Short answer: For most OEM paddle lines, choose the handle material based on target player segment — EVA foam1 or PU wrap2 for recreational and beginner paddles (best balance of cost, comfort and moisture control), perforated PU or synthetic leather for mid-level paddles (better tack and durability), and molded thermoformed composite or wrapped high-density polymer handles for competitive paddles where stability, vibration damping and consistent ergonomics matter. Manufacturing method (hot pressing / cold pressing / thermoforming3), MOQ and customization needs will determine the final choice and unit cost.

Why this decision matters now

- The handle is the first physical point of contact between player and paddle. It affects perceived comfort, ball feel, shot control, and long-term durability.

- For B2B buyers (product managers, OEM procurement, brand owners), the handle choice impacts material cost, assembly steps, lead time, MOQ, branding options and warranty claims.

- Below is a practical comparison and procurement checklist to finalize a handle spec that aligns with your product positioning and manufacturing process.

Quick comparison (at-a-glance)

| Material / Type | Feel & Grip | Shock Absorption | Durability | Manufacturability | Cost estimate (per handle, USD) | Best for |

|---|---|---|---|---|---|---|

| EVA foam wrap | Soft, cushioned | Good | Medium | Easy: adhesive wrap | $0.30–0.80 | Beginner / recreational |

| PU wrap (tacky) | Moderate softness, high tack | Medium | High | Easy, roll-to-roll or cut-and-wrap | $0.50–1.20 | Recreational / mid |

| Perforated PU | Enhanced sweat wicking, tack | Medium-high | High | Slightly more handling (alignment) | $0.6–1.4 | Mid / club players |

| Synthetic leather | Firm, consistent feel | Low-medium | Very high | Easy to attach; good for printing | $0.6–1.5 | Premium aesthetic / retail |

| Cork / Cork-Blend | Unique feel, light | Good | Medium | Needs adhesive & sealing | $0.7–1.6 | Eco-friendly lines |

| Injection-molded / Thermoformed handle (composite) | Rigid, precise ergonomics | High (if designed) | Very high | Tooling & molds required; ideal for thermoforming | $1.5–4.0+ | Competitive / high-end |

| Wood / Composite lamination | Traditional, solid | Low | Variable | Additional machining, staples/adhesive | $0.4–1.2 | Budget / classic designs |

Notes: cost ranges vary by annual volume, location, and customization (printing, embossing). Use these as procurement starting points.

Material deep-dive and manufacturing implications

- EVA foam wraps

- Advantages: EVA foam is light, soft and provides good shock absorption. It’s economical and widely available. It offers a comfortable grip that reduces short-term vibration and is forgiving for new players.

- Disadvantages: EVA can compress over time and lose shape faster than PU or synthetic leather. It’s less tacky, so players may add overgrips.

- Manufacturing: Easy to apply in roll form. Compatible with both hot pressing (when done carefully) and cold pressing paddle assembly. Minimal tooling needed—advantageous for low MOQ pilot runs.

- PU wraps (including tacky & perforated)

- Advantages: PU wrap combines tackiness and good durability. Perforated PU improves moisture wicking and long-term grip. Many club and retail paddles use PU for perceived quality.

- Disadvantages: Slightly higher cost. Perforation increases production alignment needs.

- Manufacturing: Roll-to-roll application or pre-cut wraps. Works well with hot/cold pressing the paddle face — be mindful of adhesive compatibility and heat exposure during hot pressing. If using thermoforming for the paddle body, ensure wrap adhesive tolerates forming temperatures.

- Synthetic leather

- Advantages: Premium look, consistent feel, high abrasion resistance, excellent for printed branding and embossing.

- Disadvantages: Firmer feel (less cushioning) unless layered with foam. Can be slippery if not textured or perforated.

- Manufacturing: Simple to attach. Good for paddles aimed at retail where appearance matters. Cost moderate to high depending on finish.

- Cork / natural blends

- Advantages: Eco-friendly appeal, light feel and unique tactile response. Good shock dampening.

- Disadvantages: More expensive, may require sealing and special adhesives. Durability varies with moisture exposure.

- Manufacturing: Requires precise gluing and protective topcoats. Consider for niche eco product lines.

- Injection-molded / thermoformed composite handles

- Advantages: Consistent geometry, built-in ergonomics (curved shapes, palm swell), integrated vibration damping zones, and space for internal inserts (weight tuning).

- Disadvantages: High upfront tooling cost. Longer lead time for mold design.

- Manufacturing: Ideal when pairing with thermoforming production methods or when high stability is required. Thermoformed handles can be overmolded onto the paddle core; ensure material compatibility and that the molding process doesn’t compromise the paddle face during hot press cycles.

