Quick Answer: Advanced manufacturing techniques and innovative materials are revolutionizing pickleball paddle production, leading to enhanced performance, durability, and market competitiveness.

In today’s fast-evolving sports equipment market, B2B buyers and product development specialists face increasing pressure to deliver high-performance pickleball paddles that combine durability, precision, and innovative design. Advances in material science1 and manufacturing processes such as hot pressing, cold pressing, and thermoforming2 have elevated paddle performance and redefined the competitive landscape. This article explores the challenges, underlying factors, and detailed solutions that companies can adopt to stay ahead in the industry.

Modern pickleball paddle manufacturers are grappling with the need to balance performance with durability while keeping production efficiency high. As market demands shift, companies are transitioning from traditional materials and processes to more advanced ones. Several challenges emerge:

• Adapting to faster game speeds and higher performance requirements

• Integrating advanced materials like 3K, 12K, and T300 Carbon Fiber3 into paddle design

• Choosing optimal production processes that maximize paddle resilience, control, and overall quality

• Ensuring that new techniques do not compromise on the tactile feel important to players

• Managing production costs and equipment investments amidst new technological requirements

Historically, early paddle generations relied on basic honeycomb cores and minimal process enhancements. However, increasing player expectations drive the need for a robust, tech-driven approach that goes beyond mere aesthetics.

The evolution of pickleball paddles is tightly intertwined with several key factors:

-

Material Limitations:

Early paddles featured wood constructions and basic polymer cores, which were heavy and lacked finesse in performance. As the sport evolved, there was a clear need for paddles that combined lightweight materials with improved shock absorption and rebound control. -

Production Process Barriers:

Traditional manufacturing processes such as simple pressing techniques limited design innovation. Advanced processes like thermoforming now allow for creating intricate designs and distributing materials evenly across the paddle face. Without these technological upgrades, it would be hard for manufacturers to meet the performance expectations of competitive players. -

Market Competition:

With paddle innovation gaining traction from both OEM partners and direct competitors, manufacturers must continuously innovate. B2B procurement managers are not only looking at performance but also the cost-effectiveness and scalability of production methods. -

Consumer Expectations:

Modern players demand paddles with a precise blend of power, control, and comfort. The integration of diverse materials such as carbon fiber, fiberglass, and various composite cores has a direct impact on these attributes. Each material type, while offering unique benefits, also introduces new design and production complexities.

