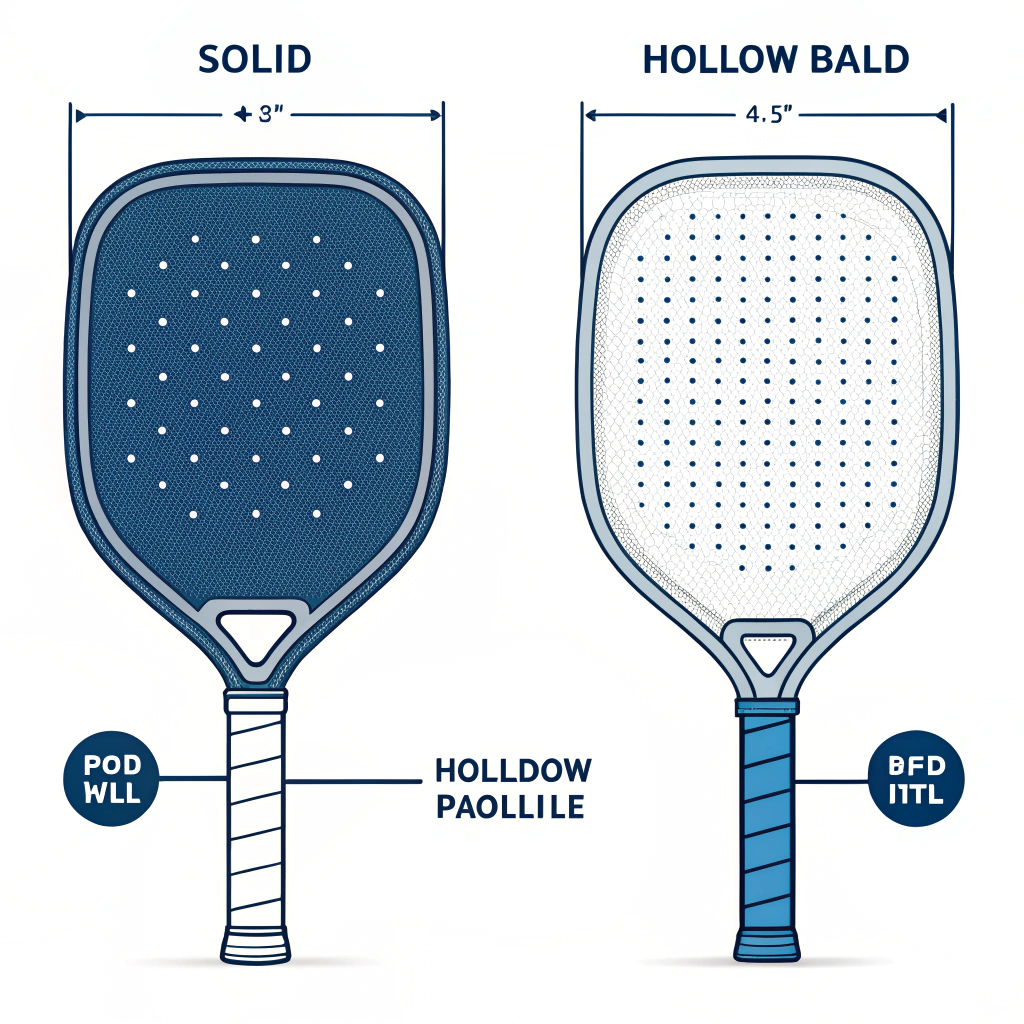

A solid pickleball paddle is typically constructed with a denser, reinforced core and surface materials that deliver superior durability and performance, while a hollow paddle design focuses on reducing weight and production costs with a more open structure that still meets competitive standards. This article dives deep into the manufacturing differences between solid and hollow paddle designs—comparing performance, durability, and cost implications—to help B2B decision-makers in the sports equipment sector make informed inventory and customization decisions.

In a rapidly evolving market, manufacturers and distributors are continually challenged to balance performance with cost efficiency. The choice between a solid paddle and a hollow paddle design can significantly impact product performance and price points. Understanding the differences in manufacturing processes, material selection, and production techniques is paramount for those seeking a competitive edge in the sports equipment market.

