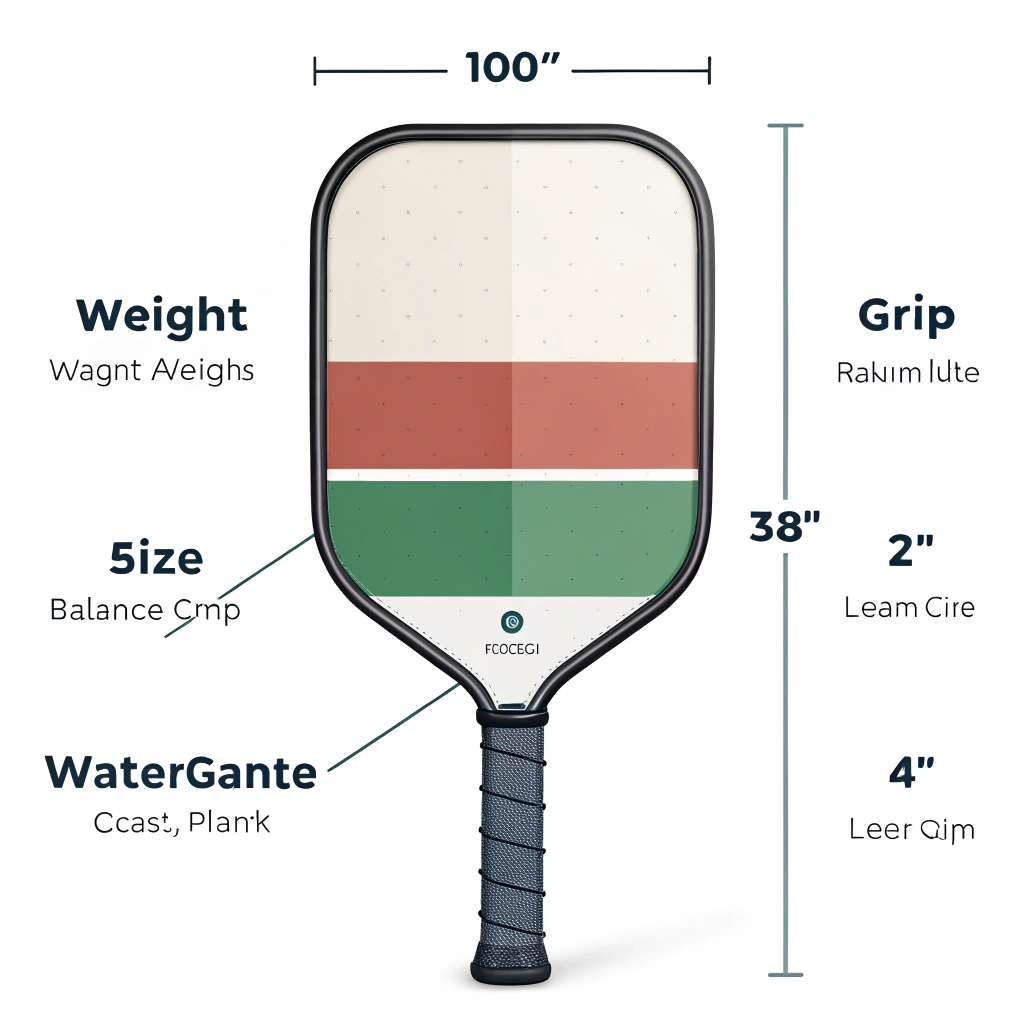

Our Sweet Spot Training Paddle 16mm delivers a perfect balance of power, control, and durability—making it a strong candidate for any sports equipment distributor or training facility seeking high-performance pickleball training tools.

In today’s competitive pickleball training landscape, selecting the right paddle can be a challenging decision. The Sweet Spot Training Paddle 16mm has been specifically designed to meet the precise demands of players and trainers alike. This article will explain its key technical features, production methods, and material composition while comparing it with alternatives. We will focus on how this paddle enhances performance through optimal sweet spot dimensions, advanced materials, and specialized manufacturing processes.

