In summary, the advanced T700 RAW Carbon Fiber1 delivers higher performance, precision, and durability compared to many traditional materials used in high-performance pickleball paddles. Its unique properties, when combined with modern production techniques, offer manufacturers a competitive edge in quality and cost-effectiveness.

Manufacturers today are continually seeking materials that provide a balance of strength, light weight, and cost efficiency. T700 RAW Carbon Fiber is emerging as a go-to option for paddle manufacturing, particularly for high-performance pickleball paddles. As a technical buyer or procurement manager, understanding how T700 stacks up against other carbon fiber variants—in both performance and production efficiency—is critical to making informed sourcing decisions.

The T700 variant is designed to maximize the benefits of carbon fiber. Compared to other types like 3K, 12K, or T300, T700 offers a unique combination of tensile strength, rigidity, and controlled flexibility that is ideal for sports equipment. Its raw form means less processing-induced alterations and a purer manifestation of the carbon fiber’s inherent properties, enabling manufacturers to achieve superior precision and final product performance.

T700 RAW Carbon Fiber is engineered for high-performance applications. It delivers:

• Enhanced Tensile Strength – Ensuring the paddle can withstand high-impact play.

• Reduced Weight – Facilitating quicker maneuverability and faster strikes.

• Greater Flexibility Control – A crucial feature for precision ball handling and improved spin dynamics.

When compared to its counterparts, T700 offers a refined balance. While 12K Carbon Fiber emphasizes extreme durability and a smoother surface ideal for high-intensity competitive play, and T300 is known for a balanced performance of strength and light weight, T700 integrates these benefits with a raw material quality that minimizes processing mediations. This can lead to a more authentic demonstration of the carbon fiber’s inherent strengths.

With modern manufacturing processes such as hot pressing, cold pressing, and thermoforming, T700 is particularly advantageous. These methods allow for:

• Consistent thickness control

• Precise weight distribution

• Superior surface finishes for enhanced grip and ball control

Because of its raw form, additional quality control measures are essential to maintain consistency throughout production. However, advances in raw carbon fiber processing have minimized variability, ensuring that each paddle not only meets industry standards but also elevates the game.

