The process of developing high-performance pickleball paddles at NEX Pickleball involves advanced production methods and a rigorous quality control system. In short, our approach blends innovative manufacturing techniques with premium materials to deliver paddles that maximize performance and durability. This article details the challenges, analytical insights, and solutions employed to become a leading B2B supplier in the competitive pickleball market.

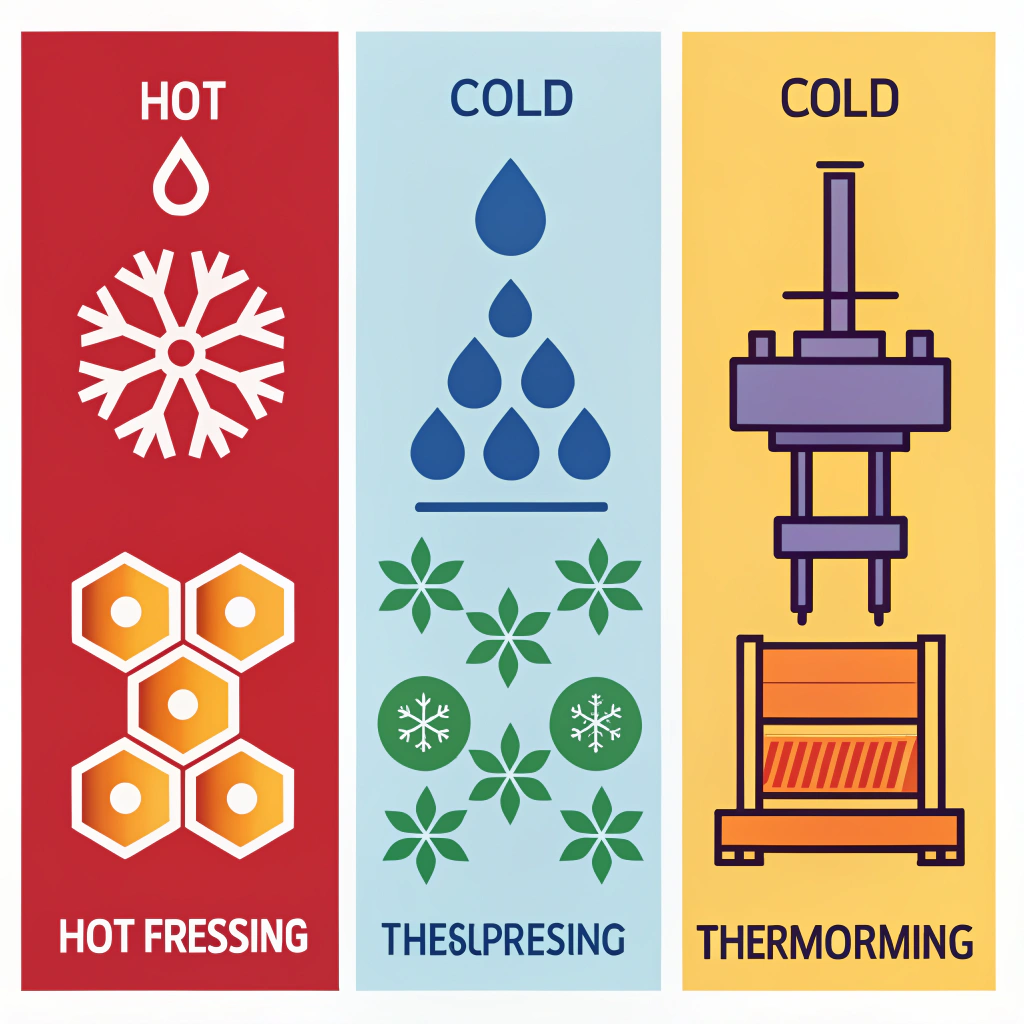

When partnering with a manufacturer, procurement specialists and business development managers need clarity on the entire product development cycle. The pickleball industry is evolving rapidly, and ensuring efficient production processes while maintaining high-quality standards is essential. There are several challenges in balancing production efficiency, customization, and meeting competitive market demands, which is why understanding our production methodologies—hot pressing1, cold pressing2, and thermoforming3—is critical.

At NEX Pickleball, we address these challenges using a structured, solution-oriented approach that comprises the following steps:

- Detailed problem identification, focusing on the need for consistency in quality while managing production speed and customization.

