The article begins by addressing the main question: Which production process offers the best balance between performance, manufacturing efficiency, and tooling cost for high-demand pickleball paddle production? In short, each process—hot pressing, cold pressing1 and thermoforming2—offers unique advantages and trade-offs in tooling investments and production outcomes. In this article, we break down these processes from an economic and technical perspective, providing data-supported comparisons and real-world examples to help you make the best decision for your manufacturing needs.

In today’s competitive sports equipment market, especially for high-performance pickleball paddles, manufacturers face the challenge of selecting the optimum production process. The decisions surrounding tooling investments3 and mold economics4 are critical for balancing performance characteristics, production efficiency, and cost-effectiveness. For decision-makers and procurement specialists, understanding the economic nuances behind hot pressing, cold pressing, and thermoforming is essential. Each method impacts material properties, production throughput, and overall paddle performance in different ways.

The core problem is how to choose a production process that meets high-quality product requirements while staying within budget. Many companies are forced to navigate conflicting needs such as production speed, quality consistency, and raw material integrity. Whether you prioritize advanced material benefits like those from carbon fiber5 variants or the durability factors provided by composites, the selection of tooling and the associated costs play a critical role.

Several factors contribute to the complexity of tooling investments and production cost analysis:

-

Material Costs and Selection:

Advanced materials, including 3K, 12K, and T300 carbon fiber along with fiberglass and composite materials, come at different price points. Higher-quality materials often require more precise tooling to maximize their performance benefits, which in turn drives up tooling costs. -

Production Efficiency and Volume:

When mass-producing paddles, production speed is a key metric. For example, hot pressing allows for greater production efficiency but may compromise on some material properties. Cold pressing, although slower, ensures a consistent feel, while thermoforming offers the best design flexibility for complex paddle profiles but comes with a higher cost and longer lead times. -

Tooling Lifespan and Maintenance:

Each production process demands specific tooling investments that have varied lifespans. High-performance tooling for thermoforming, for instance, requires robust molds that can withstand high temperatures and pressure cycles. Conversely, cold pressing machinery demands precision calibration, and any deviation can lead to defective outputs and additional costs. -

Operational and Capital Expenditure Balance:

Deciding between investing in premium tools versus saving on initial capital at the expense of operational efficiencies requires a detailed cost-benefit trade-off analysis. Factors such as equipment depreciation, maintenance schedules, and energy consumption all feed into long-term cost structure considerations.

