NEX Pickleball leverages advanced production techniques and premium materials to manufacture high-performance pickleball paddles. In essence, our paddles are engineered with cutting-edge technology—using carbon fiber1, fiberglass, and composite materials2 through hot pressing, cold pressing, and thermoforming3—to ensure durability, precision, and superior playability.

In the competitive world of pickleball equipment, manufacturing quality and performance are vital. B2B professionals seeking reliable suppliers require thorough comparisons of production methods, material properties, and overall design excellence. NEX Pickleball stands out by blending traditional craftsmanship with advanced production techniques. Our commitment to quality is evident in every paddle we produce, making us the preferred partner for distributors, procurement managers, and retail buyers in the sporting goods industry.

Today, manufacturers are judged on their ability to balance performance with durability and cost efficiency. With increasing demand for high-performance paddles, our focus is on integrating innovative materials and production techniques to meet market needs effectively.

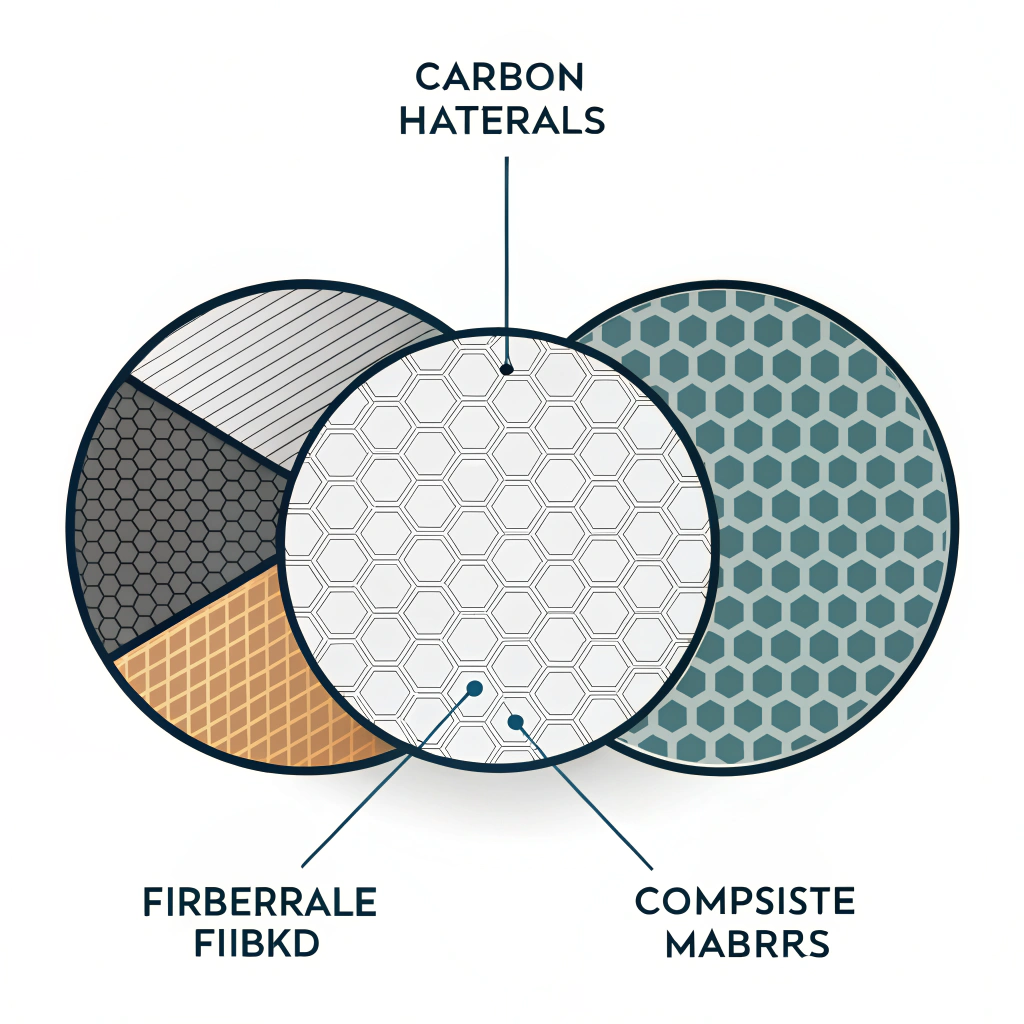

The performance of any pickleball paddle begins with its underlying materials. At NEX Pickleball, we carefully select from a range of premium materials, each offering unique performance benefits:

