Pickleball paddles designed for high performance typically benefit from innovative materials and optimized manufacturing techniques. In short, carbon fiber1, especially when paired with advanced manufacturing like cold pressing2 or thermoforming3, often stands out as the best overall choice for premium pickleball paddle4, balancing strength, playability, and durability.

In today’s competitive sports equipment market, procurement managers and product developers must make informed decisions when selecting materials and manufacturing processes for pickleball paddles. This article provides a comprehensive comparison of various pickleball paddle materials—such as different grades of carbon fiber, fiberglass, and composite structures—and manufacturing techniques including hot pressing, cold pressing, and thermoforming. Our goal is to detail the technical merits and trade-offs to help you choose the best solution for your business needs.

Producing a high-performance pickleball paddle is more than just assembling components. The choice of materials directly affects a paddle’s weight distribution, control, rebound, and overall durability. The manufacturing process further influences these properties by either enhancing material performance or introducing trade-offs.

-

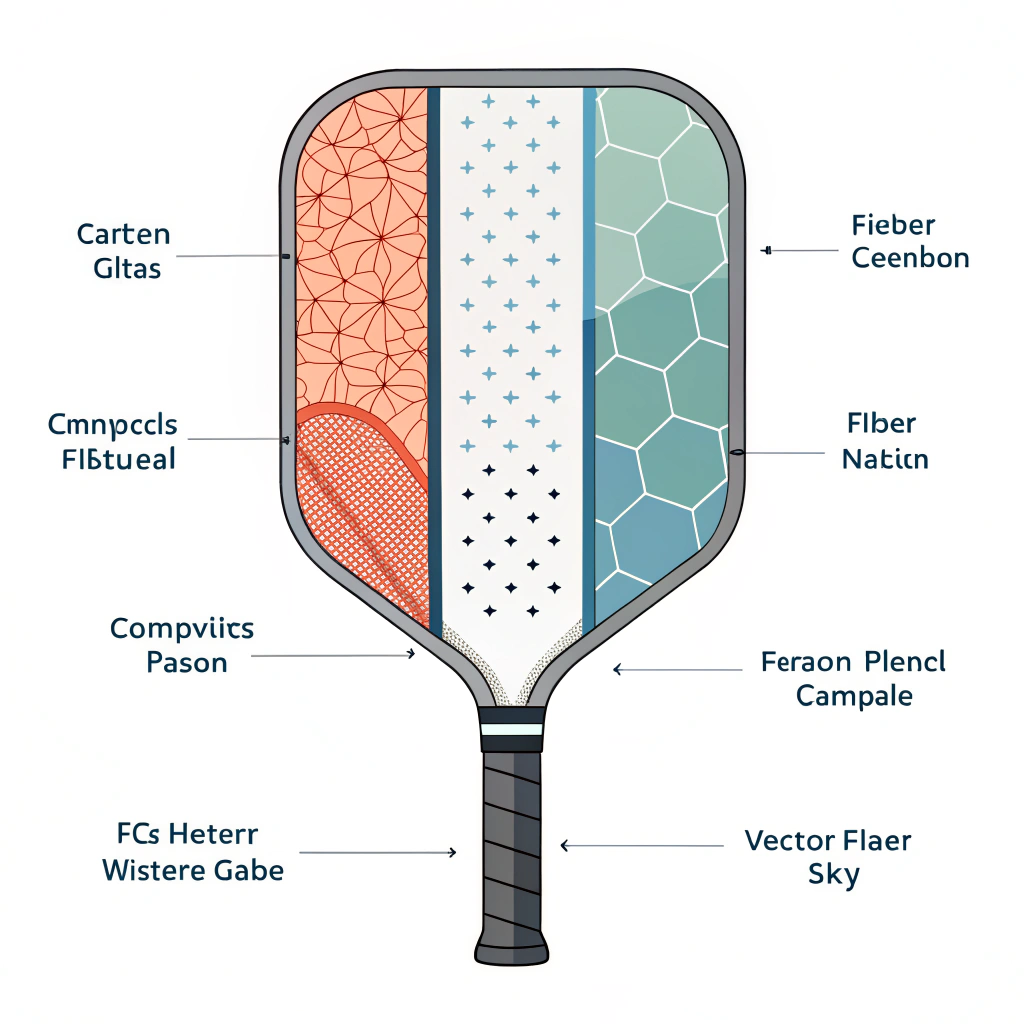

Carbon Fiber (3K, 12K, T300):

