Quick Answer: Advanced pickleball paddle materials and production techniques—such as various types of carbon fiber1, innovative composite structures, and tailored core materials—are revolutionizing paddle performance, offering enhanced power, durability, and control for competitive play. These innovations combine cutting-edge manufacturing processes like hot pressing, cold pressing, and thermoforming, ensuring that sports equipment distributors and product developers can meet market demands with superior, cost-effective solutions.

In today's rapidly evolving sporting goods industry, procurement managers and product development specialists face increasing pressure to deliver pickleball paddles that not only stand out in the marketplace but also push the boundaries of performance. Innovations in advanced paddle materials2 and production technologies are at the heart of meeting these demands. In this article, we explore and compare cutting-edge materials, including various grades of carbon fiber, fiberglass, and composites, as well as review manufacturing processes that are transforming paddle design. Our goal is to provide actionable insights and a clear framework for decision-makers looking to adopt the most effective solutions in paddle production.

Pickleball, a sport that has seen unprecedented growth, now demands equipment that can match its fast-paced and competitive nature. With more players at all skill levels stepping onto the court, distributors need to source paddles that offer reliability, durability, and exceptional performance. The traditional approach to paddle manufacturing no longer guarantees a competitive edge. Instead, what sets market leaders apart is their dedication to integrating high-performance materials3 and optimizing production processes.

Challenges in traditional paddle design include:

• Suboptimal weight distribution affecting precision.

• Compromised durability under high-impact play.

• Limited flexibility, reducing both control and power during game situations.

These challenges have led to an industry-wide shift toward exploring advanced materials and cutting-edge production methods to meet the rigorous standards of modern play.

-

Carbon Fiber Varieties

- 3K Carbon Fiber: Known for high strength and flexibility, it delivers robust rebound force and reduces vibration, making it suitable for players requiring high durability and impact resistance.

- 12K Carbon Fiber: Offers a smoother surface finish, greater hardness, and exceptional durability—ideal for competitive play and high-impact situations.

- T300 Carbon Fiber: Balances light weight and tensile strength, delivering a well-rounded performance for quick and agile paddling.

-

Fiberglass

- E-Glass Fiberglass: Combines moderate power and high control with broader sweet spots for players who need enhanced ball control and a comfortable playing experience.

-

Composite Materials

- Carbon Fiber and Fiberglass Composite: This combination balances the rigidity of carbon fiber with the flexibility of fiberglass, ensuring paddles are both powerful and controllable.

- Bamboo Core Composite: Offers superior impact resistance while providing an authentic hitting feel; this is particularly popular among distributors looking to emphasize eco-friendly and sustainable options.

- Honeycomb Core: Utilized in high-density polymers, these cores significantly reduce vibration, ensuring that players benefit from a consistent and comfortable hitting experience.

-

Core Material Options

- Nomex Honeycomb Core4: Renowned for its shock-absorption capabilities and long-lasting stability, making it perfect for high-intensity use.

- Aluminum Honeycomb Core: Delivers a balanced mix of strength and precision, merging power with targeted control.

- Polymer Honeycomb Core: Reduces vibration and offers improved elasticity, targeting recreational players and those focused on extended comfort during long sessions.

Each of these materials offers distinct benefits depending on the desired performance profile, from reducing vibrations to enhancing rebound power.

The manufacturing techniques employed further refine these material benefits. Advanced production processes are essential in turning these raw materials into paddles that can perform consistently at the highest levels.