The key determinants in this decision include:

• Core material density and composition

• Reinforcement and surface material properties

• Production methods such as hot pressing1, cold pressing, and thermoforming

• Overall cost efficiency and scalability for high-demand production

• Customization potential for different player levels and use cases

When comparing solid and hollow designs, solid paddles generally feature a dense core made from materials like Nomex honeycomb2 or aluminum honeycomb. These cores, combined with high-strength surface materials such as 3K or 12K carbon fiber, result in paddles that offer exceptional stability and impact resistance. The production processes like hot pressing1 reinforce the structural integrity, ensuring that these paddles maintain their performance even under intense, repeated impacts, making them particularly attractive for high-level competitive play.

In contrast, hollow paddle designs use a structure that includes voids or internal channels, reducing overall weight without significantly compromising durability. Hollow designs may integrate alternative core materials like polymer honeycomb or incorporate composite blends where materials such as fiberglass are used to balance form and function. This design is often achieved through cold pressing3 or thermoforming4 processes, where maintaining an optimal balance of material distribution is crucial to avoid reducing performance efficacy.

A key comparative table can help illustrate the crucial differences between these two paddle designs:

| Aspect | Solid Paddle | Hollow Paddle |

|---|---|---|

| Core Material | Dense cores (Nomex, Aluminum, or Bamboo Core) | Lighter cores (Polymer honeycomb, partial composites) |

| Surface Materials | High-density carbon fiber (3K, 12K, T300) | Mix of fiberglass and carbon fiber composites |

| Manufacturing Process | Often utilizes hot pressing1 for strength | Uses cold pressing3 or thermoforming4 for precision |

| Durability | High; resistant to heavy impacts | Moderate to high; optimized for weight reduction |

| Production Efficiency | Higher quality control but higher cost investment | Cost-effective with quicker production cycles |

| Customization Potential | Suitable for high-performance needs | Ideal for large-scale, cost-effective product lines |

| Performance (Impact Resistance) | Superior rebound and control | Balanced control with enhanced manuveability |

When evaluating manufacturing processes, each technique comes with distinct advantages:

-

Hot Pressing:

- Benefits include high production efficiency and a strong, durable paddle finish.

- Solid paddles often benefit from this process due to its ability to create tightly bonded layers and reinforce core stability.

- However, the investment in specialized equipment and the possibility of altering some material properties need to be considered.

-

Cold Pressing:

- This process allows for precise thickness control and maintains material properties intact, ideal for designs focused on control and flexibility.

- While it takes longer than hot pressing, cold pressing often suits hollow designs where precision shapes are essential to maintain the right balance between weight and durability.

-

Thermoforming:

- Particularly useful when creating paddles with intricate designs, thermoforming4 involves heating materials until malleable, then shaping them with precision molds.

- This technique provides excellent stability and is adaptable for both solid and hollow designs, although it demands more production time and cost.

Manufacturers must weigh these production methods not only based on manufacturing cost but also on the specific performance attributes required by professionals and recreational players alike.

