Thermoformed pickleball paddles offer a unique manufacturing advantage by combining complex design flexibility, enhanced material distribution, and superior performance characteristics compared to traditional methods. In this article, we explore how thermoforming stands out against alternative production processes, providing key insights for purchasing agents and product managers making strategic decisions for high-performance sports equipment.

Pickleball equipment manufacturers are continuously seeking methods that deliver paddles with not only remarkable durability and performance but also cost-effective production efficiencies. When comparing thermoformed1 paddles to those made using hot pressing2 or cold pressing3 techniques, one must consider multiple factors: production speed, material integrity, design flexibility, and overall performance. In today’s competitive market, making an informed decision requires a clear understanding of the pros and cons of each process.

The challenge lies in balancing innovative design with consistent quality. Manufacturers like NEX Pickleball, who serve as the OEM4 for well-known brands such as Joola and Selkirk, have embraced advanced production techniques to meet the evolving demands of competitive and recreational pickleball players alike.

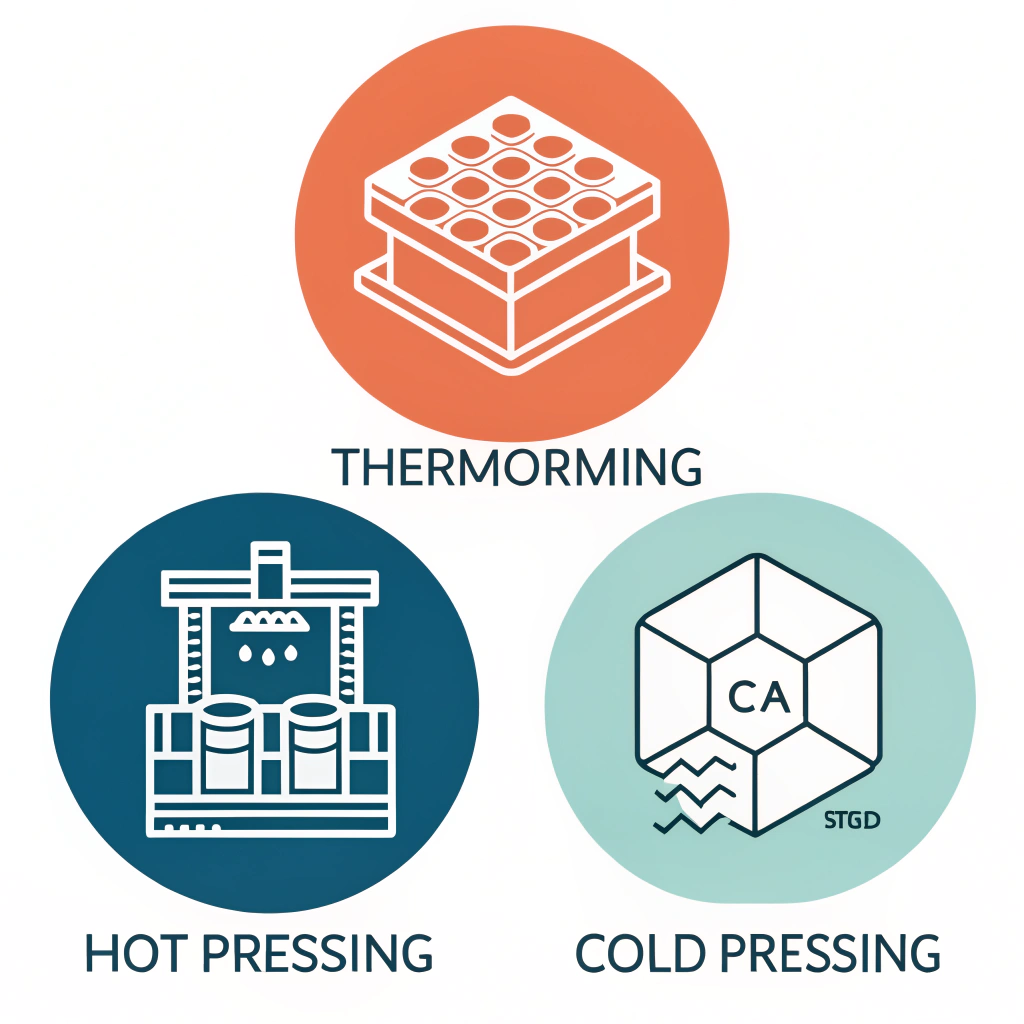

To make a prudent purchasing decision, it is crucial to understand the three primary production methods used in high-performance pickleball paddles:

- Thermoforming: Involves heating the material to a softening point and then molding it into a specific shape using precision molds.

