Quick Answer: The evolution of pickleball paddles has seen a transformation from basic wooden designs to advanced composites incorporating carbon fiber1, fiberglass2 and innovative core materials. Today’s high-performance paddles boast cutting-edge manufacturing methods like Hot Pressing3, cold pressing, and Thermoforming4, providing players with superior power, control, and durability while offering strategic advantages for B2B procurement decisions.

Pickleball’s explosive growth has been paralleled by rapid innovations in paddle design and production. For B2B professionals, understanding the technological progression—from early wooden and composite models to today’s high-tech materials and production techniques—is essential when evaluating suppliers and planning product portfolios. This article provides a detailed analysis of how paddle technology has evolved, the materials driving these changes, and the manufacturing processes that ensure consistent, high-quality production.

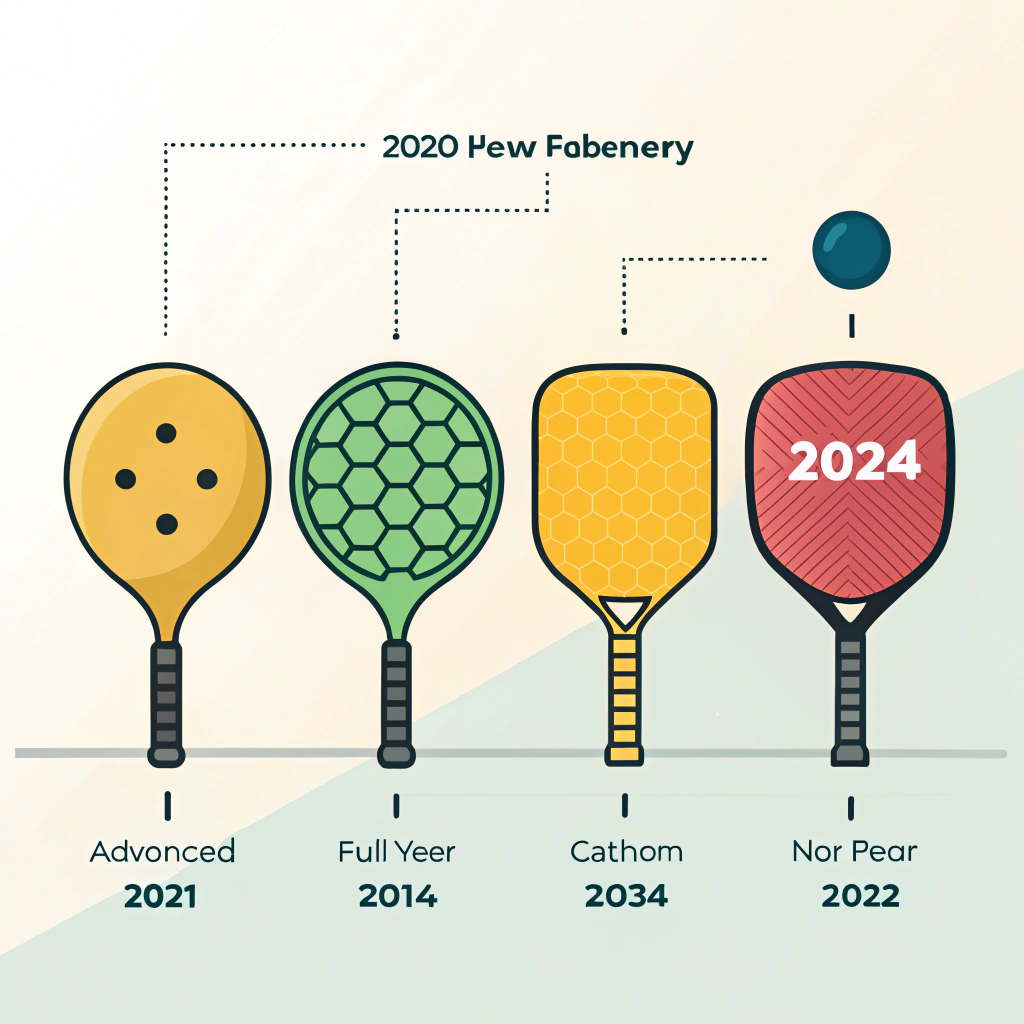

The transformation in paddle technology can be segmented into four distinct generations:

-

Gen 1 – The Basics:

Initially, paddles were simple, largely made of wood and rudimentary composite materials. Their design offered limited power and control, primarily focusing on durability rather than performance. -

Gen 2 – Honeycomb Cores5 & Composite Surfaces:

As the game evolved, manufacturers introduced honeycomb core structures and composite surface materials. These innovations improved shock absorption and ball responsiveness, offering a more balanced playing experience. -

Gen 3 – Raw Carbon Fiber & Power Tech (2018-Present):

The development of carbon fiber1 materials, such as 3K, 12K, and T300, ushered in an era of high-performance paddles. These paddles deliver exceptional power, control, and rebound characteristics while reducing vibration during play. -

Gen 4 – Full-Foam & Edge-to-Edge Sweet Spots (2024-Present):

The latest generation leverages high-density foam cores and design innovations such as edge-to-edge sweet spots. This ensures a larger effective hitting area, improved spin generation, and overall enhanced responsiveness.

