Australia's explosive pickleball growth since 2020 offers a significant opportunity for manufacturers to capitalize on the rising demand by leveraging advanced production techniques and innovative materials.

Australia has witnessed a remarkable surge in pickleball’s popularity over the past few years. Driven by increasing awareness and the sport's unique blend of agility and strategy, pickleball is rapidly becoming a household name. In 2020, initiatives such as Pickleball Australia’s nationwide launch created the foundation for widespread growth. By December 2023, membership nearly doubled, with rapid increases in both casual players and paid members. This data highlights the immense potential for partners in the sports equipment industry.

The Australian market’s expansion is fueled by several factors:

- Community Engagement: Grassroots programs and community courts have increased accessibility.

- Media Exposure: Coverage of national tournaments and success stories has enhanced visibility.

- Health and Wellness Trends: With a global focus on active lifestyles, sports that combine fitness with fun are particularly appealing.

For B2B decision-makers, understanding these trends offers valuable insight into future procurement and production strategies, ensuring that supply chains not only meet demand but also maintain high standards of quality and innovation.

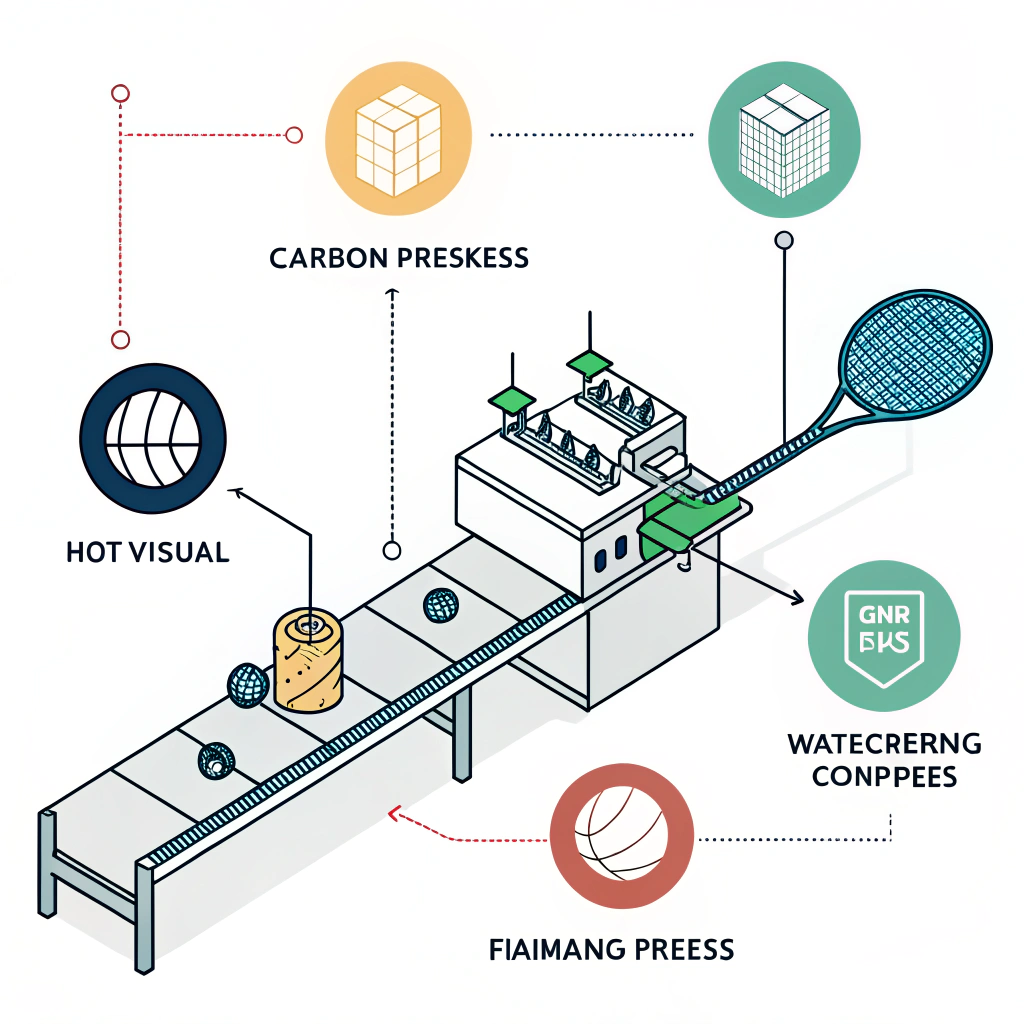

Meeting the rising demand in Australia and other markets requires manufacturers to push innovation and efficiency. At NEX Pickleball, we use cutting-edge production processes that guarantee both performance and durability of our paddles. Our expertise lies in integrating advanced techniques such as hot pressing, cold pressing, and thermoforming1.

The performance of a pickleball paddle depends significantly on the material selection, and our approach is deeply rooted in quality. We employ various high-performance materials that cater to different needs:

-

- 3K Carbon Fiber: Offers excellent strength and flexibility, ideal for paddles that demand a high rebound force and reduced vibrations.

- 12K Carbon Fiber: Provides a smoother surface and higher durability, perfect for competitive play where impact resistance is vital.

- T300 Carbon Fiber: Known for its balanced combination of weight and tensile strength, making it a top choice for performance-driven players.

-

Fiberglass:

Fiberglass paddles excel in providing a wider sweet spot, enhanced ball control, and excellent durability due to their inherent flexibility and elasticity. The use of E-Glass Fiberglass in our paddles creates a reliable and consistent performance balance. -

Composite Materials3:

Combining the best of both worlds, our composite materials (including carbon fiber & fiberglass composites) ensure an optimized balance between strength, lightness, and flexibility. Additional innovations like bamboo core and honeycomb structures further enhance durability and shock absorption. -

Core Materials:

The core of the paddle is crucial for controlling vibration levels and improving impact resistance. Our range includes:- Nomex Honeycomb Core: Provides excellent shock absorption and durability.

- Aluminum Honeycomb Core: Achieves a balanced mix of power and precision.

- Polymer Honeycomb Core: Offers superior elasticity for a more comfortable playing experience.

This blend of advanced materials ensures that every paddle not only meets the demands of high performance but also delivers an exceptional player experience.

For competitive manufacturing, optimizing production processes is critical. Our three main techniques offer distinct advantages tailored to different design requirements and product specifications.

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Superior impact resistance and strength - Ensures structural integrity suitable for high-performance play | - May change material properties - Requires substantial investment in equipment |

| Cold Pressing | - Precise control over paddle thickness and structure - Retains original material properties, offering better ball control and flexibility | - Longer production cycles - Demands high-quality machinery for exact pressure control |

| Thermoforming | - Produces paddles with intricate designs and exact material distribution - Enhances overall paddle stability and performance | - Longer production time - Higher equipment cost, mainly ideal for premium or custom paddles |

Each production process is chosen based on the paddle’s intended use, ranging from recreational to professional-level competition. In a competitive market like Australia’s, ensuring that production techniques harmonize efficiency with precision is key to maintaining a competitive edge and meeting escalating performance demands.

Quality control remains central to our commitment at NEX Pickleball. Every paddle undergoes rigorous testing at multiple stages of production. Our quality control process is designed to guarantee that the paddles maintain consistency in performance, durability, and player comfort.

-

Rigorous Testing Protocols:

Each batch of paddles is subject to performance tests that measure impact resistance, vibration absorption, and ergonomic stability. This testing ensures that the paddles perform predictably in the dynamic environment of competitive play. -

Customization Options4:

Recognizing the diverse requirements of players and organizations, we offer a range of customization options. Clients can specify design elements such as weight, balance, grip size, and even personalized graphics for team branding. Additionally, our on-demand printing services allow for rapid customization without sacrificing quality. -

Advanced Quality Control Tools:

Implementing state-of-the-art measurement and diagnostic tools ensures that each paddle meets predefined specifications. This commitment to precision manufacturing not only reduces the rate of defects but also builds a robust relationship with our B2B partners who value consistent product excellence.