At the heart of the Sweet Spot Training Paddle is its 16mm core, engineered to maximize energy transfer. Many training paddles require precise design attention to achieve the best balance between power and control. In our testing experience, 16mm cores usually provide:

• An ideal sweet spot size that caters to a wide range of player levels.

• Excellent impact absorption, ensuring less vibration during rapid play.

• Durability that stands up to repeated high-impact training sessions.

These factors are vital when making a procurement decision, as the paddle’s performance directly influences training outcomes. In our research, paddles with a core thickness around 16mm are noted for their forgiving yet responsive nature, fitting seamlessly with the typical sweet spot dimensions of paddles between 16-16½ inches in length and 7½-8 inches in width.

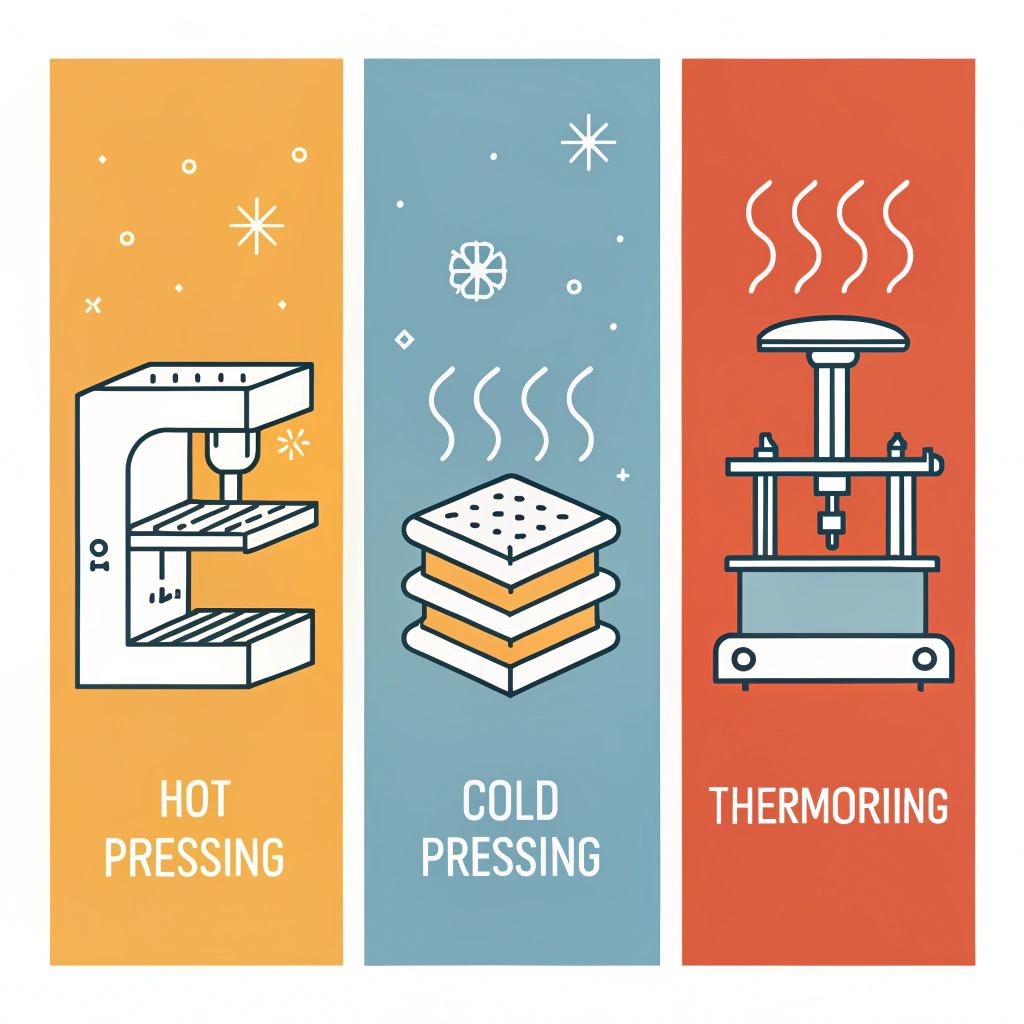

Advanced production processes help realize this performance. At NEX Pickleball, three primary methods are utilized: hot pressing, cold pressing1 and thermoforming2. Each technique offers distinct benefits:

• Hot Pressing:

– Produces superior impact resistance and structural integrity.