Renowned for its strength and light weight, carbon fiber is engineered to reduce vibration and maximize rebound force. Different types are used:- 3K Carbon Fiber: Offers flexibility and durability, reducing vibration during play.

- 12K Carbon Fiber: Provides a smoother surface and greater hardness, ideal for competitive play.

- T300 Carbon Fiber: Balances lightweight properties with high tensile strength.

-

Fiberglass (E-Glass):

This material balances power with enhanced control due to its elasticity. It is typically used when a larger sweet spot and excellent ball control are needed. -

Composite Materials:

Composite paddles often combine the strengths of carbon fiber and fiberglass, or integrate unique cores such as bamboo, honeycomb, or polymer, to achieve both power and comfort.- Carbon Fiber & Fiberglass Composite: Merges the attributes of both materials to produce a paddle that is strong yet flexible.

- Bamboo Core Composite: Increases impact resistance while keeping the paddle light.

- Nomex honeycomb core5: Each variant offers distinct benefits from shock absorption to enhanced control.

-

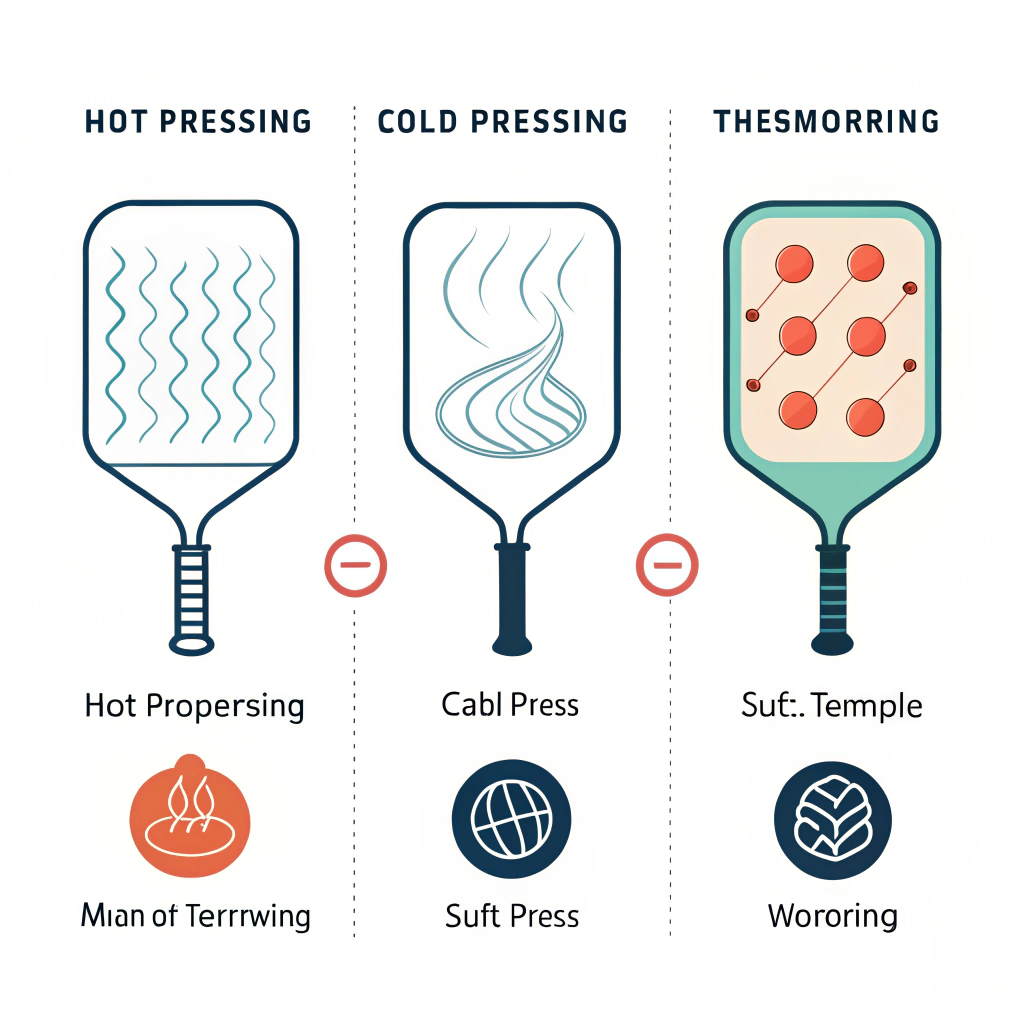

Hot Pressing:

Efficient for large-scale production, this process involves applying heat and pressure to form the paddle structure. It results in robust paddles but may slightly alter material properties, impacting tactile performance. -

Cold Pressing:

By shaping materials under mechanical pressure at room temperature, cold pressing provides precise control over the paddle’s internal structure, preserving material properties and delivering an excellent ball feel. -

Thermoforming:

Heating materials to a soft state and then molding them allows for intricate designs and well-distributed material. Although it requires longer production cycles and higher costs, it is best suited for premium, custom-made paddles.

To help you evaluate the options, consider the technical breakdown below:

| Material Type | Key Benefits | Performance Metrics | Typical Use Cases |

|---|---|---|---|

| 3K Carbon Fiber | High flexibility and vibration control | Moderate rebound, durable | Recreational to competitive paddles |

| 12K Carbon Fiber | Smoother surface and enhanced hardness | High rebound, superior durability | High-level competitive play |

| T300 Carbon Fiber | Balanced strength and weight | Lightweight yet strong | Precision play in competition |

