A thick core construction in a pickleball paddle can greatly enhance shock absorption and durability while balancing power and control. In today’s competitive landscape, choosing the right thick core option is critical for manufacturers looking to optimize performance and cost-efficiency.

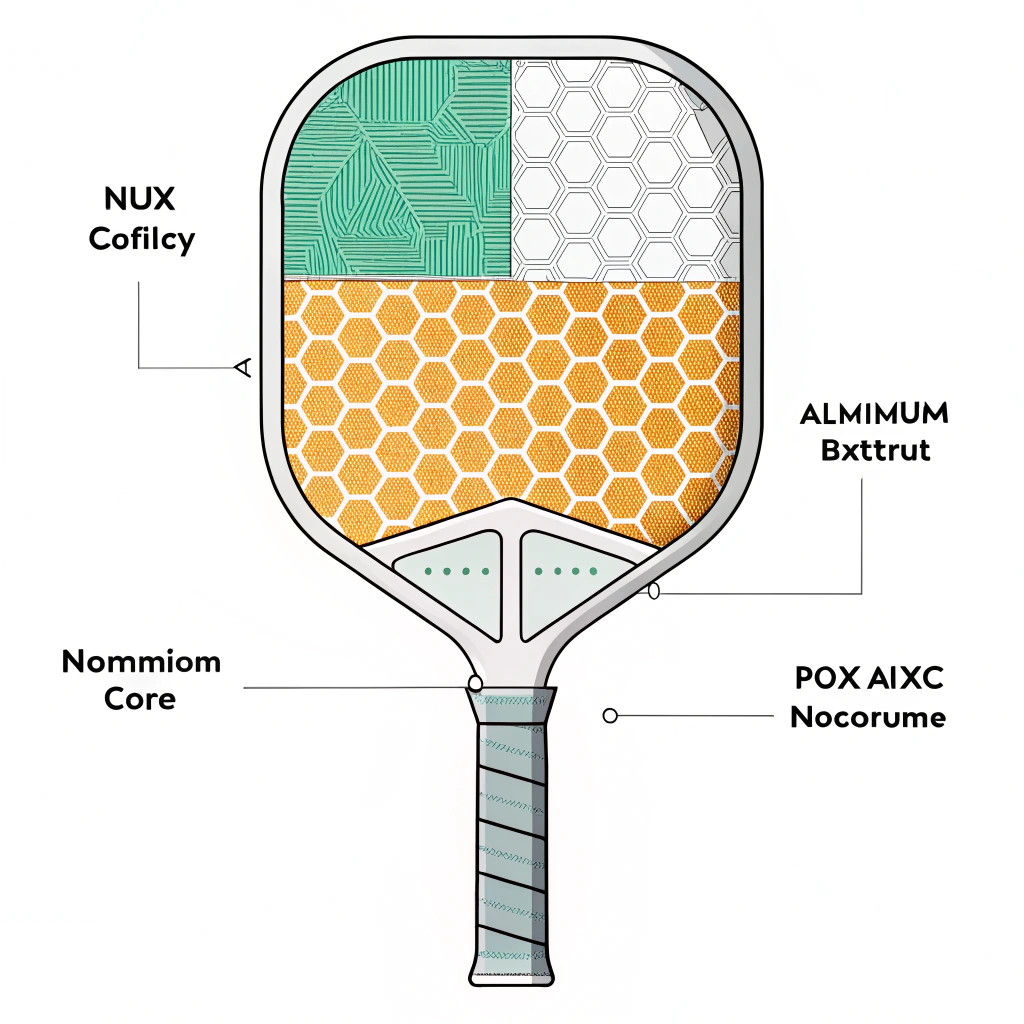

Manufacturers and procurement specialists must carefully assess the trade-offs among various thick core designs, especially when considering applications for high-performance pickleball paddles. A thick core can provide enhanced durability and vibration dampening, but the choice of core material—whether Nomex Honeycomb1, Aluminum Honeycomb2 or Polymer Honeycomb—directly influences both the performance characteristics and the manufacturing process. This article provides a detailed, comparative analysis to help industry professionals make informed decisions.