- 3K Carbon Fiber: Renowned for its strength and flexibility, this fiber is perfect for paddles that demand high rebound force. Its ability to reduce vibration ensures a comfortable yet powerful playing experience.

- 12K Carbon Fiber: With a higher thread density, the 12K variant delivers a smoother surface, enhanced hardness, and greater durability. This makes it ideal for paddle designs that require both extreme strength and impact resistance.

- T300 Carbon Fiber: This high-performance material is balanced in strength and weight, providing an excellent blend of power and speed for competitive play.

Fiberglass tackles the need for a broader sweet spot and enhanced ball control. Our E-Glass Fiberglass offers elasticity and tensile strength, ensuring every hit feels both controlled and responsive.

To capture the benefits of both carbon fiber and fiberglass, we also employ composite designs:

- Carbon Fiber and Fiberglass Composite: This combination is ideal for players who desire both power and control.

- Bamboo Core Composite: Lightweight yet impact-resistant, it provides a clear hitting feel for pulsating gameplay.

- Honeycomb Core: Engineered from high-density polymer or pulp, honeycomb cores are designed to absorb shocks effectively, reducing vibration and enhancing durability.

Each material is selected based on its specific role in contributing to the paddle’s overall performance characteristics. For instance, the superior rebound and vibration dampening of 3K Carbon Fiber make it a popular choice for offensive play, while the composite blend caters to versatile playing styles.

