Quick Answer: To avoid pitfalls when sourcing pickleball products online, procurement managers should evaluate supplier credibility by checking certifications, production processes, quality control measures, and by looking for red flag indicators such as vague product descriptions, inconsistent compliance data, and unclear warranty policies.

In today’s competitive sports equipment market, ensuring that your sourcing decisions align with high-quality standards and regulatory compliance is paramount. With the rapid rise in demand for pickleball products, procurement managers must be vigilant and methodical in identifying red flags when purchasing online. This article explains the common pitfalls in online sourcing of pickleball products and offers a comprehensive checklist to guide your due diligence process.

When sourcing pickleball paddles and equipment online, there is an inherent risk of receiving products that do not meet quality or regulatory standards. Some suppliers may offer counterfeit items, misrepresent certifications, or use substandard materials. Issues such as inconsistent product descriptions, lack of transparent quality control processes, or unclear production methodologies can lead to significant operational and financial losses. Moreover, with evolving consumer protection regulations and industry standards, picking a credible supplier has never been more critical.

Procurement managers, particularly those operating in B2B environments, must balance the pressures of cost-effectiveness with the guarantee of performance and reliability. The consequences of a misstep can not only impact immediate inventory needs but also tarnish the reputation of retailers or sports organizations relying on these products.

Supplier red flags can arise from several sources, each impacting your procurement decision on a fundamental level:

-

Quality Control Inconsistencies: Inadequate quality control often results from outdated production methods or poorly maintained manufacturing facilities. Suppliers that do not provide clear information on their production techniques, such as hot pressing1, cold pressing2, or thermoforming3, may be hiding underlying quality issues.

-

Certification and Compliance Ambiguities: Reputable suppliers rigorously verify their products through industry-standard certifications. When producers lack visible, verifiable certification—such as those associated with USA Pickleball-approved equipment4—the risk of receiving non-compliant products increases.

-

Transparency in Material Composition: Pickleball products often incorporate advanced materials like 3K carbon fiber5, 12K carbon fiber, T300 carbon fiber, and various composite materials. Suppliers must clearly disclose the types and quality of these materials so procurement managers can assess long-term durability and performance.

-

Misleading Online Information: Online channels sometimes contain exaggerated product claims or testimonials that are not backed by technical specifications. This practice can lead to significant discrepancies between advertised and actual product performance.

Understanding these causes not only clarifies what to avoid but also helps shape a robust framework for due diligence when evaluating potential suppliers.

When evaluating a supplier online, it is essential to follow a structured approach. Below is a checklist that provides a systematic guide to identifying potential red flags:

| Checklist Item | Key Questions to Ask | Red Flag Indicators |

|---|---|---|

| Supplier Credibility | - Is the supplier a recognized manufacturer? | - Vague company history or no verifiable business info |

| - Do they have longstanding industry partnerships? | - Inconsistent or outdated certifications | |

| Quality Control Measures | - What production processes are used (hot pressing, etc.)? | - Lack of detailed production process description |

| - Are there quality testing protocols in place? | - Missing independent testing reports | |

| Certification Verification | - Are their products certified by industry standards? | - No references to regulatory bodies or certification logos |

| - Do they display approvals from relevant sports organizations? | - Uncertainty regarding product approval and warranties | |

| Material Transparency | - What materials and core types are used in the product? | - Generic descriptions without technical details |

| - Is there documentation on the use of carbon fibers, composites, etc.? | - Lack of material specification analysis | |

| Warranty and After-Sales Support | - What warranty terms are provided? | - Ambiguous warranty conditions or after-sales service lacking clarity |

| - How responsive is the supplier to customer inquiries? | - Poor customer support or no clear escalation process |

Following this checklist can help B2B procurement professionals make informed sourcing decisions by systematically eliminating risks.

