Smart factory1 technologies can drastically improve pickleball paddle manufacturing by integrating automation, IoT2, and digital transformation3 into production processes. These advancements lead to heightened production efficiency, consistent quality control, and significant cost savings for manufacturers.

In today’s competitive B2B marketplace, manufacturers of pickleball paddles face increasing pressure to optimize production while maintaining high quality standards. Traditional manual processes may hinder efficiency and lead to inconsistencies in product performance. With the rise of Industry 4.04 technologies, production managers now have innovative tools at their disposal to transform production lines. This article outlines the challenges in traditional pickleball manufacturing, explores the underlying causes, proposes smart and integrated solutions, and provides actionable steps to enhance your production process.

In many traditional manufacturing plants, production lines for pickleball paddles suffer from issues such as:

• Low production efficiency due to manually controlled processes.

• Inconsistent quality as each paddle may not be subjected to the same rigorous standards.

• Delay in detecting defects that could lead to larger quality issues downstream.

• High costs stemming from equipment downtime and maintenance inefficiencies.

These challenges are especially detrimental in the high-performance sports equipment sector where even slight flaws can impact paddle performance. Manufacturers need reliable processes that ensure maximum product consistency for both recreational use and high-level competition.

Several factors contribute to production issues in conventional pickleball manufacturing:

-

Manual Processes and Limited Automation:

Traditional production lines often rely on manual interventions. This can result in errors and inconsistent application of production techniques such as hot pressing, cold pressing, and thermoforming. Without automation, production rates tend to be lower, and quality control steps become more challenging. -

Lack of Data Integration:

In older setups, information about process parameters and machine performance is not integrated. This makes it difficult to perform real-time adjustments or address deviations immediately. The absence of IoT integration means that predictive maintenance and automated quality checks are seldom practiced. -

Process Inflexibility:

Manufacturing methods that involve complex procedures require precision in material handling and environmental control. Without digital tools to monitor these variables, production managers may struggle to achieve the balance between speed and quality consistency that competitive markets demand. -

Resource Intensive Maintenance:

Traditional equipment maintenance often occurs on a set schedule, rather than being driven by machine condition. This reactive approach leads to unexpected downtime and increased operational costs.

