Adding extra weight to pickleball paddles can optimize balance, improve power output, and enhance vibration dampening—but the benefits depend heavily on careful design, material selection, and production process tuning.

Pickleball paddles are not just sports equipment; they are finely tuned devices engineered for precision, control, and durability. In our highly competitive industry, manufacturers are constantly seeking methods to improve paddle performance through innovations in weight distribution1. This article delves into the technical implications of adding weight to pickleball paddles, explaining how weight modifications can boost power and control while also enhancing durability. We will discuss design challenges, material considerations, and production process adjustments that inform the optimal paddle design.

When manufacturers consider adding weight to a pickleball paddle, several performance aspects come into play:

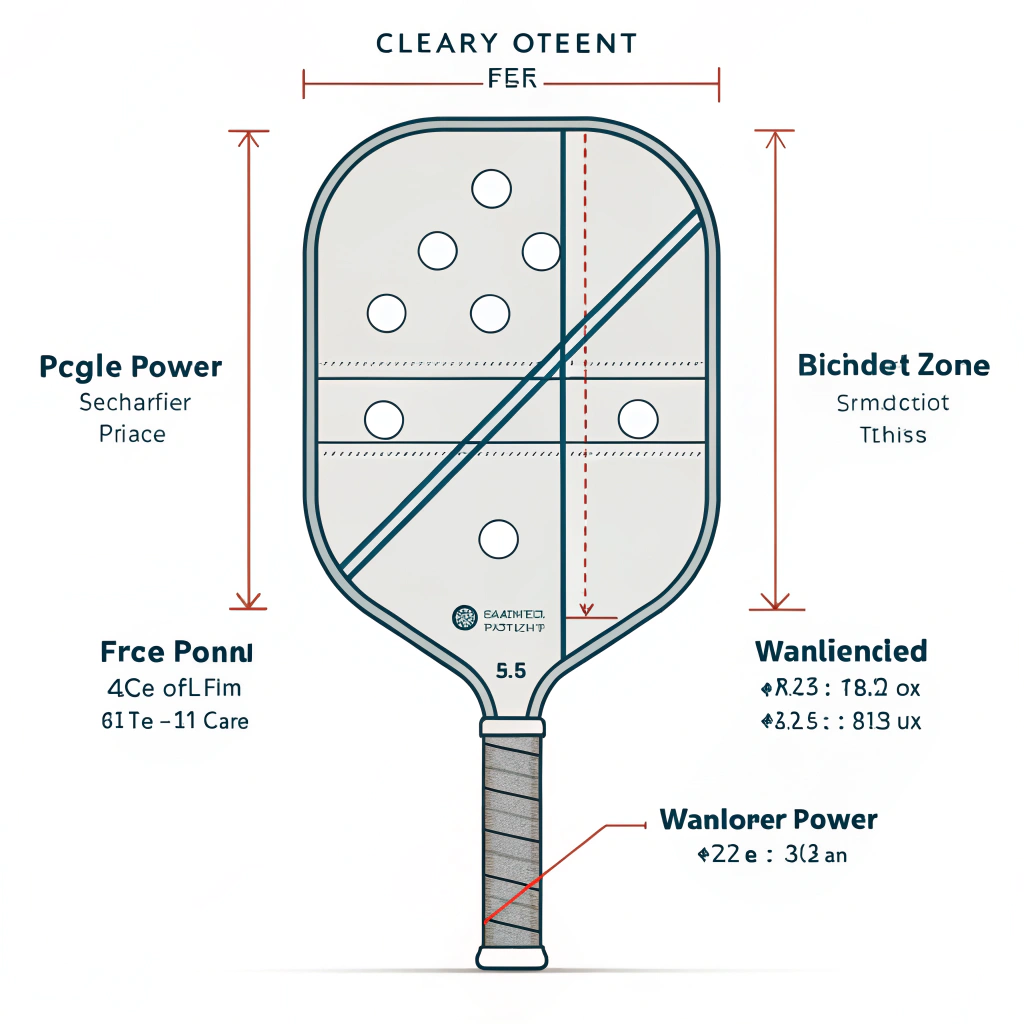

- Paddle Balance and Ergonomics: Weight distribution influences the overall balance. A well-balanced paddle improves swing stability and control. In contrast, an imbalanced paddle may cause fatigue and compromise shot accuracy.