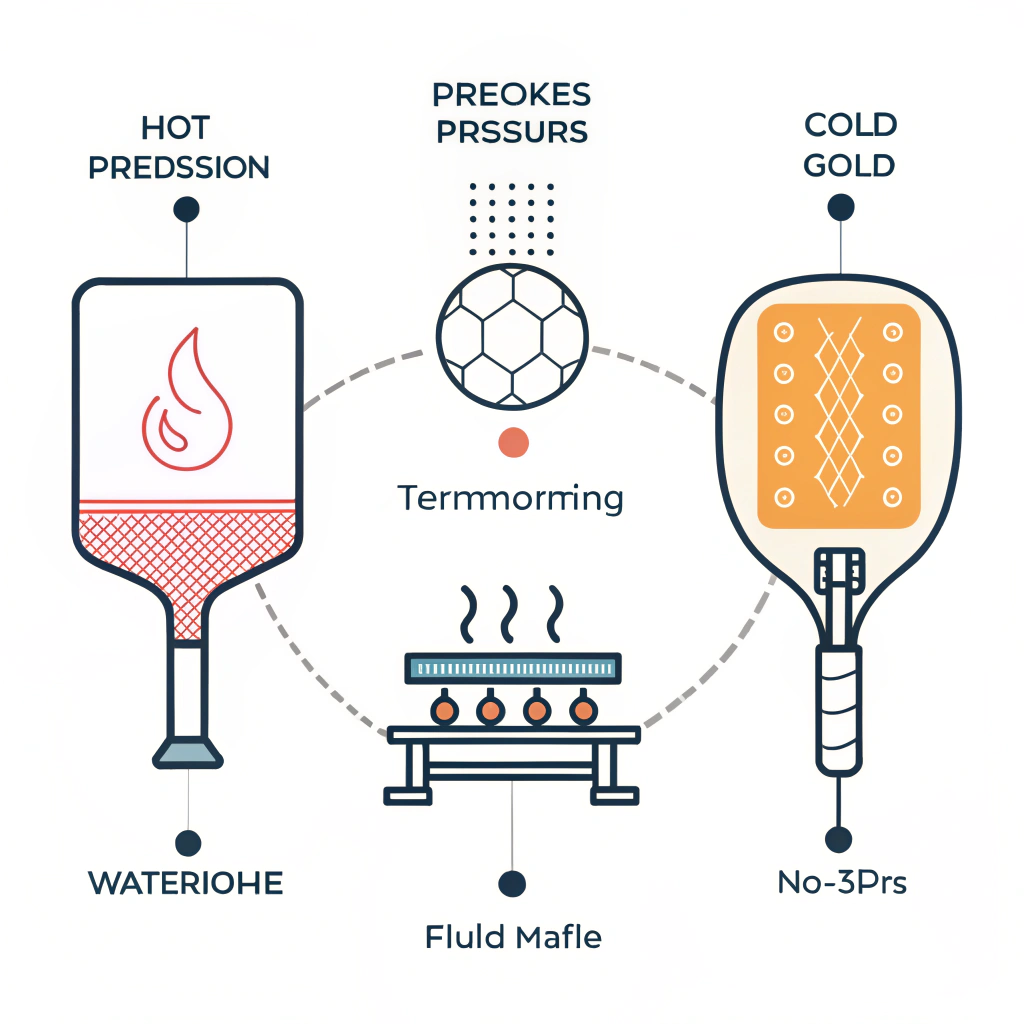

Below, we offer a detailed comparison of the three primary production processes used in pickleball paddle manufacturing. This comparison is based on tooling investments, production efficiency, material performance, and overall cost-benefit trade-offs.

| Process | Advantages | Disadvantages | Tooling Investment |

|---|---|---|---|

| Hot Pressing | High production rate; strong, durable paddles; excellent impact resistance. | Potential material property alterations; expensive equipment. | High initial investment; lower operational complexity. |

| Cold Pressing | Precise control over thickness and structure; preserves material qualities; excellent ball feel. | Longer production cycles; requires high precision equipment. | Moderate investment; higher machine calibration costs. |

| Thermoforming | Enables intricate designs; optimal material distribution; maintains paddle stability. | Long production times; higher equipment and maintenance costs. | Very high investment; suited for premium products. |

Each process presents a trade-off between the initial cost of tooling and the ongoing production efficiencies. A key takeaway is that the choice should be driven primarily by your required balance between throughput and paddle performance.

