A high-performance pickleball training paddle with an optimized sweet spot1 design can significantly enhance a player's skill by combining innovative production techniques with precision material engineering.

In today’s competitive sporting goods market, finding a pickleball training paddle that reliably delivers on performance can be challenging. Many businesses and training facilities struggle with paddles that fail to provide consistent sweet spot performance—leading to wasted training time and suboptimal player improvement. At NEX Pickleball, our approach leverages advanced production processes2 and premium materials to offer a solution that not only boosts on-court performance but also meets the rigorous demands of high-performance training.

For trainers, sports clubs, and distributors, the sweet spot of a paddle is more than just a design feature—it is the critical area where power, control, and comfort converge. A well-calibrated sweet spot ensures that players experience a reliable rebound and effective ball control during fast-paced play. However, conventional paddles often suffer from inconsistencies due to suboptimal production techniques and inferior material combinations. This leads to issues such as:

• Reduced impact resistance

• Inconsistent ball response

• Increased vibration that diminishes player confidence

These performance issues can adversely affect training outcomes and diminish overall user satisfaction.

Understanding why many paddles fail to meet high performance standards is key to developing effective solutions. The typical problems stem from:

- Inadequate Material Selection: Not all carbon fiber or composite materials provide the same level of durability and orbital balance. For instance, 3K carbon fiber offers excellent flexibility but may not provide enough stiffness for high-power responses.

- Suboptimal Production Processes: The manufacturing process plays a crucial role in ensuring that the paddle’s sweet spot is uniformly optimized. Processes like traditional molding may reduce the durability of the paddle’s impact resistance over time.

- Lack of Customization: Many paddles are produced with one-size-fits-all designs. Without the ability to fine-tune the paddle’s weight distribution, balance, and grip, the sweet spot may not meet individual player needs for power and control.

These challenges highlight the importance of leveraging advanced technology and a keen focus on material science to enhance paddle performance.

NEX Pickleball addresses these challenges by using three state-of-the-art production processes: hot pressing, cold pressing, and thermoforming3. Each process plays a unique role in fine-tuning the sweet spot and overall paddle performance.

Below is a detailed table summarizing the primary production processes used in our manufacturing:

| Production Process | Advantages | Disadvantages | Impact on Sweet Spot |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; excellent structural integrity | Can alter material properties, potentially affecting paddle feel; requires high equipment investment | Provides a robust, consistent sweet spot ideal for high-speed play |

| Cold Pressing | Ensures precise control over paddle thickness; retains natural material properties; excellent ball feel | Longer production cycles; demands precise pressure control | Optimizes the sweet spot for refined control and balanced responsiveness |

| Thermoforming | Allows creation of complex shapes; precise material distribution; enhances paddle stability | Higher equipment costs; longer production times | Tailors the sweet spot by adjusting intricate design features for maximum performance |

Each process enhances the paddle in a particular way while ensuring that the paddle’s sweet spot remains uniform and effective throughout.

