Quick Answer: Strength testing standards for pickleball accessories involve a systematic approach that evaluates material durability, impact resistance, and long-term performance through rigorous testing protocols1 aligned with industry and regulatory guidelines. These procedures help ensure that products meet quality assurance and safety requirements while providing performance consistency under competitive and recreational use.

In the B2B sports equipment industry, ensuring the durability and safety of pickleball accessories is paramount. Quality assurance teams and procurement managers invest significant effort into establishing solid testing protocols1 to assess factors like impact resistance, material fatigue, and overall durability. This article outlines the comprehensive strength testing standards used to qualify pickleball accessories, with an emphasis on testing methodologies that validate performance, reliability, and compliance with industry requirements.

As the popularity of pickleball surges, manufacturers face the challenge of maintaining high standards in paddle construction and other accessories. Strength testing is critical because:

• It offers a measurable way to confirm that products meet safety standards.

• It aids in identifying potential weaknesses in high-performance or custom-made accessories.

• It provides data-driven insights that can lead to enhanced manufacturing processes and improved product longevity.

For B2B buyers, understanding these testing processes is essential for benchmarking quality and ensuring that the accessories purchased can withstand the rigors of competitive play.

When assessing pickleball accessories, several key parameters are considered:

-

Material Durability: This includes the assessment of core materials such as Nomex honeycomb2, aluminum honeycomb, and polymer cores. These materials must resist degradation and withstand repeated impacts without failure.

-

Impact Resistance: Evaluates how the accessory behaves under sudden forces, which is especially important for paddle face materials like 3K carbon fiber3, 12K carbon fiber, and fiberglass.

-

Fatigue and Material Stress: Repeated cycles of stress can lead to material fatigue. Testing simulates extended play conditions to ensure the accessory won’t degrade prematurely.

-

Structural Integrity: Ensures that accessories, particularly paddles, maintain proper geometry and weight distribution even after rigorous use. This includes testing for edge guards, butt caps, and other design elements that may affect performance.

-

Environmental Conditioning: Temperature and humidity can affect material properties. Accessories undergo tests under varying conditions to simulate real-world environments.

Understanding these parameters helps manufacturers fine-tune their production processes and enables procurement managers to benchmark performance using consistent metrics.

The rigorous testing processes combine a variety of methods to evaluate the strength of pickleball accessories. The primary testing methodologies include:

Impact testing generally involves simulating collision or strike forces using standardized drop tests or impact machines. This helps quantify how accessories respond to sudden shocks.

In fatigue testing, the accessories are exposed to repetitive stress cycles, thereby simulating long-term wear and tear. This helps in evaluating how the materials hold up under continuous use.

Testing accessories in controlled weather conditions (extreme temperatures, humidity variations, etc.) is crucial for determining the accessory’s reliability in diverse environments.