This focus on quality control and customization supports our broader mission of delivering high-performance products that can seamlessly adapt to market trends and consumer preferences.

The rapid expansion of the pickleball market in Australia presents an exciting opportunity for B2B partnerships and growth. As a procurement manager or operations lead in the sports equipment industry, aligning with a manufacturer that emphasizes both innovation and quality is crucial.

-

Market Potential and Growth:

The explosive growth of pickleball, indicated by rapidly increasing participation and membership numbers, underscores a robust market. As more Australians embrace pickleball, the demand for high-quality paddles will continue to rise. -

Innovative Production Techniques:

The integration of advanced techniques such as hot pressing, cold pressing, and thermoforming provides a strong competitive advantage. These methods enhance the performance and durability of the paddles and position manufacturers like NEX Pickleball ahead of the curve. -

Customization Capabilities:

The ability to rapidly customize products to meet the specific needs of different markets is a vital competitive edge. Customization not only differentiates products in a crowded marketplace but also builds a loyal customer base among professional players and sports organizations. -

Quality Assurance:

Utilizing stringent quality control measures ensures that every product meets international standards, thus building trust with distributors and end-users alike. -

Supply Chain Efficiency5:

Leveraging advanced production processes aligns with the need for expedited manufacturing cycles and robust supply chains, especially when scaling up production to meet market demand.

By addressing these key points, companies can make informed decisions that mitigate risks while maximizing market potential.

The rapid growth of pickleball in Australia is not just a trend—it is a clear signal of evolving consumer demands and emerging market opportunities. Manufacturers and distributors must leverage advanced production techniques and embrace innovation to maintain relevance and competitiveness.

At NEX Pickleball, our focus on integrating advanced manufacturing processes, engaging cutting-edge materials, and emphasizing quality control enables us to meet the rapidly increasing demands of this market. We are uniquely positioned to assist our partners in capturing new opportunities while ensuring that every paddle meets the highest performance standards.

For procurement managers and B2B decision-makers in the sports equipment industry, partnering with a manufacturer that understands market dynamics and production intricacies can be a game-changer. Evaluate your current product line, assess market trends, and consider integrating innovative techniques to capture the pickleball boom in Australia.

We invite you to explore our capabilities further, discuss your specific needs, and embark on a journey to gain a competitive edge in the dynamic sports equipment landscape.

When did pickleball become popular in Australia?

Pickleball began gaining traction in Australia as early as 2020, thanks to initiatives led by Pickleball Australia. The sport rapidly grew in popularity, with membership nearly doubling by 2023, indicating a surge in participation across multiple states and territories.

How fast is pickleball growing in Australia?

Recent data outlines a rapid expansion, with over 92,000 Australians aged 15 and above engaging in pickleball over the past year. Moreover, Paid membership has skyrocketed from under a thousand in 2020 to around 15,000, underscoring the sport’s exponential growth and potential market opportunities.

What is Australia's fastest growing sport?

While football holds the title for Australia’s fastest-growing sport by overall participation, pickleball is emerging as a formidable contender within its niche, characterized by its rapid growth in membership and active participation across the country.

-

Thermoforming: Click to explore an in-depth guide on thermoforming, detailing its role in modern manufacturing processes, key benefits, and how it enhances product design for high-performance industries. ↩ ↩

-

Carbon Fiber: Click to read about Carbon Fiber technology, its material properties, advantages in strength-to-weight ratios, and its applications in advanced sports equipment manufacturing. ↩ ↩

-

Composite Materials: Click to understand Composite Materials, including how combining different fibers improves performance, durability, and flexibility in products aimed at professional markets. ↩ ↩

-

Customization Options: Click to learn about Customization Options available in manufacturing, why they're crucial for meeting diverse client needs, and how they enhance competitive positioning in B2B markets. ↩ ↩

-

Supply Chain Efficiency: Click to discover strategies for Supply Chain Efficiency, exploring how optimized logistics and production alignment support scalable manufacturing and market responsiveness. ↩ ↩