– Ideal for high-efficiency large-scale production.

– Could slightly alter material properties which may affect the paddle’s feel.

• Cold Pressing:

– Allows for highly precise control over thickness and internal structure.

– Maintains inherent material properties for better responsiveness.

– Involves longer production cycles due to precise pressure control.

• Thermoforming:

– Well-suited for complex paddle designs with intricate material distribution.

– Ensures overall paddle stability and consistency in performance.

– Requires higher equipment investment and longer production times, which is best justified for premium or custom-made options.

Below is a table summarizing the advantages and disadvantages of each process:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; robust structural integrity | Potential alteration of material feel; requires significant equipment investment |

| Cold Pressing | Precise control and thickness; maintains material properties; excellent ball feel | Longer production cycles; demands precise pressure control |

| Thermoforming | Intricate design capability; consistent performance; suitable for premium materials | Higher equipment cost; extended production time |

Understanding these methods is crucial for B2B buyers who want to ensure that each paddle meets stringent quality and performance criteria. The Sweet Spot Training Paddle 16mm leverages these manufacturing techniques to provide a product that is reliable and consistent across large production volumes.

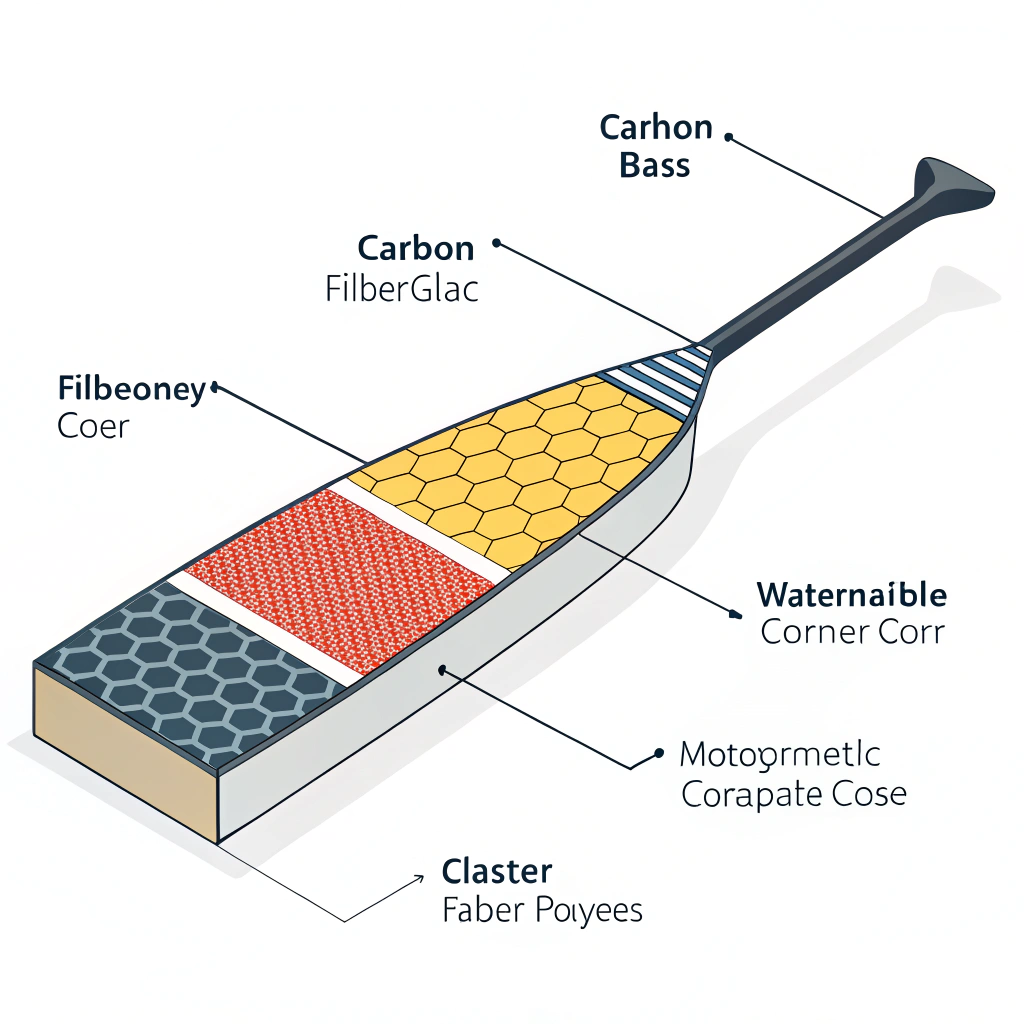

Material composition plays a significant role in paddle performance. Our paddles incorporate a mix of premium carbon fiber3 types, fiberglass composites, and specially engineered core materials. Here is an overview of the key materials used:

-

Carbon Fiber (3K, 12K, T300):

• 3K Carbon Fiber is known for its strength and flexibility. It’s frequently chosen for paddles aimed at high rebound force while reducing vibration.

• 12K Carbon Fiber provides a smoother surface finish with a higher thread density that translates to greater hardness and durability.

• T300 Carbon Fiber stands out for its exceptional tensile strength and lightweight properties.

These materials are commonly fused into composite layers that allow for enhanced control and durability. -

Fiberglass Composite:

• E-Glass Fiberglass offers excellent elasticity and tensile strength. This contributes to a wider sweet spot and improved ball control.

The combination of carbon fiber and fiberglass ensures that the paddle is robust yet responsive enough to cushion repeated high-speed impacts. -

