Quick Answer: High-performance pickleball paddles combine advanced materials with precision production techniques to achieve the optimal sweet spot design, ensuring enhanced power, control, and durability. In this article, we compare key materials and processes—such as various carbon fibers1, fiberglass2 and composite cores3—along with production techniques like hot pressing, cold pressing, and thermoforming4, to help you decide which manufacturing option best suits your needs.

Manufacturers and procurement managers face unique challenges when sourcing high-performance sports equipment. For pickleball paddles, every technical specification—from the choice of material to the production process—can greatly influence the paddle’s performance and feel on the court. To successfully meet market demands, a thoughtful comparison of materials and processes is essential. In this article, we break down the differences between popular production techniques and material choices, providing detailed analyzes and recommendation guidance to support your decision-making.

For competitive play, every paddle must be engineered for precision. The key challenge is balancing the right amount of power, control, and comfort while ensuring the paddle is durable enough for high-performance use. This balance is achieved through:

- The selection of premium materials, such as different types of carbon fiber (3K, 12K, T300) and fiberglass.

- Tailored production methods that preserve core material properties and provide a consistent sweet spot.

- Customization options that cater to ergonomic grip design and weight distribution.

Achieving this balance is critical for both recreational players and professionals. Suppliers like NEX Pickleball have grown to prominence by using advanced production processes and a deep understanding of material engineering, allowing them to produce paddles that meet rigorous industry performance standards.