Understanding these generations helps B2B decision-makers assess product quality and determine if a manufacturer’s technological capabilities align with the needs of competitive and recreational markets.

Modern pickleball paddles utilize a diverse range of premium materials engineered for performance and durability. Here’s a closer look at how these materials contribute to the paddle’s features:

carbon fiber1 is a cornerstone for many high-performance paddles. Manufacturers differentiate between several types:

-

3K Carbon Fiber:

Offers a balance of high strength and flexibility. Ideal for paddles that require significant rebound force and durability while minimizing vibration. -

12K Carbon Fiber:

Known for its tighter weave and smoother surface, enhancing hardness and durability. It is well-suited for competition-level products needing high impact resistance. -

T300 Carbon Fiber:

This variant provides exceptional tensile strength and low weight, ensuring a balanced mix of power and control, a key requirement for competitive players.

fiberglass2 paddles, especially those made with E-Glass Fiberglass, provide a wider sweet spot and promote excellent ball control. While they might not deliver the same level of power as carbon fiber-based paddles, their flexibility and robustness make them a popular choice for players seeking a more controlled feel.

Combining different materials amplifies performance characteristics. For example:

-

Carbon Fiber and Fiberglass Composite:

This blend offers a unique combination of lightness, strength, and flexibility. -

Bamboo Core Composite:

Bamboo cores contribute to lightweight designs that maintain high impact resistance, offering a crisp, clear hitting experience. -

Honeycomb Core:

Typically made from high-density polymers or pulp, honeycomb cores ensure superb shock absorption, reducing vibrations while preserving paddle longevity.

The core of the paddle is critical, influencing its balance, control, and overall feel. Manufacturers employ several options:

-

Nomex Honeycomb Core:

Provides excellent shock absorption and sustained durability, suitable for players demanding stability and longevity. -

Aluminum Honeycomb Core:

Strikes an ideal balance between weight and control, delivering robust power with precise feedback. -

Polymer Honeycomb Core:

Known for its elasticity, the polymer core reduces vibration and increases player comfort—highly regarded among recreational players.

