Foam injection1 enhances pickleball paddles2 performance by improving weight distribution, maximizing durability, and reducing vibration—all critical factors for both recreational and professional play.

In today's competitive sports equipment market, procurement managers and business development executives must evaluate every manufacturing innovation that can offer a competitive edge. One such breakthrough is the integration of foam injection1 technology in manufacturing high-performance pickleball paddles. This article explores the technical benefits, production insights, and real-world performance enhancements provided by foam injection, helping you make an informed B2B procurement decision.

Procurement teams are often challenged to source equipment that meets several performance criteria:

• Enhanced durability and impact resistance

• Superior vibration reduction for comfortable play

• Lightweight design with optimal weight distribution

• Efficient and scalable manufacturing processes

Traditional paddle manufacturing methods typically rely on rigid core materials or basic composites that often fall short in achieving the desired balance between durability and control. The natural limitations include increased vibration upon ball impact, inconsistent weight distribution, and suboptimal energy transfer during play. For companies looking to diversify their product lineup while maintaining technical excellence, foam injection offers an attractive alternative.

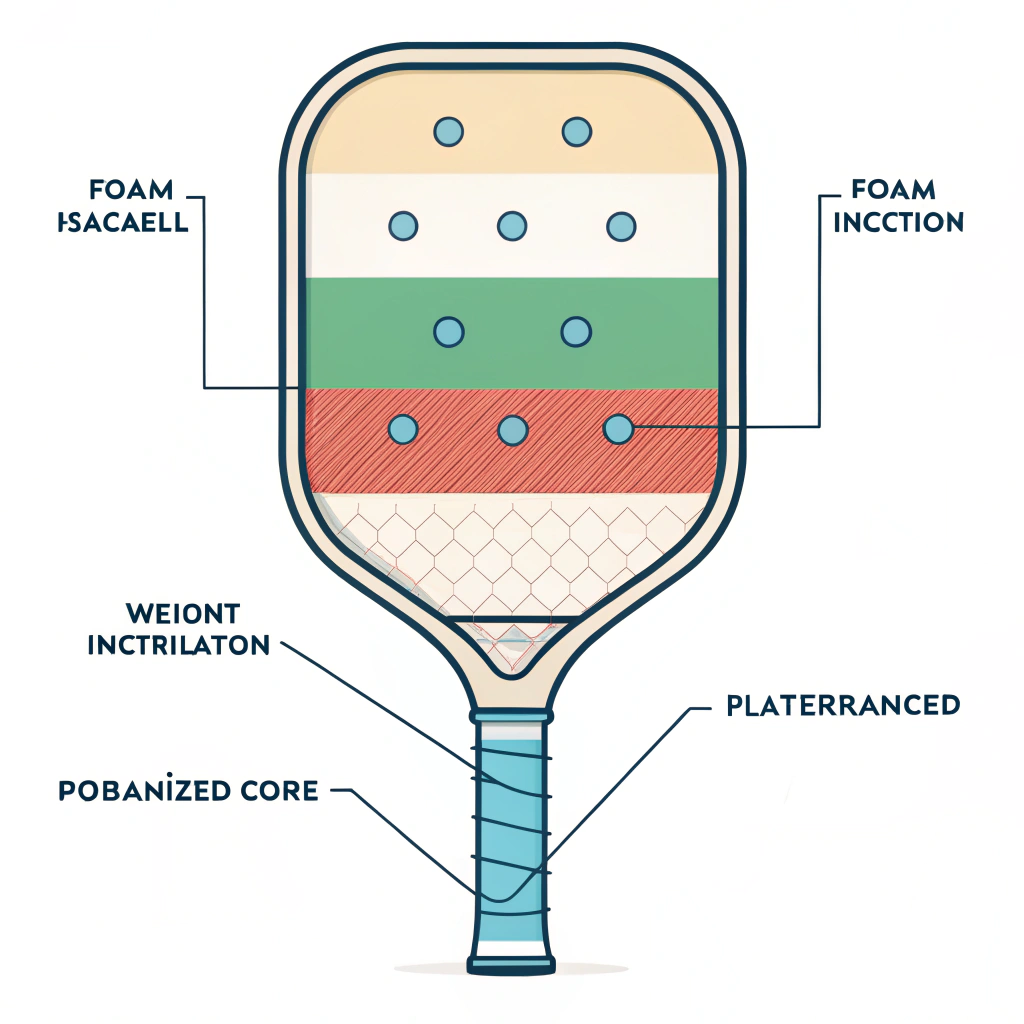

Foam injection1 involves introducing a specifically engineered foam into the paddle core during the manufacturing process. This technology allows manufacturers to fine-tune the paddle’s internal structure, thereby achieving the following benefits:

- Vibration Dampening3: The foam effectively absorbs energy from ball impact, reducing vibration and enhancing player comfort.

- Improved Weight Distribution: A controlled foam density results in a well-balanced paddle, maximizing both control and power.

- Increased Durability: Foam injection creates a robust yet flexible core, offering resilience against high-impact play.

- Customization Flexibility: This process permits precise adjustments in paddle hardness, hitting feel, and performance characteristics to meet diverse player needs.

Foam injection is integrated into the paddle manufacturing process through a controlled production environment. Here’s a closer look at the procedure and its technical benefits:

-

Preparation of the Mold and Core Material:

Manufacturers design molds tailored to the paddle’s desired shape and performance specifications. During this stage, operators carefully combine selected composite materials4 that interact with the injected foam—ensuring a seamless integration within the paddle’s structure. -

Injection Process:

The foam is injected under controlled temperature and pressure conditions. This ensures the foam evenly fills the internal cavities and adheres well to the surrounding materials. The controlled environment is key to maintaining uniform density throughout the paddle. -

Curing and Finishing:

