Quick Answer: Custom OEM pickleball paddle solutions offer sports equipment retailers a chance to tailor high-performance paddles using advanced materials and production processes that ensure optimal durability, control, and playability. This guide compares production techniques and material options to help you make an informed, value-driven decision.

In today’s competitive sports equipment market, partnering with a reliable OEM (Original Equipment Manufacturer)1 manufacturer is key to expanding your product line with high-quality, custom-branded pickleball paddles. OEM (Original Equipment Manufacturer)1 partnerships not only offer the benefit of customizations but also guarantee production consistency and quality control2. For retailers and product managers, understanding the technical nuances behind production processes and material choices is essential. This guide will walk you through the critical factors when selecting an OEM partner, focusing on production processes, material innovation, and customization options.

The decision-making process involves evaluating performance-enhancing materials, such as advanced carbon fiber3 types and composites, alongside innovative production methods like hot pressing, cold pressing, and thermoforming4. Each of these factors contributes to the paddle's performance characteristics including optimal weight balance, vibration reduction, and superior tactile response.

One of the primary decisions in OEM manufacturing for pickleball paddles is choosing the appropriate materials. Different materials offer distinct performance qualities that directly influence the paddle’s control, power, and durability.

Carbon fiber is a preferred material for paddle construction due to its superb strength-to-weight ratio and resilience. The main types utilized include:

-

3K Carbon Fiber: Known for its flexibility and strength, this material offers high rebound force. It is excellent for minimizing vibrations during play while maintaining durability.

-

12K Carbon Fiber: With a higher thread density, 12K carbon fiber delivers a smoother surface and improved hardness. This type is best suited for competitive play where extreme strength and impact resistance are vital.

-

T300 Carbon Fiber: A high-performance option, T300 represents a balanced combination of strength and light weight. It is ideal for players who demand both control and power.

Fiberglass serves as another key material, offering a wider sweet spot and great ball control due to its inherent flexibility. In addition to pure fiberglass, many OEM partners incorporate composite materials to further enhance performance:

-

E-Glass Fiberglass: This material stands out with its elasticity and tensile strength, providing an excellent ball feel.

-

Carbon Fiber and Fiberglass Composite: By combining both materials, this composite ensures a balance between strength, lightness, and flexibility.

-

Bamboo Core Composite: Utilizing bamboo benefits, this option provides a lightweight yet highly impact-resistant paddle that delivers a direct hitting sensation.

-

Honeycomb Core Composites: Materials like Nomex, aluminum, and polymer honeycombs offer superior shock absorption. For instance, a Nomex Honeycomb Core is renowned for its durability and stability, while an Aluminum Honeycomb Core provides excellent power and control.

These materials not only affect durability but also play a crucial role in the paddle’s overall performance, allowing manufacturers to design products that cater to both entry-level and professional players.

