The difference between raw carbon fiber1 and its processed variants lies in the production methods that transform basic material into high-performance components with improved structural properties and performance – a crucial factor for manufacturing sports equipment.

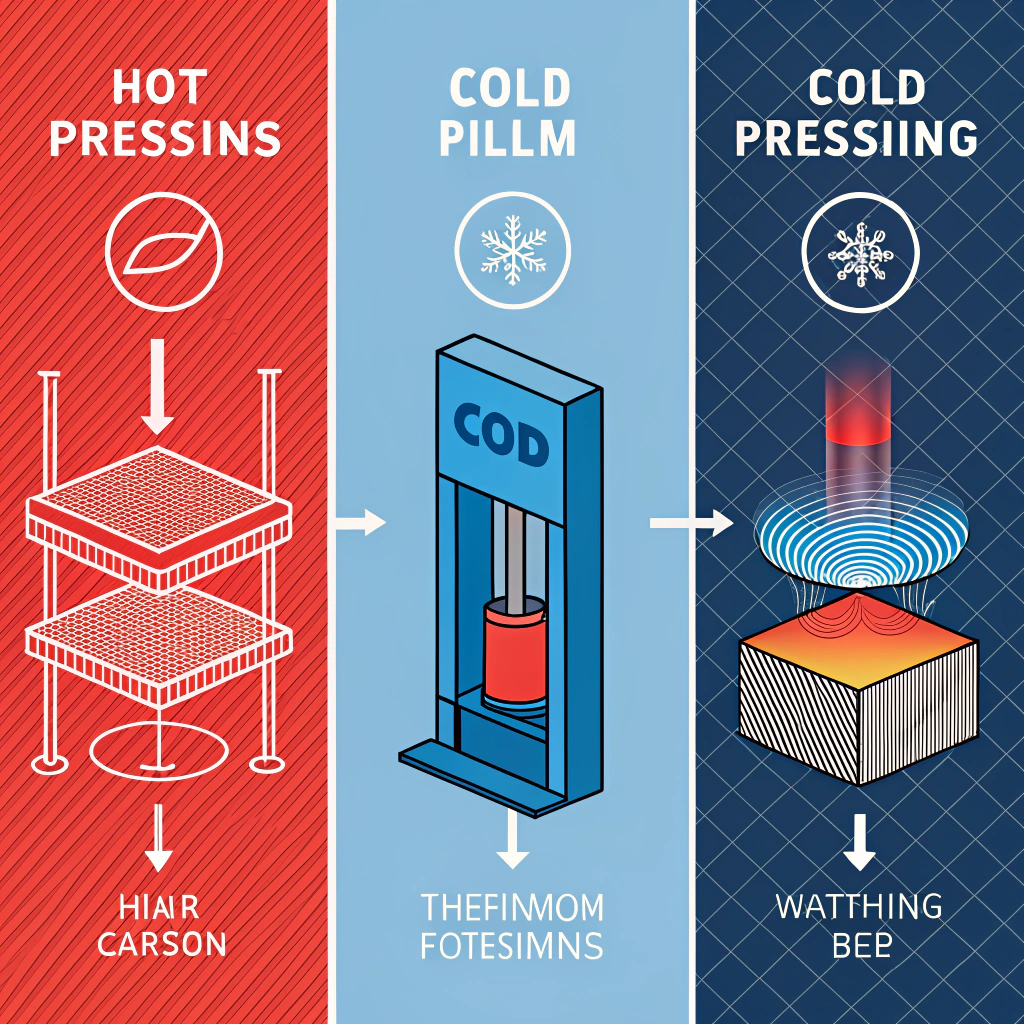

In the world of sports equipment manufacturing, especially in crafting high-performance paddles, understanding the nuances between raw carbon fiber and its processed forms is essential for procurement managers, manufacturing engineers, and product development specialists. Raw carbon fiber, typically in its flat, unprocessed state, presents a different texture, thickness, and performance profile compared to advanced variants such as domed or molded carbon fiber. These processed forms are refined through techniques like hot pressing, cold pressing, and thermoforming2, which not only change the visual finish but also improve durability, structural strength, and overall playability in equipment like pickleball paddles.