- Hot Pressing: Uses heat and pressure simultaneously to form the paddle, ensuring high structural integrity.

- Cold Pressing: Shapes the material at room temperature with mechanical pressure, preserving the material's innate properties.

Each method has distinct advantages and drawbacks that impact the paddle’s final performance, durability, and cost-efficiency.

Thermoforming is a sophisticated process where materials such as premium plastics and composites are heated until malleable. The material is then transferred into high-precision molds that shape the paddle. This technique is particularly beneficial for achieving an intricate design with a well-distributed material layout, which can enhance the size and quality of the "sweet spot" on the paddle face.

Advantages:

- Design Flexibility: Enables the creation of paddles with intricate geometries that optimize performance and ergonomics.

- Enhanced Material Distribution: Even heat distribution helps maintain material properties, resulting in better impact resistance and durability.

- Stability: The process provides excellent structural stability, contributing to precise weight distribution and balance.

Disadvantages:

- Higher Equipment Costs: Thermoforming requires specialized machinery and molds, increasing initial capital expenditure.

- Longer Production Times: The method involves heating and cooling cycles, leading to extended production times as compared to hot pressing.

In contrast, hot pressing applies heat and pressure simultaneously to form a paddle. This method is widely used for high-volume production and usually results in products that have robust impact resistance and strong structural integrity.

Advantages:

- Efficient for Mass Production: High throughput is possible due to the rapid production cycle.

- High Impact Resistance: Produces a durable paddle suitable for high-performance and competitive play.

Disadvantages:

- Material Property Alterations: The intense heat may alter some intrinsic material properties, potentially affecting the paddle's surface feel.

- Equipment Investment: The need for high-temperature equipment can be a barrier for smaller manufacturers.

Cold pressing is a method that shapes the paddle material using mechanical pressure without applying heat. This technique is ideal for designs that demand precise control over the material’s thickness and structure, preserving the natural flexibility and responsiveness of the material.

Advantages:

- Maintains Material Integrity: The absence of heat allows the material to retain its original properties.

- Superior Ball Feel: Offers excellent tactile feedback, making the paddle ideal for controlled, precision play.

Disadvantages:

- Longer Production Cycle: Takes more time to achieve desired accuracy compared to hot pressing.

- Sensitivity to Pressure: Requires very precise pressure control and high-quality machinery.

Below is a table summarizing the key factors for thermoforming, hot pressing, and cold pressing:

| Production Process | Design Flexibility | Production Efficiency | Material Integrity | Cost of Equipment | Impact Resistance |

|---|---|---|---|---|---|

| Thermoforming | High | Medium | High | High | High |

| Hot Pressing | Medium | High | Medium | Medium | High |

| Cold Pressing | Medium | Low | Very High | Medium | Medium |

This table provides a quick reference for decision-makers evaluating the critical performance parameters triggered by each manufacturing technique.

