Thermoforming offers an efficient, high-precision solution for manufacturing high-performance pickleball paddles by using controlled heat and pressure to create intricate designs. This process not only ensures an expanded sweet spot for improved performance on the court but also delivers excellent material distribution, quality control, and customization capabilities. In this article, we compare thermoforming1 with traditional methods such as hot pressing2 and cold pressing3 so that production managers and procurement specialists can make a well-informed decision.

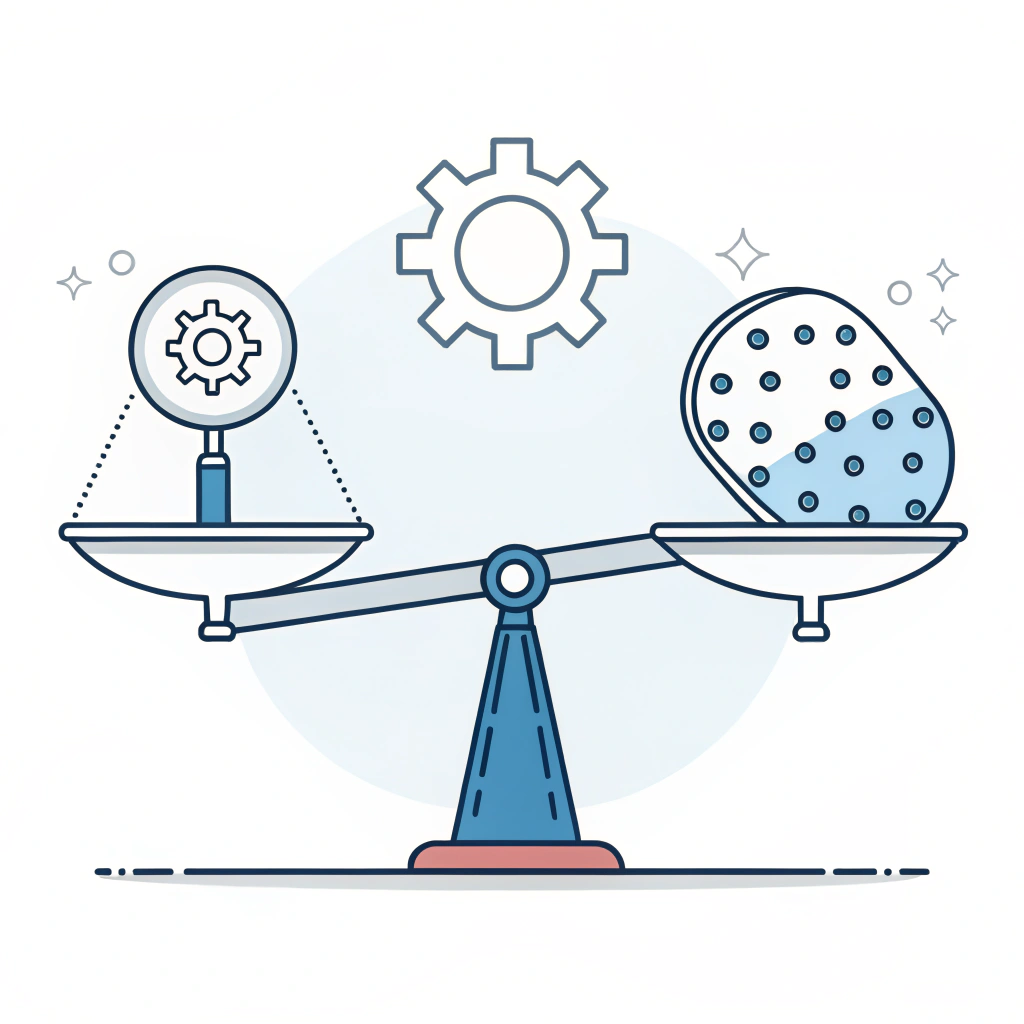

Selecting the right production process for pickleball paddles involves balancing performance, cost-efficiency, and material integrity. For sports equipment companies, especially those designing high-performance paddles, ensuring precise control over material distribution and structural durability is critical. Traditional methods like hot pressing and cold pressing have served the industry well. However, as production and design requirements evolve, thermoforming has emerged as a viable alternative.