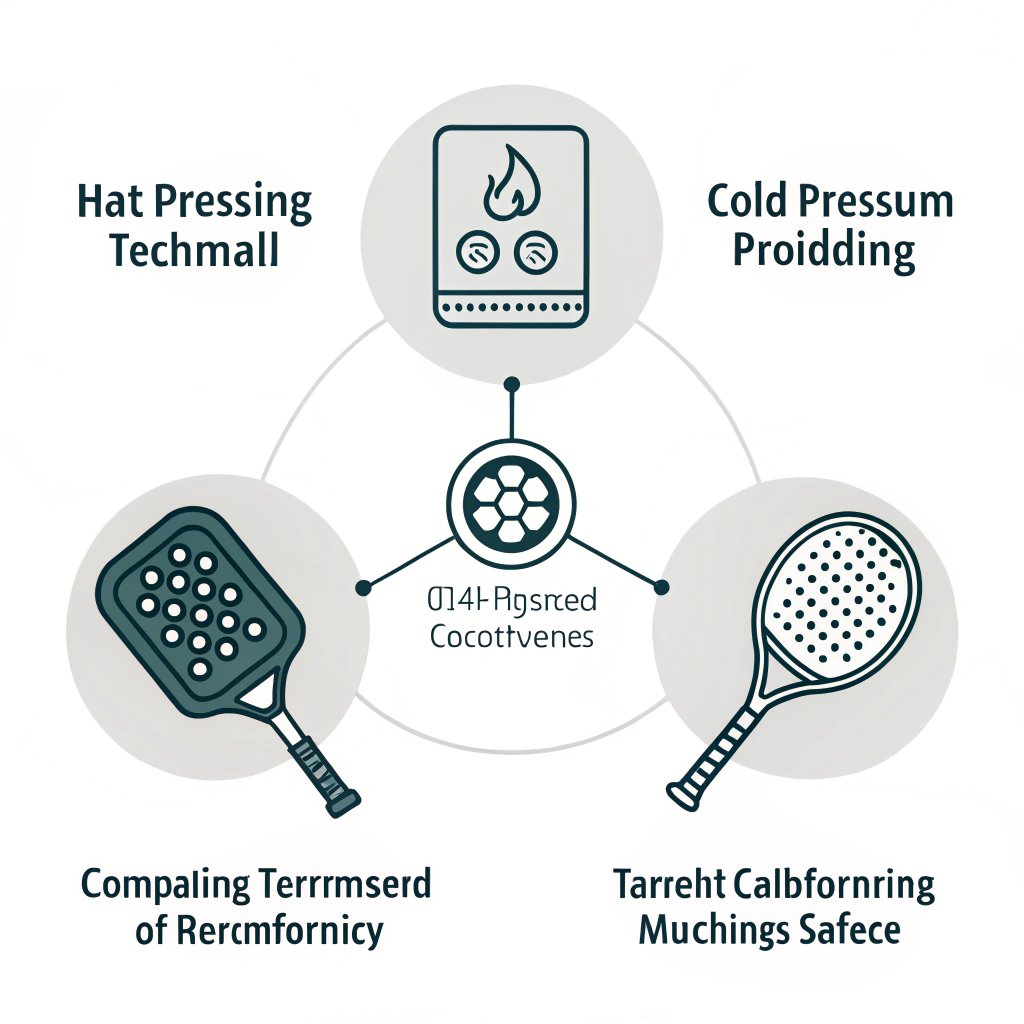

Hot pressing is widely adopted for high-volume production due to its efficient cycle times and robust paddle outcomes. Here’s a closer look at the reasons why manufacturers might choose hot pressing:

-

Production Efficiency:

Hot pressing significantly reduces cycle time. The process relies on heating the material and applying pressure simultaneously, promoting a rapid curing process that can support mass production. In applications where production time is paramount, such as large-scale distribution, this method is a clear winner. -

Tooling Costs:

While the initial tooling investment for high-pressure molds capable of withstanding the heat is substantial, the benefits of reduced cycle times and higher output rates often offset this cost. Manufacturers who have the budget for high upfront costs but require rapid scaling typically lean towards hot pressing. -

Product Durability:

The resultant paddles are known for their strong impact resistance—a critical factor for sustaining long-term performance. However, manufacturers must be cautious of potential alterations in material properties which may influence the paddle feel. -

Example:

A sports equipment factory that geared its production line solely for hot pressing reported a 30% increase in daily output compared to manual assembly. Even with high initial tooling costs, the return on investment (ROI) was achieved within two years due to the efficiency improvements.

Cold pressing offers a more nuanced approach, emphasizing precision and the preservation of material properties:

-

Fine-Tuned Control:

The absence of thermal inputs means that the innate properties of materials such as fiberglass or composite cores (e.g., Nomex and polymer honeycomb) remain unchanged. This results in paddles with a superior and consistent feel, making them popular among players who value ball control and consistency. -

Tooling Investments & Operational Costs:

Although the capital cost for the machinery may be lower than that of thermoforming, operational expenses tend to be higher. The machinery requires constant calibration to ensure uniform pressure distribution, and the longer cycle times can lead to reduced overall throughput. -

Applications in Specialty Production:

For manufacturers focused on premium product lines or custom orders, the enhanced control offered by cold pressing justifies the longer production cycle. In cases where the market values exceptional performance and tailored paddle characteristics, cold pressing is a preferred method. -

Example:

A mid-sized manufacturer reported that by implementing cold pressing, they could offer customized paddle designs that were 15% more expensive—a margin that justified the slower production rate and precision-controlled process.

