Quick Answer: On-site factory visits to Chinese pickleball paddle manufacturing facilities provide critical insights into production processes, quality control measures, and operational efficiency. These visits help procurement managers make informed decisions, mitigate supply chain risks, and foster stronger supplier relationships.

In today’s competitive sports equipment landscape, procurement managers need a deep and transparent understanding of the manufacturing processes behind the products they source. For companies sourcing pickleball paddles, on-site factory visits in China offer a unique opportunity to evaluate production capabilities, ensure adherence to quality standards, and build long-term trust with suppliers like NEX Pickleball. This article outlines the challenges in remote supplier evaluations, provides a step-by-step guide to maximizing factory visits, and presents actionable insights for enhancing supply chain resilience.

Problem Description

Procurement and operations managers often face significant challenges when relying solely on virtual assessments or third-party audits to gauge a supplier’s manufacturing capability. In the pickleball paddle industry, where precision, durability, and performance are critical, understanding the full context of production practices becomes essential. Many companies have encountered issues such as unexpected quality deviations or delayed shipments due to production bottlenecks that were not apparent from remote inspections.

Key challenges include:

- Uncertainty about the consistency of quality control processes.

- Limited visibility into material sourcing and production methods.

- Potential misalignment between reported capabilities and actual performance.

- Difficulty in evaluating the supplier’s commitment to continuous improvement and innovation.

These issues underscore the importance of direct engagement with your manufacturing partner through an on-site factory visit.

Why On-Site Visits Matter

On-site visits allow you to experience firsthand the production environment, assess technical capabilities, and interact directly with management and workers. Here are the primary reasons such visits are invaluable:

-

Enhanced Quality Control Verification

Observing production lines—whether it’s the hot pressing, cold pressing, or thermoforming processes1—lets you verify that the standards reported on paper match those on the ground. Each process, from the use of 3K Carbon Fiber2 to Nomex Honeycomb Core3 assemblies, requires strict quality checks that are best evaluated in person. -

Direct Communication for Relationship Building

Face-to-face meetings help create lasting professional relationships. They enable clearer communication, foster better mutual understanding, and cultivate an environment where suppliers are more transparent and accountable. This relationship-driven approach is critical for negotiating terms, handling unexpected issues, and planning joint innovation initiatives. -

Real-Time Risk Assessment and Mitigation

A factory visit provides the opportunity to identify potential production risks early on. For example, you can observe if production equipment is up-to-date, if environmental factors might affect production stability, or if workforce skill levels meet rising quality demands. Early detection of such issues allows for proactive risk management. -

Verification of Supply Chain Integrity

On-site assessments may reveal how well suppliers manage their own supply chains, including raw material sourcing and internal logistics. For instance, NEX Pickleball uses a variety of advanced materials, and understanding how these materials are handled can shed light on overall production reliability.