The major challenge lies in understanding how each process influences the paddle’s performance attributes—such as weight distribution, impact resistance, and ergonomic design—and whether these benefits justify potential increases in production time or costs.

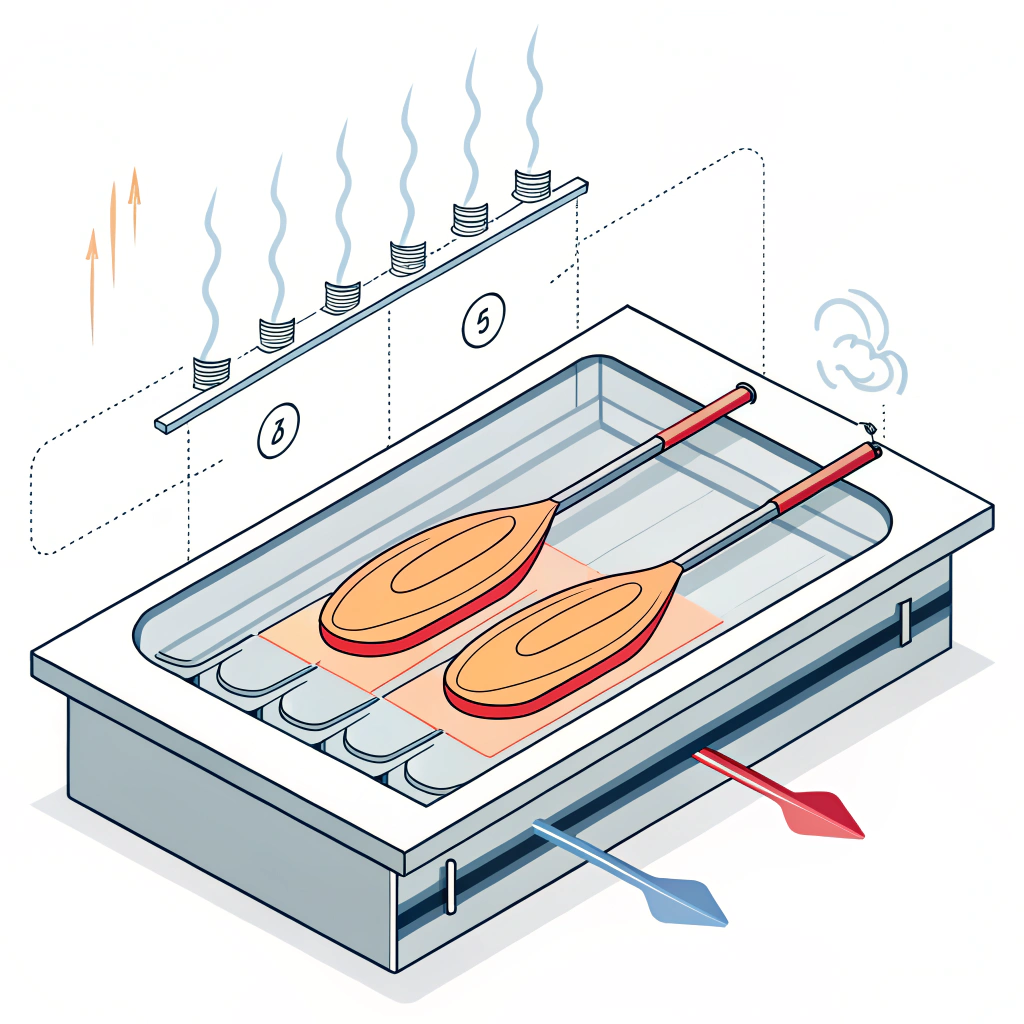

Thermoforming involves heating the paddle materials to a controlled softening point before they are shaped using precision molds. This method supports the creation of paddles with complex geometries, optimized material distribution, and an expanded sweet spot, which is crucial for competitive play.