-

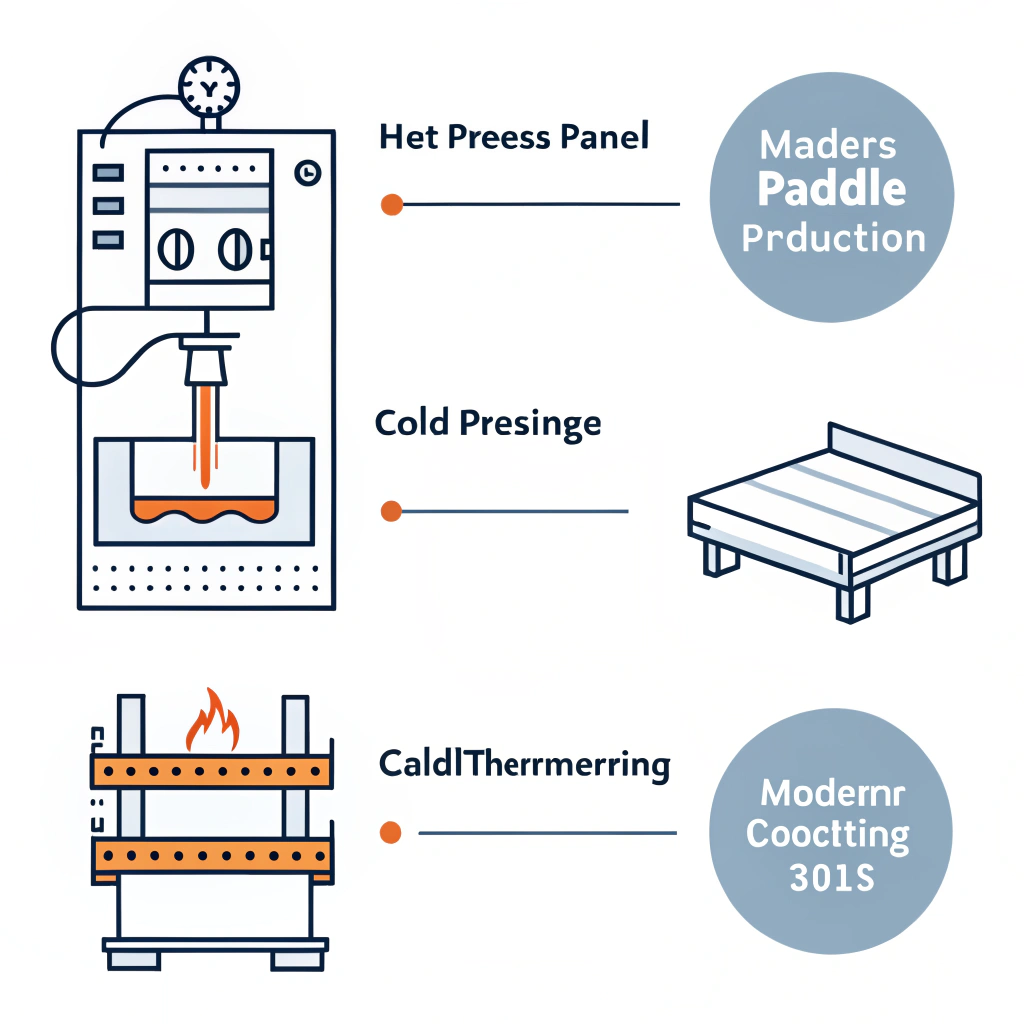

Hot Pressing Process

- Description: Utilizes heat and pressure to bond materials, yielding paddles with superior strength and durability.

- Advantages:

• High production efficiency, allowing cost-effective scaling for large orders.

• Strong structural integrity ideal for high-impact and competitive usage. - Disadvantages:

• The alteration of certain material properties may affect the paddle’s touch and feel.

• Requires significant investment in specialized equipment.

-

Cold Pressing Process

- Description: Shapes materials at room temperature through mechanical pressure to ensure precise control over paddle thickness and structure.

- Advantages:

• Maintains the inherent properties of materials, ensuring better control and flexibility.

• Enhanced ball feel and responsiveness are preserved. - Disadvantages:

• Slower production cycles can affect output efficiency.

• Necessitates precise pressure control with high-quality machinery.

-

- Description: Involves heating materials to a softening point and molding them using predefined forms, perfect for paddles with complex geometries.

- Advantages:

• Enables the creation of intricate, performance-specific designs.

• Ensures even material distribution for optimized stability. - Disadvantages:

• Longer production time and higher equipment costs, best suited for premium product lines.

To visualize the key differences between these processes, consider the following comparison table:

| Process | Advantages | Disadvantages | Ideal Applications |

|---|---|---|---|

| Hot Pressing | High efficiency, high impact resistance | Alters material touch, high equipment cost | Large-scale production, high-performance paddles |

| Cold Pressing | Precise control, maintains material properties | Longer production cycles | Paddles where feel and control are paramount |

| Thermoforming | Intricate design capability, uniform material distribution | Longer process, premium cost | Custom-designed or premium paddles |

By integrating these production processes with advanced materials, manufacturers can customize paddles to meet diverse performance needs. This level of customization allows sports equipment distributors to differentiate their product lines and target specific market segments.

Procurement managers and product development specialists must weigh several factors when evaluating new paddle innovations:

-

Material Performance vs. Cost:

Advanced materials such as 12K carbon fiber deliver unmatched performance but come with higher production costs. Alternatively, composite materials or fiberglass options can provide a balance of quality and cost-effectiveness. The ideal choice depends on the target market and expected price point. -

Production Efficiency and Sustainability:

Efficient production processes such as hot pressing can lower unit costs through mass production, while cold pressing offers higher quality for premium segments. Sustainability considerations, including the use of eco-friendly materials like bamboo composites, are increasingly influential in purchase decisions. -

Customization Capabilities:

Offering options for custom paddle designs—including grip sizes and custom prints—enables distributors to cater to niche markets and enhance brand value. This flexibility can drive customer loyalty and broaden market reach. -

Industry Trends and Competitive Advantage:

Keeping abreast of industry trends such as the rising popularity of composite structures and innovative core designs helps procurement managers ensure that their products remain current, competitive, and aligned with the demands of both recreational and competitive players.