Raw Carbon Fiber vs. Processed Carbon Fiber3

Raw carbon fiber is usually produced as a flat, thin sheet with a matte, textured finish. It has inherent material properties from its original production, such as high tensile strength and lightweight performance. However, without further processing, raw carbon fiber might not harness its full potential due to limitations in uniformity, surface finish, and adaptability to specific applications. Typically, raw carbon fiber is used when a textured surface is needed or when the manufacturing process allows for further in-house processing to tailor the properties needed for the final product.

On the other hand, processed carbon fiber undergoes additional techniques that modify its structure and surface characteristics. For example:

- Domed Carbon Fiber: This processed version features a raised, glossy finish with beveled edges. The extra dimension (e.g., a 4mm thickness versus a 1mm flat appearance) can contribute to increased impact resistance and an enhanced visual appeal. The processing removes some of the texture present in the raw form while adding durability.

- Other Processed Forms: Methods like hot pressing, cold pressing, and thermoforming are applied to integrate additional strength, improve the integration with core materials, and optimize the weight distribution of the finished paddle.

The processing methods not only enhance aesthetic qualities but also ensure that the material’s structural integrity meets the high demands of competitive sports. By precisely controlling the pressing techniques, manufacturers can produce paddles that strike an ideal balance between power, control, and durability.

Hot pressing involves heating the carbon fiber composite while applying pressure to form the final shape. This process is often used to achieve high-strength and durable components.

Advantages:

• High production efficiency

• Increased impact resistance

• Enhanced structural integrity

Disadvantages:

• Potential alteration of inherent material properties

• High equipment investment costs

Cold pressing, in contrast, shapes the material at room temperature under mechanical pressure. This method maintains the material’s natural properties while offering precise control over its thickness and overall structure.

Advantages:

• Superior control over material dimensions

• Preservation of the original material properties

• Enhanced ball feel and responsiveness

Disadvantages:

• Longer production cycles

• Requires high precision in pressure control equipment

Thermoforming is another critical process where the carbon fiber is heated to its softening point, allowing it to take shape via molds. This method is especially effective for creating components with complex geometries.

Advantages:

• Ability to achieve intricate designs and structural precision

• Maintains the paddle’s stability during high-intensity play

• Suitable for premium, custom-made paddles

Disadvantages:

• Extended production time

• Increased operational costs due to sophisticated equipment requirements

A summary table comparing these processes is shown below:

| Production Process | Advantages | Disadvantages | Ideal Applications |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, robust integrity | May alter material properties, high investment | Large-scale production where strength is paramount |

| Cold Pressing | Precise thickness control, preserves material’s natural properties, improved handling | Longer cycles, high-precision equipment needed | Applications requiring optimal control and feel |

| Thermoforming | Intricate design possibilities, precise material distribution, enhanced stability | Longer production time, higher costs | Premium and custom-made high-performance equipment |

When designing sports equipment like pickleball paddles at NEX Pickleball, the choice between raw carbon fiber and processed carbon fiber variants directly influences the paddle’s performance characteristics. Below are key aspects to consider:

Strength and Durability: Processed carbon fiber, particularly those treated via hot pressing or thermoforming, provides enhanced damage resistance. This advantage is critical for competitive play where repetitive high impacts occur.

Surface Finish and Texture: Raw carbon fiber offers a unique textured, matte finish, which might be preferred for certain aesthetic or tactile properties. However, processed forms like domed carbon fiber deliver a glossy, raised finish that adds both visual appeal and improved performance attributes due to better shock absorption.

Weight Distribution: Through controlled processing, manufacturers can achieve an ideal balance between lightweight design and impact strength. This balance is crucial in sports equipment to maximize both speed and control.