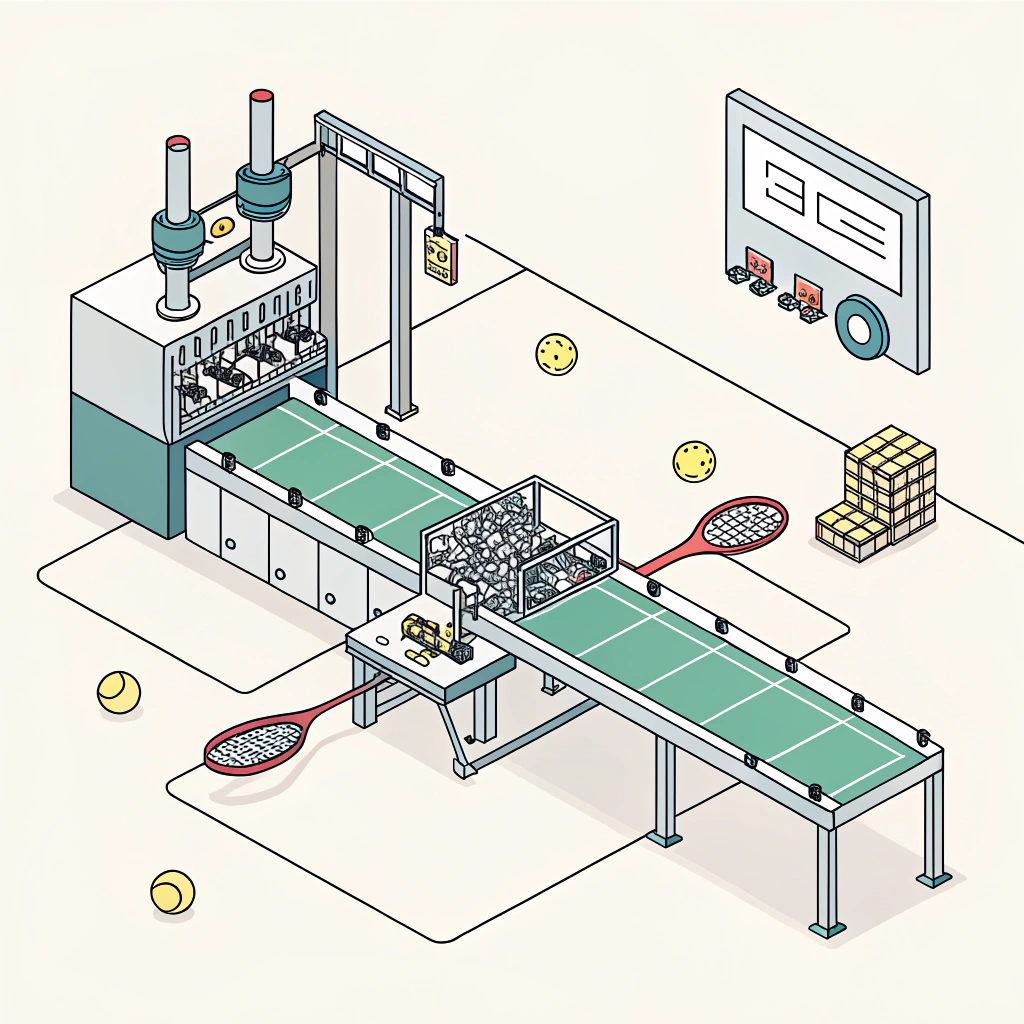

To overcome the identified challenges in pickleball manufacturing, companies should consider a comprehensive integration of smart factory technologies across the production process. The following solutions can serve as a roadmap for process transformation:

Automating production steps minimizes manual errors and ensures uniform application of advanced production techniques. By integrating sensors and IoT devices, manufacturers can monitor real-time metrics such as temperature during hot pressing, pressure in cold pressing, and material consistency in thermoforming. This not only improves production efficiency but also enables:

• Predictive Maintenance5: Sensors monitor equipment conditions to predict failures before they happen, reducing downtime and maintenance costs.

• Real-Time Quality Control: Continuous monitoring of process parameters ensures that each paddle meets strict specifications.

• Energy and Resource Optimization: Data-driven insights help optimize energy use and material allocation.

Implementing a digital transformation strategy involves integrating information systems into every part of the production process. Digital platforms can collect, analyze, and act upon data from manufacturing lines. Key benefits include:

• Enhanced Traceability: Digital records allow manufacturers to trace every paddle’s journey from raw material to final product, facilitating recalls if necessary.

• Process Adjustments: Instant feedback loops mean that operators can fine-tune process variables.

• Cost Control: Digital dashboards highlight areas where efficiency improvements are possible, leading to cost savings.

Leveraging advanced production techniques such as hot pressing, cold pressing, and thermoforming can be optimized through smart factory integration. Below is a comparison table illustrating key parameters across different production methods:

| Production Technique | Key Advantages | Limitations | Smart Enhancements Needed |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong, durable paddles | May alter material properties; high equipment cost | Temperature control sensors; automated clamping |

| Cold Pressing | Precise control over structure; retains material properties | Longer cycle times; requires exact pressure calibration | Integrated pressure sensors; digital pressure adjustment systems |

| Thermoforming | Capable of complex designs; improved material distribution | Longer production time; high mold costs | Real-time mold monitoring; adaptive heating controls |

With these enhancements, each production technique can be monitored and adjusted in real time using connected systems, ensuring that advanced production techniques lead to consistently high-quality paddles.

Quality control remains central to production efficiency. Implementing smart monitoring across production lines ensures that defects are caught early and resources are not wasted on rework. Smart quality control strategies include:

• Automated Visual Inspection: High-resolution cameras paired with AI algorithms inspect each paddle for surface irregularities.