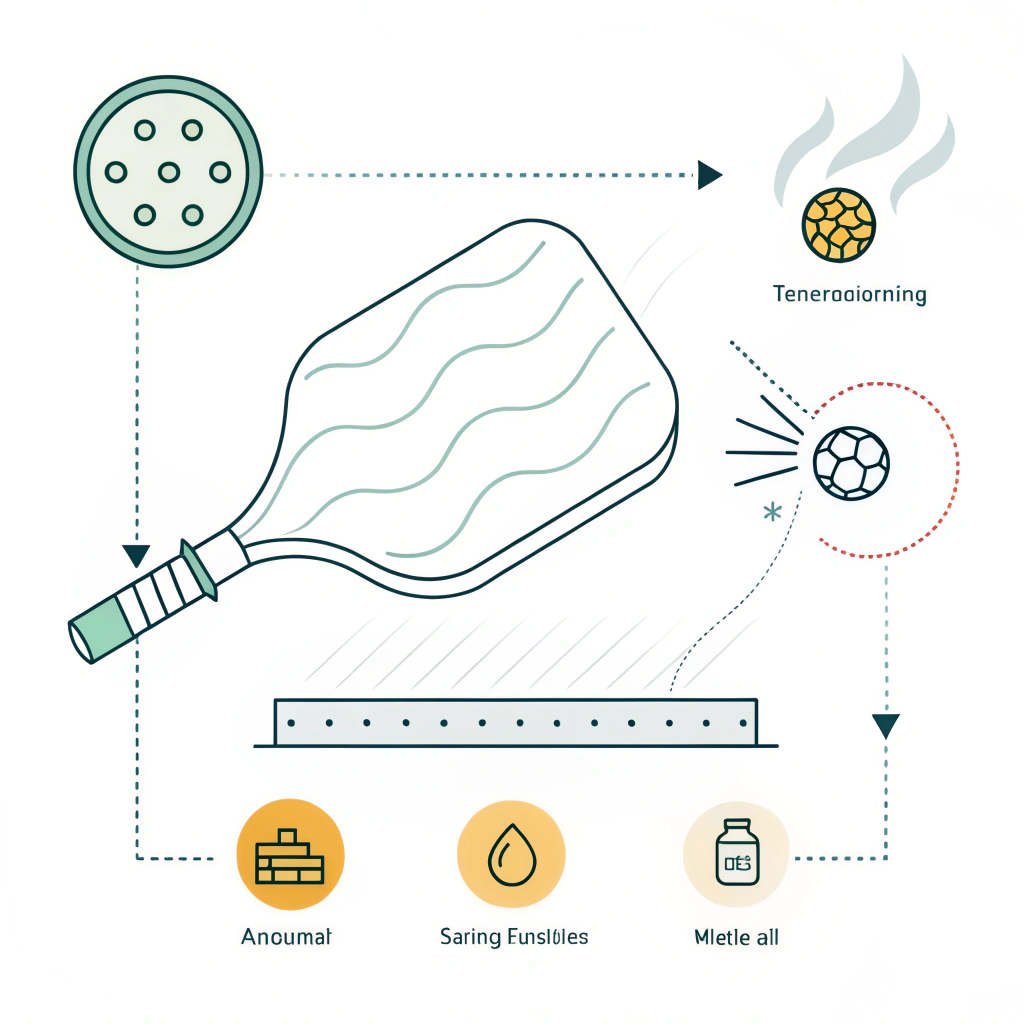

Thermoforming represents the cutting edge of production techniques, offering unmatched design flexibility and complex material layering:

-

Design and Performance Flexibility:

By heating materials to a pliable state before forming them in precise molds, thermoforming allows for the creation of paddles with complex geometries. This process is ideal for achieving optimal weight distribution and ergonomic designs that enhance player comfort and control. -

High Tooling and Equipment Investment:

The machinery associated with thermoforming is the most expensive among the three options. It requires high-quality molds that can endure extended production cycles and rigorous testing. The cost is justified by companies looking to produce top-tier paddles that command a premium in competitive markets. -

Economic Considerations:

The longer production time can be a bottleneck in high-volume scenarios. However, the unique design capabilities make thermoforming more than just a production method—it is a value-added process for premium paddle segments. -

Example:

A large sports brand, after switching to thermoformed paddles, saw a notable increase in player performance metrics. Although the initial tooling cost was 40% higher, the differentiated product allowed the brand to capture a niche market segment willing to pay a premium.

When deciding which production process aligns with your manufacturing and budgetary strategies, consider the following factors:

-

Production Volume and Timeline:

- High-volume manufacturers may benefit from hot pressing due to faster cycle times.

- For specialized, lower-volume production, cold pressing or thermoforming may offer the quality and customization needed.

-

Material Selection:

- The choice of materials plays a significant role in the final paddle performance. High-end carbon fiber5 and composite materials may require more nuanced tooling investments and may be better suited for thermoforming or cold pressing to maximize their properties.

- If durability is the primary concern with less sensitivity to exact tactile performance, hot pressing may be sufficient.