-

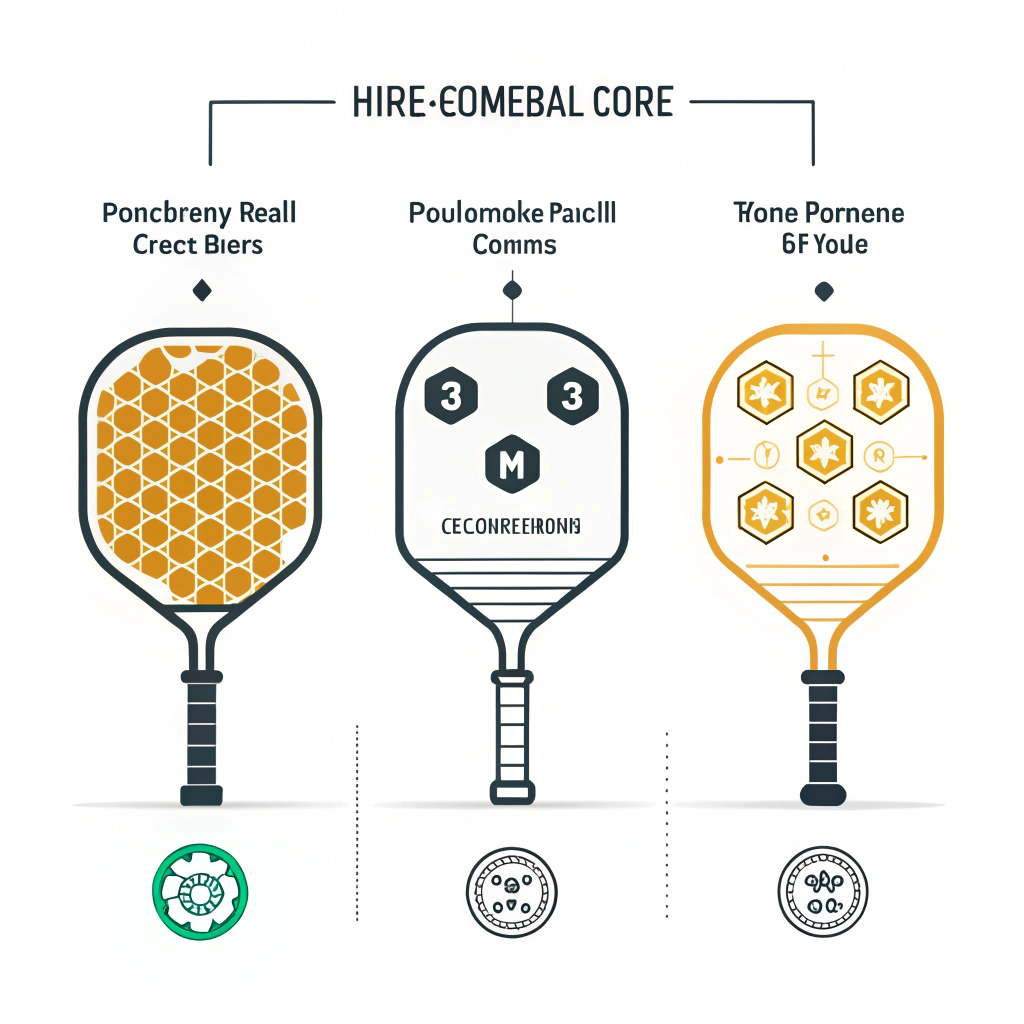

Nomex Honeycomb Core

- Strengths: Superior shock absorption and long-lasting durability.

- Performance: Ideal for players seeking stability and resistance to repeated impacts.

- Considerations: Slightly higher cost due to its premium properties.