| E-Glass Fiberglass | Excellent elasticity and extended sweet spot | Enhanced control, flexible | Entry-level to mid-range paddles |

| Composite (Carbon-Fiberglass) | Combines benefits of carbon fiber and fiberglass | High power with controlled responsiveness | Versatile range of play styles |

| Bamboo Core Composite | Lightweight with excellent impact resistance | Clear hitting feel | Long-lasting recreational paddles |

| Nomex Honeycomb Core | Superior shock absorption and stability | Stable performance, enhanced durability | High-performance paddles for pros |

| Aluminum Honeycomb Core | Balanced weight for power and control | Even weight distribution | Competitive play requiring precision |

| Polymer Honeycomb Core | Improved elasticity and reduced vibration | Comfortable hitting experience | Recreational players and beginners |

This table summarizes the key benefits and metrics of each material, providing a direct comparison to help in procurement decisions. Notice that carbon fiber types are favored for their unmatched strength-to-weight ratio and consistency in high-level performance.

Understanding the nuances in manufacturing provides additional context for the material selection process. Below is a detailed look at the three production processes:

| Production Technique | Advantages | Disadvantages | Recommended For |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Strong impact resistance | - May change some tactile properties - High equipment costs | Mass production of robust paddles |

| Cold Pressing | - Precise control over thickness and structure - Maintains material integrity leading to superior control | - Slower production cycles - Requires precise equipment control | Custom, high-precision paddles |

| Thermoforming | - Enables intricate designs - Precise material distribution | - Longer production times - Higher manufacturing cost | Premium products and bespoke orders |

When determining the optimal production process, it is important to weigh throughput against quality. For businesses that require consistent quality with high production volumes, hot pressing may be a viable option. However, if the priority is maintaining the full range of material properties—thereby offering enhanced control and feel—cold pressing or thermoforming may be better suited despite higher costs and longer cycles.

