Thermoforming for Pickleball Paddles: A Game-Changer in Manufacturing

Quick Answer: Thermoforming1 offers enhanced durability, stability, and performance by using controlled heat and pressure to mold paddles, resulting in minimized vibrations and improved shot control.

In today's competitive sports equipment market, manufacturers face the challenge of delivering paddles that not only perform under rigorous play conditions but also cost-effectively meet production demands. Thermoforming1 is emerging as a solution that addresses these issues, offering a balance between high performance, durability, and innovative design. This article explores the thermoforming process in pickleball paddle manufacturing, compares it with traditional methods, and provides actionable insights for procurement specialists and product managers seeking to optimize production.

Modern pickleball players demand paddles that provide peak performance, energy efficiency, and comfort. Traditional manufacturing processes—such as hot pressing and cold pressing—have been reliable in producing paddles, but they come with trade-offs. For example:

• Hot pressing allows rapid production and structural strength but can alter material properties and affect the paddle's feel.

• Cold pressing maintains material properties and ensures precise control over thickness, but extended production cycles and equipment precision requirements raise costs.

Thermoforming1 offers an innovative alternative by applying heat to soften materials, allowing them to be easily molded into a design that maximizes performance. This process produces paddles with better resilience and improved overall control.

Thermoforming distinguishes itself through its unique combination of pressure and heat during production. Unlike the sandwich construction method, where distinct layers are visible, thermoforming integrates materials into a single cohesive structure. This integration brings several advantages:

-

Enhanced Stability and Impact Resistance:

The thermoforming process minimizes vibrations during play—a benefit that is critical for maintaining shot stability. By using controlled heat and pressure, materials achieve a uniform bond that absorbs shock effectively. -

Superior Material Integration:

When materials are molded together during thermoforming, there is no visible separation of layers. This yield a consistent and resilient paddle surface that is less prone to delamination or damage over time. -

Flexibility in Design:

The ability to mold paddles into intricate shapes opens up a broad design spectrum. Manufacturers can achieve optimized weight distribution and ergonomic designs that appeal to players at all levels, from recreational enthusiasts to competitive athletes. -

Cost-Effective Production for Premium Quality:

While the thermoforming process may involve higher initial equipment costs, its long-term benefits—such as reduced material waste, consistent quality, and fewer production errors—can translate to considerable cost savings over time.