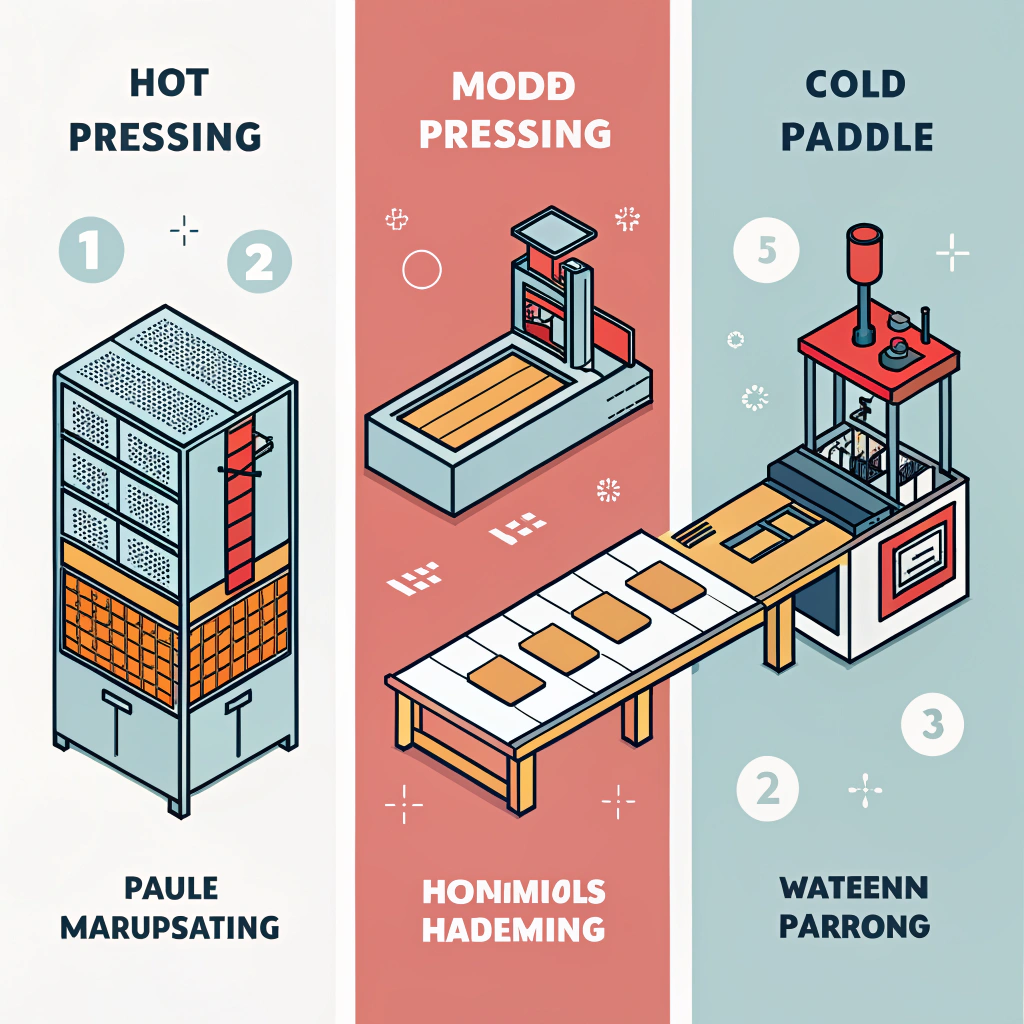

High-performance paddles require advanced manufacturing techniques to guarantee quality and consistency. At the forefront of these processes are Hot Pressing3, cold pressing, and Thermoforming4.

Hot Pressing3 involves applying heat and pressure to mold the paddle materials into their final shape. This method is preferred for producing paddles with:

- High Production Efficiency: Suitable for large-scale manufacturing.

- Enhanced Structural Integrity: Offers excellent impact resistance, making the paddles robust and durable.

However, hot pressing can alter some material properties, affecting the overall "feel" of the paddle, and it demands a significant capital investment in equipment.

Cold pressing utilizes mechanical force at room temperature, preserving the inherent properties of the materials. This technique offers:

- A more precise control over thickness and structural integrity.

- Enhanced ball feel and responsiveness due to the retention of material properties.

The trade-offs for cold pressing include longer production cycles and the necessity for precise pressure control, which requires high-quality machinery.

Thermoforming4 heats the material to a pliable state before forming it into the required shape using sophisticated molds. This process is especially ideal for paddles with intricate designs and varying thicknesses. Key advantages include:

- The ability to create intricate designs and maintain precise material distribution.

- Improved paddle stability and performance consistency.

The downside is that thermoforming has a longer production time and generally higher equipment costs, making it a choice usually reserved for premium or custom-designed paddles.

Below is a comparative table for the three primary production processes:

| Process | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, structural integrity | May alter material feel, high investment in equipment | Large-scale manufacturing |

| Cold Pressing | Precise control, maintains material properties, excellent feel | Longer production cycles, requires precise pressure control | Detailed design and control-focused products |

| Thermoforming | Intricate designs, precise material distribution, enhanced stability | Longer production time, higher cost | Premium products and custom orders |

For sports equipment distributors, product developers, and procurement managers in the B2B landscape, the technological progression in pickleball paddle manufacturing provides several strategic advantages:

-

Performance Optimization:

Advanced materials and production techniques directly contribute to superior paddle performance. B2B buyers can offer products that not only meet but exceed the performance benchmarks required by competitive players. -

Customization and Flexibility:

The ability to combine different core and surface materials means that manufacturers can tailor paddles for niche markets or individual performance needs. For instance, custom paddle options allow clients to define design aspects such as weight distribution, balance, and grip size, which adds value for team branding or direct consumer markets. -

Consistency and Reliability:

With rigorous quality control measures and state-of-the-art production processes, manufacturers like NEX Pickleball ensure that every paddle consistently meets high standards of durability, flexibility, and performance. This translates to long-term reliability, reducing complaints and increasing brand trust among distributors and sporting goods retailers. -

Market Responsiveness:

Today’s production techniques, including thermoforming and advanced cold pressing, enable manufacturers to rapidly iterate on designs based on market feedback. This agility in production ensures that companies remain competitive by quickly adapting to emerging trends and regulatory standards.