• Data Analytics: Process data analytics identify trends and variations that may indicate underlying issues.

• Feedback Systems: Continuous feedback systems adjust machine parameters dynamically to ensure uniform quality.

No matter how advanced technology becomes, human oversight remains crucial. Training the workforce to understand digital dashboards and smart monitoring tools is essential. Empowered employees can leverage these systems to make informed decisions quickly, resulting in:

• Faster Troubleshooting: Well-trained staff can quickly interpret alerts and address issues before they escalate.

• Process Ownership: Operators feel more in control and are better able to maintain quality standards.

• Continuous Improvement: An engaged workforce is more likely to contribute ideas that lead to further process optimization.

NEX Pickleball has successfully integrated Smart Factory principles into its manufacturing process, emerging as a leader in high-performance pickleball paddles. By combining advanced production techniques such as hot pressing, cold pressing, and thermoforming with automation and digital monitoring, NEX Pickleball has achieved:

• Increased production efficiency by 30% through automated process adjustments.

• Improved quality control by integrating real-time data analytics across multiple production stages.

• Reduced maintenance downtime by employing predictive maintenance strategies through IoT sensors.

• Enhanced product consistency, ensuring that each paddle benefits from a uniform application of advanced materials like 3K, 12K, or T300 Carbon Fiber.

This approach has allowed NEX Pickleball to cater to both recreational players and competitive athletes, offering custom paddle options that meet a range of performance needs. The smart technology integration has not only streamlined production but also provided a scalable model for future growth.

To summarize, integrating smart factory technologies into pickleball paddle manufacturing can yield significant benefits:

• Enhanced production efficiency through automation and IoT integration.

• Improved quality control and product consistency using real-time digital monitoring.

• Cost reductions by minimizing downtime with predictive maintenance.

• Better resource optimization and adherence to advanced production techniques.

Manufacturers looking to remain competitive in the B2B marketplace should consider taking the following action steps:

- Assess current production methodologies and identify areas for digital integration.

- Invest in automation and sensor technologies that align with your production techniques.

- Train your workforce to confidently use digital tools for quality control and process adjustments.

- Regularly review data analytics from your smart systems to drive continuous improvement and innovation.

By following these steps, production managers can harness the potential of Industry 4.0 to drive efficiency, improve quality, and secure a competitive edge in the rapidly evolving sports equipment market.

Q: What companies make pickleball equipment?

A: Many prominent brands manufacture pickleball equipment, including JOOLA, Six Zero, Selkirk, Skechers, Engage, KSwiss, Gearbox, and Wilson. Each company brings its own unique approach to paddle design and production.

Q: What advantage does carbon fibre construction offer in a pickleball paddle?

A: Carbon fibre paddles are generally stiffer and more responsive compared to those made from other materials. This construction offers players greater power and precision, ensuring that every shot is executed with improved accuracy and stability.

Q: Where are engage pickleball paddles manufactured?

A: Engage Pickleball is manufactured in the United States, where the production process is managed internally. This ensures that all design and innovation processes are conducted by experienced engineers within the country.

-

[Smart factory]: Click to learn how integrating smart factory concepts can revolutionize manufacturing processes by leveraging automation and system connectivity to enhance efficiency. ↩

-

[IoT]: Click to understand the role of the Internet of Things in manufacturing, including how sensor integration enables real-time monitoring and data-driven maintenance. ↩

-

[digital transformation]: Click to discover how digital transformation strategies can streamline production, enhance traceability, and facilitate faster decision-making in industrial environments. ↩

-

[Industry 4.0]: Click to explore how Industry 4.0 transforms traditional factories into digitalized and interconnected production systems, supporting innovation and process optimization. ↩

-

[Predictive Maintenance]: Click to learn about predictive maintenance strategies that utilize data analytics and sensor monitoring to forecast equipment failures and reduce downtime. ↩