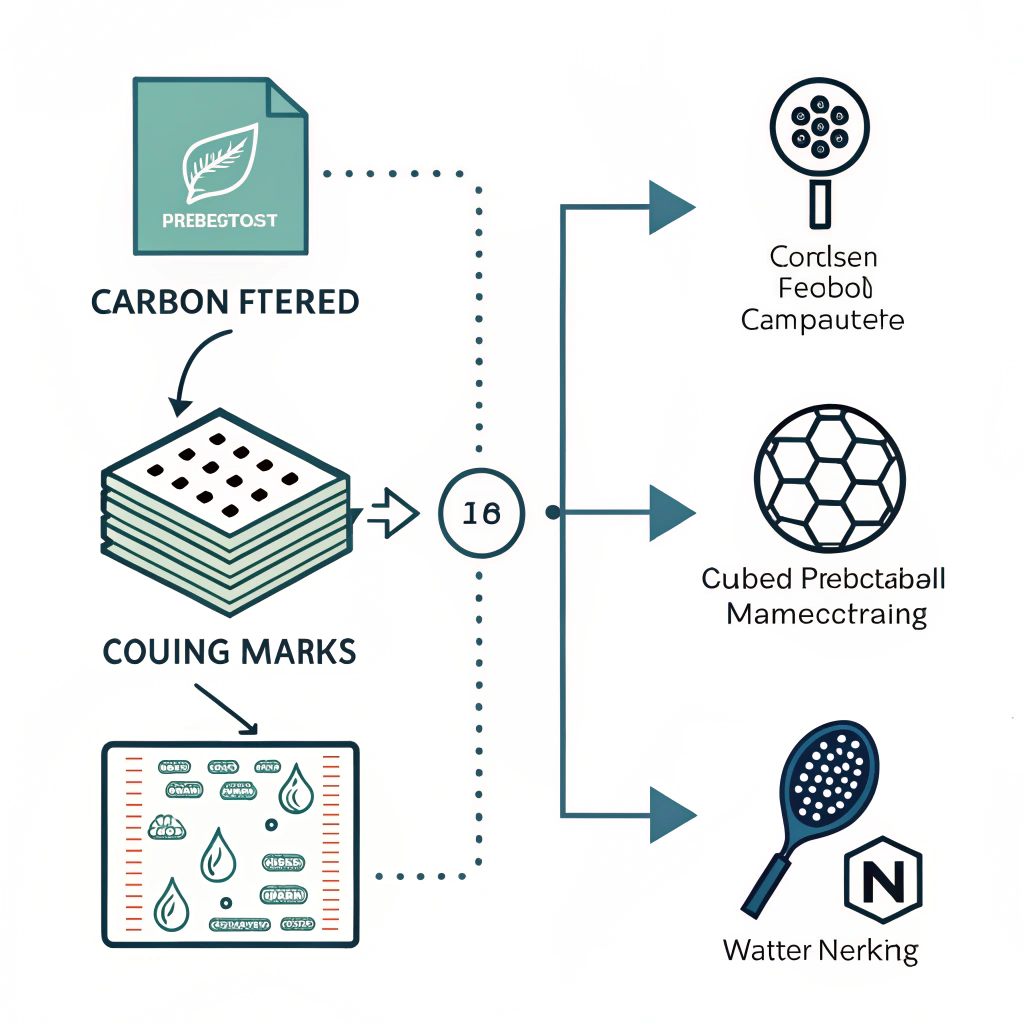

The thermoforming process involves several key steps that set it apart from traditional methods:

-

Material Preparation:

Materials such as advanced carbon fiber, fiberglass, and composite cores2 (for example, Nomex honeycomb3 or polymer honeycomb) are prepped to ensure they have the right properties for heat absorption and molding. -

Heat Application:

The materials are heated to a softening point. This temperature control is critical; too little heat fails to produce the ideal flexibility, while excessive heat might compromise the material’s structural integrity. -

Molding:

Once the material reaches the optimal temperature, it is placed in a mold where mechanical pressure shapes it into the desired paddle form. This step integrates the surface with the core, achieving an edge-to-edge fusion that enhances durability. -

Cooling and Curing:

After molding, the paddle is cooled, allowing the structure to set permanently. Rare or inconsistent cooling can lead to distortions in the paddle’s profile, affecting performance. -

Quality Verification:

Each paddle undergoes rigorous testing to ensure it meets specifications such as impact resistance, balance, and comfort. This step is vital to maintain high production standards.

To better understand the benefits of thermoforming, consider the following comparison of manufacturing techniques:

| Feature | Thermoforming | Hot Pressing | Cold Pressing |

|---|---|---|---|

| Production Process | Heat + Pressure Molding | High pressure with heat | Mechanical pressure at room temperature |

| Material Integration | Cohesive, no visible layers | Layered; potential material alteration | Maintains distinct material layers |

| Impact Resistance | High due to vibration minimization | High structural strength, but can be rigid | Excellent control but may lack shock absorption |

| Production Efficiency | Moderate; benefits offset by quality | High volume; slightly compromised feel | Lower volume, precise control |

| Cost Implications | Initial high cost; long-term efficiency | Lower investment cost; potential quality issues | Higher production time; precision cost |

| Design Flexibility | High; complex, ergonomic designs feasible | Limited by mold constraints | Limited; mainly uniform thickness control |

This table illustrates that while each method has its own strengths, thermoforming offers a unique combination of design flexibility and performance enhancements. For manufacturers looking to set their products apart in a competitive market, these factors can be decisive.