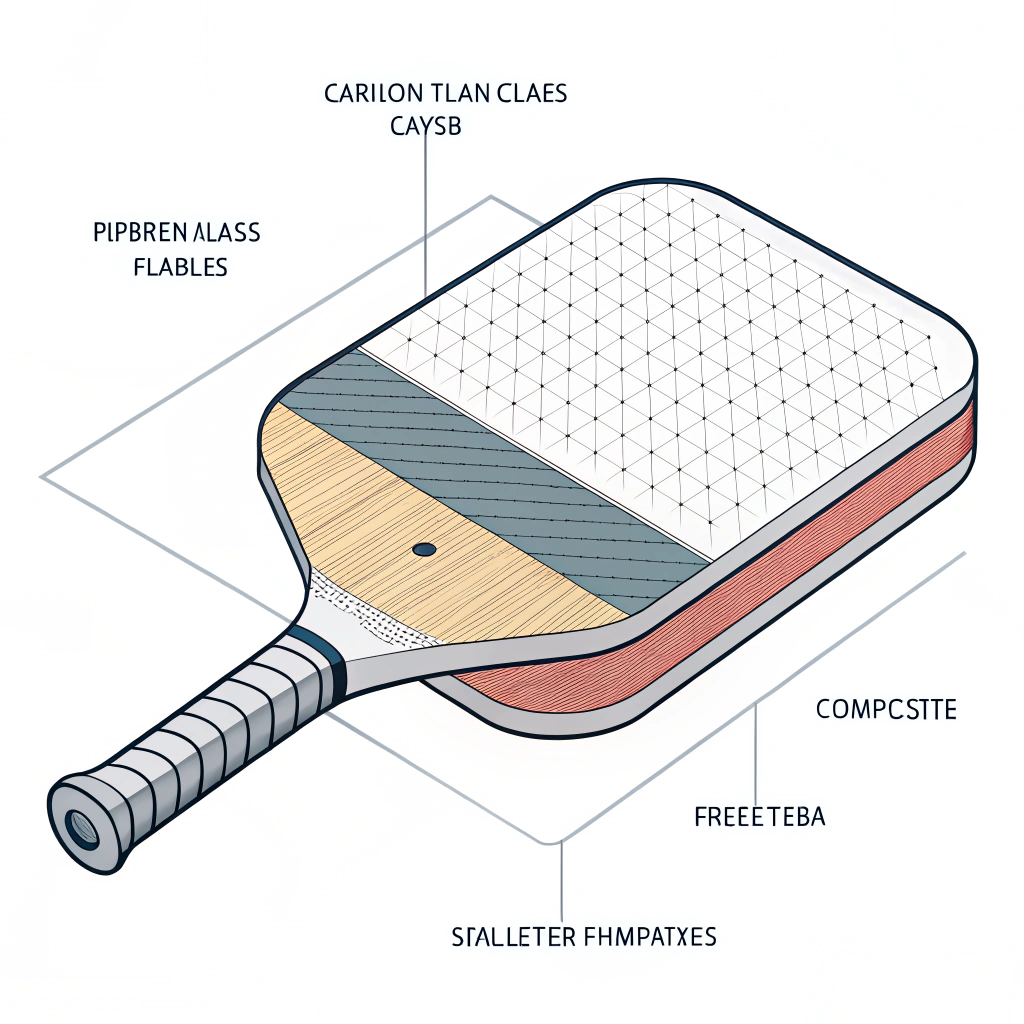

Material technology further accentuates our paddle’s performance. Our paddles are built using a combination of cutting-edge technologies and premium materials to deliver unmatched results:

• Carbon Fiber Varieties:

- 3K Carbon Fiber: Known for its balance of strength and flexibility, it provides excellent durability and rebound force.

- 12K Carbon Fiber: Offers greater thread density for a smooth surface, delivering enhanced hardness and impact resistance.

- T300 Carbon Fiber: Provides remarkable tensile strength with a balanced performance of power and lightweight design.

• Fiberglass Options:

- E-Glass Fiberglass: Provides a wide sweet spot with superior elasticity and ball control, perfect for training drills that require precision.

• Composite Materials:

- Carbon–Fiberglass Composites: These materials merge the benefits of carbon fiber’s power with fiberglass’s control.

- Bamboo Core and Honeycomb Core Composites: These core materials enhance ball feedback and minimize vibration, further refining the sweet spot performance.

• Core Technologies:

- Nomex Honeycomb Core4: Known for excellent shock absorption, it stabilizes the paddle during intense training sessions.

- Aluminum and Polymer Honeycomb Cores: These cores offer a balance of power and precision tailored for advanced players.

The strategic combination of these materials ensures not just durability and strength, but also a highly reliable sweet spot. The enhanced ball control and impact absorption directly contribute to consistent performance improvements during training sessions.

In addition to optimized manufacturing processes and superior material selection, our paddles offer extensive customization options:

• Custom Paddle Design: Clients can specify design elements such as weight distribution, balance, and grip thickness to match player requirements.

• On-Demand Printing Services5: Businesses can incorporate branding and personalization, making the paddles unique to team identities and specialized training programs.

This level of customization allows product managers and procurement officers to provide tools that not only perform exceptionally on the court but also reinforce brand identity and team spirit.