Reasons and Solutions: A Step-by-Step Factory Visit Guide

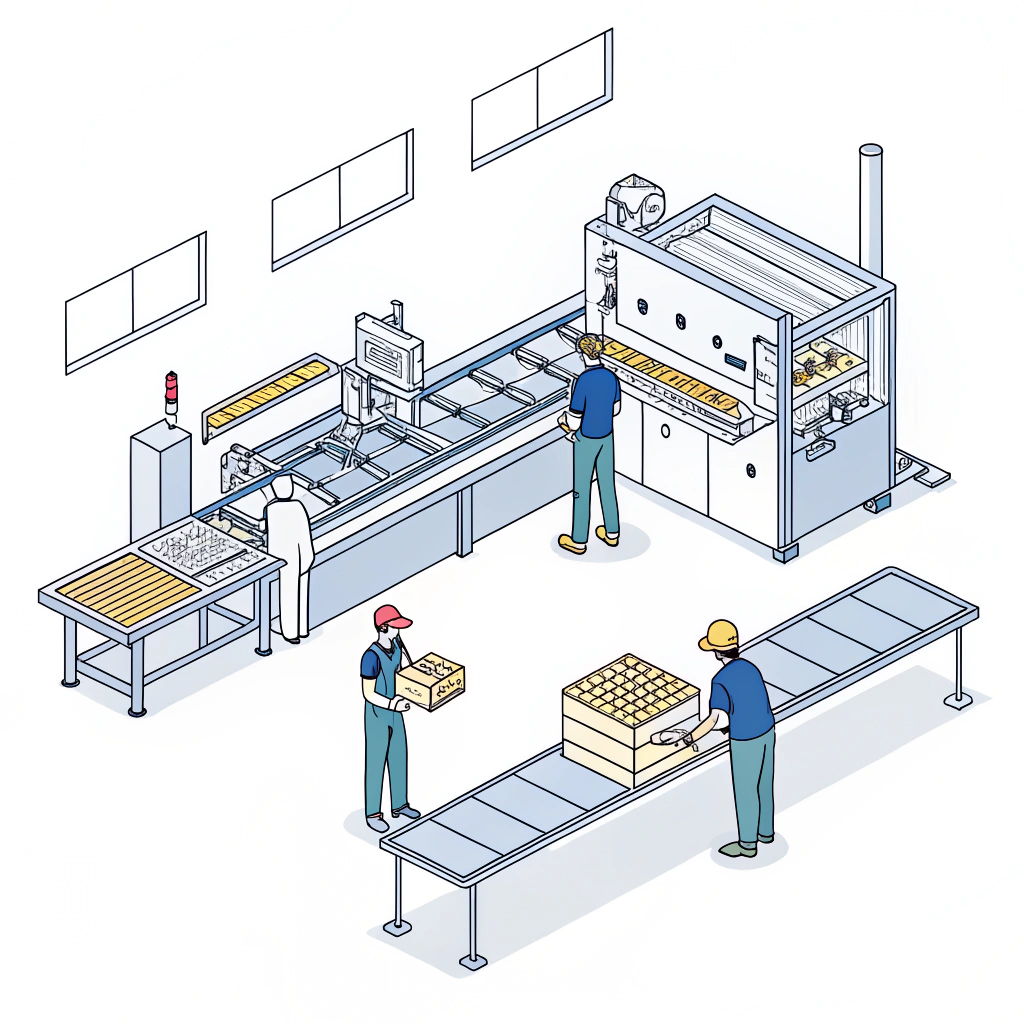

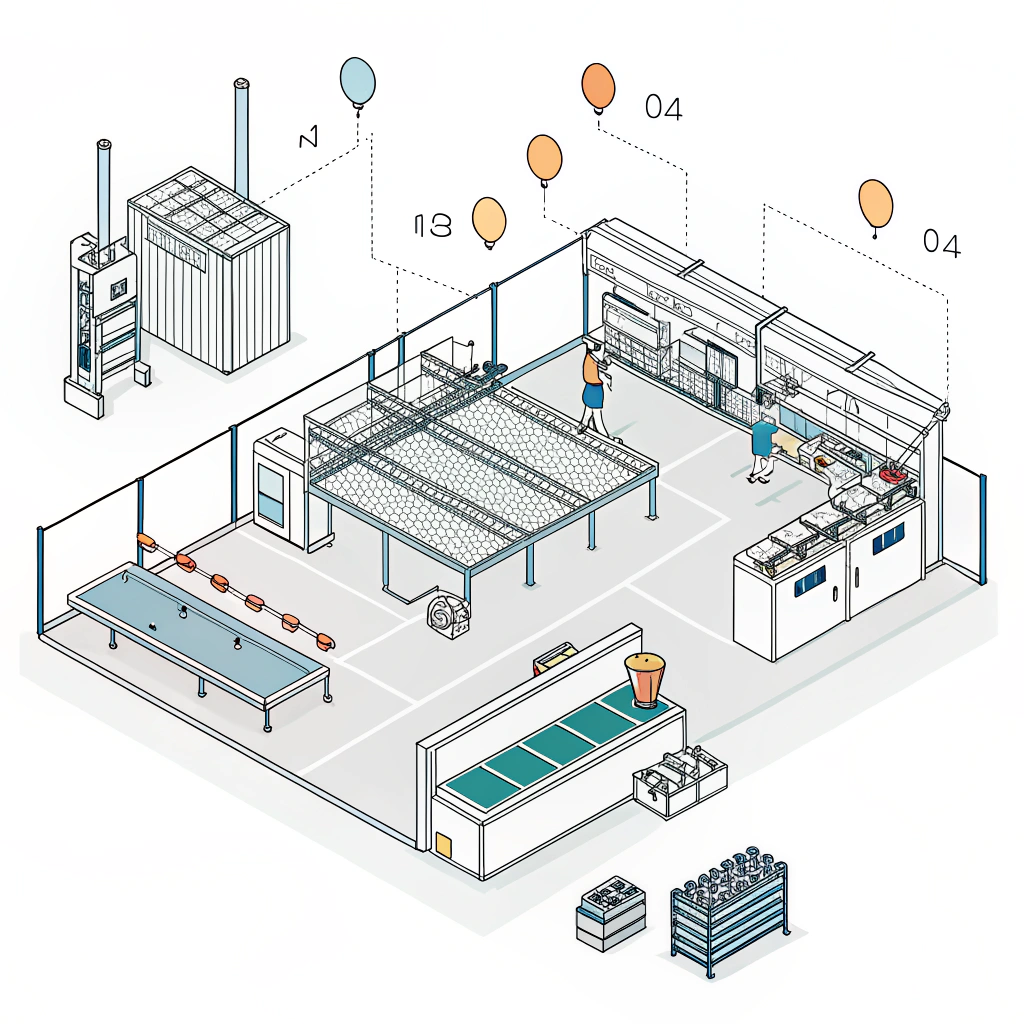

A systematic approach to on-site inspections can streamline the evaluation process and ensure you capture all the key details. Below is a checklist to guide your visit:

| Step | Action Item | Notes |

|---|---|---|

| Pre-Visit Planning | Define objectives and key performance indicators (KPIs) | Identify areas to scrutinize: quality control, production capacity, etc. |

| Establish a Visit Agenda | Schedule meetings with management and operations teams | Request detailed walkthrough of production stages |

| On-Site Production Walkthrough | Observe the different production processes: hot pressing, cold pressing, thermoforming | Verify material handling procedures, such as the application of T300 Carbon Fiber4 or E-Glass Fiberglass5 |

| Quality Control Evaluation | Inspect quality control areas, examine testing equipment, review inspection protocols | Look into how paddles are tested for impact resistance and performance consistency |

| Supply Chain and Material Sources | Check storage areas for raw materials and inventory management | Confirm the origin and quality of materials like carbon fiber composites |

| Safety and Compliance Check | Evaluate workplace safety measures and compliance with local regulations | Essential for long-term partnership sustainability |

| Post-Visit Review and Action | Gather feedback from your team, schedule follow-up calls, and document findings | Create an internal report for decision-making |

This checklist not only helps ensure that no detail is overlooked but also provides a clear record that can be revisited during supplier performance reviews.

Real-World Examples and Data Support

Several companies have successfully leveraged factory visits to drive operational improvements and cost saving. For instance, a leading sports equipment supplier noticed discrepancies in the production line during a factory visit which led to immediate changes in quality oversight. The result? A 20% reduction in quality-related complaints and improved production efficiency. Such examples highlight that the benefits of on-site evaluations extend beyond risk mitigation into tangible operational gains.