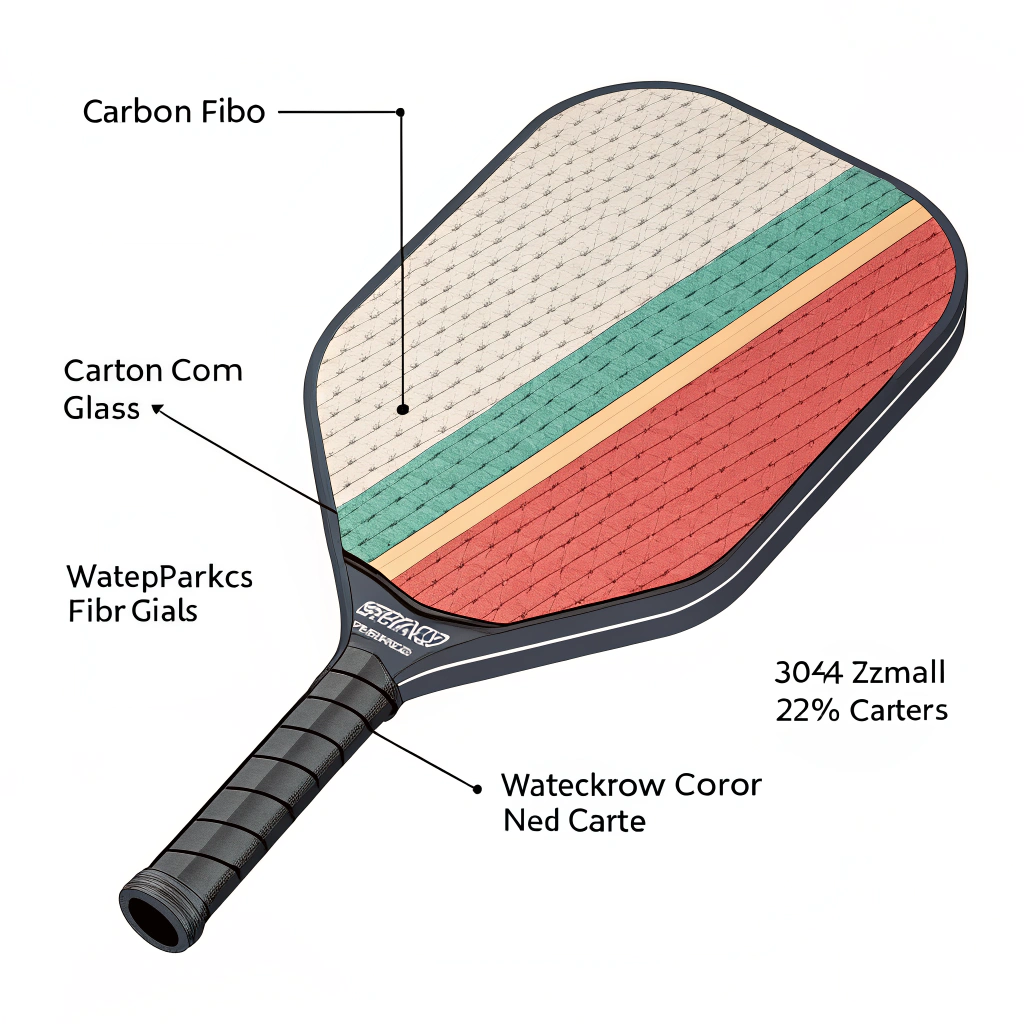

A paddle’s performance largely depends on its materials. Below is a look at some of the most common material options:

Carbon fiber is popular in paddle production due to its excellent strength-to-weight ratio and durability. Among the types available:

- 3K Carbon Fiber: Known for its strength and flexibility, it provides high rebound force and reduces vibration during play.

- 12K Carbon Fiber: This variant offers higher thread density, which contributes to a smoother surface, increased hardness, and superior durability—ideal for competitive play.

- T300 Carbon Fiber: Valued for its balance between strength and weight, T300 fiber strikes an ideal compromise for players looking for both power and maneuverability.

Each variant brings distinct characteristics to the table, making it essential to select a type that aligns with your target market’s requirements.

Fiberglass offers a solid balance between power and control. Often known as E-Glass Fiberglass, it is valued for:

- Its elasticity, which contributes to a wider sweet spot.

- Enhanced durability while still providing excellent ball control.

- Better performance in scenarios where flexibility is required, making it a favorite among many players.

Some paddles combine multiple materials to harness the advantages of each:

- Carbon Fiber and Fiberglass Composite: Integrates the toughness of carbon fiber with the flexibility of fiberglass, delivering a balanced performance.

- Bamboo Core Composite: Utilizes bamboo’s natural lightweight properties and high impact resistance, ideal for sustained play.

- Honeycomb Core: Constructed from high-density polymer or pulp, this option is excellent for shock absorption, thus reducing vibration and extending paddle lifespan.

The internal core of the paddle is just as important as its outer materials:

- Nomex Honeycomb Core5: Offers robust shock absorption and durability.

- Aluminum Honeycomb Core: Strikes a balance in weight distribution, delivering optimal power and control.

- Polymer Honeycomb Core: Provides elasticity and decreased vibration, enhancing overall player comfort and control.

These choices allow manufacturers to offer customizable performance characteristics, ensuring that each paddle meets the specific demands of different competitive environments.

