OEM manufacturing for premium pickleball paddles hinges on advanced production techniques and carefully selected materials. In brief, high-performance paddles are crafted using processes like hot pressing, cold pressing, and thermoforming1, alongside premium materials such as carbon fiber2, fiberglass3, and innovative composites4. This article provides a detailed comparison of these methods, a breakdown of material advantages, and insights into quality control and customization, all essential factors when selecting an OEM manufacturing5 partner for pickleball paddles.

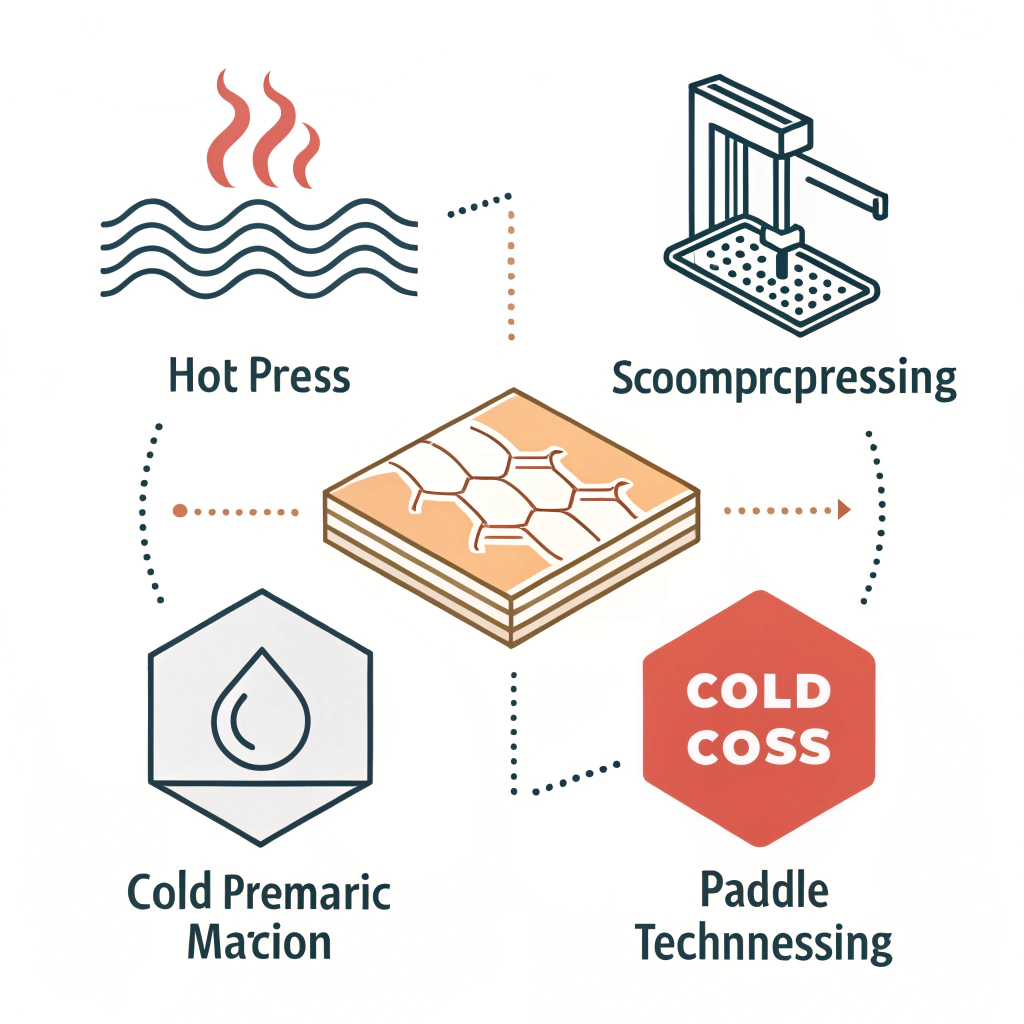

Choosing an OEM partner involves weighing various production processes. At NEX Pickleball, our manufacturing expertise lies in three advanced techniques:

- Hot Pressing: This process uses heat and pressure to mold paddle materials, generating strong, durable paddles suited for high-impact play.

- Cold Pressing: By shaping materials at room temperature under pressure, cold pressing yields precise control over the paddle’s thickness and structural integrity, ideal for those requiring enhanced ball feel and responsiveness.

- Thermoforming: In this method, materials are heated to a soft state before forming, allowing complex designs with a uniform distribution of materials.

