harder surface with superior durability. Ideal for competitive use but might slightly reduce the soft feel preferred in pure control models.

- T300 Carbon Fiber: Balances light weight with high tensile strength, offering a refined control experience and rapid responsiveness.

-

Fiberglass Paddles:

- E-Glass Fiberglass: Provides enhanced elasticity and precision ball control. Fiberglass paddles are known for their wider sweet spot, which simplifies shot accuracy for players emphasizing control.

-

Composite Materials:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials—power from carbon fiber and control from fiberglass—for a balanced performance.

- Bamboo Core Composite: Lends exceptional impact resistance and a crisp hitting response, ensuring responsive control with every shot.

- Honeycomb Core Options (Nomex, Aluminum, Polymer):

- Nomex Honeycomb: Emphasizes shock absorption and stability, making it ideal for long-lasting durability in control-focused paddles.

- Aluminum Honeycomb: Offers a balanced mix of weight and precision, giving players both fine control and robust power.

- Polymer Honeycomb: Reduces vibration effectively, resulting in a softer touch and improved control for beginners and recreational players.

A detailed comparison is provided below:

| Material/Component | Advantages | Best For |

|---|---|---|

| 3K Carbon Fiber | High rebound, reduces vibrations | High-power control, competitive play |

| 12K Carbon Fiber | Smoother surface, extreme durability | High-performance competitive play |

| T300 Carbon Fiber | Balanced strength and light weight | Balanced control and power |

| E-Glass Fiberglass | Wider sweet spot, excellent ball control | Recreational and intermediate players |

| Carbon Fiber & Fiberglass Composite | Combines benefits of both, balanced performance | Versatile performance needs |

| Bamboo Core Composite | Lightweight, high impact resistance | Long-lasting control for consistent play |

| Nomex Honeycomb Core | Superior shock absorption, stability | Precision control in demanding play |

| Aluminum Honeycomb Core | Balanced weight and impact control | A mix of power and precision |

| Polymer Honeycomb Core | Better elasticity, reduced vibration | Comfortable play with soft touch |