-

Aluminum Honeycomb Core

- Strengths: Provides a balanced weight distribution with excellent power and control.

- Performance: Suited for competitive play where precision is critical.

- Considerations: Requires precise manufacturing due to potential weight fluctuation.

-

Polymer Honeycomb Core

- Strengths: Offers improved elasticity and reduced vibration.

- Performance: Popular among recreational players due to its comfort and forgiving nature.

- Considerations: May not offer the same long-term durability as Nomex.

Manufacturers also consider the Polymer/Polypropylene Core3, which is commonly found in the market. This core provides the essentials needed across all player levels, balancing performance with cost efficiency.

The following table highlights key performance metrics and considerations for each thick core material:

| Core Material | Shock Absorption | Durability | Control | Cost Efficiency | Ideal For |

|---|---|---|---|---|---|

| Nomex Honeycomb Core | Excellent | High | Good | Moderate-High | Competitive/High-performance |

| Aluminum Honeycomb Core | Good | Moderate | Excellent | Moderate | Precision-based play |

| Polymer Honeycomb Core | Good | Moderate | Excellent | High | Recreational & Beginner Levels |

| Polymer/Polypropylene Core | Fair | Moderate | Fair | High | Versatile, all-level usage |

For B2B decision-makers in sports equipment procurement, this table acts as a quick reference to align product performance with target demographics.