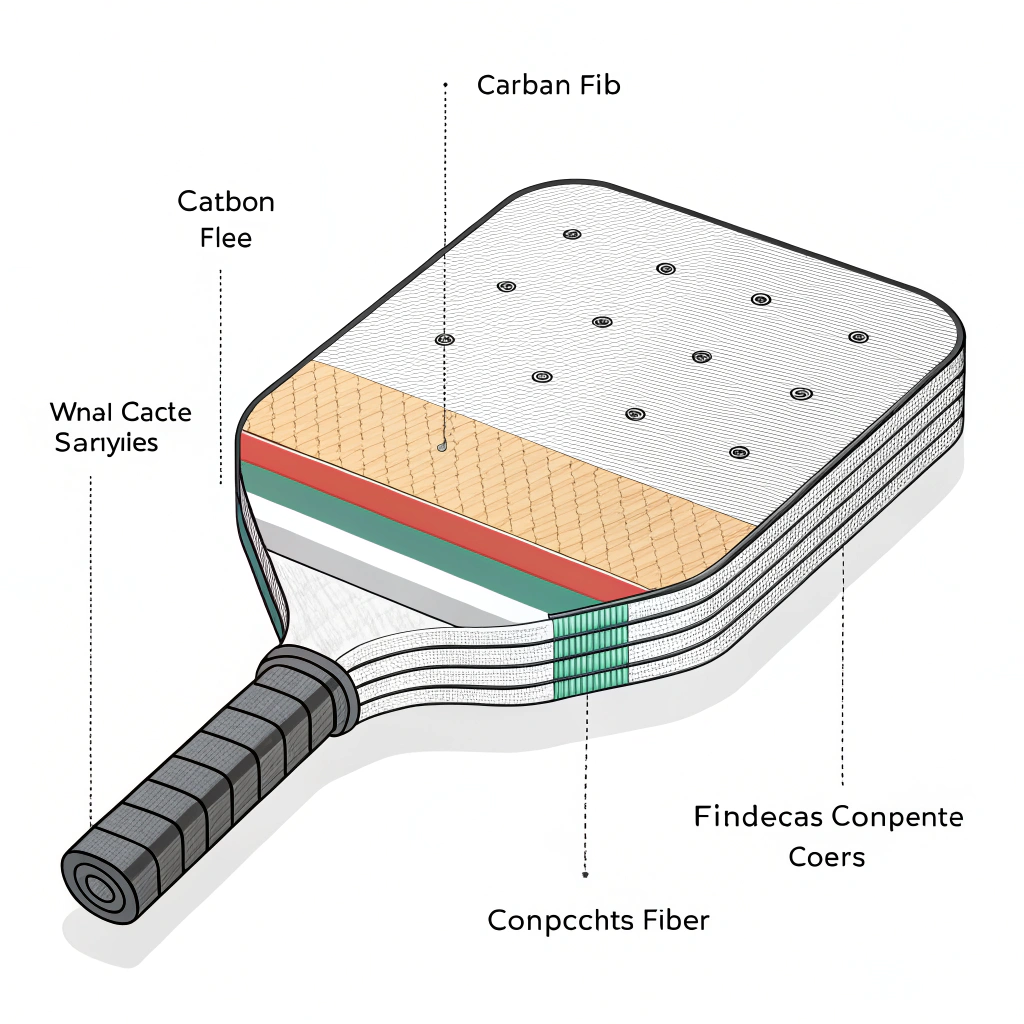

The use of premium materials significantly influences the performance of pickleball paddles. At NEX Pickleball, the selection of materials such as carbon fiber5, fiberglass, and composite materials is driven by the need for both enhanced power and precise control.

- 3K Carbon Fiber: Recognized for its flexibility and strength, this material minimizes vibration and is ideal for paddles requiring high rebound forces.

- 12K Carbon Fiber: With a higher thread density, these paddles achieve a durable and smooth surface, essential for competitive play.

- T300 Carbon Fiber: Balances strength and lightweight properties, making it suitable for paddles where precision and agility are critical.

Beyond carbon fiber, composite materials combine the benefits of different elements:

- Carbon Fiber and Fiberglass Composite: Offers a balanced mix, giving players both power and control.

- Bamboo Core Composite: Delivers a lightweight feel with high impact resistance.

- Honeycomb Core (Nomex, Aluminum, Polymer): Each type provides distinct advantages ranging from superior shock absorption to better elasticity, enhancing paddle comfort and precision.

The production process used—whether thermoforming, hot pressing, or cold pressing—can influence how these materials behave in the final product. With thermoforming, the controlled heating cycle helps to preserve and optimize the properties of these materials, ensuring that players get a paddle that is both durable and performance-rich.

Manufacturing high-performance pickleball paddles requires a balance of cutting-edge technology and precise engineering. Let us break down the real-world application using thermoforming:

-

Enhanced Sweet Spot: Through thermoforming, manufacturers can engineer a larger and more consistent sweet spot. This is achieved by precisely controlling the mold design and material distribution. A larger sweet spot means greater forgiveness during off-center hits and improved overall game performance.

-

Ergonomic Design: Thermoforming allows for intricate molding that results in paddles with ergonomic grips and balanced weight distribution. This is crucial for reducing player fatigue and enhancing control, especially during long matches.