Key advantages of thermoforming include:

- Intricate Designs: Ability to craft elaborate shapes and maintain even material thickness.

- Quality Control: Highly accurate molds that ensure consistent production and paddle stability.

- Enhanced Performance: Expanded sweet spot and balanced weight distribution result in improved control and power.

- Customization: Flexibility in choosing advanced materials such as various types of carbon fiber and composite formulations.

Despite its many advantages, thermoforming comes with a few caveats:

- Longer Production Times: The process requires meticulous temperature control and longer production cycles.

- Higher Equipment Costs: Investment in high-precision molding systems4 is necessary.

- Best Suited for Premium Products: Given the cost and time implications, thermoforming is generally adopted for high-value, custom-made paddles rather than mass-market items.

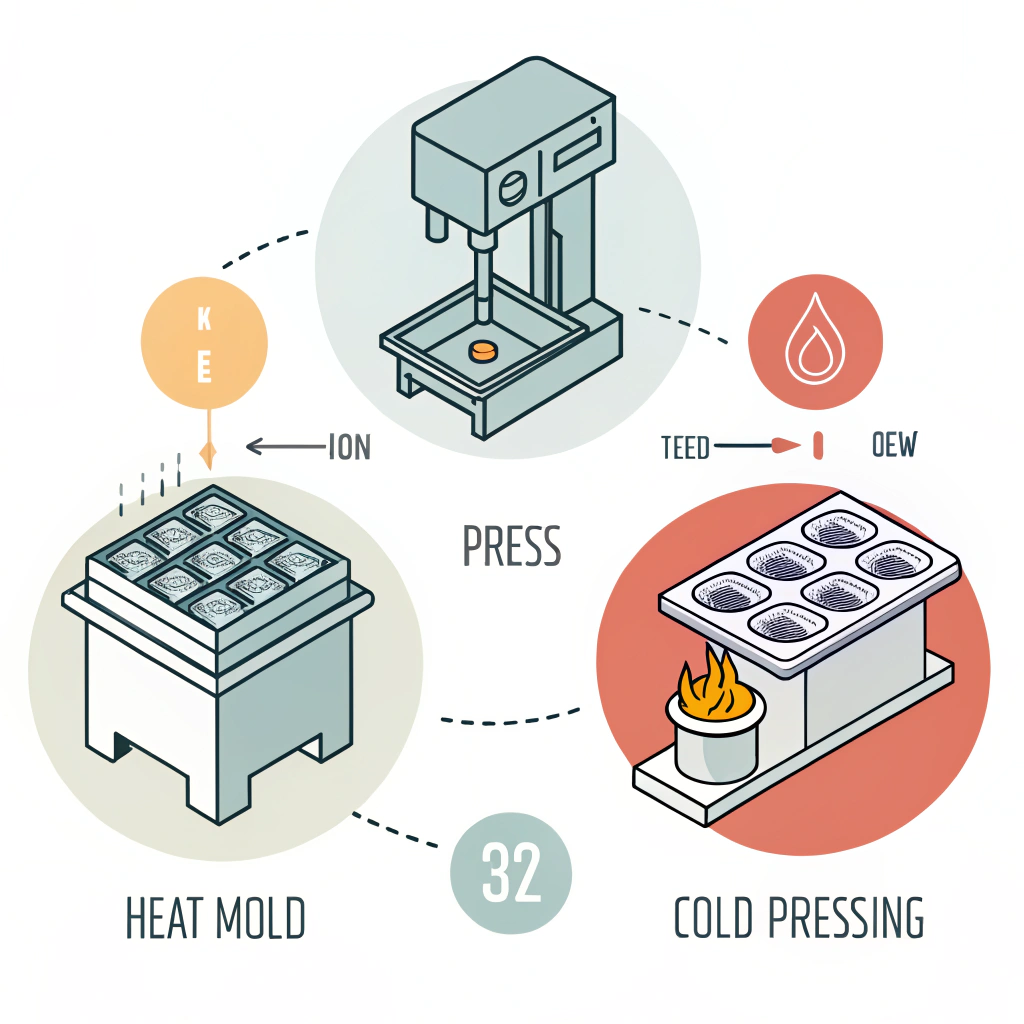

Hot pressing is a widely-used method in paddle manufacturing that employs heat and high pressure to form the material. This process generates paddles with excellent structural integrity and is particularly effective for producing high-strength paddles.

Advantages include:

- High Efficiency: Suitable for large-scale production due to its speed.

- Durability: Produces paddles with strong resistance against impacts.

- Structural Integrity: Ensures that the paddle maintains a reliable structure even under heavy use.

However, limitations are also evident:

- Altered Material Properties: High temperatures may modify the intrinsic properties of certain materials, potentially affecting paddle feel.

- Equipment Intensity: Requires substantial investment in industrial machinery.

- Limited Customization: Less flexibility in crafting intricate paddle designs compared to thermoforming.

Cold pressing shapes paddle materials at room temperature using mechanical pressure. This meticulous process is ideal for ensuring a more precise control over thickness and overall paddle structure.

Notable benefits include:

- Material Preservation: Maintains the original properties of the materials for better control and flexibility.

- Enhanced Ball Feel: Superior responsiveness due to the integrity of material properties.

- Precision Control: Ideal for designs requiring exact thickness and detailed edge work.

Challenges associated with cold pressing:

- Longer Production Cycle: Requires time to achieve precision, reducing overall throughput.

- Stringent Quality Equipment: Demands high-quality machinery to maintain consistent pressure and results.

- Limited Scalability: Best used for lower volume productions or specialized products.