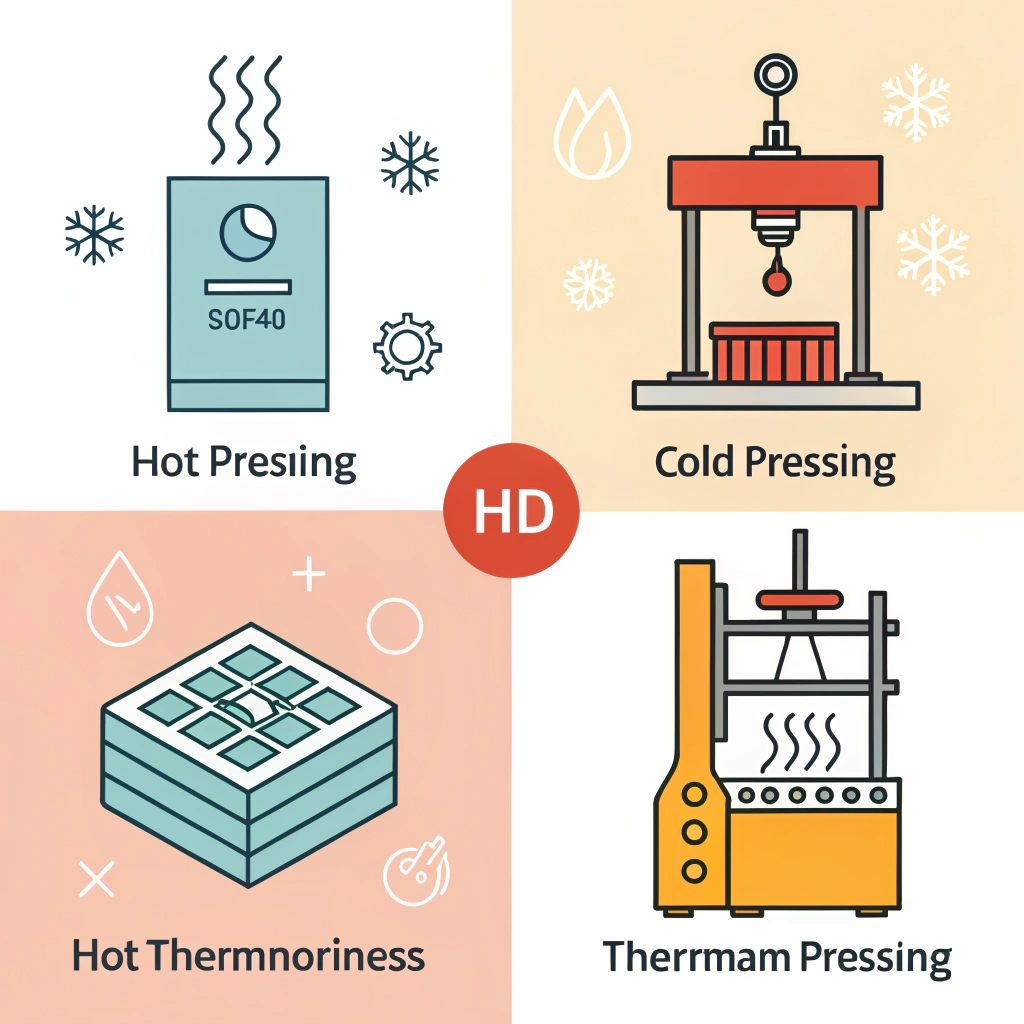

Manufacturing excellence relies not only on high-quality materials but also on robust production processes. At NEX Pickleball, our manufacturing involves three main processes:

Hot pressing involves applying high temperature and pressure to the material.

- Advantages:

- High production efficiency which is vital for large-scale manufacturing.

- Produces paddles with remarkable impact resistance and structural integrity.

- Disadvantages:

- High investment in equipment.

- Potential alteration of some material properties, which may affect the paddle’s feel.

Cold pressing shapes materials using mechanical pressure at room temperature.

- Advantages:

- Offers precise control over paddle thickness and structure.

- Maintains the material’s inherent properties, ensuring excellent ball control and responsiveness.

- Disadvantages:

- Longer production cycles, which can reduce overall manufacturing efficiency.

- Demands high-precision equipment to tightly control pressure parameters.

Thermoforming involves heating the material to a softening point before using molds to shape it.

- Advantages:

- Enables the production of paddles with intricate designs and precise material distribution.

- Supports the creation of paddles with enhanced stability and performance due to the controlled distribution of weight and materials.

- Disadvantages:

- Higher equipment costs and longer production times, limiting it primarily to premium or custom paddle orders.

The table below presents a concise comparison of these production methods:

| Production Process | Efficiency | Precision Control | Equipment Investment | Material Integrity |

|---|---|---|---|---|

| Hot Pressing | High | Moderate | High | May alter natural properties |

| Cold Pressing | Moderate | High | High | Preserves material properties |

| Thermoforming | Moderate to Low | High (for complex shapes) | Very High | Maintains performance features |

This comparison is crucial for procurement decisions, as each method offers distinct benefits that align with different product goals and market segments.

Our commitment to excellence in materials and production processes puts us at the forefront of the pickleball paddle manufacturing industry. Here are key reasons why NEX Pickleball is the best partner for your business:

-

Advanced Materials and Techniques: We combine high-grade carbon fiber1, fiberglass, and innovative composite materials with our refined production processes to deliver paddles that meet the highest performance standards.

-

Customized Solutions: Understanding that each client has unique requirements, we offer custom paddle options. From weight distribution to grip size and design, our solutions are tailored to match your business needs, whether for team branding or retail distribution.