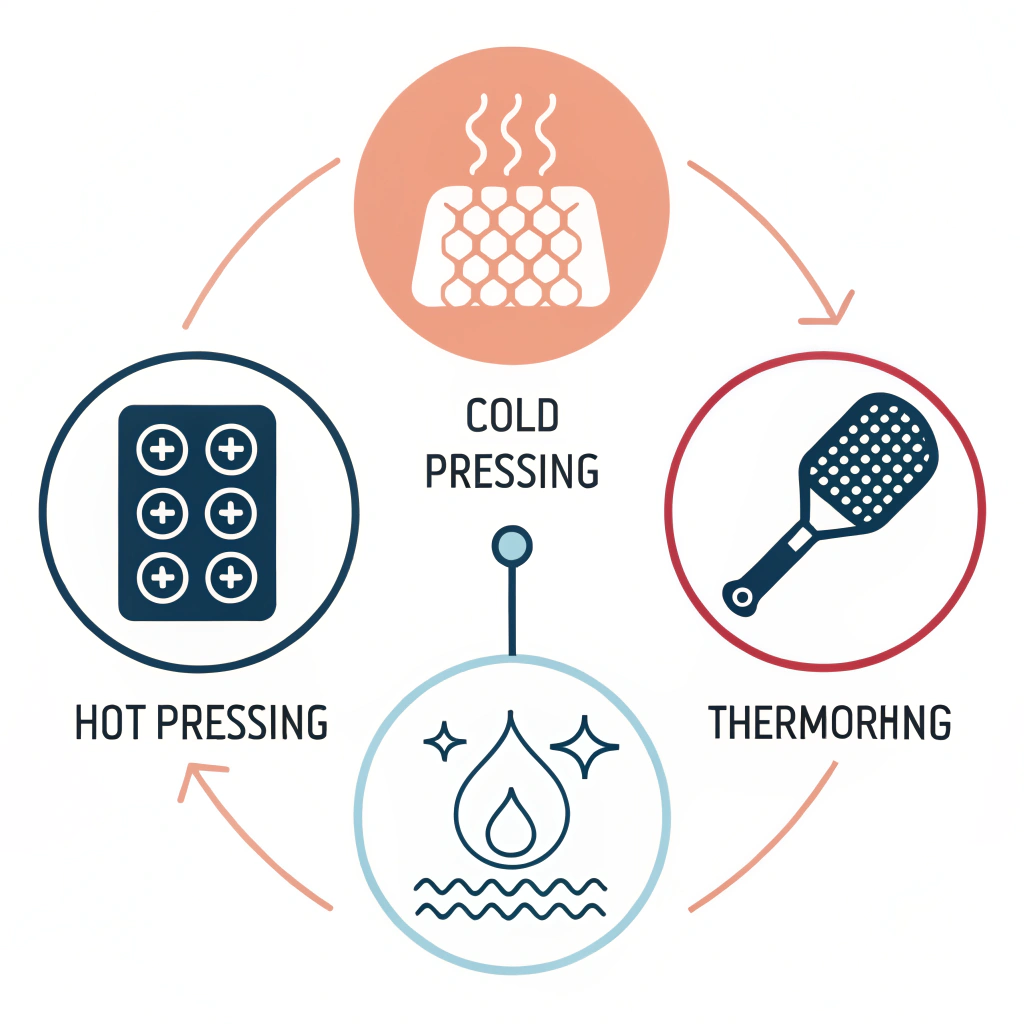

At the core of every high-performance pickleball paddle lies a strong, well-defined production process. Understanding the differences between various methods helps elucidate potential areas where quality may be compromised:

This process involves the application of heat and pressure to form the paddle, effectively ensuring strong impact resistance and structural integrity. However, if the process is not carefully controlled, it might alter material properties, leading to a less optimal playing feel.

- Advantages:

- Achieves high production efficiency.

- Provides strong, durable paddles.

- Disadvantages:

- Requires significant investment in high-end equipment.

- Possibility of altering the paddle's intended tactile properties.

Cold pressing is renowned for maintaining the intrinsic properties of paddle materials, providing excellent ball control and precise thickness control. Its longer production cycle and need for precision can pose challenges for large-scale production.

- Advantages:

- Superior control over paddle thickness.

- Maintains the original material integrity for better play performance.

- Disadvantages:

- More time-consuming production cycles.

- Demands high-quality pressure controlling equipment.

This technique involves heating materials to form complex shapes with uniform material distribution. It is particularly useful for premium products but comes with higher equipment and production time costs.

- Advantages:

- Allows the creation of intricate designs.

- Supports consistent performance due to thorough material distribution.

- Disadvantages:

- Longer production cycles.

- Higher costs, making it best suited for custom or premium products.

Suppliers that offer detailed insights into their production processes usually demonstrate higher reliability. Always request production process documentation and quality control certifications when evaluating suppliers.

Compliance is a critical aspect of B2B procurement, and genuine certification acts as a guarantee of quality and adherence to industry standards. Key certifications and approvals might include regulatory lab tests, industry organization endorsements (such as USA Pickleball), or detailed third-party assessments. These certifications not only validate the product’s quality but also confirm that the manufacturer’s production processes meet the required industry standards.

- Request Documentation: Ask suppliers to provide copies of all relevant certifications and testing reports.

- Cross-Check Information: Verify provided certifications through official regulatory bodies or industry websites.

- Look for Standard Logos: Ensure that websites contain clear, verified certification logos and that these logos correspond to actual approvals.

- Inquire About Warranty and Recourse: Confirm that the supplier offers clear warranty policies and after-sales support in case of compliance-related issues.

