A custom pickleball paddle’s price is driven by a blend of material quality, advanced production methods, and rigorous quality control processes. Understanding how factors such as raw material selection1 and production techniques like hot pressing, cold pressing, and thermoforming2 contribute to overall costs can empower procurement managers to make informed decisions and optimize manufacturing strategies.

Procurement managers in the sports equipment industry face the complex task of balancing cost efficiency with high-performance quality. When developing a custom pickleball paddle, every stage—from selecting premium materials to choosing the right production process—affects the final cost. With evolving market demands and increasing competition, comprehending these cost components becomes critical. For instance, high-performance paddles that utilize advanced carbon fiber or composite materials may offer superior durability and control, but their production can be more expensive compared to those produced with standard materials.

Moreover, the manufacturing processes employed significantly influence the cost and performance of the paddle. Processes such as hot pressing, cold pressing, and thermoforming have unique advantages, and each brings different cost implications in terms of production speed, equipment investment, and material properties. Decision-makers need a clear cost breakdown to identify where savings are possible without sacrificing paddle performance.

To effectively evaluate the custom manufacturing strategy, it is essential to break down the cost components into clear categories:

- Raw Materials: The cost of materials like 3K Carbon Fiber, 12K Carbon Fiber, T300 Carbon Fiber3, and Fiberglass significantly impacts production. High-quality materials such as T300 carbon fiber provide excellent performance but come with a higher price tag.

- Composite and Core Materials: Options, including bamboo core composite and Nomex Honeycomb Core4, offer varying levels of shock absorption, impact resistance, and feel. Procurement managers must balance the benefits of these materials with budget constraints.

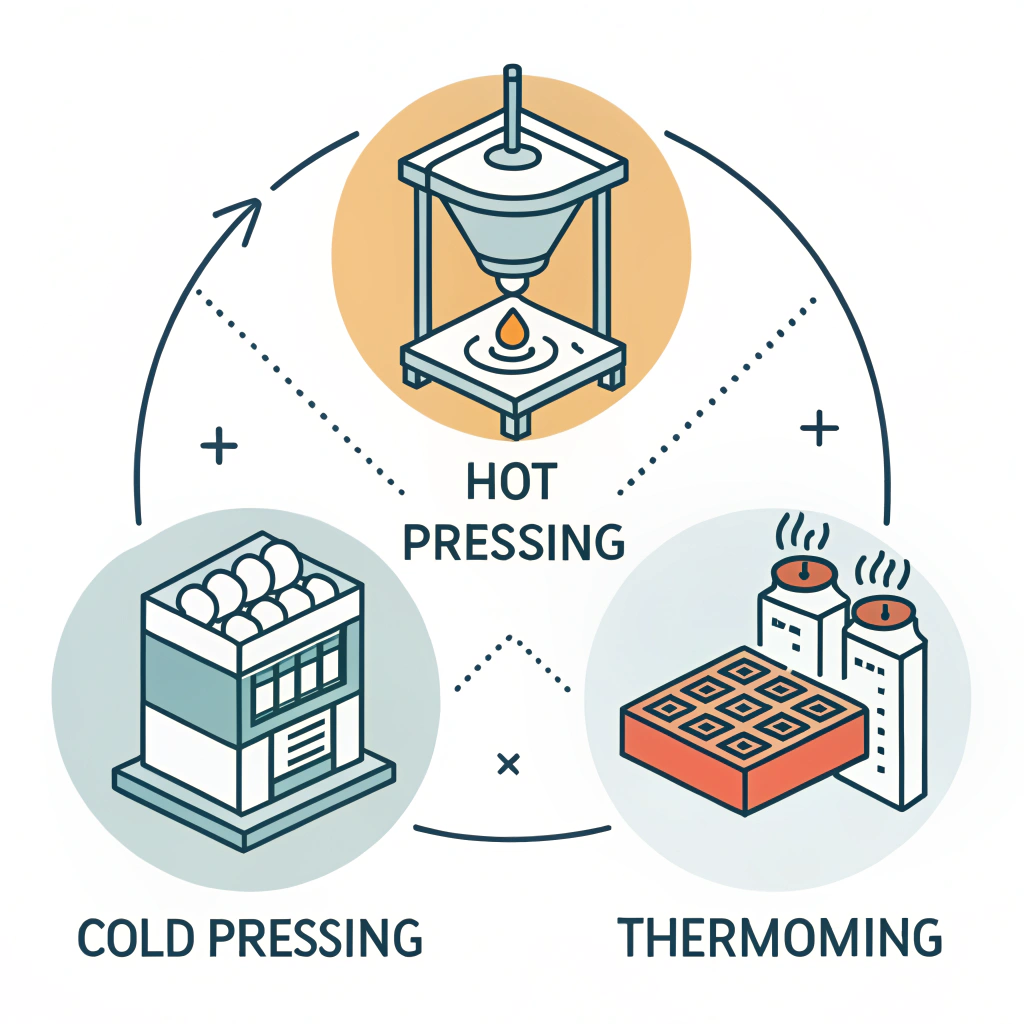

The chosen production process not only affects the paddle’s performance but also its manufacturing cost:

- Hot Pressing:

- Advantages: High efficiency, strong structural integrity, and suitability for large-scale production.