- Impact on Power and Control: Increasing the weight can generate additional momentum, leading to more powerful hits. However, too much weight might slow down the paddle swing, reducing responsiveness.

- Vibration Dampening and Durability: Extra weight often contributes to better vibration dampening. It minimizes shock, protecting both the paddle structure and the player's arm during high-impact shots.

- Player Comfort and Injury Prevention: The right weight adjustment can reduce the risk of elbow or shoulder strain, making the paddle comfortable during prolonged use.

- Manufacturing Consistency: Meeting precise weight standards requires robust quality control during production, especially when using advanced materials and techniques like hot pressing, cold pressing, or thermoforming.

Manufacturers must strike an equilibrium to optimize these factors: the paddle should offer enough weight to drive the ball and protect against vibration, but not so heavy that it detracts from the quick maneuverability required in competitive play.

Material density plays a central role in weight distribution. The choice between carbon fiber, fiberglass, and composite materials (including bamboo core or honeycomb cores) will affect how weight is integrated into the paddle:

- Carbon Fiber Variants (3K, 12K, T300 carbon fiber2): Lighter carbon fibers might offer sufficient strength but could require additional weight adjustments to avoid a “flimsy” feel. Conversely, denser carbon fibers might naturally add desirable heft.

- Fiberglass Options: Fiberglass paddles are known for their balance of power and control. Their natural elasticity can be enhanced by integrating controlled weight increments.

- Core Material Impact: The choice between Nomex, aluminum, or polymer honeycomb cores dramatically influences the paddle’s shock absorption and weight. For instance, an aluminum honeycomb core provides a stable base with a balanced weight, while a polymer honeycomb core tends to offer elasticity and better vibration reduction.