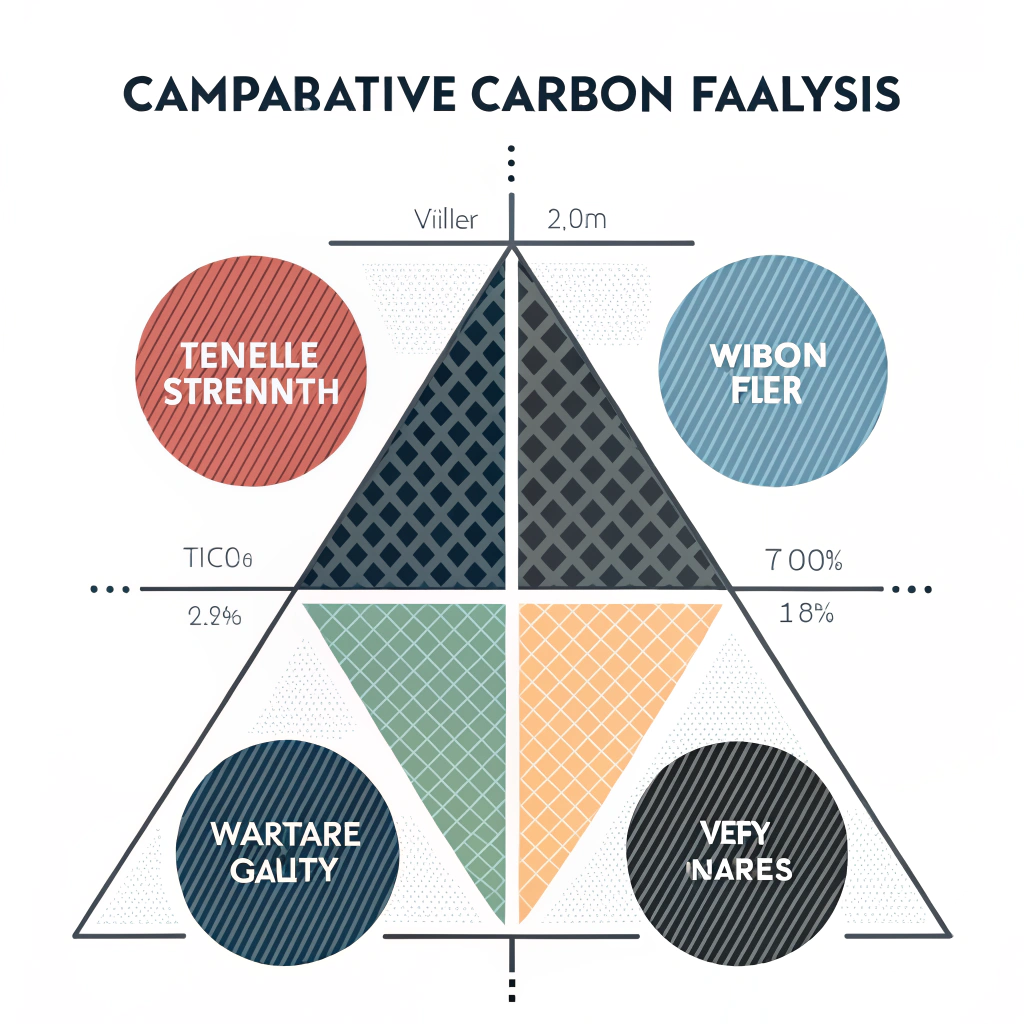

For technical buyers, comparing the performance and production attributes side by side is essential. The following table outlines key comparisons between T700 RAW Carbon Fiber and other commonly used carbon fibers in paddle manufacturing:

| Attribute | T700 RAW Carbon Fiber | 12K Carbon Fiber | T300 Carbon Fiber | 3K Carbon Fiber |

|---|---|---|---|---|

| Tensile Strength | High – optimized for impact | Very High – extreme durability | High – balanced performance | Moderate – strong yet flexible |

| Weight | Lightweight – improves maneuverability | Lightweight – very competitive | Lightweight – superior balance | Slightly heavier |

| Surface Quality | Consistent finish from raw form | Smoother, polished finish | Balanced texture | Standard finish, less refined |

| Processing Impact | Minimal processing alteration | Extensive finishing may alter raw properties | Moderate processing impact | Minimal processing influence |

| Production Efficiency | Requires precise control but highly repeatable | Requires additional finishing | High repeatability with controlled parameters | Efficient but less advanced |

| Ideal for Competitive Play | Excellent – high precision and control | Excellent – highest durability | Good – balanced performance | Suitable for intermediate play |

This table clearly illustrates that while each material has its own merits, T700 RAW Carbon Fiber offers a superior blend of robustness, performance, and longevity which is critical for competitive sports equipment.