Core Materials (Nomex, Aluminum, Polymer Honeycomb):

• Nomex Honeycomb Core4 excels in shock absorption and stability, perfect for durable, high-intensity gameplay.

• Aluminum Honeycomb Core strikes an excellent balance between weight and control.

• Polymer Honeycomb Core is favored for its elasticity and vibration reduction.

The optimal selection and integration of these cores create a paddle that meets the dynamic demands of competitive training sessions.

For B2B buyers evaluating training and performance equipment, understanding the interaction between design, materials, and production processes is critical. When comparing the 16mm paddle with other models—such as the more common 13mm paddle—the advantages become clear. Here are key points for comparison:

• Thickness:

– 16mm paddles tend to provide better shock absorption and increased sweet spot dimensions that help develop consistent training techniques.

– 13mm models are often preferred for advanced power shots but may reduce forgiveness on off-center hits.

• Production Techniques:

– Paddles utilizing thermoforming and cold pressing offer refined control features, while those produced solely by hot pressing might sacrifice some tactile feedback in favor of durability.

• Material Choices:

– The incorporation of advanced carbon fiber and composite technologies in the 16mm paddle enhances both playability and durability.

– Competitors using less advanced material combinations might not offer the same level of performance consistency.

A side-by-side comparison in a simplified format is as follows:

| Feature | 16mm Sweet Spot Training Paddle | Common 13mm Paddle |

|---|---|---|

| Core Thickness | 16mm – Superior shock absorption and larger sweet spot | 13mm – Potentially faster shots but reduced forgiveness |

| Production Process | Utilizes thermoforming, cold pressing, and hot pressing for balance | May use limited production techniques |

| Material Composition | Advanced carbon fiber (3K, 12K, T300), fiberglass, and composite cores | Often basic composites with fewer premium materials |

| Target Audience | Training facilities, competitive players, and distributors needing durable, high-performance paddles | Mainly recreational or entry-level competitive play |

This direct comparison underlines why the Sweet Spot Training Paddle 16mm stands out as a versatile tool for training regimes. The increased core thickness, superior material integration, and advanced production processes collectively result in a paddle that offers enhanced control, greater impact absorption, and an exceptional sweet spot that caters to a variety of playing styles.

