A balanced pickleball paddle places its center of mass close to the geometric center of the paddle face, delivering a neutral swing weight1 and moderate moment of inertia (MOI) — the result is a paddle that blends control and power, suits the widest range of players, and is generally the safest product choice for private-label lines targeting broad retail segments. For B2B buyers, specify balance point2 (mm from butt end), swing-weight target (± g·cm²), and acceptable mass tolerance (± g) to ensure repeatable OEM production and consistent on-court feel.

For product and sourcing managers building a private-label pickleball line, a balanced paddle is the most versatile SKU: it minimizes complaints about “too heavy in the head” or “too light for drives,” reduces returns, and targets the largest customer segment — social to intermediate players. To control balance in OEM manufacturing, specify (1) balance point, (2) swing weight or MOI range, (3) total mass, (4) core type, and (5) face material. Choose production methods and tolerances early: hot pressing gives structural strength and scale; cold pressing preserves face responsiveness; thermoforming3 enables complex thickness maps for tuned MOI. NEX Pickleball can integrate these choices, supply test data, and deliver on-demand printing and low-to-medium MOQs for retail launches.

- Balance point2: linear distance from the butt end of the handle to the center of mass. Commonly reported in millimeters (mm) from the butt.

- Swing weight: a practical measure of how heavy a paddle feels during a swing. Expressed in g·cm², it factors in mass distribution relative to the rotation axis (near the handle).

- Moment of inertia (MOI): a physical property (inertia about a chosen axis) often used interchangeably with swing weight. Higher MOI means more resistance to angular acceleration — perceived as “head-heavy.”

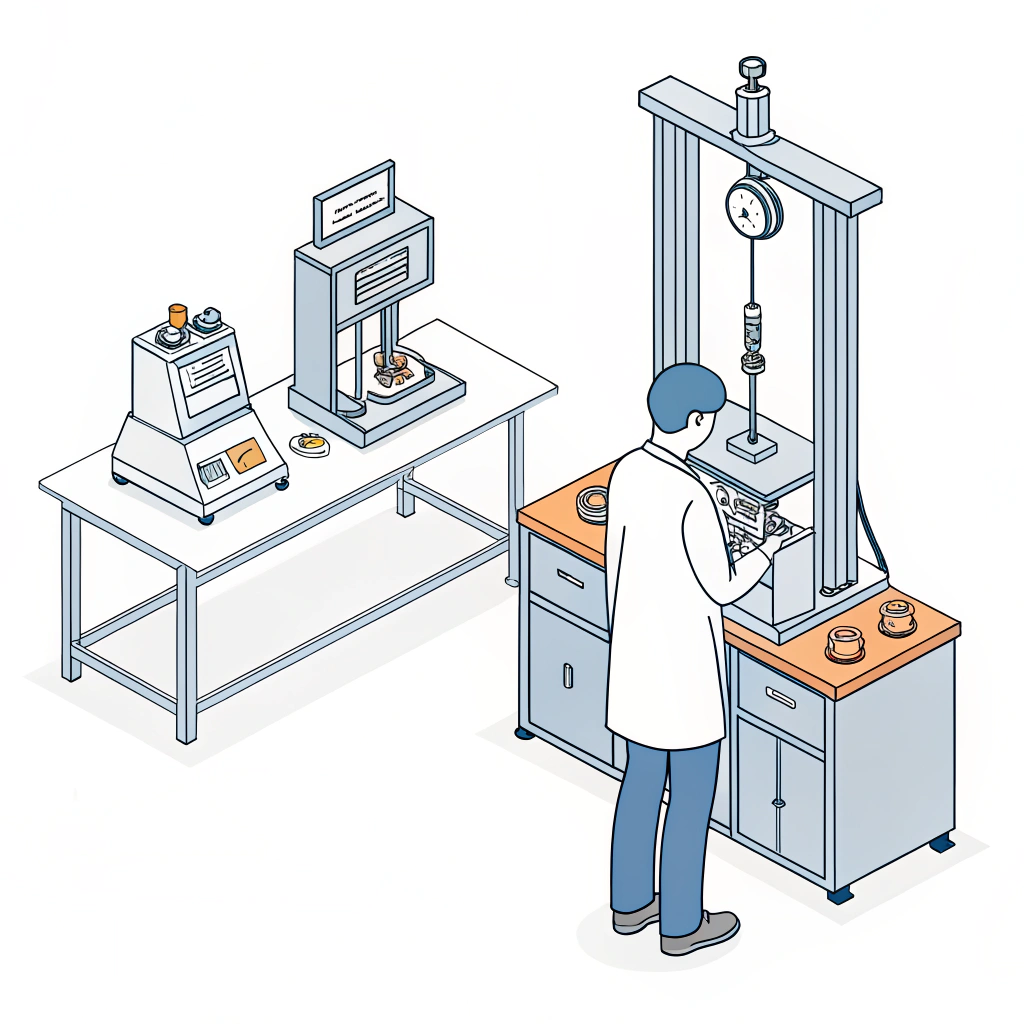

- Measurement methods:

- Static balance4: place paddle on knife-edge or jig to find balance point (simple, repeatable).