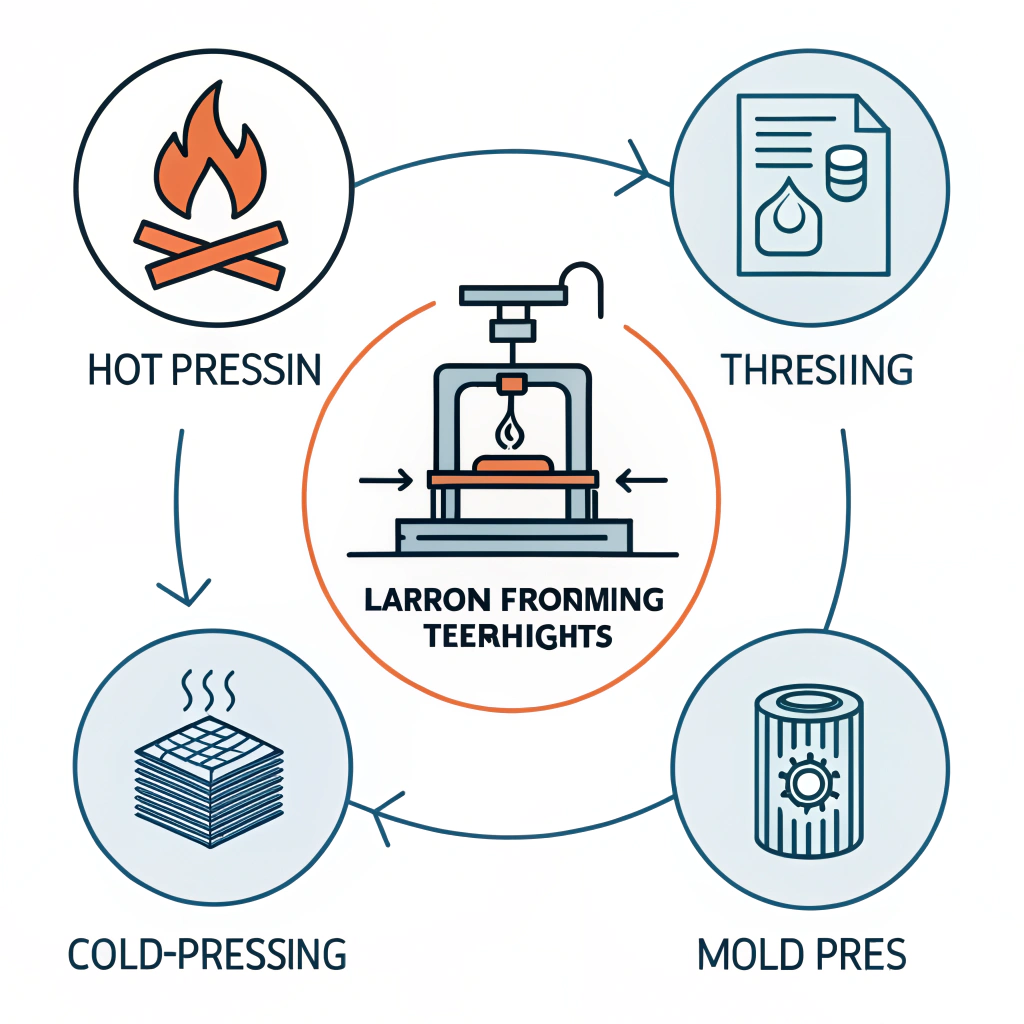

Advanced production techniques are central to maximizing the performance of T700 RAW Carbon Fiber paddles. Manufacturers employ several methods:

Hot pressing applies heat and pressure to bond materials into a resilient structure.

• Advantages:

- High production efficiency with strong, durable paddles.

- Excellent impact resistance and overall structural integrity.

• Considerations: - The process may slightly alter material properties, impacting the natural feel of T700.

- Requires significant equipment investment.

Cold pressing shapes the paddle at room temperature using mechanical pressure.

• Advantages:

- Preserves the intrinsic orientation of T700 RAW Carbon Fiber for superior control.

- Offers greater precision, resulting in a highly responsive paddle.

• Considerations: - Longer production cycles compared to hot pressing.

- Needs high-quality machinery for precise pressure control.

Thermoforming involves heating the material to achieve the desired pliability before molding.

• Advantages:

- Allows for complex designs and high-performance tailoring of weight distribution and grip ergonomics.

- Enhances paddle stability while preserving material integrity.

• Considerations: - Longer production times and higher equipment costs.

- Best suited for premium products or custom manufacturing.

To provide a quick reference, the following table summarizes these techniques:

| Production Process | Advantages | Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structure, impact resistance | Equipment investment, potential material alteration | Large-scale manufacturing |

| Cold Pressing | Precise control, preserves material properties | Longer production cycles, requires precision equipment | Products requiring high response |

| Thermoforming | Complex design capability, stable material distribution | Longer cycle times, higher cost | Premium or custom-made paddles |

These modern production techniques can help manufacturers unlock the full potential of T700 RAW Carbon Fiber. By carefully selecting the appropriate process, it is possible to optimize both performance and production efficiency—key factors for success in the competitive sports equipment market.

For high-performance pickleball paddles, the choice of carbon fiber directly impacts key performance metrics such as:

• Power and Responsiveness – T700’s high tensile strength ensures that each paddle strike is delivered with optimal force.

• Precision and Control – The raw form minimizes interference from processing, maintaining the natural stiffness and recoil properties essential for advanced play.

• Durability – Long-term durability is achieved as T700 maintains its performance without significant wear, even under rigorous conditions.