For procurement managers and B2B product developers, the decision matrix extends beyond simply choosing the strongest material. Additional factors include production cost, expected lifespan, and the target market segment’s preferences.

-

Material Performance vs. Durability:

- Carbon fiber variants (especially 12K and T300) excel in performance. However, their cost is higher. Evaluating game intensity levels and typical usage frequency is essential.

- Fiberglass is more flexible and cost-effective, but may not provide the same enhanced performance at high competition levels. It is ideal for wider recreational markets.

-

Manufacturing Efficiency:

- For large-scale production aimed at retail distribution, hot pressing offers cost efficiency and high durability.

- For custom orders or high-end products, where exceeding customer expectations is critical, cold pressing and thermoforming are preferable despite lower throughput.

-

Core Material Selection:

- Nomex honeycomb cores offer robust shock absorption for players in intense, competitive environments.

- Polymer cores provide a comfortable hitting experience, appealing to recreational markets seeking control and reduced vibration.

- Aluminum cores strike a balance between the two, suitable for players looking for a blend of precision and power.

Imagine a sports equipment distributor aiming to introduce a premium line of pickleball paddles. They target professional leagues and competitive amateurs. In this scenario, selecting 12K carbon fiber for the face and a Nomex honeycomb core could yield a product that delivers high impact resistance and consistent ball response. Using cold pressing, the manufacturer can guarantee precision in paddle thickness and surface treatment, which is essential for a product marketed as high-performance equipment.

For contrast, a distributor serving community centers and recreational sports clubs may opt for E-Glass Fiberglass combined with a polymer honeycomb core. The slightly higher flexibility and lower cost allow the paddles to be produced in larger quantities, while still ensuring a satisfactory playing experience for less intense use.

A final decision should integrate these material and process distinctions with additional considerations of price, anticipated production volume, and market segment.

When selecting the optimal pickleball paddle solution, procurement managers should strategically address the following technical guidelines:

- Performance Metrics: Prioritize materials that deliver quantifiable benefits such as rebound rate, shock absorption, and vibration reduction.

- Cost-Benefit Analysis: Determine whether the performance gains of premium materials, like T300 or 12K carbon fiber, justify the potentially higher production and material costs.

- Production Scalability: Understand the trade-offs between methods such as hot pressing (ideal for high volume) and cold pressing (ideal for performance). Materials may behave differently under each process; hence, sample testing is crucial.

- Customization Needs: For businesses looking to offer customized paddles (e.g., branded or tailored performance specifications), processes that allow for design variations such as thermoforming should be considered.

- Quality Control: Ensure that every paddle undergoes rigorous testing to validate consistency in performance, regardless of the production process. This is critical for maintaining a trusted brand reputation in the marketplace.

By using these guidelines, procurement professionals can confidently weigh the merits of each material and process, ensuring that the final product meets both market expectations and performance benchmarks.

People Also Ask

Q: What is the best pickleball paddle material?

A: Experts generally recommend carbon fiber for pickleball paddles due to its superior strength, reduced vibration, and excellent impact resistance, which combine to offer enhanced performance in competitive play.

Q: Which is better wood or polypropylene pickleball paddle?

A: While wood paddles tend to be heavy and basic, modern refinements using composite materials such as polymer cores provide a lighter feel and better control. Polymer stands out as the most popular choice, combining performance efficiency with a quieter, more controlled play experience.

-

carbon fiber: Click to read more about advanced composite materials, their manufacturing benefits, and how they enhance performance in sports equipment. ↩

-

cold pressing: Click to explore the process of cold pressing, which preserves material integrity and ensures precise structural control. ↩

-

thermoforming: Click to learn about thermoforming, a manufacturing technique that allows intricate design and optimal material distribution. ↩

-

pickleball paddle: Click for an in-depth overview of pickleball paddle design, performance factors, and manufacturing innovations crucial for B2B procurement. ↩

-

Nomex honeycomb core: Click to discover how Nomex honeycomb cores provide superior shock absorption and durability, ideal for high-performance sports equipment. ↩