- Traditional wood / laminated cores

- Advantages: Low cost for basic lines. Familiar manufacturing processes.

- Disadvantages: Potential for loosening, twisting (as PAA3 notes) if staples/adhesives degrade. Less consistent feel.

- Manufacturing: Avoid for lines aiming at consistent premium performance unless reinforced.

Ergonomics, grip size and vibration damping

- Specify grip size clearly (circumference and length) in the tech pack. Small variations affect player comfort and control, and will impact your returns and user reviews.

- For vibration damping, prefer multi-layer handles: a rigid core + thin damping layer (EVA or polymer) + outer tacky wrap. This gives consistent feel and reduces arm fatigue.

- Add options for tapered or palm-swell handles for competitive lines. Thermoformed or molded handles give the tightest tolerances.

Customization, branding & on-demand print

- Printing options: Direct color printing on synthetic leather, heat-transfer logos on wraps, debossing on molded handles, and full-color on-demand paddle face printing (we support on-demand-print on the face; for handles, recommend heat transfers or embossing).

- Color matching: Use Pantone references, and require pre-production color samples. For multi-color grips, ask suppliers about layer adhesion under hot pressing.

- MOQ: Standard stocked materials (EVA, standard PU) may have low MOQs; custom colors, perforations, or molded handles typically require MOQ of 500–2,000 units depending on the factory and tooling.

- Lead times: Std materials 2–6 weeks; custom wraps or molded handles 8–12+ weeks due to tooling and sample cycles.

Quality checks and testing (what to require from suppliers)

- Peel/adhesive strength between handle wrap and handle core (after thermal cycles).

- Abrasion resistance4 (ASTM D4966 or equivalent).

- Slip resistance / tack test (after sweat exposure).

- Torque test for handle twist under load (simulate staples/adhesive degradation).

- Accelerated aging (humidity + heat) for material breakdown.

- Player feedback panel: 20–50 playtests across target segments.

Procurement checklist (spec items to include in your PO)

- Handle material (exact compound), thickness, and finish.

- Grip circumference and length tolerance.

- Adhesive type and heat tolerance rating.

- Surface treatment (perforation, emboss, print).

- Assembly method with paddle core (glue type, mechanical fasteners if any).

- MOQ, unit price, sample lead time, and tooling costs.

- Testing criteria and warranty terms.

Recommendations by product positioning

- Beginner / Budget (mass-market clubs): EVA foam wrap, simple wood/composite core handle. Low tooling, lowest cost, MOQ friendly.

- Recreational / Retail: PU wrap (perforated optional) with medium-density core. Good balance of comfort, sweat control and perceived quality.

- Club / Tournament-level: Perforated PU or synthetic leather over a reinforced core. Add a slim damping layer. Consider molded palm-swell option for consistency.

- Competitive / Professional: Thermoformed or injection-molded composite handles with integrated damping zones and precise geometry. Invest in tooling and rigorous testing.

Action steps before issuing the RFQ

- Freeze grip size and finish choices for the first SKU group.

- Request two material samples per option (raw and applied on a handle core).

- Run a 100–200 unit pilot with your chosen handle + paddle face production method (test hot vs cold press compatibility).

- Verify adhesives after your chosen press process and any thermoforming steps.

- Confirm MOQ and lead time for any custom-colored or printed wraps; budget tooling amortization into unit price.

Summary

Selecting a handle material is a trade-off of cost, feel, durability and manufacturability. For quick launch cycles, EVA and standard PU wraps are the fastest and most cost-effective. For premium lines where consistency and performance matter, invest in thermoformed or molded handles with tailored damping and tight tolerances. Include clear specs for grip size, adhesive compatibility with your chosen pressing method (hot/cold/thermoforming), and require supplier testing on adhesion, abrasion and torque. At NEX Pickleball we can support sample runs across hot pressing, cold pressing and thermoforming processes and provide guidance on MOQ and tooling to align your handle choice with production realities.

People Also Ask

What is the best material for pickleball paddle control?

- For control-focused play, carbon fiber blades and a handle that provides a secure, low-slip interface work best. A tacky PU wrap or thin foam over a stable core gives good touch and minimizes unwanted movement in the hand. Lightweight, softer handles (like EVA) improve feel but may reduce micro-stability versus firmer, wrapped handles.

What is the best grip for a pickleball paddle?

- The most versatile hand placement is the Continental grip5 (also called hammer grip) — it allows quick transitions between forehand and backhand and is useful for dinking, volleys and defense. From a material perspective, choose a grip that provides tack and moisture control (perforated PU or tacky wrap) so the Continental grip stays reliable during long play.