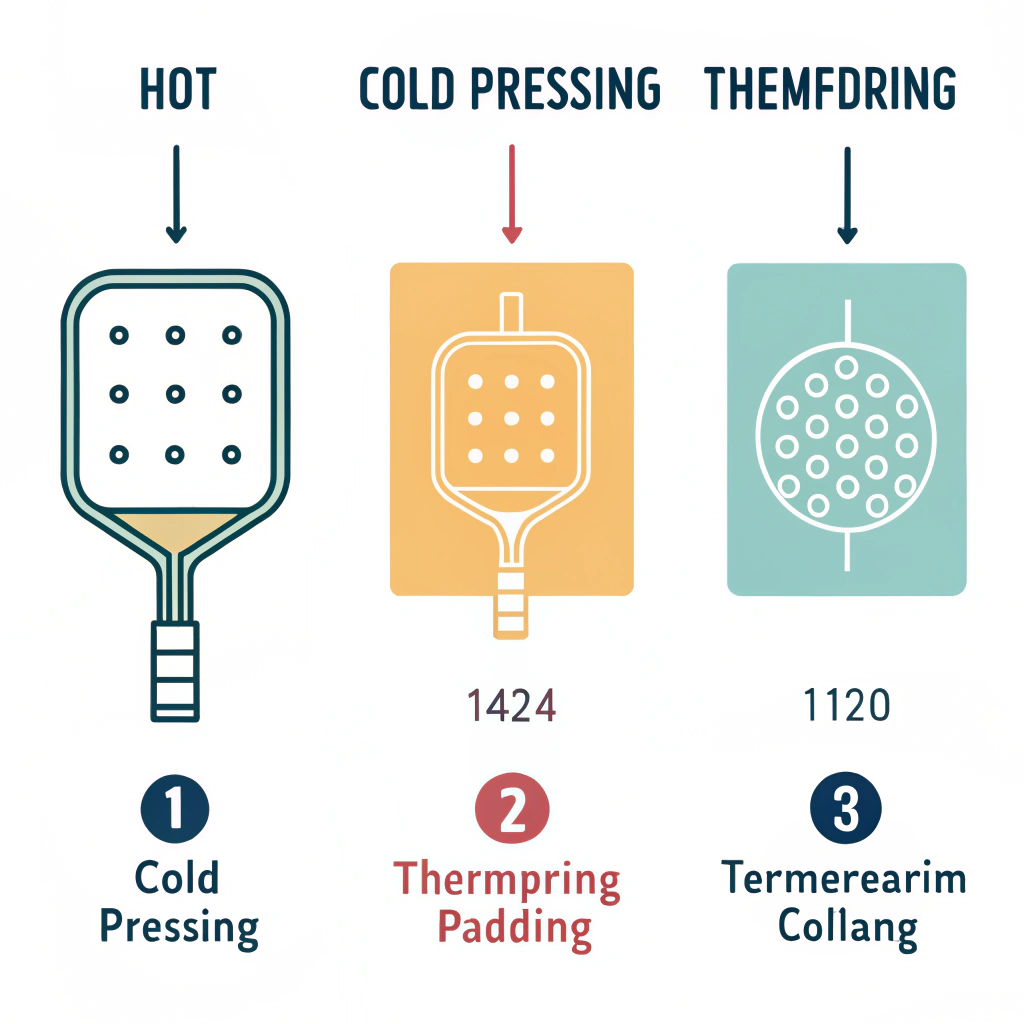

Optimizing control in pickleball paddles is not only about material selection. The production process plays a critical role in determining the final paddle quality. Here’s an overview of the three main production techniques employed:

Hot pressing involves heating materials and applying pressure to form a strong, durable paddle structure.

Advantages:

- High Production Efficiency: Suitable for large-scale manufacturing.

- Enhanced Strength: Results in paddles with excellent impact and vibration resistance.

- Structural Integrity: Consistent quality, making them ideal for high-performance play.

Disadvantages:

- Material Alteration: Heat may change some material properties that impact the paddle’s feel.

- High Investment: Requires significant investment in specialized equipment.

Cold pressing shapes paddle materials at room temperature through controlled mechanical pressure. This method is essential when precision in thickness and responsiveness is required.

Advantages:

- Precision Control: Maintains the original properties of the materials, enhancing ball feel.

- Enhanced Flexibility: Provides a more responsive paddle surface.

- Improved Ergonomics: Greater control over structure and weight distribution.

Disadvantages:

- Longer Production Cycles: Slower processing reduces overall efficiency.

- Equipment Demand: Requires high-quality machinery for precise control.

Thermoforming softens materials with heat and molds them into shape, making it perfect for paddles requiring complex designs.

Advantages:

- Intricate Design Possibilities: Offers precise material distribution and detailed surface textures.

- Paddle Stability: Maintains paddle integrity for improved control.

- Versatility: Suitable for various high-performance materials.

Disadvantages:

- Extended Production Time: Requires more time which might affect scalability.

- Higher Equipment Costs: Investment in molds and heating systems is high.

Below is a quick comparison table summarizing these production techniques:

| Production Process | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Possible alteration of material feel, high investment | Mass production of durable paddles |

| Cold Pressing | Precise control, maintains material properties | Longer cycle time, high equipment precision | Premium control paddles with enhanced touch |

| Thermoforming | Intricate design and precise material distribution | Longer production time, higher costs | Custom-made paddles for high-performance competitions |

When selecting control-focused pickleball paddles for retail or club distribution, consider the following strategic factors:

- Client Expectations: Identify if your clientele values control, power, or a combination. For instance, players in high-speed competitive settings may lean toward paddles that emphasize power alongside control.

- Market Trends: Research trends within the sports equipment sector. Increasingly, consumers seek products that offer smart technology like vibration dampening and ergonomic handles.

- Rigorous Testing: Ensure that the manufacturer, such as NEX Pickleball, applies stringent quality control measures. Each paddle should undergo tests to verify its strength, elasticity, and overall performance.