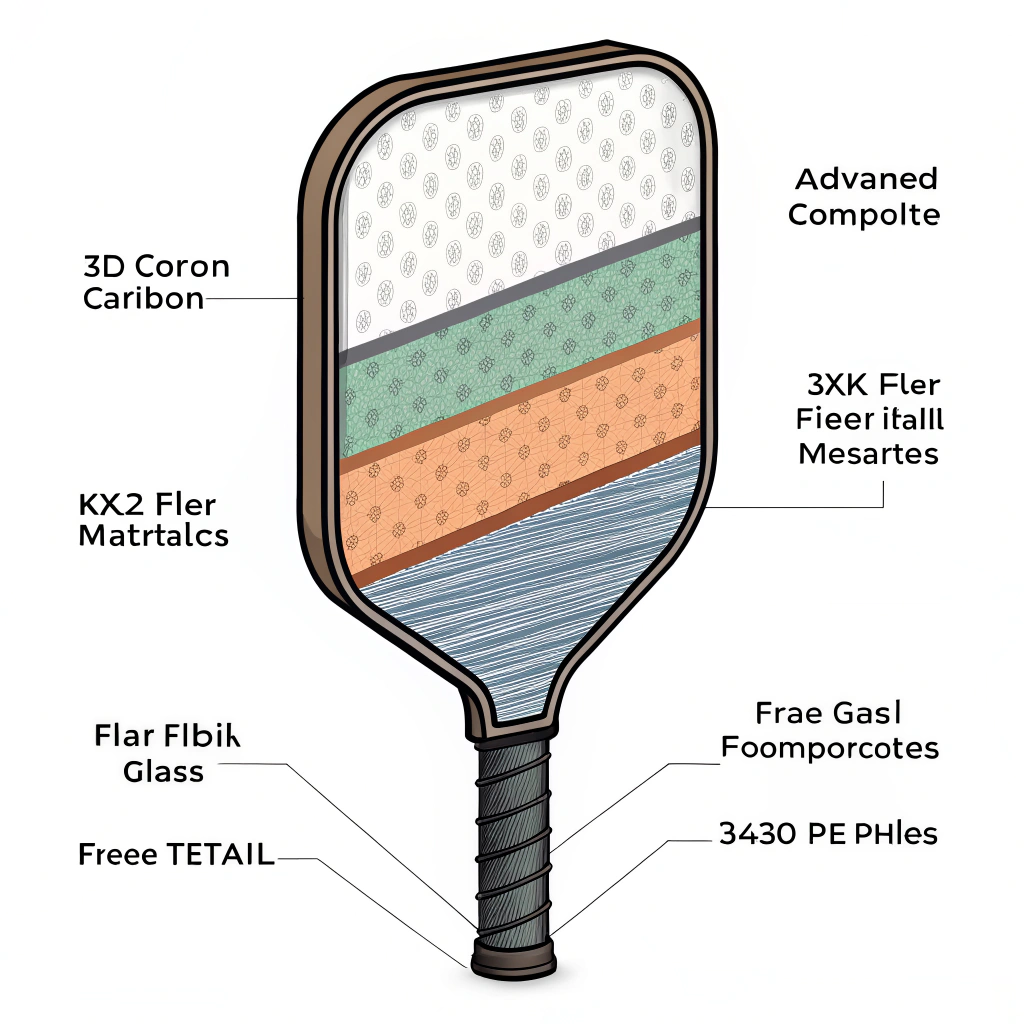

The performance of a paddle is heavily determined by its constituents. Carbon fiber variants—such as 3K, 12K, and T300—are the top choices for solid paddles due to their high tensile strength and vibration reduction capabilities. The selection between these materials often depends on the targeted performance level:

- 3K Carbon Fiber is well-known for its flexibility and strength, delivering an excellent balance of durability and rebound force.

- 12K Carbon Fiber provides an even smoother surface and greater hardness, ensuring durability for high-impact situations.

- T300 Carbon Fiber blends the benefits of strength with a lightweight profile, ideal for paddles that demand both power and agility.

Hollow paddles, on the other hand, can benefit from composite materials5 where fiberglass is used either on its own or in combination with carbon fiber. E-Glass Fiberglass offers elasticity and superior control, meeting the need for a wider playing "sweet spot" and excellent ball feel. The use of composite materials allows for creative engineering designs that reduce weight while maintaining unexpected performance benefits.

For B2B decision-makers in retail or distribution, cost efficiency is as critical as performance. Solid paddles typically require a higher initial investment in high-grade materials and more advanced manufacturing processes. This investment, however, translates into a product that delivers exceptional durability and high-level competitive performance. When targeting a niche market willing to pay a premium for durability and performance, solid designs are the ideal path.

Hollow designs can often offer a viable cost-effective alternative for broader markets such as recreational players or facilities that demand a higher turnover of equipment with reasonable performance output. Due to reduced material usage and more efficient production cycles, manufacturers can maintain competitive pricing while still offering products that meet performance benchmarks set by high-level sporting events.

The decision between these two designs should thus be weighed not only by the unit cost but by the lifecycle value and performance expectations of the end user. For instance, facilities management may lean toward hollow designs due to lower initial costs and acceptable performance for everyday use, while professional sports venues might prefer solid designs that withstand rigorous competitive play.

Another important aspect for B2B clients is the potential for customization. Paddle manufacturers such as NEX Pickleball are embracing on-demand printing services that allow businesses to personalize paddles for team branding or specific performance requirements. Whether you opt for a solid paddle with reinforced integrity through advanced hot pressing1 techniques or a hollow design optimized for lightweight and cost-effective production, customization options can fine-tune each paddle’s characteristics to precisely meet your needs.

Businesses can choose from various core materials:

• Nomex Honeycomb Core: Offers outstanding shock absorption resulting in improved stability and extended product longevity.

• Aluminum Honeycomb Core: Balances power and control with its medium density, facilitating vibrant gameplay.

• Polymer Honeycomb Core: Delivers reduced vibration, making it ideal for players who prioritize a smooth and comfortable hitting experience.