Each method has its advantages and trade-offs, which are crucial for assessing production capabilities. The following table offers a clear comparison:

| Production Process | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Excellent impact resistance - Strong structural integrity | - Potential alteration of material feel - High equipment investment | High-strength, durable paddles |

| Cold Pressing | - Precise thickness and control - Maintains material properties - Great ball feel | - Longer production cycle - Requires quality pressure control | Paddles requiring precision control |

| Thermoforming | - Allows intricate designs - Uniform material distribution - Elevated paddle stability | - Longer production time - Higher equipment costs | Premium, custom-made products |

These production techniques allow manufacturers to fine-tune paddle attributes, ensuring performance, durability, and quality—a critical consideration for procurement managers and business owners evaluating OEM partners.

The material composition of pickleball paddles plays a vital role in determining their performance characteristics. At NEX Pickleball, we use a variety of high-performance materials tailored to meet the demands of competitive play:

Carbon fiber2 offers unmatched strength and responsiveness. We utilize several types:

- 3K Carbon Fiber: Known for its excellent flexibility and strength, 3K carbon fiber is ideal when high rebound force and durability are required.

- 12K Carbon Fiber: With a higher thread density, this type results in a smoother paddle surface, elevating hardness and impact resistance, which is perfect for competitive play.

- T300 Carbon Fiber: Renowned for its tensile strength, T300 provides a balanced performance of strength and lightness, making it a popular choice for performance-oriented designs.

Fiberglass3 paddles provide a larger sweet spot and exceptional ball handling capabilities.

- E-Glass Fiberglass possesses excellent elasticity and tensile strength, delivering a superior feel and precise control on each hit.

To harness the benefits of more than one material, composite options blend top-quality elements ensuring optimum performance.

- Carbon Fiber & Fiberglass Composite: This fusion delivers a harmonious blend of strength, lightness, and flexibility.

- Bamboo Core Composite: Bamboo offers a lightweight yet impact-resistant option, delivering a crisp hitting feel that endures long play sessions.

- Honeycomb Core: Constructed using high-density polymers or pulp, honeycomb cores absorb shocks efficiently, reducing vibration and extending the paddle's lifespan.

The choice of materials directly influences the paddle's behavior, affecting power, control, and durability. For procurement managers in the sports equipment industry, understanding these material benefits is essential when evaluating OEM offerings.

High-performance pickleball paddles demand rigorous quality control throughout the manufacturing process. At NEX Pickleball, every paddle undergoes multiple rounds of testing to ensure precision and durability.

- Precision Weight Distribution: Our processes ensure that each paddle is balanced perfectly for both power and control.

- Ergonomic Grip Design: The paddles are engineered with advanced grip designs to cater to various hand sizes, ensuring comfort during prolonged play.

- Surface Texture Treatment: Special treatments enhance ball grip, which improves spin and accuracy during game play.

- Testing Protocols: Each paddle is subjected to rigorous impact, vibration, and performance tests to maintain top-tier quality standards.

- Tailored design specifications including grip size, weight, and balance.

- Custom branding for sports organizations or retail lines.

- On-demand printing for personalized paddle designs, accommodating both individual and bulk orders.

This focus on quality assurance and customization is paramount. It allows our clients—be they local distributors or international retail chains—to offer products that stand out in competitive markets while meeting specific performance criteria.

For businesses sourcing OEM products, several factors must be considered beyond production techniques and materials. A structured evaluation framework can help your decision-making process:

- Production Efficiency: How quickly can the OEM manufacture paddles without compromising quality?

- Material Quality: Are premium materials like carbon fiber2 and fiberglass3 used, and do they meet the required performance standards?

- Customization Capabilities: How flexible is the manufacturer in adapting designs for your unique requirements?

- Quality Control: What rigorous testing and quality assurance measures are in place?

- Cost-effectiveness: Does the OEM offer competitive pricing without compromising on quality or technical precision?

- Delivery Compliance: Can they guarantee timely production and delivery, which is critical for maintaining supply chain consistency?