By following these steps, procurement managers can significantly reduce the risks associated with potential non-compliance and counterfeit products.

When conducting due diligence, it is important to be able to spot obvious signs of potential supply risks. Common red flag indicators include:

- Inconsistent Product Descriptions: Ambiguities in material specifications such as vague mentions of “high-quality carbon fiber” without a clear type (e.g., 3K, 12K, or T300) are cause for concern.

- Lack of Transparency: Suppliers who do not disclose details regarding their production processes, or who avoid discussing their quality control measures, may be trying to hide subpar manufacturing practices.

- Unverified Certifications: Any absence or reliance on self-declared certifications, rather than those endorsed by independent and reputable organizations, should raise a red flag.

- Poor Communication: Delays in responses or unsatisfactory answers to critical quality inquiries often indicate potential problems with supplier reliability.

Addressing these red flags early in your sourcing process can prevent ineffective procurement decisions and long-term operational setbacks.

A thorough due diligence process not only protects your business from quality and compliance risks but also contributes to building long-term relationships with reputable suppliers. Here are the core benefits:

- Improved Product Quality: Ensuring that you source from reliable suppliers guarantees that your customers receive high-performance, durable pickleball products.

- Cost Efficiency: Avoiding investments in substandard products results in less frequent replacements and lower warranty claims, ultimately leading to significant cost savings.

- Brand Reputation: Partnering with trusted suppliers enhances your company’s brand reputation over time. It signals to your customers that your products meet high quality and compliance standards.

- Risk Mitigation: Proper due diligence minimizes risks related to recalls, legal challenges, and potential liability issues associated with non-compliant products.

Implementing a streamlined, data-driven process of evaluating supplier quality can set the stage for sustained operational excellence and market competitiveness.

Here are some practical steps to enhance your sourcing strategy:

- Develop a Standard Evaluation Template: Utilize checklists similar to the one provided above, tailored to fit the unique requirements of your pickleball product portfolio.

- Engage in Direct Communication: Schedule video or phone conferences to discuss production processes in detail. This direct engagement can often clarify any ambiguities.

- Request On-Site Audits: Whenever possible, arrange for an independent audit of the supplier’s manufacturing facilities. This practice can uncover potential issues that might not be visible through online interactions alone.

- Monitor Customer Feedback and Reviews: Look for patterns in customer feedback regarding product performance and quality. This information, combined with your internal evaluations, provides a more comprehensive supplier assessment.

- Stay Updated on Industry Standards: Regularly review industry updates and regulatory changes related to pickleball products. This proactive approach ensures that your sourcing criteria remain aligned with the latest quality and compliance benchmarks.

By integrating these recommendations into your procurement process, you can create a robust framework that not only mitigates risks but also fosters strategic, long-term supplier partnerships.

In the fast-paced and ever-evolving world of pickleball, making informed procurement decisions is more important than ever. By understanding the potential pitfalls in online sourcing—from ambiguous product descriptions to unreliable certifications—and by applying a systematic due diligence checklist, procurement managers can confidently select suppliers that uphold the highest standards of quality and regulatory compliance.

Adopting a solution-oriented approach, with clear guidelines and actionable recommendations, not only minimizes risks but also sets a strong foundation for sustained operational success. Ultimately, a thorough evaluation process will help ensure that your business remains competitive, resilient, and trusted by your customers.

Q: What to look for when buying a pickleball racquet?

A: Key factors include paddle shape, core and face materials, handle length, paddle weight, and a grip that fits your hand. These components ensure that the paddle aligns with your play style while meeting performance standards.

Q: Are licensed products available for pickleball?

A: Yes, many suppliers offer licensed and approved pickleball products. Reputable manufacturers provide access to equipment that has been tested and certified by recognized bodies such as USA Pickleball, ensuring compliance with industry standards.

Q: What is the average life of a pickleball paddle?

A: The lifespan of a pickleball paddle varies with usage. Frequent players who use the paddle six times a week may need to replace it within a year, while casual players might experience a longer lifespan, often exceeding one year.

-

hot pressing: Click to read more about the hot pressing process, its advantages in manufacturing, and potential quality implications for sports equipment production. ^return ↩

-

cold pressing: Click to read more about cold pressing, how it preserves material integrity, and its impact on product performance. ^return ↩

-

thermoforming: Click here for an in-depth explanation of thermoforming, including its benefits for creating complex shapes and the challenges involved. ^return ↩

-

USA Pickleball-approved equipment: Click here to explore the certification process for USA Pickleball-approved equipment, the standards involved, and how these certifications assure quality and compliance. ^return ↩

-

3K carbon fiber: Click to learn more about 3K carbon fiber, its properties, and why its precise use is integral for ensuring high-quality, durable pickleball equipment. ^return ↩