- Costs: High equipment investment and potential alterations in material properties.

- Cold Pressing:

- Advantages: Precise control over paddle thickness, excellent ball feel due to retained material properties.

- Costs: Longer production cycles and the need for precise pressure control equipment.

- Thermoforming:

- Advantages: Increases design complexity and allows for optimal material distribution which ensures performance consistency.

- Costs: Extended production time and higher capital costs due to specialized molds and equipment.

- Manual vs. Automated Processes: The extent to which production is automated can influence labor costs. Automated processes, though involving higher initial capital investment, often yield fewer errors and improve long-term cost efficiency.

- Quality Control and Testing: Every paddle undergoes rigorous testing to meet high performance standards. Consistent quality control increases reliability but also adds to production time and costs.

- Custom Design Requirements: When producing custom paddles, individual client specifications (such as unique weight, grip, and balance) may require additional production steps and design alterations.

- Order Volume: Higher order quantities can reduce per-unit costs due to economies of scale, but lower volume orders might incur premium manufacturing expenses.

Below is a table summarizing the key differences among the three primary production processes used in paddle manufacturing:

| Production Process | Advantages | Disadvantages | Typical Use Case |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; reliable for large-scale manufacturing | High equipment costs; potential alteration of material properties | High-performance paddles where impact strength is critical |

| Cold Pressing | Superior control over paddle thickness; preserves raw material integrity for better feel | Longer production cycles; requires precise equipment | Custom paddles requiring precise control and ball feel |

| Thermoforming | Allows complex shapes and optimal material distribution; maintains paddle stability | Extended production time; high mold and equipment costs | Premium products or custom designs with intricate features |

These production methods allow manufacturers to tailor the paddle’s performance to different market segments—ranging from recreational to competitive play. For procurement managers, the decision between these methods involves a trade-off between initial investment, production rate, and the specific performance characteristics of the final product.

To achieve cost-effective manufacturing of custom pickleball paddles without compromising quality, several solutions can be implemented:

- Evaluate Material Trade-offs: Use high-performance yet cost-effective materials. For instance, combining carbon fiber with fiberglass in composite constructions can yield a balance between durability and flexibility while managing costs.

- Bulk Purchasing: Negotiate bulk purchasing agreements for raw materials like carbon fibers and composite materials to reduce unit costs.

- Material Substitution: Explore alternative or hybrid materials that can provide similar mechanical properties at a lower cost. For example, a bamboo core composite might deliver performance benefits comparable to more expensive options.

- Lean Manufacturing5: Implement lean production techniques to minimize waste in the production line. Optimize each process stage through continuous improvement methods.

- Automation: Invest in automation for cold pressing and thermoforming processes where applicable. Although the upfront cost may be higher, the long-term benefits include reduced labor expenses and improved consistency.

- Process Selection Based on Product Tiering: Use hot pressing for high-volume, cost-sensitive orders, and reserve thermoforming for premium products requiring intricate designs.

- Energy Efficiency: Apply energy-saving measures during high-temperature processes, such as hot pressing, to reduce operational costs.

- Integrated Quality Systems: Incorporate automated quality control systems to reduce labor costs and ensure each paddle meets stringent quality standards.

- Modular Designs: Develop design templates that can be easily customized. This reduces setup time and costs while allowing clients to personalize paddle features, such as grip size or balance.

- Rigorous Testing: Regularly monitor and test paddles during production to catch issues early and reduce rework, thus saving costs in the long run.

Creating a detailed cost analysis model is key to informed decision-making. Consider developing a spreadsheet that includes:

- Material costs per unit

- Labor costs per process step

- Overhead costs (including equipment depreciation and energy)

- Potential savings from automation or bulk purchasing

A simple model might look like this:

| Cost Factor | Estimated Cost per Unit | Notes |

|---|---|---|

| Raw Materials | $X | Varies by type: carbon fiber, fiberglass, etc. |

| Labor | $Y | Varies with process automation |

| Equipment Depreciation | $Z | Spread over production volume |

| Quality Control | $A | Includes automated testing systems |

| Overheads | $B | Energy, maintenance, and facility costs |

| Total Production Cost | $Total | Sum of all individual components |

This model can be adjusted based on specific production scenarios to help procurement managers compare the efficiency of different manufacturing partners or internal production setups.