To provide a clearer picture, consider the following table summarizing key differences among the three processes:

| Process | Production Time | Equipment Investment | Design Flexibility | Material Integrity | Ideal For |

|---|---|---|---|---|---|

| Thermoforming | Longer (due to heating and cooling cycles) | High (precision molds and controlled heating systems) | High – supports complex geometries and customization | Very Good – maintains consistency through controlled process | High-performance, custom, and premium paddles |

| Hot Pressing | Fast, suitable for mass production | Medium to High (industrial pressing equipment) | Medium – limited by heat effects on materials | Good – may alter some material properties | Large-scale production of durable paddles |

| Cold Pressing | Moderate to Long (precision-based) | High (requires precise pressure control machinery) | Medium – precise control with some limitations | Excellent – preserves natural material qualities | Specialized paddles with superior control and ball feel |

In making your decision, weigh factors such as production volume, desired product performance, and the specific quality attributes that your customers value.

A significant benefit of using thermoforming in paddle production is the expanded sweet spot. This is achieved by optimizing material distribution, resulting in a larger impact area during play. An enhanced sweet spot allows players to execute more consistent and powerful shots, delivering a competitive edge on the court.

Thermoforming’s process, which leverages exact heat application and mold design, guarantees high precision in paddle construction. This precision ensures that each paddle exhibits uniform structural integrity, making it ideal for competitive sports where performance inconsistencies can affect outcomes. The reduced vibration and improved stability are critical performance aspects that are directly linked to this controlled process.

One of the standout features of thermoforming is its flexibility. Manufacturers can experiment with combinations of advanced materials5 like various carbon fibers (3K, 12K, T300) and composite cores (Nomex, aluminum, polymer, bamboo) to suit different player styles and market demands. This versatility not only boosts product performance but also opens the door to innovative paddle designs that cater to evolving consumer preferences.

For manufacturers looking to push the boundaries of design, thermoforming offers the necessary tools to create paddles that are not just functional but aesthetically appealing. The ability to incorporate complex shapes and textures can set a product apart in a competitive market, providing both functional excellence and attractive design cues.