Below is a decision table summarizing how critical factors align with various production processes and material use:

| Factor | Hot Pressing | Cold Pressing | Thermoforming |

|---|---|---|---|

| Production Efficiency | High | Moderate | Moderate to Low |

| Material Compatibility | Strong for durable paddles | Ideal for precise ball control | Excellent for complex designs |

| Customization Potential | Standard customization | Enhanced due to precision | Premium, for custom orders |

| Quality Control | High strength testing | Detailed material retention | Careful molding tests |

| Cost-effectiveness | Economical in mass production | Higher due to longer cycles | Premium pricing |

| Delivery Time | Fast | Longer cycle times | Longer due to process complexity |

Selecting the right OEM partner involves balancing these factors against your business goals and customer expectations. With our advanced techniques and a proven track record, NEX Pickleball integrates these elements to deliver paddles that satisfy both performance and economic requirements.

Over recent years, industry trends show that competitive players and sports organizations are increasingly seeking OEM partners who not only deliver on performance but also provide design flexibility and customization options. For example, manufacturers like Joola and Selkirk have set benchmarks by partnering with experienced OEM factories, helping them refine their product lines based on consumer feedback and brand requirements.

A mid-sized sports equipment distributor recently partnered with our team to launch a newly branded line of pickleball paddles. Through our expertise in cold pressing, we were able to produce paddles with enhanced control and consistent weight. The project involved:

- Custom grip sizing based on market research.

- Incorporation of a 12K Carbon Fiber layer for improved hardness.

- Detailed surface treatment for optimal ball spin.

The result was a product line that quickly gained market acceptance, affirming the importance of selecting the right production process and materials. This case underscores that an optimal balance between innovative technology, material selection, and proactive quality control is vital for success in the sports equipment industry.

Furthermore, market data shows that the global demand for premium pickleball equipment has grown significantly over the past few years, driven by the sport's rapid expansion. Businesses that prioritize quality and innovation in their OEM partnerships are well-positioned to capitalize on this growth. Our commitment to using advanced production techniques and state-of-the-art materials ensures that our paddles are always game-ready—meeting the exacting standards of professionals and enthusiasts alike.

When deciding on an OEM partner for high-performance pickleball paddles, it is essential to consider the following:

- The production process (hot pressing, cold pressing, or thermoforming) that best aligns with your quality and delivery expectations.

- The material choices, including premium carbon fiber2, fiberglass3, and composite materials, which directly affect paddle performance.

- Rigorous quality control measures and the ability to customize based on specific market or brand needs.

At NEX Pickleball, we are dedicated to delivering paddles crafted with precision and innovation. Our comprehensive approach—spanning advanced production techniques, a diverse range of premium materials, and stringent quality control—ensures that your products not only meet the market demands but exceed industry standards.

If you are a procurement manager or business owner in the sports equipment distribution industry, partnering with an OEM that marries engineering excellence with consistent quality can significantly enhance your product lineup and market reputation. We invite you to explore how our customized manufacturing solutions can help drive your business forward.

Take the next step in elevating your sports equipment offerings by contacting us today for a detailed consultation and product demonstration.

Who makes the highest quality pickleball paddles?

Manufacturers offering premium quality generally include well-known brands like JOOLA and Selkirk, which rely on top-tier OEM partners. In the market, premium models are engineered with advanced materials and production methods to ensure durability, precision, and performance.

What paddle do most professional pickleball players use?

Many professional players prefer control and power through paddles like the JOOLA Perseus, known for its enhanced spin, and models from Selkirk that focus on balanced performance. These paddles are designed using precise manufacturing techniques to meet the rigorous demands of professional play.

Are all pickleball paddles made in the same factory?

While most pickleball paddles are manufactured in China due to the advanced manufacturing infrastructure available, not all are made in a single facility. Many leading brands collaborate with specialized OEM partners that focus on quality, precision, and customization, ensuring each paddle meets high-performance standards.

-

Thermoforming: Click here to explore how thermoforming techniques allow for complex, high-precision designs by reshaping heated materials, a method widely used in advanced manufacturing sectors. ↩ ↩

-

Carbon fiber: Learn about the benefits of carbon fiber, including its high strength-to-weight ratio and durability, which are crucial for high-performance sports equipment. ↩ ↩ ↩2 ↩3 ↩4

-

Fiberglass: Discover why fiberglass is chosen for its flexibility and cost-effectiveness, offering enhanced performance and control in paddle manufacturing. ↩ ↩ ↩2 ↩3 ↩4

-

Innovative composites: Read further on innovative composites to see how blending materials can optimize performance through improved strength, durability, and cost efficiency in manufacturing. ↩ ↩

-

OEM manufacturing: Read more to understand how Original Equipment Manufacturer processes enable businesses to outsource production while maintaining quality control, cost efficiency, and scalability. ↩ ↩