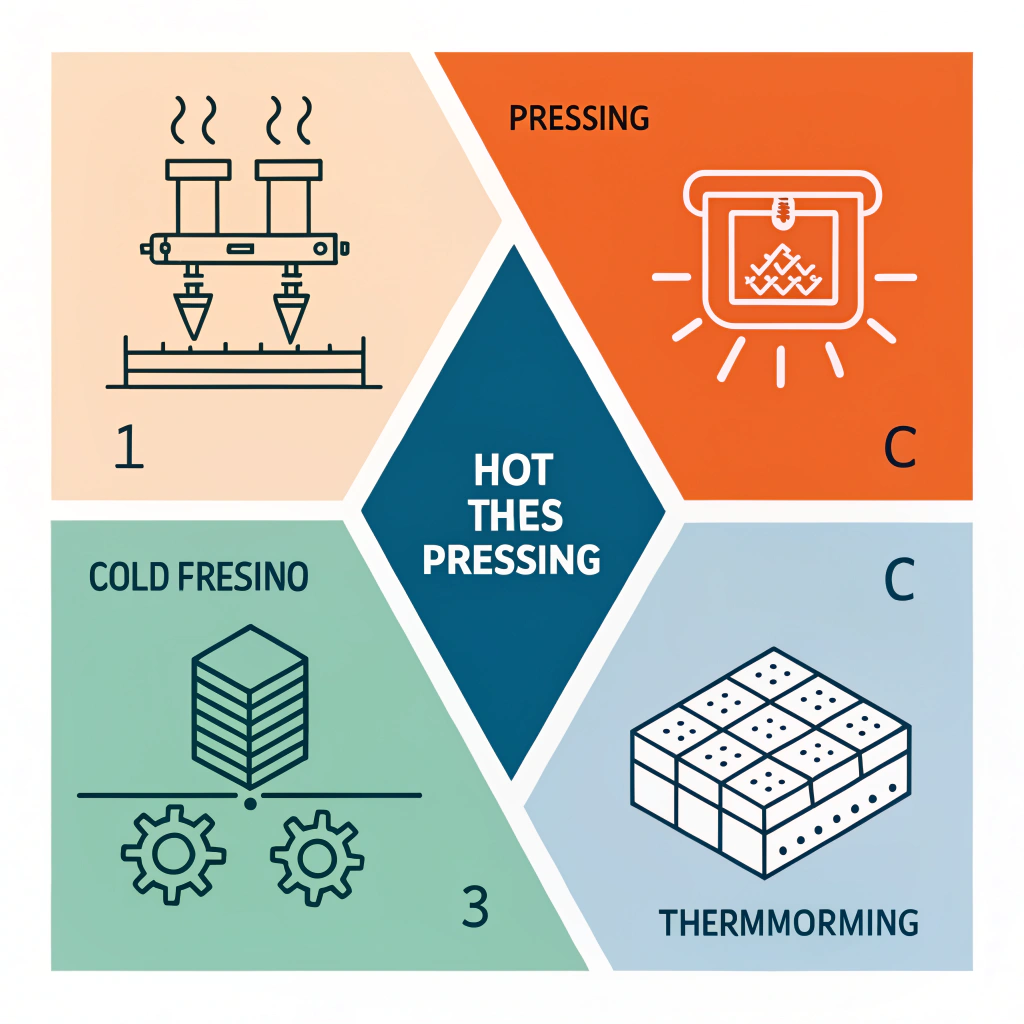

The production process of a pickleball paddle largely determines its final quality, performance, and durability. The three main production techniques—hot pressing, cold pressing, and thermoforming4—each have unique advantages and disadvantages.

Hot pressing involves heating the paddle material and applying pressure to ensure the components bond effectively. This process is commonly used for high-strength paddles. Its advantages include:

- High production efficiency, ideal for large-scale manufacturing.

- Superior impact resistance and structural integrity.

However, there are trade-offs:

- Material properties may alter slightly, affecting the paddle’s feel.

- High equipment costs due to the need for specialized machinery.

Cold pressing uses mechanical pressure at room temperature to form the paddle. It is ideal for designs where precise control over thickness and structure is essential. Advantages include:

- Better retention of the material’s inherent properties.

- Enhanced ball feel and responsiveness, which is critical for performance paddles.

Disadvantages include:

- Longer production cycles, potentially lowering overall efficiency.

- Necessity for highly precise pressure control, demanding advanced equipment.

Thermoforming4 involves heating the material until it softens and then forming it under a mold. This method allows for complex designs and precise material distribution. Key benefits are:

- Ability to create intricate, stable paddle designs.

- Enhanced performance through accurate thickness distribution.

Nevertheless, thermoforming requires:

- Increased production time and investment in high-end equipment.

- It is best suited for premium or custom-made paddles, which could raise costs.

Below is a comparative table summarizing these production processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency • Strong impact resistance • Structural integrity | • Potential alteration of material feel • High equipment costs |

| Cold Pressing | • Precise control over structure • Preserves material properties • Excellent ball feel and responsiveness | • Longer production cycles • Demands precise pressure control |

| Thermoforming | • Allows intricate designs • Precise material distribution • Enhanced stability | • Longer production time • Higher equipment and process cost |

Each production method presents unique benefits and challenges, and the choice will significantly influence the performance characteristics of the final product. For retailers and manufacturers, understanding these differences is vital when considering an OEM partner.

Customization options are a key differentiator when partnering with a reliable OEM. Modern OEM manufacturers offer extensive customization to reflect your brand’s identity and cater to specific performance needs.

With on-demand print services5, you can personalize paddle designs easily. Whether you require company logos, team branding, or unique designs tailored to consumer preferences, OEM partners can incorporate printing techniques during production. This results in highly reproducible, aesthetically pleasing paddles that stand apart in a competitive market.

Quality control2 is non-negotiable in sports equipment manufacturing. A top-tier OEM partner implements rigorous testing protocols throughout the production cycle. These measures include:

- Material testing: Verifying the structural integrity and performance properties of carbon fiber, fiberglass, and composite materials.

- Process validation: Regularly monitoring production processes like hot pressing, cold pressing, and thermoforming to ensure consistency.

- Final product testing: Evaluating each paddle for vibration reduction, rebound force, and ergonomics.

These quality control measures assure that every paddle not only meets but often exceeds market expectations for high performance.