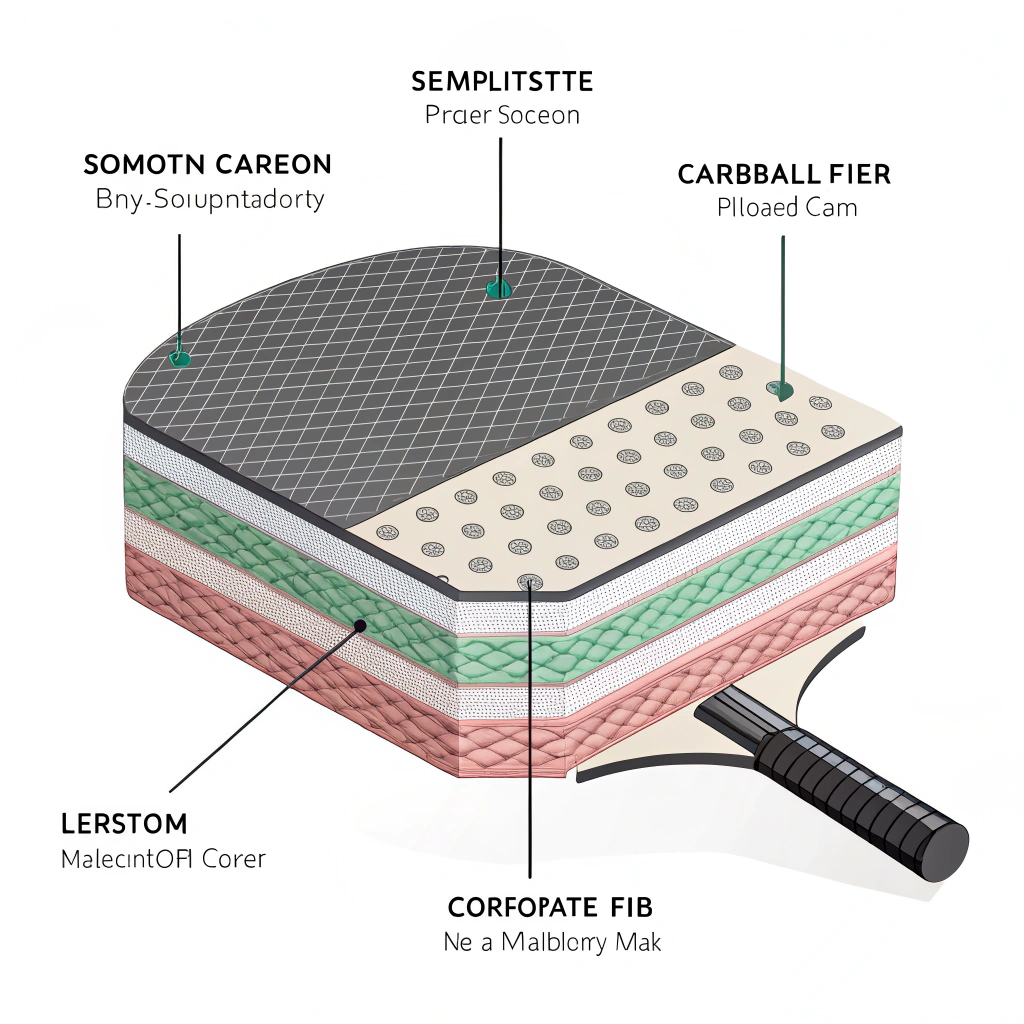

To address these challenges, integrating advanced materials into paddle production is essential. Let’s explore the key materials that have reshaped paddle technology:

• 3K Carbon Fiber: Offers great flexibility and strength, reducing vibration during play and providing high rebound force.

• 12K Carbon Fiber: Known for its higher thread density and smoother surface; ideal for competitive play that demands extreme strength and impact resistance.

• T300 Carbon Fiber3: Balances strength with lightweight performance – a critical factor for achieving precision and responsiveness during fast-paced play.

These materials not only reinforce the paddle’s structure but also enhance the overall durability essential for long-lasting performance.

• E-Glass Fiberglass: Combines elasticity with high tensile strength, offering excellent ball control while delivering more flexibility than carbon fiber. This balance positions fiberglass as a preferred material for those looking for enhanced control without sacrificing durability.

Integrating carbon fiber with fiberglass or using bamboo core composite4 materials creates paddles that offer a unique blend of power, flexibility, and durability. Composite materials enable manufacturers to tailor the paddle’s properties to specific playing styles or levels of competitive play. For instance, companies can design paddles that cater to beginners by emphasizing comfort and durability, while advanced players might prefer a design that enhances speed and power.

The inner core of a paddle is as critical as its outer surface. Core materials such as Nomex Honeycomb Core5, Aluminum Honeycomb Core, and Polymer Honeycomb Core directly influence the paddle’s weight distribution, shock absorption, and tactile feel. By choosing the right core material, manufacturers can fine-tune the balance between power and control:

• Nomex Honeycomb Core: Provides robust shock absorption and overall durability, ensuring the paddle can withstand repeated high-impact play.

• Aluminum Honeycomb Core: Offers a balanced weight that enhances both power and precision, making it suitable for players prioritizing a mix of strength and accuracy.

• Polymer Honeycomb Core: Known for its elastic properties, reducing vibration and offering a more comfortable hitting experience ideal for recreational players.

