Carbon fiber is the clear choice for high-performance pickleball paddles because it offers exceptional durability, superior rebound force, and improved impact resistance compared to alternative materials. In this article, we compare materials and manufacturing processes while deep diving into why carbon fiber1—in its various forms such as 3K2, 12K3 and T3004—leads to paddles that meet the rigorous demands of professional and competitive play.

When selecting materials for pickleball paddles, B2B procurement managers and product developers must balance performance with reliability and long-term durability. Carbon fiber stands out due to its balanced characteristics: it is lightweight yet strong, offers excellent energy transfer during impact, and minimizes vibration. In contrast, other materials like fiberglass or composite cores may not provide the same level of performance for high-end products.

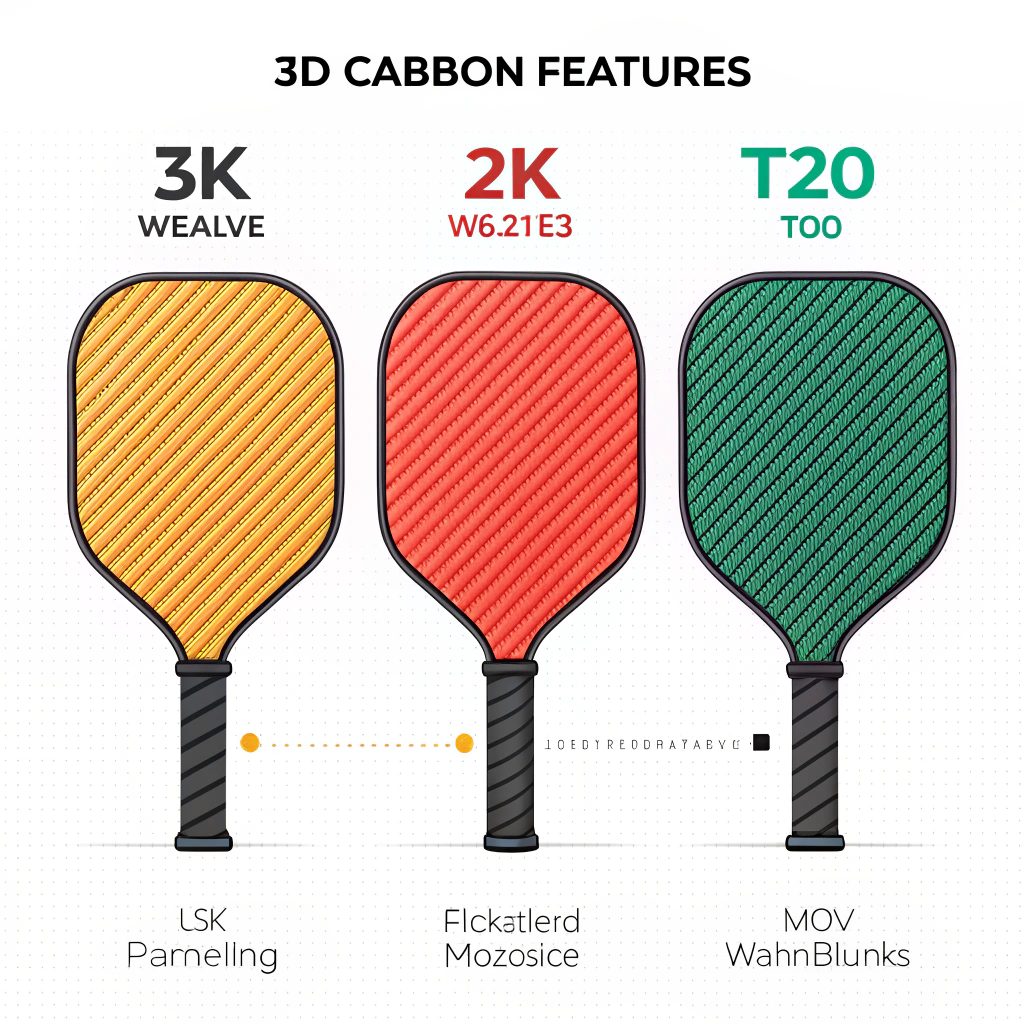

There are several types of carbon fiber used in paddle manufacturing:

• 3K2 Carbon Fiber: Known for its strength and flexibility, it delivers high rebound force and reduced vibration.