NEX Pickleball stands out as a leading manufacturer in the pickleball paddle OEM space. Headquartered in Jiaxing, Zhejiang, China, NEX Pickleball leverages advanced production techniques such as hot pressing, cold pressing, and thermoforming to create paddles that uphold high standards of performance and durability.

-

Advanced Materials: With a range of premium materials – from various types of carbon fiber to unique composite blends – NEX Pickleball ensures that each paddle is optimized for power, control, and longevity.

-

Tailored Customization: We offer extensive options for custom branding and design, enabling you to launch a product line that is uniquely yours. On-demand print services5 allow for agile production cycles responding to market trends.

-

Proven Production Processes: Employing robust techniques like hot pressing, cold pressing, and thermoforming ensures that each paddle delivers consistent quality and performance.

-

Strict Quality Control: Every paddle is subject to rigorous testing, ensuring that only products meeting the highest standards reach the market.

-

Competitive OEM Partnership: Serving as the OEM for brands like Joola and Selkirk, our track record in the industry demonstrates our capability to support high-volume, high-demand production with precision and reliability.

By choosing NEX Pickleball as your OEM partner, you not only obtain a product that meets market needs but also benefit from our continuous investment in innovation and quality assurance. Our experience in tailoring products for both recreational and professional players makes us the ideal partner for expanding your sports equipment lineup.

When evaluating OEM partners for custom pickleball paddles, consider the following criteria which serve as a comprehensive checklist:

| Evaluation Criteria | Considerations |

|---|---|

| Material Quality | Assess the range of high-performance materials available, such as carbon fiber3, fiberglass, and composites. |

| Production Process | Evaluate production techniques (hot pressing, cold pressing, thermoforming) and their impact on paddle performance. |

| Customization Options | Check for capabilities in custom branding, on-demand print services5, and bespoke design adjustments. |

| Quality Control | Review the testing protocols and quality control2 measures the OEM has in place. |

| Turnaround Time | Consider production timelines and their alignment with your delivery schedules. |

| Price Competitiveness | Ensure that production costs and order volumes provide a favorable pricing structure. |

Using this framework, you can systematically compare potential OEM partners and make an informed decision that aligns with your strategic objectives and market demands.

In summary, custom OEM pickleball paddles are a strategic opportunity for sports equipment retailers to offer products that combine durable construction, high performance, and brand-specific customization. By understanding key material choices—from the nuances of 3K, 12K, and T300 carbon fibers to innovations in fiberglass composites—and by closely evaluating production processes like hot pressing, cold pressing, and thermoforming, you can find an OEM partner that meets your quality and performance expectations.

NEX Pickleball, with its proven track record, rigorous quality control, and advanced manufacturing techniques, provides a robust solution for private label and custom pickleball paddles. As you move forward with your decision-making process, use the evaluation checklist provided to compare potential partners and ensure that your chosen OEM aligns with your operational requirements and brand vision.

Take action now by reaching out to NEX Pickleball for a detailed consultation and to explore how our custom OEM solutions can help your brand stand out in the competitive sports equipment market.

People Also Ask

Q1: What are the benefits of using custom OEM pickleball paddles?

A1: Custom OEM pickleball paddles allow retailers to offer personalized, high-performance products that meet specific design and performance needs, enabling better brand differentiation and customer satisfaction.

Q2: How do production processes like hot pressing, cold pressing, and thermoforming affect paddle performance?

A2: These production processes influence paddle characteristics by balancing impact resistance, ball feel, and structural integrity. Hot pressing offers high efficiency with strong impact resistance, cold pressing preserves material properties for superior control, and thermoforming allows for intricate designs with precise material distribution.

Q3: What customization options are available for pickleball paddles?

A3: OEM partners often provide a range of customization options including on-demand printing, custom branding, and tailored design features such as paddle weight, grip size, and material combinations, allowing each paddle to reflect a brand’s unique identity.

-

OEM (Original Equipment Manufacturer): Click to learn about OEMs—companies that design and manufacture products based on another company's specifications, ensuring consistent production quality and scalability. ↩ ↩ ↩2

-

quality control: Click to gain insight into quality control measures that ensure products meet strict performance and reliability standards essential for market success. ↩ ↩ ↩2 ↩3

-

carbon fiber: Click to explore the properties and advantages of carbon fiber in enhancing product durability and performance in sports equipment manufacturing. ↩ ↩ ↩2

-

thermoforming: Click to understand the thermoforming process, its benefits for complex designs, and how it contributes to product innovation in manufacturing. ↩ ↩ ↩2 ↩3

-

on-demand print services: Click to discover how on-demand print services enable rapid and flexible customization, allowing brands to quickly adapt to market trends and consumer demands. ↩ ↩ ↩2 ↩3