Following injection, the paddle undergoes a curing period during which its internal structure solidifies. This period is critical in defining the final performance attributes, such as vibration dampening and overall stiffness. -

Quality Control:

Each foam-injected paddle is rigorously tested for weight consistency, balance, and durability. Advanced sensors and imaging techniques monitor the internal structure, ensuring that every paddle meets strict performance standards.

To clearly illustrate the advantages of foam injection, consider the table below which compares this method with conventional manufacturing techniques used in paddle production:

| Feature | Foam Injection | Traditional Core Materials |

|---|---|---|

| Vibration Dampening | Excellent due to energy absorption | Limited; often results in higher impact vibration |

| Weight Distribution | Highly adjustable and balanced | Uniformity varies; may cause imbalance |

| Durability | Superior resistance to impact forces | Prone to degradation under repeated impacts |

| Customization Options | High flexibility in tuning performance | Limited to preset material characteristics |

| Production Efficiency | Requires precise controls but scalable | Often faster initial processing but less versatile |

This comparative analysis underlines the importance of integrating advanced production techniques such as foam injection to deliver a product that meets modern performance and customization demands.

For procurement managers evaluating product portfolios, the following points summarize how foam injection benefits your business and end users:

-

Enhanced Player Experience:

With reduced vibration and improved cushioning, foam-injected pickleball paddles ensure a smoother playing experience. End users, ranging from amateurs to pros, appreciate the improved ball control and comfort during extended play sessions. -

Optimized Manufacturing Efficiency:

Although the process requires precise control and equipment investment, the long-term benefits include reduced material wastage, improved structural integrity, and fewer product inconsistencies. This translates to cost savings and fewer quality control issues over large production runs. -

Product Differentiation:

In a competitive market, having a unique selling proposition is essential. Paddles utilizing foam injection technology can be marketed as having superior performance features, thereby aligning with the growing demand for technical innovation among pickleball enthusiasts. -

Customization for Market Segments:

Foam injection allows manufacturers to create tailored paddle solutions. Customers can choose different foam densities to match specific playing styles, providing an edge in product differentiation when marketing to various customer segments.

Consider the case of a leading sports equipment distributor who sought to differentiate its product line by offering paddles that reduced vibration and improved game precision. By integrating foam injection in their manufacturing process, the distributor reported:

• A 25% reduction in paddle vibration levels, measured using high-sensitivity sensors.