- Analyzing the underlying factors of product performance, from material selection (like carbon fiber, fiberglass, and composite materials4) to core composition (such as Nomex Honeycomb Core5, Aluminum Honeycomb Core, or Polymer Honeycomb Core).

- Outlining a clear set of manufacturing solutions with a comparative overview of different production techniques.

- Highlighting quality control measures and customization capabilities that ensure our paddles meet specific client requirements.

- Presenting case studies and data insights to validate our production strategies.

This systematic approach is designed to aid you, the procurement expert, in making informed decisions regarding long-term manufacturing partnerships.

The foremost challenge in manufacturing high-performance pickleball paddles is balancing cost-efficiency with the need for superior performance. When distributing sports equipment, the manufacturing process must guarantee durability, precision, and consistent performance under various conditions. The reality for many organizations is that each production method—whether hot pressing, cold pressing, or thermoforming—comes with a unique set of advantages and constraints.

- Material Integrity: Each material's properties can change under different manufacturing conditions. For instance, the strength and elasticity of carbon fibers may be affected if not processed precisely.

- Production Efficiency vs. Customization: High production speed is vital for large-scale output, but this must not compromise the opportunity for tailored specifications requested by clients.

- Quality Consistency: Rigorous testing and quality control are non-negotiable in maintaining product performance, especially when the equipment will be used in competitive environments.

- Cost Management: Adopting innovative techniques while maintaining competitive pricing requires careful investment in technology and process optimization.

Understanding these core issues lays the groundwork for evaluating the distinct production methodologies used by NEX Pickleball.

Each production technique used in our production cycle addresses the common challenges differently. Below is a comparative table that summarizes the key processes, their advantages, and limitations:

| Manufacturing Process | Advantages | Limitations |

|---|---|---|

| Hot Pressing | • High production efficiency for large volumes • Results in strong paddles with excellent impact resistance • Ensures structural integrity | • Potential alteration of some material properties • High initial investment in specialized equipment |

| Cold Pressing | • Precise control over paddle thickness and structure • Maintains material properties for better control and flexibility • Excellent ball feel and responsiveness | • Longer production cycles • Requires high-quality, precise equipment to control pressure |

| Thermoforming | • Ideal for creating complex shapes and tailored designs • Maintains stability and precise material distribution • Suitable for various high-performance materials | • Longer production time • Higher equipment costs and technical demands |

The above table illustrates how each process is tailored to optimize specific performance traits. Decision makers can compare these methodologies based on their requirement for customization versus production volume.

Quality control remains a central pillar throughout these processes. Our advanced technology and rigorous testing ensure every paddle meets strict standards for performance, vibration reduction, and durability. By methodically testing items at each production stage, we not only safeguard quality but also gather data that continually improves our manufacturing processes.