When evaluating a supplier for high-performance pickleball paddles, consider the following factors:

-

Material Quality:

Ensure that the supplier uses premium materials, such as different grades of carbon fiber1 and robust composite cores, which are critical for achieving a balance of power, control, and durability. -

Manufacturing Process:

Understand whether the supplier employs modern techniques like Thermoforming4, cold pressing, or Hot Pressing3. Each process offers unique benefits and trade-offs, and the right choice should align with your market expectations. -

Customization Options:

The ability to offer customized paddle options is a significant advantage in building brand identity and meeting specific consumer needs. Confirm if the supplier can accommodate changes in grip size, weight distribution, and surface texture according to your designs. -

Quality Control Measures:

Robust quality testing—including impact resistance, vibration reduction, and durability assessments—ensures that every paddle produced consistently meets industry and performance standards. -

Production Scalability and Delivery Times:

As market demand grows, the production efficiency of advanced processes like Hot Pressing3 can be an essential factor. Evaluate whether the supplier can scale up production quickly without sacrificing quality.

Manufacturers like NEX Pickleball have embraced these considerations by integrating cutting-edge technology with thorough testing protocols. Their ability to produce paddles that excel in both recreational and competitive gaming environments offers B2B partners the confidence that they are investing in products that drive end-user satisfaction and market growth.

The evolution of pickleball paddles does not stop at current technological achievements. The future holds promising advances that may further transform both the game and its equipment:

-

Integration of Smart Technologies:

Future paddles might include embedded sensors that track swing speed, impact force, and ball spin, providing real-time performance data for players and aiding in advanced training routines. -

Enhanced Material Composites:

Continuous research into new composite formulations may yield materials that are even lighter and stronger, dramatically improving both performance and durability. -

Sustainable Production Practices:

As environmental concerns continue to rise, manufacturers are exploring eco-friendly materials and processes. Innovations may include recycled composites and energy-efficient production techniques, which are likely to become increasingly important in B2B procurement decisions. -

Data-Driven Customization:

With the advent of big data and AI, future manufacturing may leverage consumer usage data to inform custom paddle designs, ensuring an optimal balance tailored to individual player preferences.

The historical evolution and technological advancements in pickleball paddle manufacturing demonstrate a clear trajectory toward higher performance, customization, and consistency. For B2B buyers, understanding the nuances of materials—such as carbon fiber1, fiberglass2, and innovative composite cores—and the benefits and trade-offs of manufacturing processes like Hot Pressing3, cold pressing, and Thermoforming4 is essential.

Key recommendations for strategic procurement include:

- Prioritize suppliers who use a diverse range of high-quality materials tailored to the performance and durability needs of both competitive and recreational markets.

- Evaluate production processes and quality control measures to ensure that each paddle will consistently meet high performance benchmarks.

- Consider the importance of innovation and scalability. As the market for pickleball paddles grows, partnering with manufacturers who are at the forefront of technological advancements will yield sustained competitive advantage.

- Lastly, ensure customization capabilities are available to meet the evolving needs of end-users, further enhancing your product portfolio and market differentiation.

By recognizing these trends and incorporating robust manufacturing practices into procurement decisions, distributors and product developers can confidently invest in paddle products that meet the rigorous demands of today’s fast-paced sports equipment market.

Q: What are the different generation of pickleball paddles?

A: The evolution of pickleball paddles can be divided into four generations. Gen 1 featured basic wooden and early composite models, Gen 2 introduced honeycomb cores and composite surfaces, Gen 3 saw the rise of raw carbon fiber and power technology (2018-Present), and Gen 4, emerging from 2024, incorporates full-foam constructions with edge-to-edge sweet spots.

Q: What is the new paddle technology for pickleball?

A: New paddle technology involves high-density foam cores that flex on impact, which increases dwell time. This allows players to generate more spin and control while preserving power. Innovations such as advanced composite materials and thermoforming processes also contribute to an enlarged sweet spot and consistent play across the paddle face.

Q: How has pickleball changed?

A: Pickleball has evolved into a faster, more offensive game that adopts techniques from other sports like tennis. The game now features paddles with enhanced performance capabilities due to technological advancements in materials and manufacturing processes, resulting in a more dynamic and exciting playing experience.

-

carbon fiber: Click here to learn how carbon fiber offers a high strength-to-weight ratio, contributing to superior performance and durability in high-tech sporting goods manufacturing. ^↩ ↩ ↩2 ↩3 ↩4 ↩5

-

fiberglass: Click here to explore the properties of fiberglass, its manufacturing benefits, and why it is a popular choice for creating controlled, durable sports equipment. ^↩ ↩ ↩2 ↩3

-

Hot Pressing: Click here for an in-depth look at hot pressing technology, explaining its efficiency and role in mass production as well as its impact on material properties in manufacturing. ^↩ ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

Thermoforming: Click here to understand thermoforming, a production process essential for achieving precise material distribution and complex design features in premium products. ^↩ ↩ ↩2 ↩3 ↩4 ↩5

-

Honeycomb Cores: Click here for insights into honeycomb core technology, detailing how its structure provides excellent shock absorption and stability for improved product performance. ^↩ ↩