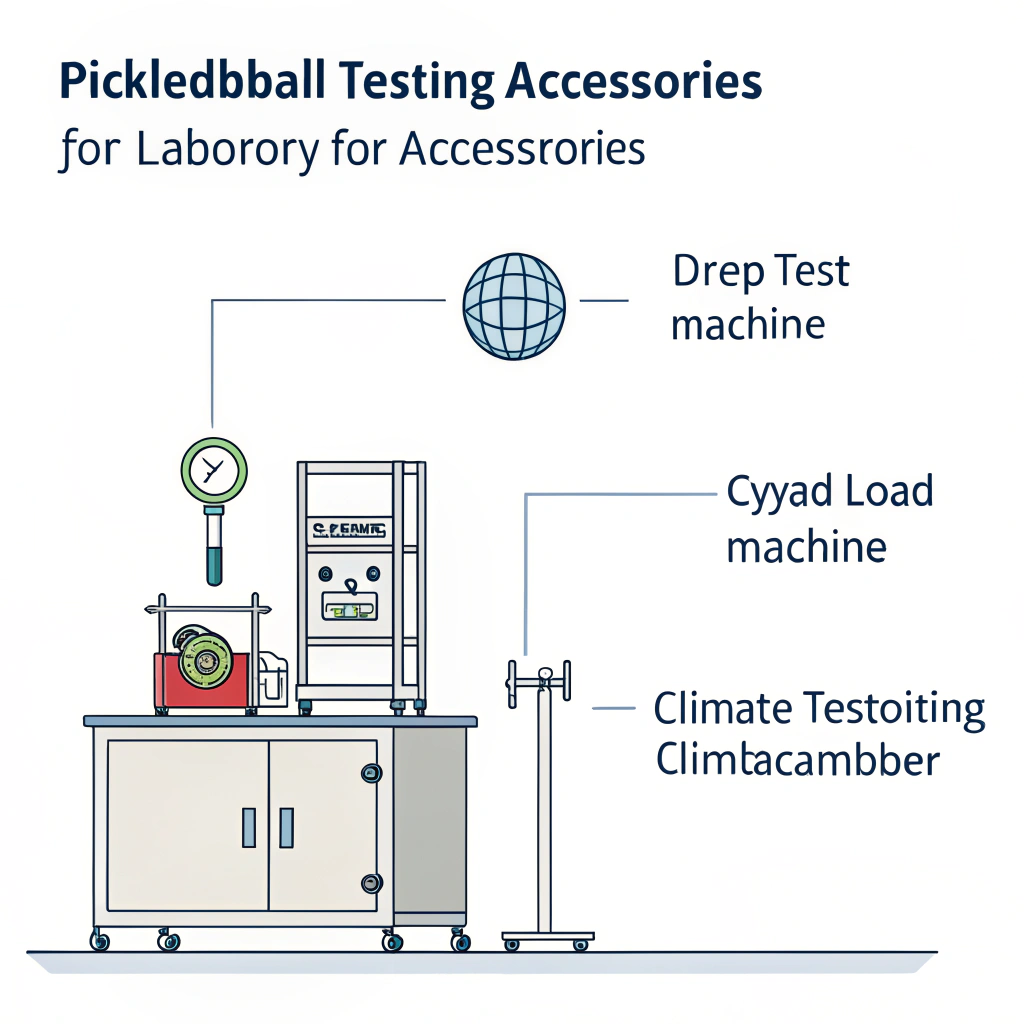

Below is a table summarizing the most common testing protocols and their key attributes:

| Testing Protocol | Equipment Used | Key Parameters | Notes |

|---|---|---|---|

| Impact Resistance | Drop test machines, impact hammers | Force of impact, energy absorption | Simulates real-play collisions |

| Fatigue Testing | Cyclic load machines | Number of cycles, material deformation | Measures longevity |

| Environmental Conditioning | Climate chambers | Temperature range, humidity levels | Assesses performance variability |

| Structural Analysis | CAD simulations and stress analyzers | Edge integrity, weight distribution, vibration reduction | Ensures design consistency |

The first step in the strength testing process is a thorough inspection of the raw materials used in manufacturing, such as various types of carbon fiber, fiberglass, and composites. Each material undergoes evaluation for consistency in composition and strength. Visual inspections and microscopic analyses help identify micro-cracks or defects that could lead to failure during use.

Impact resistance tests are conducted using dynamic shock testing. During these tests, accessories are subjected to sudden forces mimicking real-play conditions. This process includes:

• Dropping or striking the accessory from calibrated heights.

• Measuring the rebound energy and checking for structural integrity post-impact.

• Comparing the results against predefined thresholds that define acceptable product performance.

For example, paddle face materials are tested to ensure they can maintain their structural integrity even after repeated high-impact collisions.

Fatigue testing is conducted by applying repeated mechanical stress over thousands of cycles to mimic the extended use of an accessory. This testing simulates:

• The constant pressure and bending experienced during a game.

• Recurrent impacts that could gradually weaken the material.

• Potential failure points that may develop over time, such as at the core or edge guard joints.

Data collected during fatigue testing provides insights into the expected lifespan of the accessory and helps manufacturers refine their design or material selection for better longevity.

Accessories are tested under a range of environmental conditions to ensure they are capable of performing in various climates. This involves subjecting the product to:

• High and low temperatures to detect any thermal expansion or contraction issues.

• High humidity levels to simulate potentially adverse exposure conditions.

• Variations in pressure that could replicate rapid changes in playing environments.

Environmental testing confirms that the accessory does not lose its mechanical properties under stress, ensuring reliable performance even under extreme conditions.