By integrating T700 RAW Carbon Fiber, manufacturers not only enhance the product’s performance but also contribute to a better playing experience. This is particularly critical for paddle sports, where nuances in weight distribution and surface finish can mean the difference between victory and defeat.

From a business standpoint, T700 RAW Carbon Fiber is portrayed as both a technical and cost-effective solution because it:

• Reduces the need for extensive finishing processes compared to higher-grade polished fibers.

• Improves production consistency, minimizing waste and lowering the rate of defective outputs.

• Offers superior performance metrics which can be leveraged in marketing high-performance, premium paddle lines.

Given the competitive nature of sports equipment manufacturing, such advantages translate into improved production scalability5 and potentially lower overall production costs. When evaluating cost-effectiveness, it is important to factor in long-term benefits, including customer satisfaction and reduced returns due to enhanced product durability.

For procurement managers and technical buyers making tough comparisons, T700 RAW Carbon Fiber represents a modernization opportunity. Here are three key strategic insights:

-

Meeting Market Demands:

Consumers are increasingly looking for equipment that offers both high performance and durability. By selecting a material that elevates paddle performance, businesses can effectively target higher-end segments while maintaining competitive pricing. -

Leveraging Technological Advancements:

The evolution of production techniques, such as thermoforming and cold pressing, allows T700 to be processed into paddles that are not only mechanically superior but also ergonomically optimized. This integration of advanced technology with material innovation is a powerful selling point for both B2B and end users. -

Strengthening Value Propositions:

With robust data to back up material performance, procurement teams can build a compelling value proposition. The reduced downtime, increased production consistency, and achievement of high performance in manufactured paddles play directly into strategies for customer retention and brand differentiation.

Manufacturers who adopt T700 RAW Carbon Fiber can expect a ripple effect—a direct boost to product performance metrics that fuel overall market competitiveness. For procurement managers, the key is aligning material selection with both short-term production goals and long-term strategic visions.

In conclusion, for sports equipment companies looking to upgrade their product lines, T700 RAW Carbon Fiber stands out as a forward-thinking solution. It provides a unique combination of durability, precision, and cost-effectiveness that not only meets but exceeds current market demands in high-performance paddle technology.

Manufacturers are encouraged to evaluate their current production processes—whether hot pressing, cold pressing, or thermoforming—and consider how T700 can be integrated into their manufacturing protocols. By doing so, they align their business with the latest technological advancements, ensuring they remain competitive in both quality and innovation.

For procurement teams assessing next-generation materials, the measurable benefits, combined with improved scalability and efficiency, make T700 RAW Carbon Fiber a compelling choice for your upcoming projects. The market’s shift towards advanced, technology-driven materials in paddle manufacturing is clear, and adopting T700 positions your company at the forefront of this evolution.

Ultimately, whether you are revising an existing product line or planning a new one, T700 RAW Carbon Fiber can help you achieve breakthrough performance improvements, attract a discerning customer base, and drive long-term revenue growth.

• Are carbon fiber pickleball paddles worth it?

Yes, carbon fiber pickleball paddles are worth it. They are stiff and lightweight, providing excellent power and responsiveness, which are favored by intermediate to advanced players. While traditional wood paddles offer a more classic feel and heavier design, carbon fiber paddles excel in delivering a superior balance of speed and control on the court.

• What is the new paddle technology for pickleball?

The new paddle technology for pickleball revolves around advancements such as thermoforming and the use of raw carbon fiber. Thermoformed paddles have a stiffer, unibody design for added power, and the incorporation of raw carbon fiber enhances spin and control, representing the next major leap in paddle technology.

-

T700 RAW Carbon Fiber: Click to learn more about its unique material properties, production advantages, and how it delivers superior performance in high-end applications. ↩ ↩

-

Hot Pressing: Click to explore detailed insights into hot pressing, including its benefits, challenges, and impact on material integrity during manufacturing. ↩ ↩

-

Cold Pressing: Click to understand cold pressing, its role in preserving material characteristics, and the equipment requirements for this manufacturing process. ↩ ↩

-

Thermoforming: Click to read more about thermoforming techniques, their applications in complex designs, and how they enhance product performance. ↩ ↩

-

Production Scalability: Click to discover how improved production scalability can lead to lower costs, greater consistency, and competitive advantages in manufacturing. ↩ ↩