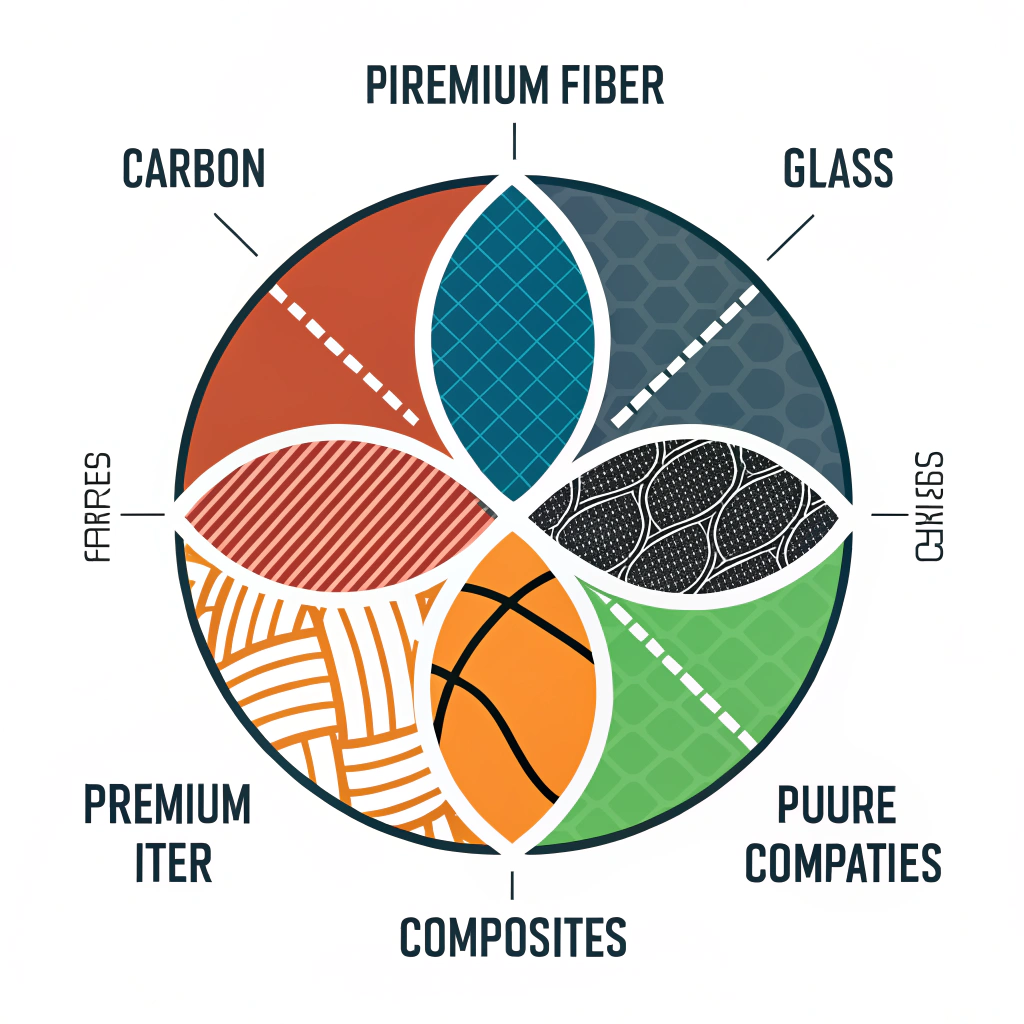

A key differentiator in our manufacturing process is the careful selection of premium materials. These materials are not only crucial for performance but also for enabling customization options that cater to different player needs. Consider the following core material choices:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Ideal for paddles requiring high rebound force, providing excellent durability.

- 12K Carbon Fiber: Offers superior hardness and smoothness for high-impact competitive play.

- T300 Carbon Fiber: Balances tensile strength and lightweight design for a well-rounded paddle.

-

Fiberglass:

- E-Glass Fiberglass: Optimized for a broader sweet spot, offering remarkable elasticity and control.

-

Composite Materials:

- Carbon Fiber & Fiberglass Composite: Combines the strengths of both materials to deliver enhanced balance between power and control.

- Bamboo Core Composite: Provides a lightweight yet impact-resistant solution, ideal for prolonged usage.

- Honeycomb Core: Utilizes high-density polymers to reduce vibration and maximize shock absorption.

Each of these materials is selected based on its specific properties, ensuring the end product meets the rigorous demands of competitive pickleball. Customization options allow clients to determine the balance of these materials, adapting each paddle for tailored performance goals.

Furthermore, the enzymatic integration of process control during material preparation plays a vital role. For example, when combining composite materials for enhanced paddle performance, our cross-functional teams work with clients to specify design, weight distribution, balance, and grip size. This level of customization is crucial for building long-term business relationships and product differentiation in the market.

Additionally, the core-structure in each paddle is carefully designed according to the following critical factors:

- Hardness: Essential for power and striking effectiveness.

- Control: Crucial for a balanced ball response.

- Comfort: Directly impacts player endurance, especially during long sessions.

For B2B buyers, the efficiency of the production cycle directly influences supply chain management and profitability. Here’s how our targeted approaches benefit your business:

-

Streamlined Production Cycle:

- By adopting high-speed production techniques like hot pressing, NEX Pickleball ensures rapid turnaround times, which is vital for large distribution orders.

- Techniques such as cold pressing are employed when the design demands minute precision. This process, though slower, preserves material properties crucial for paddles aimed at high-level competition.

-

In-Depth Quality Control:

- Every paddle undergoes rigorous quality control at multiple production stages.

- Data from quality testing is analyzed to continuously improve processes, reducing material waste and operational costs.

-

Customization for Market Differentiation:

- We provide options for bespoke paddle designs, allowing you to align with your brand's needs. Custom features include grip size adjustment, design personalization, and specific material blends tailored to performance levels.