-

Rigorous Quality Assurance: Every paddle undergoes strict quality control and comprehensive testing. This meticulous approach ensures each product delivers optimal control, power, and durability, crucial for both recreational and professional players.

-

Efficient, Scalable Production: Our state-of-the-art manufacturing equipment enables us to meet large-scale orders without compromising quality. The blend of hot pressing, cold pressing, and thermoforming technologies allows us to cater to a wide variety of market segments.

-

Industry Expertise and Reliability: As the OEM4 for renowned brands like JOOLA and Selkirk, our hands-on experience gives us unmatched insights into industry standards and future trends. This expertise translates into reliable products that sports retailers and distributors can trust.

Our strategy is supported by real-world data and performance comparisons. For example, paddles made with a Nomex Honeycomb Core5 have shown excellent shock absorption properties, making them ideal for high-impact, competitive performances. Clients have reported improved shot accuracy and reduced arm fatigue, benefits directly traceable to our emphasis on superior materials and precise production methodologies.

A sample case study within the competitive market involved a major distributor expanding its product portfolio. By collaborating with NEX Pickleball, they observed a 20% increase in customer satisfaction due to the improved consistency and performance of the paddles. Such case studies underscore our ability to consistently exceed industry standards.

Additionally, our informed use of processes, such as thermoforming, has enabled us to create paddles with complex designs that not only appeal visually but also enhance the player's control and comfort. These results have allowed us to secure our position as a trusted manufacturing partner in the global pickleball market.

In summary, NEX Pickleball brings together state-of-the-art material innovations and advanced production processes to deliver pickleball paddles that stand out in the market. Our use of carbon fiber1, fiberglass, and composite materials, combined with production strategies like hot pressing, cold pressing, and thermoforming, ensures top-tier performance and durability. For B2B clients in the sporting goods industry, partnering with us means gaining access to products that not only meet but exceed market expectations.

As you compare manufacturers and evaluate your procurement options, consider the strategic advantages of our manufacturing approach. Our commitment to quality, product consistency, and customized solutions positions us as the ideal partner for businesses looking to offer high-quality pickleball paddles. We invite you to explore a partnership with NEX Pickleball to elevate your product offering and drive business growth.

Q: Who makes the highest quality pickleball paddles?

A: Top-quality pickleball paddles are manufactured by reputable companies known for precision engineering and advanced materials. Many of the best-rated paddles on the market come from manufacturers with extensive expertise, including OEM partners like NEX Pickleball, who supply well-regarded brands such as JOOLA and Selkirk.

Q: What paddle do most professional pickleball players use?

A: Professional pickleball players typically opt for paddles that offer a balanced combination of power, control, and durability. Many pros favor paddles built on advanced technologies featuring materials like high-performance carbon fiber and innovative composite cores, akin to those produced by leading partners including NEX Pickleball.

Q: Which is better, Joola or Selkirk?

A: The choice between JOOLA and Selkirk often depends on player preference: JOOLA paddles cater to aggressive, spin-focused play, while Selkirk paddles emphasize consistency and finesse. Both manufacturers rely on robust OEM partnerships with companies like NEX Pickleball to deliver high-quality products tailored to different playing styles.

-

carbon fiber: Learn about the properties, production methods, and benefits of carbon fiber in high-performance sports equipment. ↩ ↩ ↩2 ↩3

-

composite materials: Understand how composite materials combine the advantages of different fibers to enhance durability, reduce weight, and boost performance in advanced manufacturing. ↩ ↩

-

thermoforming: Explore the process of thermoforming and how it enables the creation of complex, precision-shaped components in paddle manufacturing. ↩ ↩

-

OEM: Read about Original Equipment Manufacturer (OEM) partnerships and how they contribute to quality assurance and market reliability in the sporting goods industry. ↩ ↩

-

Nomex Honeycomb Core: Discover the technology behind Nomex Honeycomb Core, its role in shock absorption, vibration reduction, and enhancing overall paddle performance. ↩ ↩