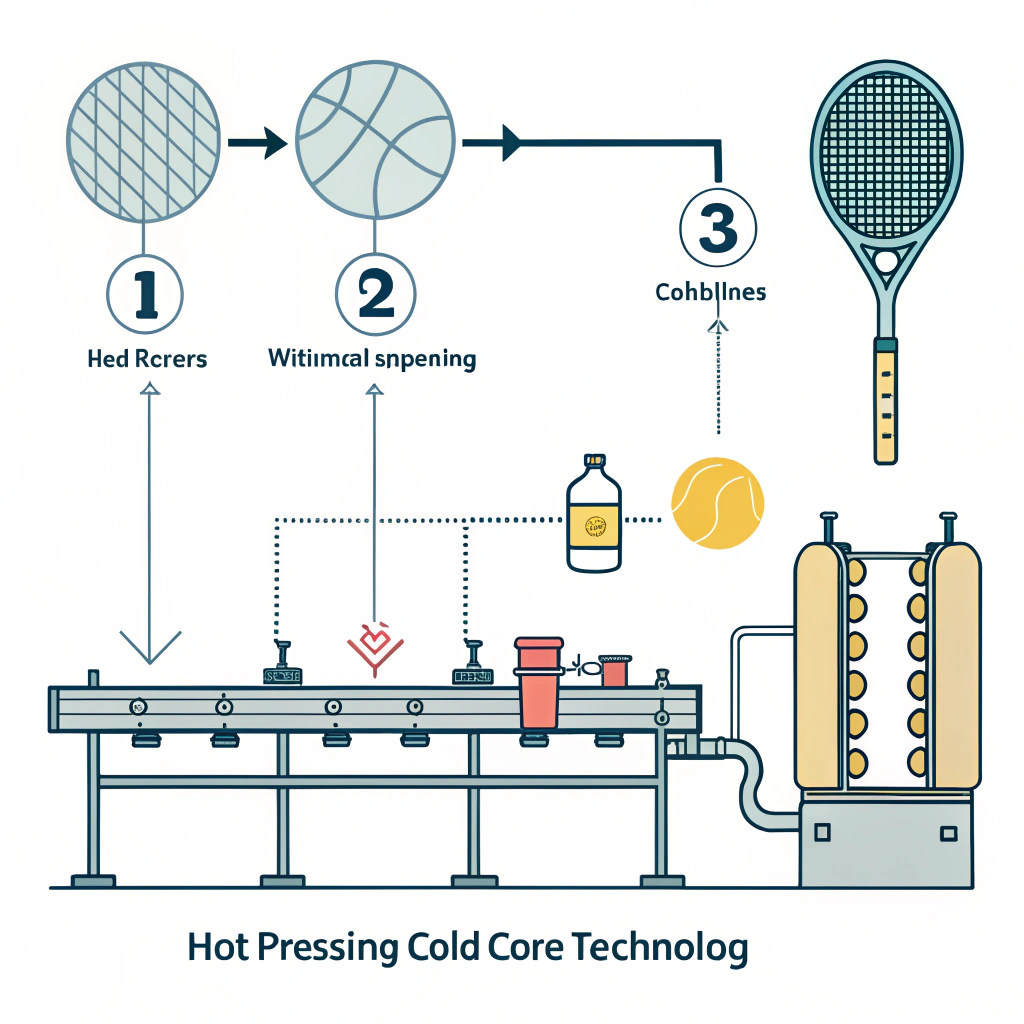

Selecting a thick core design is intrinsically linked to the chosen production process, each of which influences the final paddle properties. At NEX Pickleball, we utilize advanced manufacturing processes that cater to both precision and efficiency.

Hot pressing is a high-efficiency process that involves heating materials and applying pressure to form a paddle.

- Advantages:

- Ensures strong structural integrity and excellent impact resistance.

- High production speed, making it suitable for large-scale manufacturing.

- Disadvantages:

- The heat can alter material properties, potentially affecting the paddle’s feel.

- Requires significant investment in specialized equipment.

Cold pressing shapes the paddle material at room temperature under mechanical pressure.

- Advantages:

- Retains the innate properties of the materials, particularly beneficial for maintaining tactile feedback.

- Offers precise control over the thickness and structure for a customized feel.

- Disadvantages:

- Slower production cycles due to the longer pressing duration.

- Demands high-precision equipment, which may increase initial costs.

Thermoforming involves heating material until it softens and then molding it to a specific shape using precision molds.

- Advantages:

- Allows for intricate designs and optimized material distribution.

- Enhances paddle stability and overall performance through consistent structural properties.

- Disadvantages:

- Time-intensive and typically more expensive due to higher energy costs and longer cycle times.

- Best suited for high-end, custom paddle options rather than mass production.

Understanding the interplay between core material choice and production method is crucial. For example, when using an Aluminum Honeycomb Core in a thick paddle, a precise cold pressing method might be preferred to maintain the core’s balance and control characteristics. Conversely, using a Nomex Honeycomb Core in combination with hot pressing can produce paddles that emphasize durability and shock absorption, ideal for high-impact competitive play.

Manufacturers and R&D teams are often challenged by the need to balance paddle performance with production efficiency. Here are several key factors to consider:

-

Material Integrity vs. Production Speed:

Hot pressing achieves rapid production but can compromise some tactile qualities. Cold pressing preserves material integrity, yet the longer manufacturing time increases production costs. -

Customization and Flexibility:

Thermoforming, while slower and more costly, provides unmatched flexibility in design. This process is especially useful for custom paddle orders or low-volume, high-end products where nuanced design elements make a significant difference. -

Economic Considerations:

For OEM partners and B2B customers, understanding cost breakdowns is essential. Selecting a core material like Polymer Honeycomb may offer the best trade-off between performance and cost for recreational paddles, while competitive paddles benefit from premium cores despite higher raw material and production expenses. -

Quality Control and Consistency:

Advanced production techniques at NEX Pickleball ensure that every paddle meets the highest standards. Coupled with rigorous testing regimes, this commitment to quality across different manufacturing methods provides a competitive edge in the B2B market.

To illustrate the application of these insights, consider a scenario where a sports equipment company is developing a new line of competitive pickleball paddles. The decision-makers are evaluating if a thicker core construction would improve performance while ensuring acceptable production costs.

- Objective: Enhance durability and shock absorption without sacrificing control and precision.

- Core Options Considered: Nomex Honeycomb, Aluminum Honeycomb, and Polymer Honeycomb.