At NEX Pickleball, the evolution towards thermoforming was driven by the need to merge high-performance design with innovative production techniques. Our experience transitioning from traditional methods to incorporating thermoforming can be summarized as follows:

- Enhanced Product Performance: By leveraging thermoforming, we observed a measurable improvement in paddle balance and an expanded sweet spot. This translated into paddles that responded more robustly in competitive settings.

- Optimized Production Efficiency: While thermoforming requires a longer production cycle, the precision and consistency it provides have reduced quality control issues. Fewer material inconsistencies and better performance metrics justified the additional time and equipment costs.

- Market Differentiation: Deploying thermoformed paddles allowed us to differentiate our product line. Customers noted the superior feel and enhanced control during play, reinforcing our position as a provider of high-performance pickleball equipment.

- Cost-Benefit Justification: Although the initial setup cost is higher, the long-term benefits—in terms of brand reputation and product reliability—made thermoforming a strategic choice for our premium product offerings.

This experience underscores the critical role of advanced manufacturing techniques in elevating product quality and satisfying the increasing demands of competitive players.

Your decision should consider multiple factors:

- Volume Requirements: For large-scale production, hot pressing may be more attractive due to its speed. However, if your focus is on premium, custom production, the extra time required by thermoforming is justified by the superior quality and performance features.

- Product Performance: If an expanded sweet spot and enhanced structural stability are paramount, thermoforming outperforms traditional methods.

- Budget Considerations: While thermoforming demands higher initial investments, the long-term benefits in reduced quality issues and brand differentiation can provide better ROI for high-end products.

- Customization Needs: When innovation and design complexity are central to your product strategy, the design flexibility of thermoforming enables more creative and performance-optimized solutions.

In summary, thermoforming is particularly valuable when performance enhancement, material innovation, and product customization are prioritized over rapid mass production.

Thermoforming offers a progressive approach to manufacturing high-performance pickleball paddles. Its ability to create paddles with an expanded sweet spot, highly uniform quality, and advanced design features makes it a compelling option compared to traditional hot pressing and cold pressing methods. While the process entails a longer production time and higher equipment investment, the benefits in terms of performance and customizability deliver value, especially for premium product lines.

For manufacturing procurement specialists or product development managers looking to enhance their production techniques, considering thermoforming can lead to superior paddle performance and a strong market differentiation. It is recommended to conduct a detailed cost-benefit analysis, factoring in product performance targets, production volume needs, and innovation strategy before shifting or integrating this process into your manufacturing line.

Moving forward, evaluate your current production goals and assess if the long-term benefits of thermoforming align with your business objectives. In cases where meeting the highest performance standards is crucial, thermoforming not only meets but exceeds expectations, making it an investment in the future of competitive sports equipment manufacturing.

People Also Ask

-

Are thermoformed pickleball paddles better?

Thermoformed pickleball paddles are designed to offer an improved sweet spot by optimizing material distribution during production. This results in enhanced performance, as players experience more consistent and powerful shots due to the larger optimal contact area. -

How to tell if a pickleball paddle is thermoformed?

You can identify a thermoformed pickleball paddle by noting its construction process, where heat is used to mold the paddle material before integrating a foam core. When inspected, these paddles typically do not show defined layers as seen in multi-layered sandwich constructions.

-

thermoforming: Click to learn how the thermoforming manufacturing process uses controlled heat and pressure to create intricate designs and improve product performance. ↩

-

hot pressing: Click to explore the hot pressing method, its advantages for high-strength production, and its role in large-scale manufacturing. ↩

-

cold pressing: Click to understand the cold pressing process, its precise material control benefits, and its applications in specialized production. ↩

-

high-precision molding systems: Click to investigate high-precision molding systems and how they contribute to consistent quality control and superior product outcomes. ↩

-

advanced materials: Click to delve into advanced materials, including various carbon fibers and composite formulations, and their impact on product innovation. ↩