Before transitioning to thermoforming as a primary production method, consider the following aspects:

-

Investment in Equipment:

Although thermoforming equipment costs can be higher, the long-term benefits in quality and production efficiency often justify the initial outlay. -

Technical Expertise:

The success of thermoforming relies on precise temperature control and pressure monitoring. Manufacturers need to ensure that their production team is skilled in managing these parameters. -

Material Compatibility:

Not every material will respond well to the thermoforming process. It is critical to conduct preliminary tests with materials like T300 carbon fiber4 or E-Glass fiberglass5 to verify that they achieve the desired performance characteristics. -

Product Testing and Quality Assurance:

Post-production testing must be rigorous. By ensuring that each paddle undergoes extensive durability and performance tests, manufacturers can maintain the high standards expected in competitive sports. -

Design Customization Capabilities:

One of the greatest advantages of thermoforming is its ability to accommodate custom designs. Whether for team branding or specialized performance enhancements, the flexibility of thermoforming can meet diverse market demands.

Consider a scenario where a manufacturer using hot-pressed techniques faces recurring issues with paddle vibrations, leading to inconsistent playing performance. By switching to thermoforming, the manufacturer was able to:

• Enhance the paddle’s impact resistance, resulting in a more stable and controlled shot performance.

• Reduce the frequency of production errors, thanks to the cohesive material integration achieved during the molding process.

• Offer a broader range of customizations in terms of weight distribution and ergonomic design, thus attracting competitive players looking for a specialized edge.

Data from in-house tests revealed that players experienced a 15% reduction in mis-hits using thermoformed paddles. This direct improvement in performance not only elevated the brand’s reputation but also opened up new market opportunities.