- Warranty and Service: Evaluate the after-sales support provided. Comprehensive warranty terms can indicate the manufacturer’s confidence in their product’s durability.

- Production Techniques: Ascertain which production method aligns with your volume needs. High-order retailers may benefit from hot pressing due to its efficiency, whereas custom orders might require cold pressing or thermoforming for precise control characteristics.

- Customization Options: Consider whether the manufacturer offers personalized paddle options. Customization can include design alterations, custom grip sizes, or even unique branding to suit the specific requirements of your sporting clientele.

- Material Costs: Premium materials like T300 carbon fiber or Nomex honeycomb cores might come with a higher price tag but offer superior control and longevity.

- Economic Efficiency: Conduct a cost-benefit analysis. Sometimes slightly higher initial costs result in lower long-term returns due to enhanced durability and user satisfaction.

Successful companies within the sports equipment sector often adopt the following practices:

- Joint R&D Efforts: Collaborate with manufacturers to fine-tune paddle designs based on real-world player feedback. This ensures that the final product meets the exact market requirements.

- Adherence to Standards: Maintain high production standards that ensure every paddle matches the performance claims. This includes strict quality control at each production stage.

- Flexibility in Production: Offer on-demand customization and small batch production runs to cater to niche markets, including high-end clubs and specialty sports stores.

- Data-Driven Decisions: Leverage performance data and feedback from professional players to refine product design continually. This not only improves paddle design but also builds brand trust.

A case in point is the evolution of NEX Pickleball paddles. By integrating advanced cold pressing techniques and utilizing premium composite materials, they have effectively catered to the control-focused market segment. Their commitment to rigorous testing and strategic customization has allowed them to remain competitive in a crowded market.

In summary, the control capabilities of pickleball paddles are a product of thoughtful material selection and precise manufacturing processes. For B2B buyers, investing in paddles that emphasize control can lead to higher player satisfaction through better game precision and reduced wear on the paddle. By comparing:

- Material types (from various carbon fibers to fiberglass and composite cores),

- Production techniques (hot pressing, cold pressing, and thermoforming),

procurement managers can align paddle attributes with their market’s performance and budget expectations. Examining factors like performance alignment, quality control, production scalability, and customization ensures that the final product is not only technically superior but also economically viable.

Ultimately, the decision of whether to stock control-centric paddles or opt for a power-oriented model depends on understanding your consumer base and matching their needs with high-performance products. We recommend engaging with manufacturers who demonstrate transparency in their production processes and share robust after-sales support—a strategy that will drive both confidence and profitability in your sports equipment offerings.

What pickleball paddle has the most control?

Control-focused paddles typically feature advanced materials such as Nomex honeycomb cores and are produced using techniques like cold pressing to maintain a precise ball feel. Premium composite and carbon fiber options ensure players experience a balance of power and control.

What is the best pickleball paddle to reduce vibration?

Paddles engineered for vibration dampening often use polymer honeycomb cores and incorporate advanced shock absorption technology. Manufacturers design these paddles to minimize the transfer of vibrations, providing a smoother striking experience that is particularly beneficial for players seeking enhanced comfort and control.

Should I get a control or power paddle?

The choice depends on your gameplay or your clientele's demands. Control paddles are tailored for precision shot placement and a softer touch, while power paddles deliver stronger hits but may sacrifice a degree of control. Evaluating your market's needs and playing styles will help you make the best decision.

-

carbon fiber: Reading this article will provide insights into the properties, manufacturing, and performance advantages of carbon fiber in high-performance sports equipment. ↩

-

Nomex: Reading this article will explain how Nomex honeycomb cores contribute to shock absorption and stability, enhancing the durability and control of sports paddles. ↩

-

Hot Pressing: Reading this article will offer a deeper understanding of the hot pressing process, its benefits in high-volume manufacturing, and its impact on material properties. ↩

-

Cold Pressing: Reading this article will elaborate on the cold pressing technique, highlighting its precision advantages and how it helps maintain the original material characteristics. ↩

-

Thermoforming: Reading this article will detail the thermoforming process, including its potential for intricate design and material distribution, essential for custom-made high-performance products. ↩