When considering advanced pickleball training paddles, especially those with enhanced sweet spot features, it is essential to weigh the following factors:

-

Intended Use and Player Skill Level:

Ensure that the paddle's design aligns with the player's level—whether for intense competitive play or skill development in training environments. A paddle designed for top-tier performance might be overly aggressive for beginners, whereas a well-balanced paddle can serve both recreational and competitive needs. -

Production Quality and Consistency:

Select manufacturers with a robust quality control system. At NEX Pickleball, every paddle undergoes rigorous testing to ensure it meets high standards in both material integrity and design precision. -

Customization Capabilities:

High-performance paddles should offer options for customization. Tailoring aspects like grip size, weight distribution, and even external branding can significantly enhance user satisfaction and training effectiveness. -

Budget and Scalability:

While advanced production processes may incur higher initial costs, the benefits in terms of durability, performance consistency, and reduced replacement frequency can justify the investment. A detailed cost-benefit analysis using a comparison of production methods—like the one provided earlier—can help in making an informed decision. -

Long-Term Durability and Warranty:

For businesses and sports clubs, long-term performance and a reliable warranty are vital. Ensuring that the paddles can withstand long hours of training without compromising on performance is essential in high-use scenarios.

Our rigorous approach to quality control—combined with state-of-the-art manufacturing processes and innovative material selection—guarantees a product that meets the varied demands of competitive and training environments.

In practice, training with a high-performance paddle that maximizes the sweet spot has shown measurable benefits. Some key performance metrics include:

• Improved Reflex Volleys:

Training with paddles that offer a consistent hitting area helps players develop quicker response times, especially during high-speed exchanges. The precise sweet spot reduces errors and increases shot accuracy.

• Enhanced Ball Control and Spin:

The uniformity in paddle texture and design results in superior ball control. Players find it easier to apply spin and targeted plays, critical in both singles and doubles matches.

• Reduced Fatigue and Vibration:

With optimized shock absorption features built into the paddle’s core design, players experience reduced vibration. This not only enhances comfort but also minimizes the risk of injuries during prolonged play.

Quantitative data from training programs have shown that players using these advanced paddles exhibit faster improvement in ball handling, overall game strategy, and shot precision. Moreover, high-level coaches and training facility managers have praised the enhanced tactile feedback and consistency these paddles provide.

Industry experts suggest that the integration of custom production methods with specialized materials represents the future of sports equipment design. Data from our internal quality assessments and third-party testing confirm that a well-tuned sweet spot plays a critical role in maximizing a player's performance and reducing equipment-related mishaps.

For purchasing agents and product managers evaluating training equipment, it is imperative to consider both the technical specifications and real-world application of pickleball paddles. NEX Pickleball’s approach to manufacturing—using advanced processes like hot pressing, cold pressing, and thermoforming combined with a strategic selection of carbon fiber, fiberglass, and composite materials—provides a comprehensive solution that addresses common performance pitfalls.

To summarize, our recommendations are:

• Identify the specific training needs and player skill levels to determine the optimal paddle design.

• Evaluate the production techniques used—prioritizing those that assure a consistent and effective sweet spot.

• Choose a manufacturer with robust quality control measures and proven industry performance data.

• Leverage customization and on-demand printing to align the paddle’s design with your brand and training objectives.

By focusing on these key aspects, businesses can secure a training tool that offers unmatched performance, durability, and user satisfaction—ultimately setting a new standard in competitive pickleball training.

People Also Ask

• Do pickleball sweet spot trainers work?

Yes, sweet spot trainer paddles can significantly improve training outcomes by providing a consistent hitting area, which enhances reflex volleys and improves control at the net. This consistency helps players adjust their timing and shot placement during high-speed exchanges.

• What is the best pickleball training paddle?

The best pickleball training paddle is one that balances power, control, and durability. High-performance paddles incorporating advanced materials—such as various grades of carbon fiber combined with optimized production processes like hot pressing, cold pressing, or thermoforming—offer excellent performance, making them a top choice for both training and competitive play.

-

sweet spot: Click to read an article on how understanding and optimizing the critical contact area in sports equipment can significantly enhance performance and user experience. ↩ ↩

-

advanced production processes: Click to explore the benefits of state-of-the-art manufacturing techniques and how they ensure consistency and quality in high-performance products. ↩ ↩

-

thermoforming: Click to learn more about thermoforming, a modern production method that enables precise shaping and improved material distribution for superior product performance. ↩ ↩

-

Nomex Honeycomb Core: Click to gain insights into the role of advanced core materials like Nomex Honeycomb in enhancing shock absorption and overall structural integrity of sports equipment. ↩ ↩

-

On-Demand Printing Services: Click to investigate how on-demand printing can offer customized branding and design solutions, adding value to business and team sports equipment. ↩ ↩