Key performance data collected during visits can include:

- Production output consistency

- Rate of defect occurrence

- Turnaround times for repairs and maintenance in production equipment

- Worker training and safety measures

This quantitative information is critical when weighing the trade-offs between the cost of the visit and the benefits derived from improved quality control and reduced defect rates.

Addressing Common Concerns

While the benefits of an on-site inspection are clear, concerns about cost and time investment often arise. Here are some points to consider:

-

Justifying the Investment

The travel, accommodation, and time expenses associated with factory visits can be significant. However, these costs should be weighed against the potential risks of poor product quality and supply chain disruptions. In many cases, the improved oversight and early detection of issues translate to substantial cost savings over time. -

Optimizing Visit Impact

A well-planned visit with a clear agenda ensures that every minute on the ground is valuable. This reduces the risk of time being wasted on redundant activities and facilitates meaningful dialogue between your team and the supplier. Detailed agendas and a structured checklist are key to deriving maximum value. -

Balancing Global and Local Perspectives

While remote management tools and digital audits provide useful information, they cannot fully replace the nuanced insights gained from a physical visit. Combining these tools with in-person assessments provides a balanced view of the supplier’s capabilities.

NEX Pickleball: A Case Study in Manufacturing Excellence

NEX Pickleball serves as a prime example of how on-site inspections can reveal the strengths of a manufacturer. As a leading maker of high-performance pickleball paddles based in Jiaxing, Zhejiang, China, NEX Pickleball utilizes advanced production techniques like hot pressing, cold pressing, and thermoforming to ensure superior quality and performance.