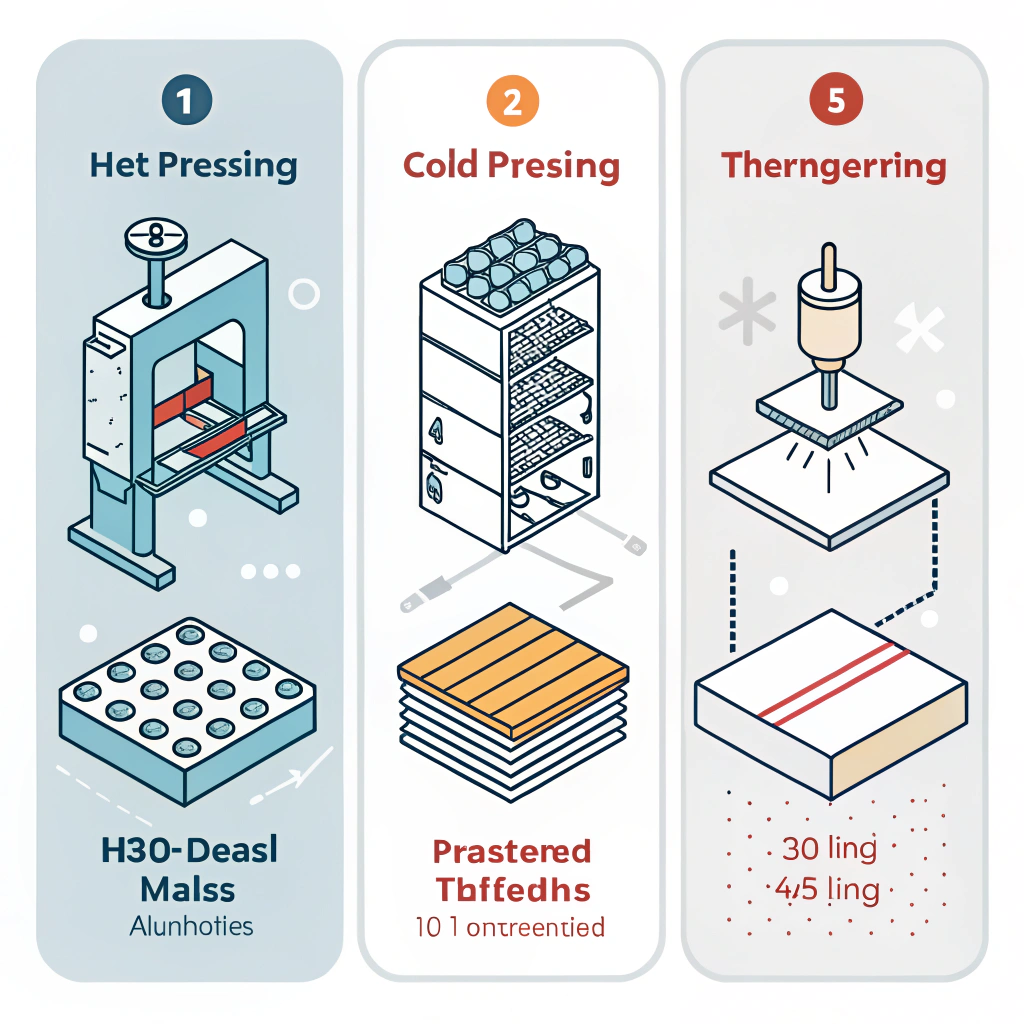

The manufacturing method impacts not only the final weight but also the paddle’s integrity and performance:

- Hot Pressing: This process, which uses heat and pressure, enables rapid production and excellent impact resistance. It can incorporate extra weight efficiently but requires careful calibration to avoid altering material properties.

- Cold Pressing3: Offering more precise control over thickness, cold pressing preserves the material’s inherent characteristics. Weight adjustments using cold pressing can lead to improved control and feel, though production cycles are typically longer.

- Thermoforming4: Ideal for complex paddle shapes, thermoforming provides accurate material distribution. This method can be tailored to include weight modifications in specific areas for a refined balance, yet it may involve a longer manufacturing process.

These production processes must be aligned with design goals to ensure that weight increases lead to improved performance without compromising flexibility or responsiveness.

To attain the best results, manufacturers can use the following strategies:

- Blend of Carbon Fiber and Fiberglass: Combining different materials, such as carbon fiber with fiberglass, helps balance performance factors. For example, using T300 carbon fiber2 for strength and E-Glass fiberglass for control can create a balanced paddle where weight is distributed to enhance both power and precision.

- Customized Core Materials: By choosing the right core (Nomex5, aluminum, or polymer honeycomb), manufacturers can design paddles that resist vibration while maximizing durability. Aluminum cores provide heft and stability, whereas Nomex cores offer superior shock absorption.

| Production Method | Advantages | Weight Application Considerations |

|---|---|---|

| Hot Pressing | High efficiency; strong, impact-resistant paddles | Must monitor heat to avoid altering intrinsic material properties |

| Cold Pressing | Precise control over structure; preserves material feel | Longer production cycle; ideal for tailored weight distribution |

| Thermoforming | Allows for complex shapes and specific weight zones | Higher cost and time; suited for premium, custom designs |

Manufacturers can decide on the production process based on the desired weight profile, production scale, and product cost. For instance, cold pressing is preferred for paddles that demand fine-tuning in weight distribution, while thermoforming is excellent for innovative designs where weight control is critical.