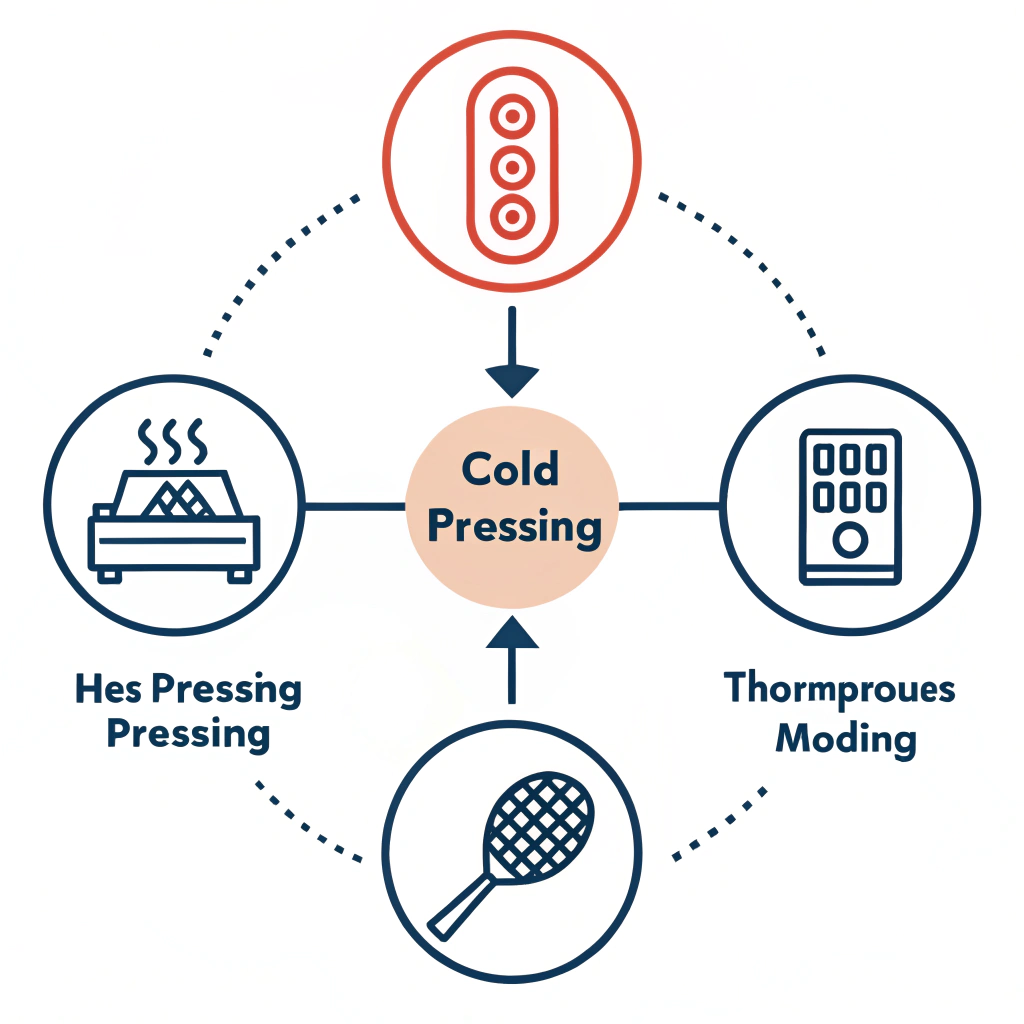

The production process plays a significant role in defining the final performance characteristics of a pickleball paddle. Let's examine three primary techniques:

Hot pressing involves using heat and pressure to bond materials:

- Advantages:

- High production efficiency, ideal for large-scale manufacturing.

- Produces paddles with excellent impact resistance.

- Ensures strong structural integrity, making them suitable for high-performance use.

- Disadvantages:

- Heat may alter some inherent material properties, slightly affecting the playing feel.

- Requires high upfront equipment investment.

Cold pressing takes place at room temperature, using mechanical pressure:

- Advantages:

- Allows precise control over the paddle’s thickness.

- Preserves the material’s natural properties, enhancing control and flexibility.

- Results in paddles with superior ball feel due to minimal alteration in material behavior.

- Disadvantages:

- Longer production cycles, which can reduce overall efficiency.

- Demands high-quality equipment for precise pressure management.

Thermoforming involves heating materials until they soften, then forming them using molds:

- Advantages:

- Enables the creation of complex designs with precise material distribution.

- Maintains paddle stability by ensuring uniform material treatment.

- Suitable for a wide range of high-performance materials, making it versatile for custom designs.

- Disadvantages:

- Involves longer production times compared to other techniques.

- Higher equipment costs, making it best for premium products or custom orders.

Below is a table summarizing these production methods:

| Production Method | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; excellent structural integrity | Potential alteration of material feel; high equipment cost |

| Cold Pressing | Superior control over thickness; preserves material properties; enhanced ball feel | Longer production cycle; stringent equipment requirements |

| Thermoforming | Complex design capability; uniform material distribution; stability | Longer production time; higher production cost |

Each technique offers unique benefits and is selected based on the paddle’s intended performance and market demands.

When evaluating manufacturing options for high-performance pickleball paddles, procurement managers should consider both the material profiles and the associated production processes. Here are some key points to guide your decision:

- Carbon Fiber options, such as 3K, 12K, and T300, are typically chosen for competitive-level performance due to their excellent strength, rigidity, and reduced vibration.

- Fiberglass is noted for its balanced performance, offering a wider sweet spot and enhanced playability, particularly beneficial for in-game maneuvers.