• 12K3 Carbon Fiber: With a higher thread density, it creates a smoother paddle surface, increased hardness, and superior durability, making it ideal for competitive play where impact resistance is critical.

• T3004 Carbon Fiber: This high-performance variant offers outstanding tensile strength while balancing weight, providing a blend of power and control.

Understanding the differences helps in making a well-informed decision. The table below provides a quick comparison of carbon fiber against other popular materials used in pickleball paddles:

| Material Type | Strength & Durability | Impact Resistance | Rebound Force | Vibration Reduction | Typical Use Case |

|---|---|---|---|---|---|

| Carbon Fiber (3K, 12K, T300) | High | Excellent | Very High | Superior | Competitive & high-performance play |

| Fiberglass | Moderate | Good | Moderate | Acceptable | Recreational use & players seeking comfort |

| Composite (Carbon + Fiberglass) | High | Good | High | Good | Players needing a balance between power and control |

| Bamboo Core Composite | Moderate | Moderate | Moderate | Moderate | Long-duration games & cost-sensitive markets |

| Honeycomb (Nomex/Aluminum/Polymer) | Variable | Excellent in shock absorption | Good | Excellent | Durable and controlled play for various levels |

This detailed side-by-side overview allows procurement managers to evaluate which material best supports their strategic goals, whether it be for improving performance in professional tournaments or ensuring durability in high-volume retail environments.