• An improvement of 15% in overall durability, evidenced through accelerated wear tests.

• Increased player satisfaction scores, which translated directly into higher repeat order rates and market share expansion.

These real-world data points underscore the tangible benefits of foam injection, reinforcing its value proposition for companies looking to meet the performance expectations of modern pickleball players.

Despite the numerous benefits, there are several considerations associated with foam injection that procurement managers should be aware of:

- Initial Investment: The equipment and precision controls required for foam injection involve upfront costs. However, these costs are often offset by long-term quality and performance gains.

- Process Complexity: Foam injection is more complex compared to traditional methods and requires specialized expertise to manage. Adequate training and maintenance are essential to ensure consistent product quality.

- Customization Balance: While customization is a powerful advantage, it can complicate manufacturing at scale if not managed properly. Companies need robust production planning to maintain both variety and efficiency.

For companies considering incorporating foam injection into their product offerings, a well-defined action plan is critical. Here are the recommended steps:

-

Evaluate Current Production Capabilities:

Conduct an internal audit of existing equipment and expertise. Determine if current manufacturing lines can be upgraded for foam injection or if new installations are necessary. -

Invest in Precision Equipment:

Purchase or lease advanced machinery capable of managing controlled temperature and pressure during the foam injection process. Consider partnerships with established manufacturers like NEX Pickleball, renowned for their precision and quality. -

Pilot Production Runs:

Begin with pilot production runs to fine-tune the foam injection process. Use data analytics and quality control metrics to adjust process parameters, ensuring the paddle meets performance expectations. -

Train Your Workforce:

Implement a training program for production staff focused on the intricacies of foam injection and the necessary quality controls. Well-trained teams are crucial for managing the higher complexity of this process. -

Market Differentiation Strategy:

Develop clear marketing and product differentiation strategies that highlight the advantages of foam injection. Include technical specifications and performance data to appeal to both technical buyers and end users.

In summary, foam injection presents a compelling technological upgrade for manufacturing high-performance pickleball paddles. Its key benefits include enhanced vibration dampening, improved weight distribution, and superior durability—all achieved through a precise and controlled production process. These technical improvements directly affect the market by delivering products that not only enhance player performance but also provide a strong competitive edge in a crowded sales environment.

For procurement managers and business development executives, the decision to invest in foam injection technology should be driven by detailed analysis and pilot testing. The initial investment in advanced machinery and training is quickly balanced by the long-term benefits of product differentiation, higher user satisfaction, and optimized manufacturing efficiency.

Proactive companies that adopt foam injection will likely see increased customer loyalty and market share, providing substantial returns on investment. As always, aligning with trusted partners like NEX Pickleball can ensure access to cutting-edge manufacturing processes and comprehensive support in implementing this technology.

People Also Ask

Q: Which material is better for pickleball paddles?

A: The choice between graphite and fiberglass depends on the desired performance. Graphite offers excellent handling and feel, while fiberglass tends to deliver more power. The optimal material selection varies based on the specific performance needs of the player.

Q: What paddle do most pickleball pros use?

A: Professional pickleball players often select paddles such as those from JOOLA and Selkirk, including models like the JOOLA Perseus and Selkirk VANGUARD Power Air Invikta, known for their combination of control, power, and advanced engineering.

-

foam injection: Click to learn more about the technology behind foam injection, its benefits in manufacturing processes, and how it enhances product performance through improved internal structure and durability. Back to foam injection ↩ ↩2 ↩3

-

pickleball paddles: Click to understand the design, performance attributes, and market trends surrounding pickleball paddles, and why they are a key product segment in sports equipment manufacturing. Back to pickleball paddles ↩

-

vibration dampening: Click to explore the science of vibration dampening, including methods to reduce vibrational impact in sports equipment, ensuring enhanced control and comfort for players. Back to vibration dampening ↩

-

composite materials: Click to discover the role of composite materials in manufacturing, how they combine different substances for improved structural integrity, and their importance in modern product design. Back to composite materials ↩