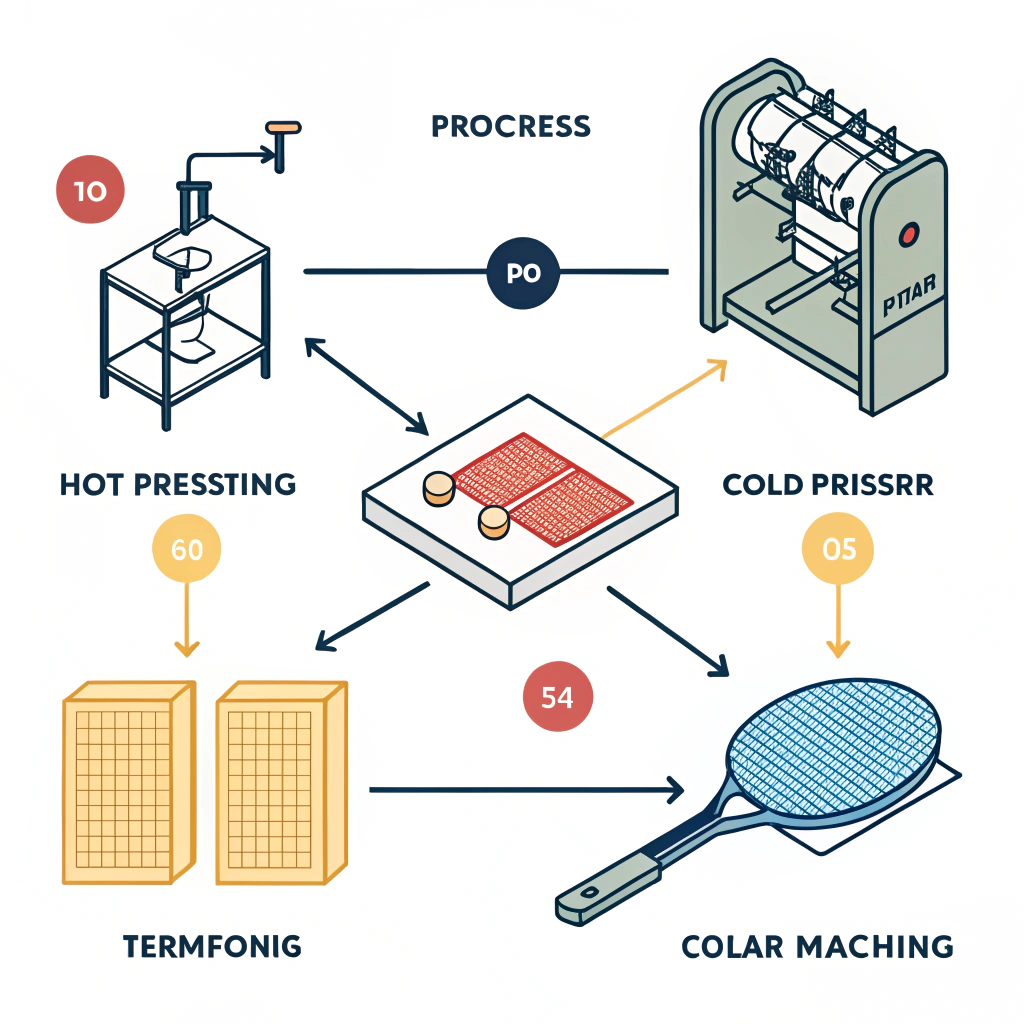

Innovative production processes serve as the backbone for transforming advanced materials into high-performance pickleball paddles. Each process comes with its benefits and considerations:

Hot pressing involves heating and applying pressure to form the paddle structure.

Advantages:

• High production efficiency suitable for large-scale manufacturing.

• Produces a robust paddle with excellent impact resistance.

• Ensures strong adherence and structural integrity.

Disadvantages:

• Potential alteration of some material properties that can affect the paddle’s feel.

• Requires a significant investment in specialized equipment.

Cold pressing is performed at room temperature under mechanical pressure, allowing for precise control over the paddle’s form.

Advantages:

• Maintains the intrinsic properties of advanced materials, preserving ball feel and responsiveness.

• Offers precise control over thickness and overall structure.

Disadvantages:

• Slower production cycles which may impact efficiency.

• Demands high-quality machinery to ensure consistency.

Thermoforming2 leverages heat to soften materials before molding them into the final paddle shape.

Advantages:

• Facilitates the creation of paddles with intricate designs and uniform material distribution.

• Increases the stability of the final product, leading to improved performance.

• Ideal for premium products or custom paddle designs.

Disadvantages:

• Longer production times and higher upfront costs for equipment investment.

• Best suited for manufacturers targeting high-end market segments.

A comparative view of these processes can be summarized in the following table:

| Process | Advantages | Disadvantages | Best Used For |

|---|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; robust structure | Alters material properties; high equipment costs | Large-scale production, high-performance play |

| Cold Pressing | Preserves material properties; precise thickness control; better responsiveness | Longer production cycles; requires precise machinery | Precision-focused paddles, specialized designs |

| Thermoforming | Creates intricate designs; uniform material distribution; improved stability | Longer production time; higher initial investment | Premium and custom paddles |

Each of these production processes plays a critical role in achieving the market’s dual demand for efficiency and high performance. B2B buyers must weigh these options in relation to their specific production volumes, budgetary constraints, and target market profiles.