These variations can easily be aligned with market positioning strategies, ensuring that products meet the demands of a specific target audience. Whether a retailer is stocking elite performance paddles for professionals or cost-effective variants for community centers, understanding the underlying manufacturing processes and material compositions is essential.

High-scale production operations benefit from different manufacturing approaches. Hot pressing1, while offering premium quality, might be more feasible for lower volume, high-end products due to its rigorous process control and equipment costs. Conversely, cold pressing3 and thermoforming4 can be scaled efficiently to meet high-volume production schedules, especially useful for hollow designs targeting mass-market applications.

A typical production flow might involve:

- Material selection and pre-processing, ensuring that the chosen carbon fiber or composite material meets stringent performance standards.

- The pressing phase (hot or cold) where layers are bonded together, ensuring the right combination of core density and surface finish.

- Post-processing, including precision cutting and finishing treatments to enhance grip and ball contact performance.

Manufacturers must invest in high-quality production equipment to maintain tight tolerances and consistent quality control across batches. These practices have a direct impact on cost, consistency, and ultimately, customer satisfaction.

A recent survey among sports equipment distributors indicated that approximately 70% of procurement managers prefer products with proven durability and predictable performance metrics, even if these come at a slightly higher cost. This industry data supports the development and marketing of solid paddle designs for competitive sports, while also affirming the viability of hollow designs in cost-sensitive segments.

Manufacturers must continuously monitor production metrics and product performance through rigorous testing protocols. Iterative improvements based on testing and user feedback help refine products, ensuring that all paddles—whether solid or hollow—deliver on their promise of quality and performance.

In conclusion, the decision between solid and hollow pickleball paddle designs rests on a delicate balance between performance, durability, customization needs, and cost efficiency. Solid paddles with dense cores and advanced materials are best suited for high-performance environments where durability and resistance to heavy impacts are key. Hollow paddles, with their efficient use of materials and ease of production, offer an attractive alternative for markets that require cost-effective and lightweight equipment.

For B2B decision-makers, a careful evaluation of manufacturing processes like hot pressing1, cold pressing3, and thermoforming4 is essential. Aligning these choices with clear market requirements—from top-tier competitive play to broader recreational use—can significantly enhance product differentiation and customer satisfaction.

Action steps for industry professionals might include:

• Conducting a thorough cost-performance analysis tailored to your market segment.

• Engaging with manufacturing partners who offer a range of production processes and customization options.

• Piloting product lines that align with both high-end and cost-effective market segments to observe performance feedback.

• Leveraging customization services to create products that stand out in retail channels.

By integrating comprehensive manufacturing insights with market data and robust production techniques, businesses can confidently select the design that best suits their operational and market needs.

People Also Ask

Q1: How do solid pickleball paddles differ from hollow designs in manufacturing?

A1: Solid paddles typically incorporate a denser core and high-strength materials through processes like hot pressing1, resulting in higher durability and performance. In contrast, hollow designs use reduced material density and efficient production techniques such as cold pressing3 or thermoforming4, which offer cost benefits and lighter weight.

Q2: What are the cost implications of solid versus hollow paddle designs?

A2: Solid paddle designs generally incur higher production costs due to the use of premium materials and more intensive manufacturing processes. Hollow designs are more cost-effective, providing quicker production cycles and lighter structures that suit broader market needs.

Q3: Which manufacturing process is best suited for high-performance pickleball paddles?

A3: High-performance paddles often benefit from processes like hot pressing1 and thermoforming4, as these methods ensure structural integrity and enhanced material distribution. The choice depends on the desired balance between durability, control, and production efficiency.

-

Hot pressing: Read the article to delve into hot pressing techniques that create strong, durable bonds in paddle layers, enhancing overall product performance. Back to Hot pressing ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8

-

Nomex honeycomb: Read the article to understand the unique properties and applications of Nomex honeycomb cores, which contribute to shock absorption and structural stability in high-performance paddles. Back to Nomex honeycomb ↩

-

Cold pressing: Read the article to learn about cold pressing, a precision manufacturing process that maintains material integrity while ensuring accurate formation in paddle production. Back to Cold pressing ↩ ↩2 ↩3 ↩4 ↩5

-

Thermoforming: Read the article to explore how thermoforming shapes materials through controlled heating, offering detailed manufacturing precision for complex paddle designs. Back to Thermoforming ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7

-

Composite materials: Read the article to gain insight into composite materials used in paddle construction, offering a balance of strength, weight reduction, and cost efficiency. Back to Composite materials ↩