- Swing-weight/MOI test: use a rotary test rig (pendulum or torque sensor) or instrumented swing machine to compute g·cm².

- Recommended spec sheet fields to request from OEM:

- Total mass (g) ± tolerance

- Balance point (mm from butt) ± tolerance

- Swing weight / MOI (g·cm²) ± tolerance

- Center of mass coordinates (optional for precise tooling)

Balanced paddles deliver an in-between feel that combines key advantages:

- Better all-court control: neutral mass distribution lets players redirect pace and place shots at the kitchen (non-volley zone) without overcompensating.

- Quick reaction and maneuverability: lower polar moment than head-heavy designs, aiding volleys, dinks, and fast exchanges.

- Consistent swing across shots: balanced paddles reduce tempo shift between soft and hard strokes, helping players retain timing.

- Reduced fatigue: neutral swing weight often requires less corrective muscle action, beneficial for long sessions or club-level tournaments.

Player archetypes best suited for balanced paddles:

- Recreational and social players who need a forgiving feel and easy control.

- Intermediate players improving transition shots and court positioning.

- Retail buyers targeting “all-round” consumers who prefer a single paddle for multiple play styles.

Performance trade-offs (short):

- Power: slightly less raw power than head-heavy paddles for the same overall mass.

- Sweet spot feel: can be optimized through face and core engineering; balanced paddles do not inherently have smaller sweet spots.

Below is a concise side-by-side of the three balance types:

| Feature / Metric | Balanced | Head-heavy | Handle-heavy |

|---|---|---|---|

| Perceived power | Medium | High | Low |

| Maneuverability | High | Lower | Highest |

| Best for | All-court players, retail SKUs | Power hitters, advanced players | Control specialists, players needing quick wrist action |

| Swing weight / MOI | Moderate | High | Low |

| Fatigue | Low-moderate | Higher | Low |

| Typical target segment | Broad retail & club | Competitive/intermediate | Niche (touch/control players) |

| Manufacturing sensitivity | Moderate (mass distribution) | High (tight head mass control) | Moderate |

Practical decision rules for B2B buyers:

- If your product line aims at the broadest consumer base, balanced is the default choice.

- If targeting tournament or power-focused players, accept higher production variance and tighter MOI specs for head-heavy paddles.

- For specialty control or junior lines, consider handle-heavy designs but be prepared for narrower market demand.

Material choice and construction determine mass distribution and how energy transfers in play.

Face materials:

- Carbon fiber (3K, 12K, T300): light and stiff. Enables thin faces and placement of mass closer to the center, useful for balanced paddles with responsive pop. Dense carbon (12K) increases surface hardness and can slightly shift perceived mass if matrix layers vary.

- Fiberglass (E-Glass): heavier flexibility — can increase face mass and slightly enlarge sweet spot, useful when you need a softer touch without sacrificing balance.

- Composite faces (carbon + fiberglass): tradeoffs can tune feel and micro-balance without changing core.

Core types:

- Polymer honeycomb: lower density, more elasticity; often yields lower swing weight for same paddle mass—good for balanced feel.

- Nomex honeycomb5: denser and rigid; can push mass outward if core thickness increases, affecting MOI.

- Aluminum honeycomb: mid-density and adds durability; affects weight distribution predictably.

Surface treatments and grip:

- Surface coatings and texture layers (UV print, PU skin) add grams; uneven lamination near the head or handle can shift balance point by several millimeters.

- Grips and end caps: thicker grips or heavy butt caps move balance toward the handle.

Manufacturing levers to tune balance:

- Adjust face ply stack (type and ply count).

- Vary core thickness and cell density.

- Add or remove micro-weights (internal shims) near the handle or perimeter to hit exact balance point.

How you produce a paddle affects the ability to hit balance targets repeatedly.

Hot pressing:

- Pros: high throughput, consistent consolidation, strong bonding — good when launching large volumes.

- Cons: heat can slightly alter resin and composite stiffness, which affects feel. If precision balance is required, tooling must account for resin flow and thickness shrinkage.

- Best when: producing competitive paddles at scale with tight dimension control.

Cold pressing:

- Pros: maintains composite mechanical properties, better for preserving intended paddle feel and slightly better control over thickness.

- Cons: slower cycles, needs precise pressure control.

- Best when: tight feel targets and MOI precision are higher priorities than throughput.

Thermoforming:

- Pros: enables complex surface profiles and localized thickness changes (thicker edges, thinner center) to tune MOI and sweet spot.

- Cons: higher tooling cost, longer cycle times; ideal for premium SKUs.

- Best when: product differentiators rely on intricate geometry.

Typical tolerances to specify:

- Total mass: ±3 g for consumer paddles; ±1–2 g for premium lines.

- Balance point: ±3 mm for retail; ±1–2 mm for competitive products.

- MOI/swing weight: ±3–5% for retail; ±1–2% for performance lines.

- Flatness/thickness: depend on tooling but specify max deviation in mm.

Quality control recommendations:

- Batch sampling with static balance and swing-weight tests.