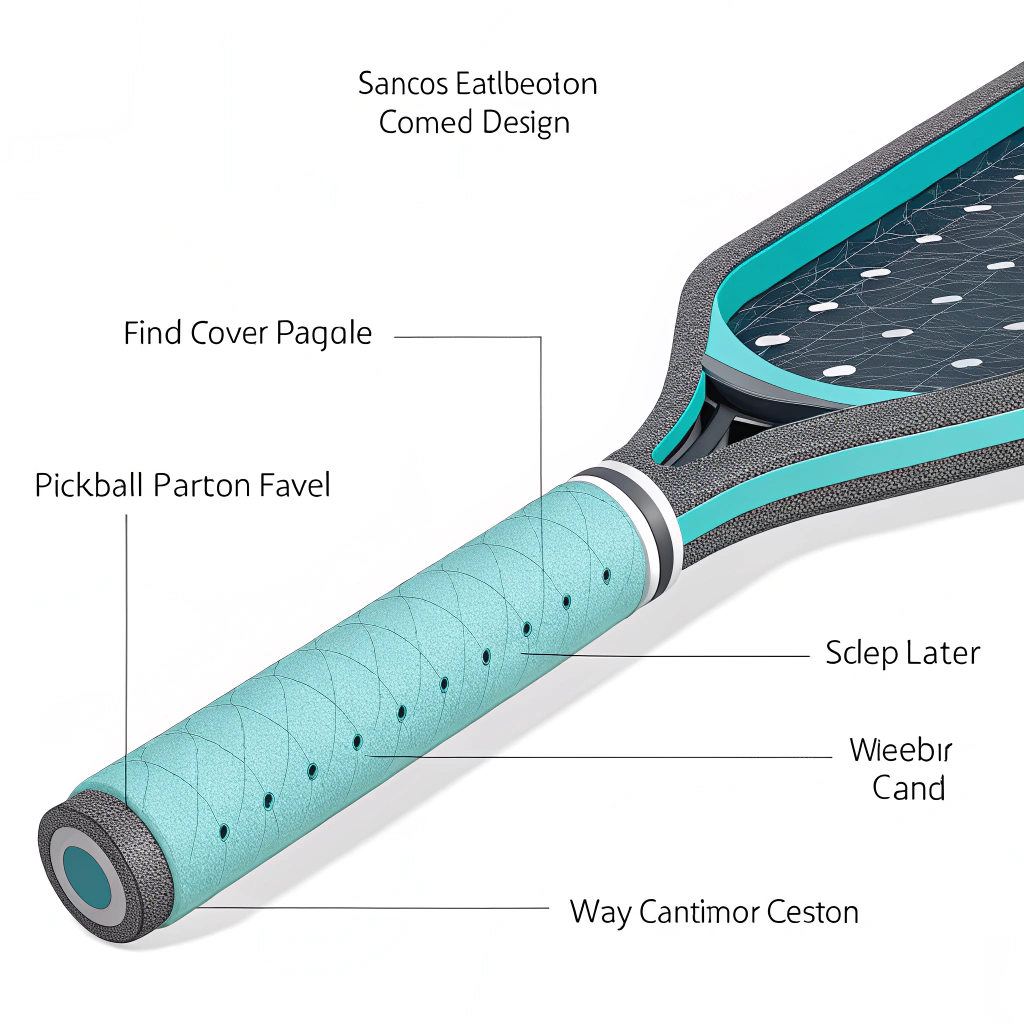

What are pickleball paddle handles made of?

- Handles can be made from layered wood, composite cores, injection-molded polymers, or thermoformed parts and are typically wrapped with EVA, PU, synthetic leather, cork or other materials. Simple wood pallets and staples are still used in some budget designs but can loosen over time; composite or molded handles with modern wraps provide better long-term stability.

-

EVA foam: Read this article to understand why EVA is widely used for economical, cushioned grips, how it performs under compression and sweat, and when to prefer it vs. higher‑tack materials. ↩

-

PU wrap: Read this article to learn about PU wrap variants (tacky, perforated), adhesive and heat compatibility, and how PU impacts perceived quality and durability in retail lines. ↩

-

Thermoforming: Read this article to get an overview of thermoforming vs. hot/cold pressing, tooling implications, material temperature limits, and when thermoforming is the right choice for integrated handle geometries. ↩

-

Abrasion resistance: Read this article to see standard test methods (e.g., ASTM D4966), acceptable thresholds for handle materials, and how abrasion results translate to expected product lifetime under real play. ↩

-

Continental grip: Read this article to review grip technique, why it suits versatile play (dinks, volleys, defense), and how handle materials and tack influence the effectiveness of this grip. ↩