- Production Constraints: Need for high production volume with minimal variation in quality, balanced against the requirement for tactile precision.

-

Material Analysis:

The Nomex Honeycomb Core was favored for its shock absorption and durability, yet its cost was higher. The Aluminum Honeycomb Core offered excellent control, but with slightly reduced shock absorption. In cases where the paddle needed to serve a wider range of players without premium pricing, the Polymer Honeycomb Core was considered. -

Processing Considerations:

Given the high production volume envisioned, hot pressing was evaluated. However, the potential change in feel led to additional tests using cold pressing. Ultimately, a hybrid approach was adopted—using a lower-temperature hot pressing method, followed by precision finishing to maintain material integrity. -

Outcome:

The final design integrated a Nomex Honeycomb Thick Core for enhanced shock absorption and durability, with minor adjustments using cold pressing techniques to retain control. This balance allowed the product to meet the performance needs of competitive players while ensuring production efficiency.

| Decision Factor | Preferred Choice | Rationale |

|---|---|---|

| Core Material | Nomex Honeycomb | Best shock absorption and durability |

| Production Process | Hybrid (Hot Press + Finishing) | Balances speed and material integrity |

| Target Market | Competitive High-Performance Paddles | Meets the needs of elite players |

This case study demonstrates that a well-informed combination of thick core materials and tailored production processes can deliver a paddle optimized for both performance and efficiency.

For companies evaluating thick core paddle options, consider the following steps:

-

Conduct In-House Trials:

Test paddles using different cores (Nomex, Aluminum, Polymer) in real match conditions to gather comparative performance data. -

Optimize Manufacturing Processes:

Factor in production speeds and cost implications when choosing between hot pressing, cold pressing, or thermoforming. A blended approach might yield the best overall quality. -

Assess Customization Requirements:

Determine if there is a market demand for custom paddle solutions. Processes like thermoforming may be more suited for low-volume, high-performance orders. -

Consider Long-Term Durability:

Evaluate the balance of shock absorption and control. In many cases, a thicker core might provide the durability needed for competitive play without sacrificing playability. -

Leverage Collaborative Partnerships:

Engaging with experienced OEM partners like NEX Pickleball can help in not only standardizing production processes but also tapping into advanced material technologies and testing regimes.

By following these steps, B2B decision-makers can better match product specifications with market demands and production realities.

What is the best core for pickleball paddles?

The best core often depends on the specific needs of the player and the intended market. For most pickleball paddles, the Polymer/Polypropylene core is widely used due to its balance of performance, cost, and durability, making it suitable for a broad range of players.

Is 19mm too thick for a pickleball paddle?

Paddle thickness generally ranges from 11mm to 16mm, but some designs explore thicker constructions like 19mm. While a thicker paddle can enhance shock absorption and durability, it must be designed carefully to ensure optimal control and power.

Which pickleball paddle hits the hardest?

Paddle hardness and performance depend on a combination of factors including core material, overall weight, and construction. While high-performance paddles from major brands can deliver exceptional power, the ideal choice varies according to playing style and specific performance needs.

-

Nomex Honeycomb: Reading this article helps you understand the properties of Nomex Honeycomb, a premium composite used for its superior shock absorption and durability in high-impact applications. ↩ ↩

-

Aluminum Honeycomb: Explore detailed insights on Aluminum Honeycomb to learn how its balanced weight distribution enhances power and control while maintaining structural efficiency. ↩ ↩

-

Polymer/Polypropylene Core: Delve into the benefits and trade-offs of the Polymer/Polypropylene Core, focusing on its role in balancing performance and cost efficiency across various paddle types. ↩ ↩

-

Cold Pressing: Understand cold pressing, a production method that retains material integrity and allows for precise control over paddle structure, ideal for maintaining tactile feedback in custom designs. ↩ ↩

-

Thermoforming: Learn about thermoforming as a manufacturing process that enables intricate designs and optimized material distribution, critical for producing high-end, custom paddle options. ↩ ↩