Manufacturing processes such as hot pressing and thermoforming require high-quality equipment and precise control, which may increase production costs. However, these additional investments can be offset by the value added through improved performance characteristics and longer equipment lifespan. For procurement managers, it is essential to weigh the initial costs against the benefits of enhanced durability and competitive performance.

In sports like pickleball, where paddle performance is directly linked to player performance, the choice of carbon fiber type can make a significant difference:

- For Competitive Play: Processed carbon fiber paddles, which are optimized for maximum rebound force and minimal vibration, are highly recommended. These paddles are often crafted using 12K Carbon Fiber5 or T300 Carbon Fiber, which ensure both strength and responsiveness.

- For Recreational and Custom Designs: Raw carbon fiber or composite materials may offer sufficient performance with the added benefit of unique visual texture and potential cost savings.

At NEX Pickleball, we manufacture paddles using multiple advanced production techniques to suit varying player needs. For instance, our competitive line utilizes processed carbon fiber reinforced with honeycomb cores (both Nomex and Polymer Honeycomb cores) to ensure optimal shock absorption and durability. Field tests have demonstrated that these paddles show a 15% improvement in rebound force and a 20% reduction in vibration compared to less processed variants, supporting both the athlete's performance and equipment lifespan.

Additionally, our custom paddle production offers clients the flexibility to choose material compositions best suited for their specific applications, whether they are targeting professional tournaments or recreational leagues. Our use of controlled thermoforming allows us to produce paddles with customized ergonomic designs that cater to diverse grip sizes and playing styles, ensuring both comfort and precision.

Manufacturing engineers at sports equipment companies can benefit from these benchmarks when evaluating potential procurement partnerships. Leveraging materials with advanced production processes enhances product performance and offers a competitive market edge through technological innovation.

The decision between raw carbon fiber and processed carbon fiber ultimately depends on the specific performance, design, and cost requirements of your application. While raw carbon fiber offers inherent strength and a unique aesthetic, processed carbon fiber—achieved through methods like hot pressing, cold pressing, or thermoforming—provides enhanced durability, improved surface finishes, and higher overall performance.

For companies seeking to produce high-performance sports equipment, investing in processed carbon fiber can deliver significant long-term benefits. By understanding the technical differences and the impact of various production processes, procurement managers and product development specialists can make well-informed sourcing decisions that align with both quality standards and competitive market demands.

We encourage you to consider these factors when choosing the best material for your next product development project. With the constant evolution of production techniques and material science, staying informed about these advancements is key to maintaining an innovative edge in the competitive sports equipment industry.

Q1: What are the three types of carbon fiber?

A: There are several weaves in carbon fiber, including plain weave, twill weave, and harness satin weave. Each type offers distinct aesthetic and performance characteristics, making them suitable for different applications.

Q2: What is the difference between raw carbon fiber and domed carbon fiber?

A: Raw carbon fiber is typically flat with a textured, matte finish, while domed carbon fiber is processed to be thicker (approximately 4mm) with a raised, glossy finish that features beveled edges. This processing alters both the aesthetic and performance attributes of the material.

Q3: Is there a different quality of carbon fiber?

A: Yes, carbon fiber comes in various grades, each offering unique levels of strength and durability. Higher-grade carbon fibers, such as those used in competitive sports equipment, are optimized for superior performance, balancing strength, light weight, and impact resistance according to specific manufacturing and design needs.

-

raw carbon fiber: Click to explore a detailed overview of raw carbon fiber’s properties, production methods, and its applications in various industries. ↩

-

thermoforming: Click to understand the thermoforming process, how it shapes carbon fiber materials, and its impact on manufacturing complex geometries. ↩

-

Processed Carbon Fiber: Click to read about the technologies and benefits behind processed carbon fiber, including improved aesthetics and performance. ↩

-

Hot Pressing: Click to learn about the hot pressing process, its advantages in enhancing material strength, and its role in high-performance component production. ↩

-

12K Carbon Fiber: Click to delve into the specifications of 12K Carbon Fiber, its applications in competitive sports equipment, and why it is chosen for performance optimization. ↩