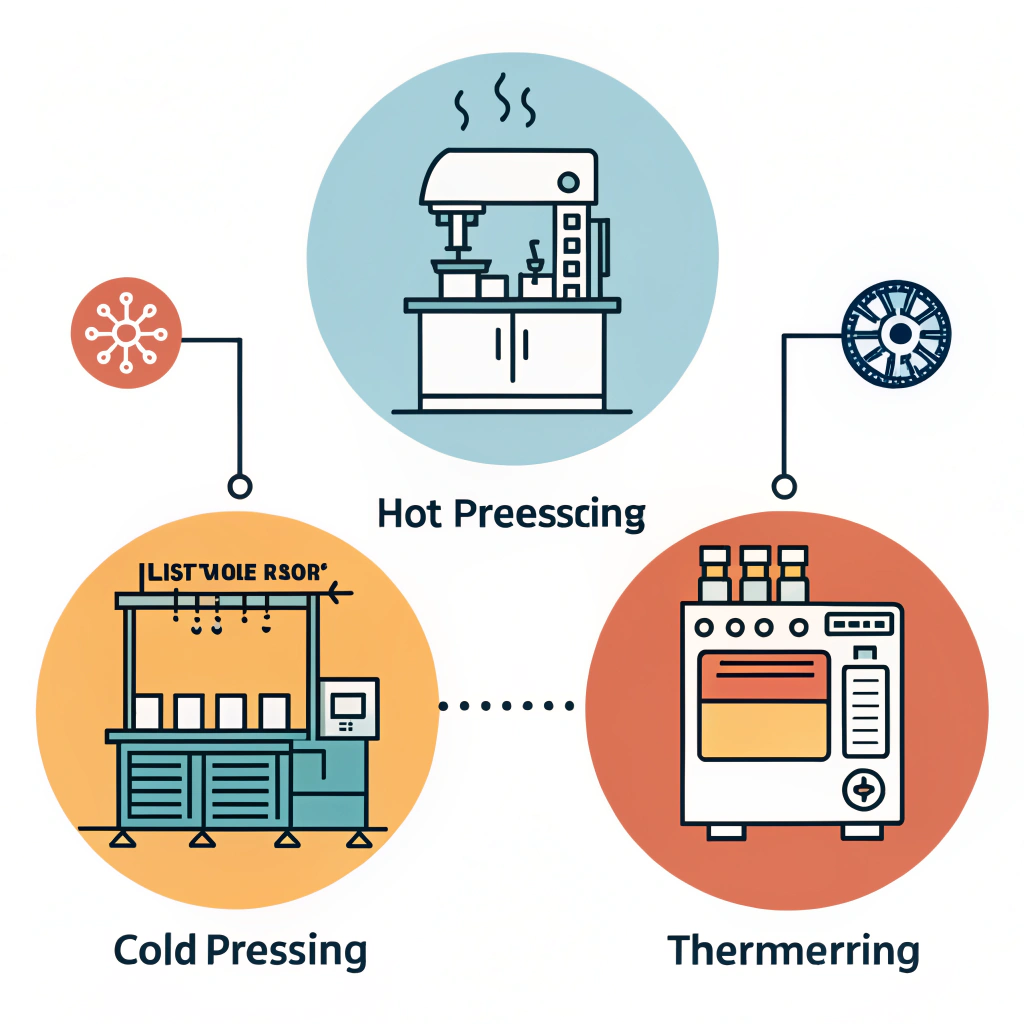

Beyond the raw material selection, the production process plays a crucial role in achieving the desired paddle performance. NEX Pickleball employs advanced manufacturing methods that ensure consistent quality and performance. Three processes dominate the production landscape:

Hot pressing involves heating the materials and applying pressure to forge the paddle. This process offers:

- High production efficiency and suitability for mass production.

- Enhanced structural integrity, ensuring paddles have robust impact resistance.

- Superior durability for high-performance use.

However, careful calibration is required as the heat can modify some of the material properties, potentially affecting the tactile feel of the paddle.

Cold pressing shapes the paddle at room temperature using mechanical pressure. Its benefits include:

- Enhanced precision in controlling paddle thickness and structural uniformity.

- Preservation of the material’s natural characteristics, thereby maintaining excellent ball response.

- A superior touch and control—a key consideration for competitive play requiring finesse.

The trade-off is that the process is slower than hot pressing, which may result in lower production efficiency.

Thermoforming uses heat to soften the material before it is molded into complex shapes. Advantages include:

- The ability to create intricate designs and ensure precise distribution of materials.

- Enhanced control over the paddle’s balance and surface texture, which directly affects performance.

- Stability that supports a dynamic playing experience in varied conditions.

This process is more time-consuming and cost-intensive, which positions it best for producing premium or custom paddles that demand the highest performance.

By aligning the choice of material (such as different carbon fiber types) with an optimized manufacturing process, companies can develop paddles that not only perform reliably under intense conditions but also meet the increasing customization demands from professional players and clubs.

The selection of carbon fiber, especially in high-end paddles, can be dissected further through its inherent performance benefits:

-

Enhanced Power and Rebound Force:

Carbon fiber paddles, due to their stiffness and lightweight properties, ensure that the energy from a player's swing is effectively transferred to the ball. Variants like T3004 Carbon Fiber provide a balanced mix of lightweight properties and high tensile strength, leading to a quick rebound effect which is crucial during fast-paced play. -

Superior Durability and Impact Resistance:

The high tensile strength of 12K3 Carbon Fiber allows paddles to withstand frequent, intense play. The resulting paddle surface is not only smooth and hard but also resilient to denting and fractures. This means a longer product life cycle and lower replacement rates, a key selling point for B2B procurement decisions. -

Reduced Vibration and Improved Ball Control:

One of the most critical aspects for performance and user comfort is vibration reduction. The inherent properties of carbon fiber ensure that not only is the paddle lightweight, but it also significantly reduces the vibration upon ball impact. This reduced vibration translates to better ball control and less fatigue during prolonged gameplay sessions.

In addition, a multi-layered construction using carbon fiber in the paddle’s face combined with advanced core materials, such as polymer or honeycomb cores, further enhances these benefits by balancing impact with comfort.