Consider a leading OEM like NEX Pickleball, which has adopted these advanced techniques to enhance the competitiveness of its product line. By utilizing a blend of T300 Carbon Fiber and Polymer Honeycomb Cores, NEX Pickleball has successfully produced paddles that offer an optimal balance of weight, rebound force, and tactile responsiveness. The company’s transition from traditional honeycomb designs to modern thermoformed paddles has significantly improved the playing experience, leading to a reduction in vibration and an increase in overall stability.

Through continuous innovation and strict quality controls, NEX Pickleball has been able to address common issues like material inconsistencies and production inefficiencies. Their strategic investment in state-of-the-art equipment has streamlined the production process, reduced downtime, and delivered consistent product quality, which is critical for catering to high-performance markets.

This case study illustrates how integrating advanced materials with sophisticated production processes not only solves existing challenges but also sets new standards in paddle performance. In doing so, manufacturers can significantly enhance the competitive position of their product portfolios.

When evaluating potential partnerships or considering an upgrade in their production processes, B2B procurement managers should heed the following recommendations:

-

Material Compatibility and Performance:

Ensure that the materials used, whether it is carbon fiber composites or specialized core materials, match the performance requirements of your target market. Assess the trade-offs between strength, weight, and tactile feel. -

Process Selection Based on Volume and Product Tier:

A detailed understanding of each manufacturing process helps in selecting the right approach. While hot pressing offers efficiency, thermoforming is better suited for premium paddle models. -

Cost-effectiveness and Scale:

Conduct a thorough cost-benefit analysis. Upfront investment in advanced equipment might be higher, but the long-term benefits include improved quality and reduced production cycles, which can result in higher market competitiveness. -

Quality Control and Consistency:

Advanced processes require precise machinery and rigorous quality testing. Implementing robust quality control protocols will mitigate risks associated with material inconsistencies and ensure that every paddle meets international standards. -

Customization and Market Trends:

With the growing demand for personalized sports equipment, custom paddle production enables brands to differentiate themselves in the market. Manufacturers should be capable of adapting their processes to offer a range of options, including custom weights, grips, and surface finishes.

In conclusion, the integration of advanced manufacturing processes and innovative materials has redefined the pickleball paddle industry. The evolution from rudimentary wooden paddles to high-performance composites of carbon fiber and advanced core materials demonstrates the potential for significant improvements in the durability, control, and overall performance of the equipment.

B2B procurement managers and product development specialists are encouraged to:

• Evaluate the material properties essential for your target market.

• Analyze the production processes (hot pressing, cold pressing, and thermoforming) to match your product goals.

• Consider cost, efficiency, and quality control when investing in new technologies.

• Collaborate with manufacturers who demonstrate expertise in crafting customized, high-performance paddles that can meet the needs of both recreational and competitive players.

The actionable steps include revisiting your supplier criteria, engaging in discussions about customized production solutions, and studying the latest trends in manufacturing technology. This proactive approach can result in better market positioning, improved product reliability, and enhanced player satisfaction.

• What is the evolution of pickleball paddles?

The evolution of pickleball paddles began with the Wood Era (Gen 0), where paddles were heavy and lacked technological enhancements. This was followed by Gen 1 featuring basic honeycomb cores made from polymer materials. The evolution continued into Gen 2, where the adoption of thermoforming and carbon fiber unibody designs—with additional features such as foam edge walls—improved paddle performance significantly.

• How long do thermoformed pickleball paddles last?

Thermoformed pickleball paddles can last several years when properly maintained. Their longevity is attributed to their robust construction and the intricate design processes that enhance impact resistance and performance durability.

-

material science: Read the article to explore interdisciplinary research on the properties and innovations of advanced materials that drive improvements in modern manufacturing. ↩

-

thermoforming: Click here to learn how thermoforming uses heat to shape materials, leading to intricate designs and enhanced performance in high-end products. ↩ ↩2

-

T300 Carbon Fiber: Discover the benefits of T300 Carbon Fiber, a high-performance material offering an optimal mix of strength and lightweight properties for precision applications. ↩ ↩2

-

bamboo core composite: Explore bamboo core composite materials and their unique combination of natural fibers and composites for superior strength and eco-friendly design. ↩

-

Nomex Honeycomb Core: Understand why Nomex Honeycomb Core is valued for its excellent shock absorption and durability, critical for high-impact sports equipment. ↩