- This customization not only meets the high expectations of athletes but also empowers distributors to offer a unique product in a crowded market.

-

Consistent Material Testing:

- Materials are tested for performance attributes like vibration absorption, rebound force, and durability using standardized protocols.

- Our detailed assessment and feedback loops ensure that even with varied production techniques, the key performance characteristics remain consistent.

Through these measures, NEX Pickleball bridges the gap between innovation, manufacturing precision, and time-tested practices. Our team is committed to delivering paddles that promise longevity and optimal playability, which in return translates into enhanced customer satisfaction and market leadership.

When evaluating manufacturing partners, consider these best practices:

-

Evaluate Process Adaptability:

The ability to switch between processes like hot pressing, cold pressing, and thermoforming is crucial. It ensures that your product lineup can adapt swiftly to market trends and changing material properties. -

Ensure Rigorous Quality Assurance:

Every stage of production should include systematic quality checks. At NEX Pickleball, quality isn’t compromised for speed. Decisions are backed by data, ensuring long-term reliability. -

Customized Solutions to Fit Your Brand:

Partnering with a manufacturer that offers deep customization options can be a game-changer. Tailored paddle designs not only enhance professional play but also offer a competitive edge in the retail market. -

Supply Chain Transparency:

Clarity in supply chain management, production timelines, and quality standards will drive your confidence in the manufacturing partner. Trust is built over time with clear, transparent processes. -

Ongoing Innovation:

A manufacturing partner that continually reinvests in technology provides resilience against market fluctuations. Our emphasis on integrating cutting-edge production techniques assures you that we stay ahead of industry trends.

A real-world example of our impact involves a major sports equipment distributor who needed a consistent supply of custom-design paddles tailored for both recreational and professional markets. Our integration of advanced production processes, from thermoforming for unique designs to cold pressing for excellent ball control, allowed the distributor to secure a competitive position in targeted markets. The result was improved product performance, enhanced customer satisfaction, and increased brand loyalty.

In conclusion, the development cycle for high-performance pickleball paddles at NEX Pickleball is built on advanced manufacturing processes, meticulous quality control, and flexible customization options. By understanding the comparative benefits of hot pressing, cold pressing, and thermoforming, as well as the importance of material selection and process adaptability, business development managers and procurement specialists can make informed decisions for long-term supply chain success.

Our approach ensures that every paddle is crafted to meet the rigorous performance demands of competitive pickleball while providing enough customization to suit individual brand requirements. The integration of precise material science and innovative production techniques positions us as a trusted partner for businesses looking to differentiate themselves in the market.

Your next step is to evaluate how these production methodologies align with your business needs and to engage in further discussions with our technical team. With a commitment to quality, efficiency, and innovation, we are ready to support your market expansion and help you stay ahead in the rapidly growing sport equipment industry.

-

What is the pickleball business model?

Answer: The pickleball business model primarily revolves around generating revenue from multiple activities, such as court reservations, memberships, coaching, clinics, and dedicated programming. Facilities and clubs often incorporate a comprehensive approach to attract avid players and pros, creating community-based and competitive environments. -

What is the marketing strategy of pickleball?

Answer: Pickleball marketing strategies effectively utilize digital platforms. This includes using Google Ads for high-intent audiences, leveraging social media channels like Facebook, Instagram, and YouTube for broader engagement, and integrating local events or sponsorships to enhance community presence. -

Is pickleball the new business sport?

Answer: Yes, many view pickleball as the new business sport. Its growing popularity has led to its adoption in professional networking, with business meetings and deal-making increasingly taking place on the court, reflecting its appeal as both a recreational and professional activity.

-

hot pressing: Read this article to understand how hot pressing is used to achieve high production efficiency and impact resistance through the application of heat and pressure in manufacturing. ↩ ↩

-

cold pressing: Click here to learn more about cold pressing, a technique that ensures precise material control and paddle structure without the use of heat. ↩ ↩

-

thermoforming: Explore this resource to discover how thermoforming allows for complex, tailored designs by shaping materials through controlled heating. ↩ ↩

-

composite materials: Learn about composite materials, their composition, and how combining fibers and resins can enhance the balance between power and control in sports equipment. ↩ ↩

-

Nomex Honeycomb Core: This article provides insights into the benefits of using Nomex Honeycomb Core, emphasizing its lightweight, high-strength qualities and its role in shock absorption. ↩ ↩