Key highlights include:

- Multiple advanced materials: The company works with various types of carbon fiber (3K, 12K, T300) to cater to different player needs, ensuring paddles offer both power and control.

- Diverse core materials: Ranging from Nomex and polymer honeycombs to bamboo cores, every production detail is optimized for durability and impact resistance.

- Strict quality control: Every paddle undergoes rigorous testing, with inspection checkpoints integrated throughout the production process to maintain exacting standards.

- Customization and innovation: On-site visits reveal the company’s willingness and capability to modify production lines for high-quality, custom paddle solutions.

The transparency observed during factory visits not only reassures buyers about quality but also builds long-term strategic partnerships. By witnessing the production process firsthand, procurement managers gain confidence in both the supplier’s process and the final product. NEX Pickleball’s investment in state-of-the-art production facilities and quality control systems has established them as a trusted partner in the global pickleball community.

Best Practices for an Effective On-Site Factory Visit

To further empower procurement managers with practical strategies, consider these best practices:

• Prepare in Advance

Conduct pre-visit research by reviewing past performance reports, quality audits, and any available customer feedback. This background knowledge enables you to ask targeted questions and focus on potential weak spots.

• Engage with Multiple Departments

Beyond management, spend time with workers on the production floor. Their insights on day-to-day operations can be invaluable. Ask about challenges they face and suggestions they might have to improve efficiency or quality.

• Utilize Digital Tools

Combine your on-site visit with digital data collection methods, such as video walkthroughs and real-time data gathering apps. This approach ensures that observations are documented accurately and can be reviewed by team members who could not attend in person.

• Follow-Up Actions

Post-visit, conduct debrief sessions with both your internal team and the supplier’s team. Share observations, ask for clarifications, and develop an action plan to address any issues raised. Such follow-ups not only improve immediate quality control but also set the stage for continuous long-term improvements.

Conclusion and Action Recommendations

Factory visits are not merely a formality; they are a strategic tool that delivers measurable improvements in quality control, operational efficiency, and relationship building. For senior procurement managers, the benefits of these visits extend far beyond initial product evaluation — they become an integral part of a comprehensive risk management and supplier engagement strategy.

In summary:

• An on-site visit allows you to verify production processes and quality control measures firsthand.

• It fosters transparent communication and builds trust between your company and your suppliers.

• Detailed checklists and structured agendas make your visit more efficient and productive.

• Real-time evaluations during the visit help identify and mitigate production risks before they impact operations.

• Companies like NEX Pickleball demonstrate how investments in production and quality controls result in products that meet the highest global standards.

We recommend scheduling regular factory visits as part of your overall supplier evaluation strategy. Consider them not as an isolated event but as a component of a continuous improvement cycle that benefits both your procurement operations and your supply chain stability.

Taking action on these insights can transform your supplier relationships, reduce operational risks, and help you secure the highest-quality pickleball paddles for your market.

People Also Ask

Q: What is the best pickleball paddle made in China?

A: While several manufacturers claim to produce top-tier pickleball paddles, companies like DinkPickleball have been recognized for their high-quality paddles, used by top players around the world. Their focus on advanced materials and trusted performance standards makes them a notable example from China.

Q: Where are Engage pickleball paddles manufactured?

A: EngagePickleball is a US-based manufacturer that handles every step of the paddle manufacturing process internally, emphasizing domestic design, innovation, and production to meet their quality standards.

Q: What is the best pickleball paddle manufacturer?

A: The best pickleball paddle manufacturers include reputed brands such as Joola, Selkirk, CRBN, and Gearbox. These companies offer a range of premium paddles with diverse designs and performance features that cater to competitive and recreational players alike.

-

Thermoforming processes: Click to explore how thermoforming processes shape materials through heat, and why understanding this is critical in modern manufacturing. ^Return ↩

-

3K Carbon Fiber: Click to read more about the properties and industrial applications of 3K Carbon Fiber, including its use in high-performance manufacturing environments. ^Return ↩

-

Nomex Honeycomb Core: Click to learn about the lightweight yet durable characteristics of Nomex Honeycomb Core, commonly used in advanced composite structures. ^Return ↩

-

T300 Carbon Fiber: Click to delve into the specifics of T300 Carbon Fiber, its performance benefits, and how it compares with other fiber variants. ^Return ↩

-

E-Glass Fiberglass: Click to discover the applications and advantages of E-Glass Fiberglass in reinforcing materials and ensuring product durability. ^Return ↩