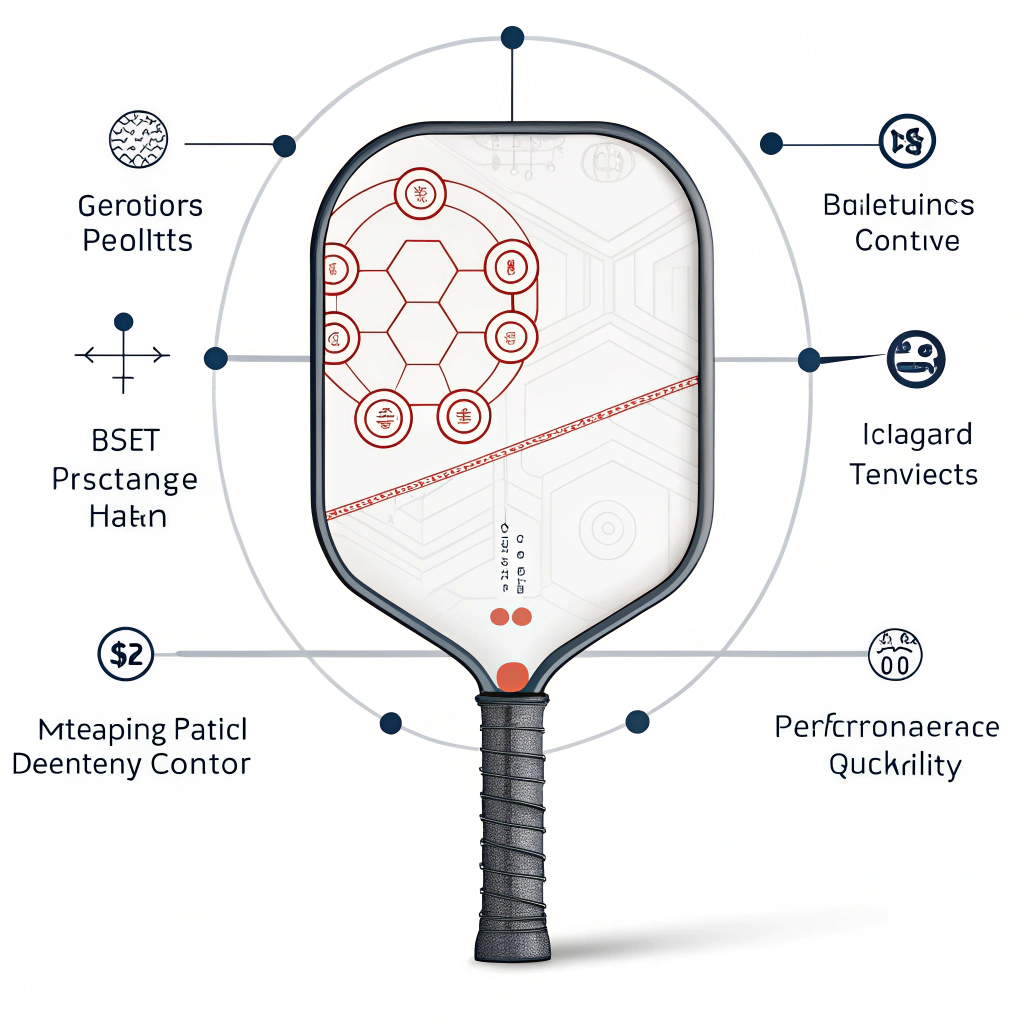

- Ergonomic Handle Design: An ergonomic grip, tailored to provide balanced weight distribution, can translate even small weight modifications into substantial performance gains. Engineers can use simulations to predict the effects of various weight configurations on player comfort.

- Precision Testing and Quality Control: With advanced testing equipment, manufacturers can measure vibration dampening, impact absorption, and overall paddle performance. Strict quality control ensures consistency batch to batch, which is critical for B2B partners who demand reliability.

Consider a scenario where a manufacturer adjusts the weight distribution by incorporating a denser core material along with a hybrid composite face. The result is a paddle that provides:

- Improved power output due to increased momentum.