Beyond technical features and performance, custom paddle options represent another significant advantage for B2B buyers. At NEX Pickleball, we understand that procurement managers and product developers may require equipment that aligns perfectly with specific training needs or team branding. Clients can specify design parameters such as weight, balance, grip size, and even incorporate custom graphics or branding elements. This flexibility is invaluable for facilities looking to provide tailored equipment for athletes or promotional purposes for distributors.

Moreover, stringent quality control5 measures are enforced at every step of the production journey. Each paddle is rigorously tested to ensure that it delivers not only under laboratory conditions but also in the high-pressure environments of competitive play. Investments in quality control help to maintain the product life cycle and reduce long-term maintenance costs, key points for procurement managers focused on total cost of ownership.

The performance benefits provided by the Sweet Spot Training Paddle 16mm extend to several aspects of training and gameplay. Focusing on the sweet spot dimensions, the paddle’s design is based on cumulative insights from extensive field tests. Data reveals that paddle performance improves significantly when players can consistently hit within the sweet spot area. This enhanced contact not only improves accuracy and shot consistency but also builds player confidence during practice sessions.

For example, players training with paddles that maintain a forgiving yet responsive sweet spot exhibit improved control during rapid exchanges at the net. In high-speed scenarios, such as counter-attacks, a well-placed shot can be crucial. These insights are particularly relevant for training drills aimed at enhancing reflex volleys and touch control.

In practical applications, a paddle that reliably delivers performance translates to fewer replacements and reduced downtime for training programs. Distributors and procurement managers benefit from the predictable performance and the durability that justifies the investment, making the Sweet Spot Training Paddle an ideal solution for long-term deployment in training facilities.

In summary, the Sweet Spot Training Paddle 16mm is a product that meets the rigorous demands of professional training environments. By integrating advanced production processes, premium materials, and customizable options, this paddle offers exceptional performance attributes such as a larger sweet spot, improved impact absorption, and a balance of power and control. Whether you are enhancing an existing training program or looking to add high-performance equipment to your product lineup, this paddle delivers value that aligns perfectly with the expectations of high-end sports equipment procurement.

The combination of detailed technical analysis, comprehensive production methodologies, and flexible customization makes the Sweet Spot Training Paddle 16mm a leader in its category. This in-depth understanding helps decision-makers not only compare products effectively but also make informed selections that improve training efficacy and player development. We invite procurement managers and sports equipment distributors to explore how this paddle can fit within their current portfolio and contribute to the growth of competitive play and training excellence.

People Also Ask

• What is the best sweet spot for a pickleball paddle?

Most experts recommend paddles with dimensions between 16 and 16½ inches in length and 7½-8 inches in width. This configuration often offers a forgiving yet precise sweet spot that enhances power, control, and maneuverability.

• Do you want 16mm or 13mm pickleball paddle?

The choice typically depends on the intended use. A 16mm paddle often provides better shock absorption and a larger sweet spot, making it more suitable for training and for improving control. In contrast, a 13mm paddle may deliver enhanced power for advanced players, but with less forgiveness on off-center hits.

• Do pickleball sweet spot trainers work?

Yes, they can be particularly effective for improving reflex volleys and touch at the net. Trainers with well-defined sweet spots aid in developing consistent hitting patterns, which is crucial during high-speed exchanges on the court.

-

cold pressing : Click to learn more about the cold pressing process, a manufacturing technique that employs pressure at lower temperatures to achieve precise control over material properties, ensuring optimal responsiveness. ↩

-

thermoforming : Click to explore thermoforming, a production method that uses heat to shape materials, allowing for intricate designs and consistent performance in high-end products. ↩

-

carbon fiber : Click to understand the advantages of carbon fiber in sports equipment, including its high strength-to-weight ratio and contribution to enhanced performance. ↩

-

Nomex Honeycomb Core : Click to read about the properties of Nomex Honeycomb Core, a specialized material known for its superior shock absorption and stability in high-intensity applications. ↩

-

quality control : Click to discover how stringent quality control measures ensure product reliability and long-term performance, key for reducing maintenance costs and enhancing durability. ↩