While the strategies outlined above offer robust solutions to optimize production costs, it’s important to be mindful of potential limitations:

- Initial Capital Investment: Advanced automated systems and high-quality materials require significant upfront costs, which might be challenging for smaller operations.

- Market Variability: Material prices and labor costs can fluctuate based on global market conditions, impacting the overall cost model.

- Customization Complexity: Highly customized designs, though appealing to clients, can lead to increased production complexity and longer lead times.

- Equipment Maintenance: The long-term efficiency of any production process depends on regular maintenance and upgrade cycles for equipment.

Understanding these factors helps in setting realistic expectations and planning for contingencies in the manufacturing process.

Consider the experience of NEX Pickleball, a leading manufacturer known for its expertise in crafting high-performance pickleball paddles. By carefully balancing material selection—using premium carbon fiber types and cost-effective composite materials—and optimizing production methods, they have successfully maintained competitive pricing while ensuring superior performance.

For example, by implementing lean manufacturing techniques and automating certain production phases, NEX Pickleball has achieved a reduction in overall production costs by a notable percentage over the past year. Their approach to using bulk raw material purchasing, combined with rigorous quality control, has set a benchmark in the industry for delivering both quality and value.

These real-world results underscore the importance of a detailed cost analysis and efficient production planning. Such data-driven approaches not only boost profit margins but also enhance market competitiveness and customer satisfaction.

To sum up, the overall cost of custom pickleball paddle production is governed by several key factors:

- The choice of raw materials such as various types of carbon fiber, fiberglass, and composite materials.

- The selection of production processes — hot pressing, cold pressing, and thermoforming — each with its own cost and performance advantages.

- The impact of labor, process automation, and quality control measures on overall production efficiency.

- The benefits of strategic sourcing, design modularity, and bulk purchasing in reducing per-unit costs.

Procurement managers and decision-makers should apply these insights to evaluate potential manufacturing partners or to refine internal production processes. By building a comprehensive cost model, investing in process optimization, and strategically selecting materials, businesses can create a cost-effective production strategy without compromising the high-performance standards that players expect.

We recommend initiating pilot projects to test the effectiveness of these strategies and monitor the impact on cost savings and product quality. Additionally, exploring partnerships with experienced manufacturers like NEX Pickleball can offer access to cutting-edge production techniques and optimized cost structures.

Embracing a proactive, data-driven approach in the custom manufacturing process will not only drive immediate cost efficiencies but also build a foundation for long-term success in the highly competitive sports equipment market.

Q1: What factors affect the cost of custom pickleball paddle manufacturing?

A1: The cost is influenced by raw material selection, production methods (hot pressing, cold pressing, thermoforming), labor expenses, and the degree of customization. Each factor contributes to both the overall quality and the production efficiency.

Q2: How do hot pressing, cold pressing, and thermoforming compare in terms of cost and quality?

A2: Hot pressing offers high efficiency and durability, ideal for large-scale productions, but involves high equipment costs. Cold pressing maintains material integrity for better control and feel, though it has longer production cycles. Thermoforming allows for complex designs and precise material distribution but is associated with extended production times and higher capital investments.

Q3: What are best practices for achieving cost-effective custom paddle production?

A3: Optimizing material sourcing, implementing lean manufacturing, investing in automation, and using integrated quality control systems are key practices. Developing detailed cost models also aids in identifying efficiency opportunities and ensuring a balanced approach between performance and cost-effectiveness.

-

raw material selection: Reading this article will provide insights into how selecting the right raw materials can impact production performance and costs, ultimately leading to more informed procurement decisions. ↩ ↩

-

thermoforming: This resource explains the thermoforming process, detailing its impact on design complexity, material distribution, and production costs in manufacturing. ↩ ↩

-

T300 Carbon Fiber: Learn about the properties and advantages of T300 Carbon Fiber, a high-performance material that plays a crucial role in delivering superior durability and control in premium products. ↩ ↩

-

Nomex Honeycomb Core: Explore how Nomex Honeycomb Core contributes to shock absorption and overall product stability, offering benefits in lightweight and durable composite construction. ↩ ↩

-

Lean Manufacturing: Understand lean manufacturing principles and how their implementation can reduce waste, enhance production efficiency, and optimize overall operational performance. ↩ ↩