- Incoming raw material certificates for composite plies and cores.

- Record production run sheets for traceability.

Spec templates (example fields to include in your OEM brief):

- SKU code

- Target mass (g) ± tolerance

- Balance point (mm from butt) ± tolerance

- Target swing weight / MOI (g·cm²) ± tolerance

- Face material (type, ply schedule)

- Core type and thickness

- Grip circumference and material

- Surface finish and print requirements (on-demand printing options)

- Packaging and labeling

- MOQ, lead time, and unit pricing targets

Suggested sampling protocol:

- Pre-production prototype (2–5 units) to verify feel and measurements.

- Pilot run (50–200 units) to test production repeatability and QC metrics.

- Full production with batch testing (e.g., 1% of units swing-weight tested + 100% static balance check).

Pricing trade-offs:

- Tight MOI and mass tolerances increase cost due to tighter process control and higher reject rates.

- Premium materials (T300 carbon, Nomex) and thermoforming raise cost but enable compelling marketing claims.

- On-demand printing adds variable cost but reduces inventory risk; suitable for seasonal or small-batch SKUs.

Essential test methods and acceptance criteria to include in contracts:

- Static balance measurement (ISO-like repeatable jig): report mean and standard deviation per batch.

- Swing-weight / MOI measurement: report g·cm² and testing method (rig type, axis).

- Impact and durability tests: repeated ball strikes, edge impact tests, delamination checks.

- Playtest summary: blind playtests with defined player cohort and standard drills (dink, volley, third-shot drive) with subjective scoring.

- Environmental tests: humidity and temperature cycling to ensure lamination stability.

Acceptance criteria samples:

- Mass within ±3 g (retail) / ±1.5 g (premium).

- Balance point within ±3 mm (retail) / ±2 mm (premium).

- No delamination after X strikes at Y energy per test.

Recommended balanced paddle specifications depending on target segment:

-

Entry / Beginner (retail bundle)

- Mass: 225–250 g

- Balance point: 240–245 mm from butt

- Core: Polymer honeycomb

- Face: E-Glass fiberglass

- Swing weight: moderate (spec 1150–1300 g·cm²)

- Price positioning: low to mid

-

Intermediate / Club

- Mass: 235–255 g

- Balance point: 245–250 mm

- Core: Higher-density polymer or thin aluminum honeycomb

- Face: Carbon-fiberglass composite

- Swing weight: 1250–1400 g·cm²

- Price: mid-range

-

Competitive / Premium

- Mass: 220–240 g

- Balance point: 245–250 mm (precise)

- Core: Engineered polymer or Nomex for firmness

- Face: T300 carbon6 or 12K carbon depending on preferred hardness

- Swing weight: tightly controlled 1200–1350 g·cm²

- Price: premium

When you brief NEX Pickleball, provide:

- Target audience and SKU positioning (beginner vs. premium).

- Exact mass, balance point, and MOI/swing-weight targets with tolerances.

- Face and core preferences (or ask for material recommendations).

- Preferred production process (hot press, cold press, thermoform) or request NEX’s suggestion based on volumes and feel targets.

- Sampling and testing requirements including acceptance criteria.

- On-demand printing needs (art files, colors, Pantone references).

- Lead-time expectations and MOQ. NEX supports scalable production, advanced testing, and private-label printing.

NEX Pickleball can run pre-production iterations, supply test reports (balance, MOI, durability), and propose optimized ply stacks or core choices to hit your balanced-paddle targets at competitive pricing.

People Also Ask

Q: What is a balanced pickleball paddle?

A: A balanced pickleball paddle has its mass centered near the paddle’s geometric midpoint so the paddle feels neutral during swings. It aims to combine reasonable power and touch, making it suitable across many face materials and player levels.

Q: Why is balance important in pickleball?

A: Balance affects how quickly a player can react, manage volleys, and control shots near the net. A neutral balance helps players move the ball around the court, maintain consistent timing, and reduce fatigue — all of which lower unforced errors and support longer rallies.

-

swing weight: Read the article to learn how swing weight is measured (g·cm²), how it correlates with perceived paddle heaviness, and how to set production targets and tolerances to hit a desired on-court feel. ↩

-

balance point: Read the article to understand how balance point (mm from butt) is defined, how small shifts affect play and MOI, and how to specify and verify balance in OEM specs. ↩ ↩2

-

thermoforming: Read the article to see when thermoforming is worth the investment, how it enables localized thickness control to tune MOI and sweet spot geometry, and the cost/lead-time trade-offs for premium SKUs. ↩

-

Static balance: Read the article to get a practical guide to static balance jigs and knife-edge tests — quick QC methods for verifying center of mass and detecting production drift during runs. ↩

-

Nomex honeycomb: Read the article to understand Nomex core properties (stiffness, density, durability), how it shifts mass distribution and impacts MOI, and when to specify it versus polymer or aluminum cores. ↩

-

T300 carbon: Read the article to compare T300 carbon with other carbon weave options (3K, 12K), learn its stiffness-to-weight profile, and assess how face choice alters feel, durability, and manufacturing considerations. ↩