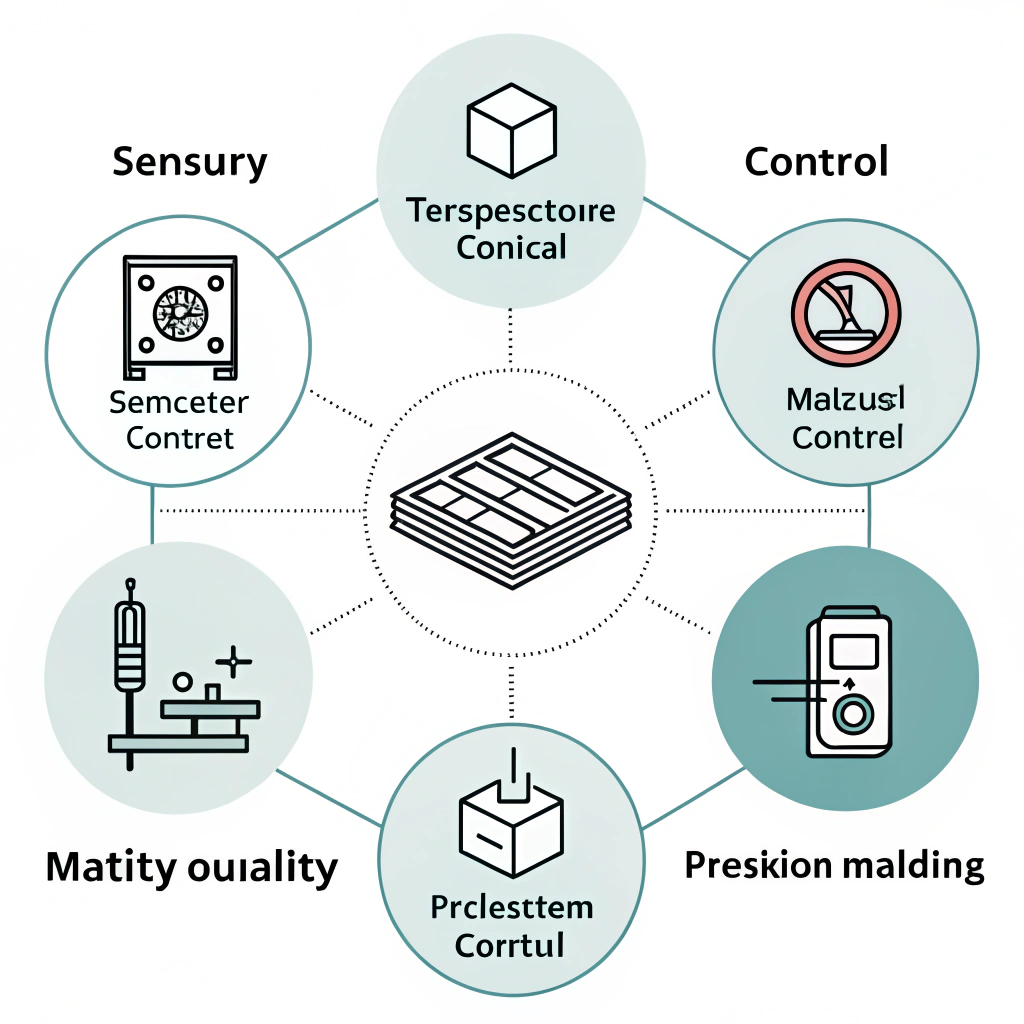

To maximize the benefits of thermoforming, manufacturers should consider implementing the following best practices:

-

Invest in Robust Quality Control Systems:

Use advanced sensors and real-time monitoring techniques during the heating and molding phases to ensure consistency in every paddle. -

Regular Equipment Maintenance:

Keeping the thermoforming equipment in peak condition ensures that temperature and pressure parameters remain accurate, preventing deviations that may affect the paddle’s integrity. -

Continuous Research and Development:

Stay ahead of industry trends by exploring new materials and innovative molding techniques. Collaborate with material scientists to fine-tune the thermoforming process for even better paddle performance. -

Customer Feedback Integration:

Leverage player experiences and professional feedback to further refine paddle designs. This cycle of continuous improvement and innovation is vital for sustained success in a competitive market. -

Employee Training and Certification:

Ensure that the production team is thoroughly trained. Regular workshops and certifications help maintain high standards in both production quality and safety protocols.

Thermoforming presents significant advantages in the manufacturing of high-performance pickleball paddles. By integrating pressure and heat, this process yields paddles that are not only durable and stable but also optimized for performance. While the initial investment in equipment and expertise may be higher, the long-term benefits such as improved design flexibility, reduced material waste, and enhanced player performance provide a compelling case for adoption. Procurement specialists and product managers looking for a reliable and innovative production method should consider thermoforming as a strategic move to differentiate their product offerings in the competitive sports equipment market.

In summary, thermoforming is a production technique that delivers on both performance and quality. By understanding its nuances and investing in robust quality control, manufacturers can achieve superior product outcomes that meet the evolving demands of today’s athletes. The next step is to evaluate your production capabilities and decide how thermoforming can align with your business objectives, setting a new standard for pickleball equipment manufacturing.

People Also Ask

Q: Are thermoformed pickleball paddles better?

A: Thermoformed paddles contribute to shot stability by minimizing vibrations upon ball impact, which in turn allows players to maintain control over their shots and reduce the likelihood of mishits.

Q: How to tell if a pickleball paddle is thermoformed?

A: Thermoformed paddles are constructed through a process in which heat and pressure mold the materials together. This means cutting the paddle won’t reveal defined layers as seen in sandwich construction methods.

Q: What is the thermoforming process of pickleball paddles?

A: The thermoforming process involves heating the paddle materials until flexible, then molding them into shape using precise temperature control and pressure, resulting in a paddle known for its resilience, stability, and enhanced performance.

-

Thermoforming: Click to learn how controlled heat and pressure are used in manufacturing to mold materials into high-performance products, enhancing both durability and stability. ↩ ↩ ↩2 ↩3

-

Composite cores: Click to understand the role of composite cores in improving structural integrity and performance in manufacturing advanced products. ↩ ↩

-

Nomex honeycomb: Click to explore the benefits of using Nomex honeycomb in composite construction, including weight reduction and enhanced strength in manufacturing. ↩ ↩

-

T300 carbon fiber: Click to discover why T300 carbon fiber is a popular choice in high-performance manufacturing, offering excellent strength-to-weight ratios and durability. ↩ ↩

-

E-Glass fiberglass: Click to read more about E-Glass fiberglass and its applications in manufacturing, highlighting its balance of performance, cost-effectiveness, and material properties. ↩ ↩