Adherence to regulatory and industry standards is a critical part of the strength testing process. For example, while USAPA5 has specific regulations for paddle dimensions (such as the combined length and width including any edge guard and butt cap not exceeding 24 inches, and a paddle length not exceeding 17 inches), similar scrutiny is applied to all components to ensure they meet high quality and safety requirements.

Manufacturers not only follow established regulations but also stay ahead of emerging industry standards that influence testing practices. In the context of B2B procurement, understanding these guidelines is essential, as they directly impact both product certification and market acceptance.

When evaluating the strength and durability of pickleball accessories, consider the following factors:

-

Material Quality: Review the properties of material components such as carbon fibers (3K, 12K, T300), fiberglass, and core compositions like Nomex or polymer.

-

Manufacturing Process: Understand whether the accessory was produced using hot pressing, cold pressing, or thermoforming, as each provides distinct advantages and limitations in terms of strength and feel.

-

Testing Data: Look for verified test results indicating performance metrics such as impact resistance, fatigue life, and environmental stability. Well-documented test results enable comparisons against industry benchmarks.

-

Design and Ergonomics: Evaluate how design elements, such as the paddle handle length, grip design, and overall balance, contribute to the accessory's performance during real play conditions.

-

Compliance Certifications: Check if the product meets both international and regional safety standards. Adherence to recognized testing standards ensures that the accessory has passed essential quality checks.

These factors are part of a systematic evaluation process that can be supported by documented test reports and certifications from recognized testing authorities.

For manufacturers and distributors alike, making procurement decisions based on documented, data-driven testing results proves invaluable. Advanced testing procedures yield quantifiable results that can be compared across different product batches and manufacturing processes, ensuring consistency and predictability in performance.

Key benefits of a strong data-driven process include:

• Increased confidence in product performance under real-world conditions.

• Identification of potential areas for product design improvement.

• Enhanced negotiation power with suppliers and testing laboratories because of documented quality metrics.

• Ability to quickly adapt to new testing standards and regulatory changes, ensuring that products remain competitive and compliant.

Integrating testing data into the overall manufacturing and procurement strategy ensures that quality is maintained and continuously improved, ultimately leading to higher customer satisfaction and fewer product returns.

Strength testing standards for pickleball accessories are comprehensive and multifaceted. From material inspection to environmental conditioning, each phase of testing helps guarantee that products meet stringent performance and safety standards. For quality assurance managers and B2B buyers, understanding these protocols is essential for ensuring that every paddle, accessory, or related product can endure the high demands of competitive play.

By adhering to rigorous testing protocols1, manufacturers can improve product reliability and quickly identify opportunities for design optimization, further enhancing quality. The process not only reinforces regulatory compliance but also provides a measurable framework for long-term durability and performance assessment. Embracing these standards is crucial for both manufacturers and procurement professionals seeking to deliver high-performance pickleball accessories in a competitive marketplace.

• What are the standards for Usapa paddles?

The standards specify that the combined length and width, including any edge guard and butt cap, must not exceed 24 inches, while the paddle length is restricted to 17 inches. There is no specified limit for the paddle thickness.

• Is there a weight limit for pickleball paddles?

While there is no official weight limit imposed by the USAPA, most pickleball paddles used by amateur and professional players typically weigh between 7.2 oz (204g) and 8.5 oz (241g).

• How to evaluate a pickleball paddle?

Evaluating a pickleball paddle involves assessing the paddle shape, core material, face material, handle length, paddle weight, and grip fit relative to the player's hand size and play style.

-

testing protocols: Click to read more about standardized testing procedures that ensure product durability, safety, and regulatory compliance, aiding B2B buyers in assessing product quality. ↩ ↩ ↩2 ↩3

-

Nomex honeycomb: Click to learn about the characteristics of Nomex honeycomb, a specialized structural material known for its durability and lightweight properties in sports equipment manufacturing. ↩ ↩

-

3K carbon fiber: Click to understand the properties of 3K carbon fiber, its manufacturing process, and why its material strength is critical in the construction of high-performance sports accessories. ↩ ↩

-

Fatigue Testing: Click to explore fatigue testing methodologies that simulate long-term wear and tear, ensuring that sports accessories can withstand repetitive use under competitive conditions. ↩ ↩

-

USAPA: Click for details on USAPA regulations and standards, including dimensional guidelines and safety requirements for pickleball paddles and accessories in the industry. ↩ ↩