-

Tooling Lifespan and Maintenance Costs:

- Assess the expected lifespan of your tooling investments. High-cost molds for thermoforming might need more frequent maintenance or replacement cycles.

- Ensure a follow-up budget that covers regular maintenance and potential upgrades, especially if using precision-based cold pressing equipment.

-

Cost-Benefit Trade-Off Analysis:

- Perform a detailed cost analysis that factors in both the immediate tooling investment and the long-term operational savings or expenses.

- Utilize data points such as production cycle time, product failure rates, and customer performance feedback to inform your decision.

-

Market Positioning and Product Differentiation:

- If your business model targets high-end competitive players, a higher initial cost in tooling may provide greater market differentiation through superior product quality.

- Alternatively, for broader market penetration, a balance between cost and performance is essential to meet diverse consumer expectations.

Consider a scenario where a manufacturing specialist from a leading sports equipment company evaluated different production methodologies for their new paddle line. The company’s primary goal was to enhance product performance while managing cost overheads.

-

Initial Analysis:

The specialist compared tooling investments for hot pressing, cold pressing, and thermoforming. They discovered that while thermoforming offered the best in terms of design flexibility and product ergonomics, its high tooling cost and longer cycle times were obstacles for scaling production. -

Implementation Decision:

Cold pressing appeared as a balanced approach, offering precise control over material properties without the extreme costs associated with thermoforming. By carefully calibrating equipment and gradually increasing production volume, they managed to produce paddles with exceptional performance characteristics and a premium feel. -

Outcome:

The cold pressing route resulted in a 20% reduction in defect rates compared to hot pressing. Furthermore, customer feedback highlighted improved tactile feel and better ball control, leading to increased customer satisfaction and a stronger brand reputation.

This case study reinforces the importance of aligning production process selection with both operational capabilities and market expectations. The decision on tooling investments should ideally be supported by quantitative data and thorough cost-benefit analysis.

In conclusion, selecting the right production process for pickleball paddle manufacturing involves a multidimensional analysis of tooling investments, production efficiency, and material performance. Here are the actionable steps to guide your decision:

- Evaluate your production volume and required throughput. High-volume production may favor hot pressing, while premium, custom orders lean towards cold pressing or thermoforming.

- Conduct a detailed cost-benefit analysis that includes both initial tooling costs and long-term operational expenditures.

- Consider the performance benefits of advanced materials like carbon fiber5 and composites—understand that these benefits come at a price that must be balanced with production capabilities.

- Engage in small-scale pilot studies where possible to assess the impact of different processes on product quality and defect rates.

- Stay updated on technological advancements in manufacturing processes, as continuous improvements can shift the cost dynamics over time.

Deploying these recommendations effectively will allow your business to achieve optimal production efficiency, superior product performance, and sustainable cost management, ensuring that the final pickleball paddles meet the highest standards for competitive play.

People Also Ask

Q: What makes expensive pickleball paddles better?

A: High-end pickleball paddles typically utilize advanced materials such as carbon fiber5 and fiberglass. These materials provide improved control, power, and spin through enhanced structural integrity and a superior balance between stiffness and flexibility.

Q: Can I create my own paddle for pickleball?

A: Yes, you can create a custom pickleball paddle by starting with a blank paddle template, choosing your preferred color, and adding a personal design, text, or photos. This process allows you to design both the front and back to fit your style and playing needs.

Q: What advantage does carbon fibre construction offer in a pickleball paddle?

A: Carbon fibre construction makes paddles stiffer and more responsive. This increased rigidity translates into enhanced power behind each shot and improved shot accuracy, making carbon fibre an excellent choice for players seeking to maximize performance.

-

cold pressing: Click to explore the cold pressing process, covering its advantages in preserving material integrity, the required precision in manufacturing, and its impact on product quality. Back to cold pressing ↩

-

thermoforming: Click to understand the thermoforming process, from mold design and material behavior to the benefits and challenges of achieving intricate product designs. Back to thermoforming ↩

-

tooling investments: Click to read an article that explains how investments in specialized manufacturing tools and molds impact production efficiency and long-term cost structures. Back to tooling investments ↩

-

mold economics: Click to discover insights into mold economics, including cost analysis, maintenance strategies, and lifecycle management for manufacturing processes. Back to mold economics ↩

-

carbon fiber: Click to learn about carbon fiber technology, its benefits in high-performance sports equipment, and how its properties influence product design and performance. Back to carbon fiber ↩ ↩2 ↩3 ↩4