-

Consistency in Quality: The heat molding process in thermoforming ensures that each paddle maintains uniform performance characteristics. This is particularly important for OEMs who supply products across various markets and need a consistent quality benchmark.

An example of thermoforming’s benefits can be seen in the production of paddles for competitive sports organizations. With enhanced design flexibility, companies can offer custom paddle options—adjusting weight, balance, grip, and surface texture—to meet the diverse needs of players at all levels. This aligns perfectly with the growing demand for customized sporting goods in B2B markets.

Furthermore, rigorous quality control measures are implemented at every production step. Each paddle undergoes comprehensive testing to ensure that it meets the highest standards of precision engineering, durability, and user comfort. This level of scrutiny is especially important in industries where equipment performance directly impacts competitive outcomes.

When evaluating production processes, a detailed cost-benefit analysis is essential. For companies considering a shift towards thermoformed pickleball paddles, the longer production time and higher initial equipment cost must be balanced against their long-term benefits.

- Enhanced Product Quality: Increased design flexibility can directly translate into a superior product with better performance metrics.

- Customer Satisfaction: End-users benefit from improved ergonomics and performance, resulting in positive reviews and repeat business.

- Competitive Advantage: High-performance paddles built with advanced production techniques can position a brand at the forefront of the market.

- Initial Capital Investment: The requirement for advanced machinery and specialized molds can be a significant financial consideration.

- Production Cycle: Longer production times may reduce output volume compared to hot pressing, necessitating careful planning in high-demand environments.

A detailed comparison table helps illustrate these trade-offs:

| Factor | Thermoforming | Traditional Hot Pressing | Traditional Cold Pressing |

|---|---|---|---|

| Design Flexibility | Very High | Moderate | Moderate |

| Production Time | Longer | Shorter | Long |

| Equipment Costs | High | Moderate | Moderate |

| Customization Potential | High | Low | Low |

| Performance Consistency | High | High | Very High |

For organizations with the capability to invest in thermoforming, this method can ultimately deliver a product that meets the high-performance standards demanded in today’s competitive market.

For purchasing agents and product managers evaluating production methods for pickleball paddles, consider the following action points:

- Evaluate your current production scale and budget. If customized high-performance features and ergonomic designs are a priority, investing in thermoforming may provide long-term advantages.

- Examine market demand for advanced paddle features, such as a larger sweet spot and improved vibration control. These aspects are key drivers for customer satisfaction and competitive differentiation.

- Conduct a trial run using thermoforming to gather real-world data on production efficiency, product durability, and overall player feedback.

- Consider a phased approach—integrate thermoforming alongside traditional pressing techniques to diversify product offerings and gradually upscale production capacity.

- Regularly consult quality control benchmarks and performance test data to ensure that each paddle adheres to the highest industry standards.

By taking these steps, decision-makers can make a data-driven choice that not only meets technical performance requirements but also enhances market positioning in an increasingly competitive sports equipment landscape.

What paddles are thermoformed?

Thermoformed pickleball paddles are made using a controlled heat molding process that shapes premium materials into intricate designs. This process not only enhances the paddle’s sweet spot and power but also ensures even material distribution and improved impact resistance.

What is the best pickleball paddle for seniors?

For seniors, paddles made from lightweight materials like fiberglass and carbon fiber are ideal. Their reduced weight and enhanced control provide better playability, making them an excellent choice for players who prioritize precision and comfort over heavy power.

-

Thermoformed: Click here to learn about the thermoforming process, which involves heating and molding materials to create complex shapes with enhanced design flexibility and performance benefits. ↩

-

Hot Pressing: Click here to explore hot pressing techniques used for high-volume manufacturing, which focus on applying simultaneous heat and pressure to ensure strong structural integrity. ↩

-

Cold Pressing: Click here to understand cold pressing processes that shape materials at room temperature through mechanical pressure, preserving essential material properties for superior performance. ↩

-

OEM: Click here to read about Original Equipment Manufacturers (OEMs) and how they collaborate with brands to deliver high-quality, custom-designed products in competitive markets. ↩

-

Carbon Fiber: Click here for insights on carbon fiber applications in manufacturing, its advantages in terms of lightweight strength and durability, and its role in enhancing product performance. ↩