To bridge the gap between cutting-edge technology and market requirements, companies like NEX Pickleball have honed a dual strategy:

-

Balancing Advanced Materials with Economies of Scale:

By employing a mix of materials based on specific performance needs, you can design paddles that cater to both high-end competitive play and more budget-conscious consumers. For instance, using T300 carbon fiber in tandem with a polymer honeycomb core can optimize the balance between strength and vibration control without compromising cost. -

Tailored Production Strategies:

Adopting a flexible production strategy that leverages the strengths of hot pressing, cold pressing, and thermoforming can help you respond quickly to varying market demands. This approach limits production bottlenecks and ensures that quality remains consistent across different product lines. -

Data-Driven Decision Making:

Utilizing data from product testing, market feedback, and performance metrics provides clarity in selecting the best mix of materials and processes. Continuous innovation must be supported by rigorous quality assurance protocols to maintain trust among distributors and end-users alike. -

Custom Order Capabilities:

Offering on-demand customization services not only attracts a broader customer base but also allows you to cater to niche market needs. This can include everything from adjusting the paddle’s weight and balance to branding elements that resonate with local markets.

One notable example is a mid-sized sports equipment distributor who collaborated with a leading manufacturer incorporating advanced carbon fiber variants and composite cores. Facing stiff competition, the distributor sought a product line that could cater to both high-performance athletes and recreational players.

By leveraging a combination of 12K carbon fiber for its competitive paddles and fiberglass for a more accessible price point, alongside a diversified production approach that utilized both hot pressing for strength and cold pressing for premium feel, the distributor experienced:

• A significant rise in product market share.

• Enhanced consumer satisfaction due to improved control, power, and durability.

• Strengthened brand reputation as an innovator in the sports equipment sector.

The success of this strategy underscores the importance of aligning product innovation with market trends and cost management, offering a robust pathway for procurement managers evaluating their next strategic investment.

In an industry where performance, precision, and innovation are critical, adopting cutting-edge materials and production techniques is no longer optional—it's essential. By understanding the intricate balance between material properties and manufacturing processes, procurement managers and product developers can achieve several key advantages:

• Enhanced product differentiation that meets both competitive and recreational demands.

• The opportunity to optimize production costs without sacrificing performance.

• Increased adaptability to market trends, ensuring long-term competitiveness.

For decision-makers, the actionable takeaway is clear: it is imperative to collaborate with partners who embrace advanced pickleball paddle innovation. Evaluate material performance, production techniques, and customization capabilities to choose a solution that aligns best with your strategic objectives. With this comprehensive approach, you can not only meet market demands but also drive long-term growth in a competitive B2B landscape.

People Also Ask

Q1: What advanced material technologies are used in modern pickleball paddles?

A1: Modern pickleball paddles utilize advanced materials such as various grades of carbon fiber (including 3K, 12K, and T300), high-performance fiberglass (like E-Glass), and composite materials that blend carbon fiber with fiberglass or incorporate eco-efficient cores like bamboo. These materials are engineered for improved strength, reduced vibration, and enhanced control.

Q2: How do production techniques like hot pressing, cold pressing, and thermoforming differ in paddle manufacturing?

A2: Hot pressing uses heat and pressure to bond materials quickly, ensuring high strength ideal for large-scale production. Cold pressing shapes materials at room temperature for precise control and a superior feel, though it requires longer production cycles. Thermoforming heats materials to softening points for creating complex designs, best suited for customized, premium products despite its longer process time.

Q3: What factors should be considered when selecting paddle innovations for a sports equipment portfolio?

A3: Key factors include balancing enhanced performance against cost, ensuring efficient production methods, offering customization to meet niche market needs, and aligning with industry trends. Evaluating the specific benefits of materials like advanced carbon fiber, fiberglass, and composite cores—alongside their respective production processes—can help in making informed procurement decisions.

-

carbon fiber: Click to read an in-depth article about carbon fiber technology, its manufacturing process, and its impact on product performance in competitive sports equipment. ↩

-

advanced paddle materials: Click to learn more about innovative materials used in paddle design and how they improve efficiency and performance in sporting goods. ↩

-

high-performance materials: Click to discover the properties of high-performance materials and why they are essential for enhancing product durability and control. ↩

-

Nomex Honeycomb Core: Click to explore detailed insights into Nomex Honeycomb Core technology, including its shock-absorption benefits and long-term stability in high-intensity applications. ↩

-

Thermoforming Process: Click to read about the thermoforming process, its advantages in manufacturing complex designs, and its role in producing premium sports equipment. ↩