For B2B buyers in sport equipment, the selection of materials and manufacturing techniques is a crucial element in offering premium products that stand up to technological advancements and consumer expectations. Here are several strategic points to consider:

-

Quality Versus Cost:

While carbon fiber might command a higher initial investment compared to other materials, its extended service life and superior performance can lead to lower overall costs in terms of replacement and brand reputation. -

Market Positioning:

High-performance paddles with advanced material construction, such as those using 12K3 or T3004 Carbon Fiber, position your brand at the forefront of innovation. This can be a significant differentiator in a competitive market. -

Customization and Flexibility:

With production processes like thermoforming, companies can offer custom paddle options. This ability to tailor paddle specifications—be it grip size, weight balance, or surface texture—caters to diverse player needs, from recreational enthusiasts to professional players. -

Production Scalability and Consistency:

Advanced manufacturing methods such as hot pressing and cold pressing ensure that every paddle meets stringent quality control measures. This reliability is crucial when fulfilling large orders from professional clubs or retail chains.

A summarized matrix of these considerations assists in the decision-making process:

| Strategic Factor | Carbon Fiber Paddles (High-End) | Alternative Materials |

|---|---|---|

| Performance & Precision | High due to superior material properties | Moderate; may compromise on rebound and vibration control |

| Long-Term Durability | Excellent, thanks to robust composition | Varies; may need frequent quality control |

| Customization Options | High with thermoforming and composite designs | Limited customization in some cases |

| Cost Efficiency Over Lifecycle | Favorable with extended product life | Potentially higher replacement rates |

| Market Differentiation | Distinct advantage in premium segments | Less competitive in high-performance niche |

In summary, carbon fiber is a superior material for manufacturing high-performance pickleball paddles because it offers unmatched durability, efficient energy transfer, reduced vibration, and excellent impact resistance. When paired with optimized manufacturing processes like hot pressing, cold pressing, and thermoforming, manufacturers can produce paddles that deliver outstanding performance and a longer service life.

For B2B procurement managers and product developers, investing in paddles that utilize advanced carbon fiber variants such as 12K3 and T3004 not only ensures premium quality but also positions your product portfolio as a leader in innovation. Prioritize material quality alongside production scalability and customization options to meet the growing market demand for reliable, high-performance sports equipment.

Action steps include:

• Evaluating your current suppliers against these material and process benchmarks.

• Requesting samples to test performance in real-world play conditions.

• Collaborating with manufacturers like NEX Pickleball who leverage these advanced technologies for consistent results.

By focusing on these key aspects, you can secure a competitive edge in the sports equipment market, drive better player performance, and ultimately enhance your brand reputation.

Q1: Why is carbon fiber used in high-performance pickleball paddles?

A1: Carbon fiber is chosen for its excellent strength-to-weight ratio, superior impact resistance, and its ability to reduce vibrations, ensuring a paddle that delivers both power and precision even under intense play conditions.

Q2: What are the advantages of 12K carbon fiber over 3K carbon fiber in pickleball paddles?

A2: While both offer high durability, 12K carbon fiber provides a smoother surface finish, higher hardness, and improved rebound force, making it a preferred choice for competitive play where enhanced impact resistance is required.

Q3: How do manufacturing processes like hot pressing and thermoforming affect paddle performance?

A3: Hot pressing ensures structural integrity and high production efficiency, leading to durable paddles, while thermoforming allows for intricate designs and precise material distribution, resulting in paddles that maintain optimal balance and superior control.

-

carbon fiber: Click to learn more about the material's structure, its advantages in terms of strength-to-weight ratio, and why it is highly favored in high-performance applications. ↩ ↩

-

3K: Click to explore how 3K carbon fiber balances strength and flexibility, making it suitable for mid-range paddle performance. ↩ ↩ ↩2

-

12K: Click to understand the benefits of 12K carbon fiber, including its smoother finish and higher durability for competitive play. ↩ ↩ ↩2 ↩3 ↩4 ↩5

-

T300: Click to delve into the specifics of T300 carbon fiber, known for its outstanding tensile strength and optimal weight characteristics for precision performance. ↩ ↩ ↩2 ↩3 ↩4 ↩5

-

Thermoforming: Click to discover how thermoforming as a manufacturing process allows for intricate design and precise material distribution, enhancing product performance. ↩ ↩