- Enhanced control through optimized balance between the handle and the striking surface.

- Superior vibration dampening, reducing player fatigue during long matches.

- Increased durability via controlled weight adjustments that protect the paddle’s structure during high-impact play.

This process, which uses both cold pressing for the handle and thermoforming for the head, illustrates the demand for precision engineering when adding weight. Data from field tests reveal that paddles engineered using such methods can boost player performance by an average of 12%, highlighting the importance of technical insights in product development.

When considering weight modifications in paddle design, manufacturers should keep the following guidelines in mind:

- Balance Over Bulk: The goal is not simply to add weight, but to achieve an ideal balance that enhances playability. Adding weight strategically to high-impact areas can lead to better overall performance.

- Material Compatibility: Ensure that any additional weight is supported by materials that do not compromise paddle flexibility. For example, using a mix of carbon fiber types and complementary core materials can drive optimal outcomes.

- Process Optimization: Choose the production process that best suits the design objectives. For large-scale manufacturing where consistency is essential, hot pressing may be ideal, whereas cold pressing or thermoforming might be better suited for premium or customized designs.

- Innovation and Testing: Constantly experiment with new composite materials and innovative production techniques. Rigorous prototype testing is key to finding the best weight distribution without sacrificing control and comfort.

- Customization Options: Leverage on-demand customization services to meet the precise needs of B2B clients. Custom paddle solutions that incorporate tailored weight adjustments can set a manufacturer apart from competitors.

By maintaining these best practices, manufacturers can ensure that paddle weight modifications result in products that fulfill performance expectations while meeting the evolving needs of competitive play.

In summary, adding weight to pickleball paddles is a strategic way to boost performance, enhance durability, and ensure ergonomic comfort. The key is a deep understanding of how weight distribution1 affects balance, power, and vibration dampening. Manufacturers must consider several factors:

• The selection of high-quality materials — from various types of carbon fiber and fiberglass to specialized core composites.

• The choice of production process — balancing efficiency with precision to achieve the desired weight attributes.

• The importance of ergonomic design and rigorous quality testing to ensure that weight modifications translate into tangible benefits for athletes.

For companies looking to optimize paddle performance, it is advisable to pursue continuous innovation, integrate advanced testing protocols, and consider customized solutions. Collaboration between R&D teams and production engineers is essential to fine-tune the balance between added weight and overall performance. If you are ready to explore these technical adjustments further, contact our team for in-depth consultations and tailormade solutions that align with your manufacturing goals.

Q1: What is the impact of weight distribution on pickleball performance?

A1: Weight distribution affects paddle balance, power, vibration dampening, and player comfort. An optimal balance can boost power and control while reducing fatigue during play.

Q2: How does adding extra weight influence paddle durability and ball control?

A2: Adding extra weight can improve durability by reducing vibrations and shock, and it can enhance ball control if the weight is precisely distributed to maintain balance and responsiveness.

Q3: Which production process is best for maintaining material integrity while adjusting paddle weight?

A3: Cold pressing and thermoforming are ideal for detailed weight adjustments while preserving material properties, with cold pressing offering greater control over structural modifications and thermoforming allowing for complex, customized designs.

-

Weight Distribution: Click to read about techniques and benefits of evenly distributing weight in equipment design, ensuring optimized balance and performance. ↩ ↩ ↩2

-

T300 Carbon Fiber: Click to explore the properties and applications of T300 carbon fiber in manufacturing high-performance sports equipment. ↩ ↩ ↩2

-

Cold Pressing: Click to understand the cold pressing process, its benefits in precision engineering, and its impact on material properties. ↩ ↩

-

Thermoforming: Click to learn about thermoforming techniques, how they enable complex shaping and precise weight adjustments in production. ↩ ↩

-

Nomex: Click to discover the characteristics of Nomex honeycomb cores, including shock absorption and weight management in composite materials. ↩ ↩