- Composite Materials provide tailored performance characteristics, combining benefits such as shock absorption with increased durability.

- With processes like hot pressing, there is high production throughput which is ideal if you aim to meet large order volumes.

- The precision offered by cold pressing presents a solution for paddles where maximum precision and control of material properties are critical.

- Thermoforming allows for exquisite control over design features including complex shapes and thickness variations, critical for maintaining an optimal sweet spot.

- For businesses that require tailored paddle features such as custom weight, balance, or ergonomic grip designs, methods like thermoforming or cold pressing can provide the necessary flexibility.

- Suppliers like NEX Pickleball offer on-demand printing services, allowing for branding or customization, which adds significant value in B2B sports manufacturing.

The following table compares key material properties:

| Material Type | Key Features | Ideal For |

|---|---|---|

| 3K Carbon Fiber | Strength, flexibility | High rebound force, competitive play |

| 12K Carbon Fiber | Smoother surface, durability | Extreme strength and impact resistance |

| T300 Carbon Fiber | Balanced strength and weight | Overall performance and agility |

| E-Glass Fiberglass | Wide sweet spot, elasticity | Recreational use, versatile play |

| Carbon/Fiberglass Composite | Balanced performance | Players needing power and control |

| Bamboo Core Composite | Lightweight, impact resistance | Long-lasting play and durability |

| Honeycomb Cores | Shock absorption | Reduced vibration; extended durability |

The above details and comparison help in making a well-informed decision based on your technical requirements and order volume expectations.

To further refine your procurement and product development strategy, consider the following recommendations:

- Prioritize Quality Assurance: Establish rigorous testing protocols for each batch of paddles, ensuring each product meets the technical specifications and performance benchmarks.

- Evaluate Manufacturing Partners: Look for suppliers with experience in advanced production techniques and a proven track record of delivering high-performance paddles. Partners like NEX Pickleball are known for their expertise in tailored production processes and stringent quality control.

- Focus on Customization: Ensure that your supplier offers a range of customization options, from material combinations to ergonomic design adjustments. This flexibility can be a competitive advantage in the market.

- Balance Cost and Performance: While premium materials and advanced production techniques may come at a higher cost, the overall performance benefits and reduced maintenance costs can justify the investment. Evaluate the total cost of ownership rather than just the upfront cost.

- Keep Up with Industry Trends: The sports equipment market is always evolving. Stay updated on new materials, production methodologies, and technological innovations to maintain a competitive edge in procurement decisions.

By focusing on these factors, procurement managers can streamline the purchasing process, ensuring that the final product not only meets but exceeds market expectations.

People Also Ask

Q: Is the Sweet Spot Pro a good paddle?

A: Yes. The Sweet Spot Pro offers exceptional control, power, and quality that ranks it among the top brands. Its design ensures the perfect grip and spin, enabling precise shot placement.

Q: Do pickleball sweet spot trainers work?

A: Yes. Sweet spot trainer paddles can help players improve reflex volleys and net touch, making them effective for developing quicker response times and enhanced ball control in high-speed play.

Q: Do more expensive pickleball paddles make a difference?

A: Yes. Higher-end paddles often incorporate advanced materials like carbon fiber and fiberglass, which deliver enhanced control, power, and spin. However, achieving optimal performance depends on the right balance of materials and design rather than price alone.

-

Carbon fibers: Reading this article will provide insights into the advanced composite materials that offer a superior strength-to-weight ratio, contributing to enhanced paddle performance and durability. ↩

-

Fiberglass: Learn more about fiberglass’s role in sports equipment manufacturing, including its elasticity and durability characteristics that impact playability. ↩

-

Composite cores: Discover how composite cores combine different materials to optimize shock absorption and performance in high-demand applications. ↩

-

Thermoforming: This article explains the thermoforming process, highlighting its capability for creating complex shapes and maintaining uniform material properties for high-performance products. ↩

-

Nomex Honeycomb Core: Explore the benefits of Nomex honeycomb cores, including their excellent shock absorption and durability, which are critical for enhancing paddle performance. ↩