NEX Pickleball is an industry-leading pickleball manufacturer known for its high-performance paddles, unmatched quality control1, and advanced production techniques. In simple terms, we are dedicated to providing sports retail and distribution companies with a reliable, customized manufacturing partner that enhances your product portfolio and supports long-term business success.

In today’s competitive sports equipment market, procurement managers and business developers face the challenge of sourcing products that not only perform exceptionally but are also manufactured with precision and consistency. With a focus on quality, efficiency, and innovation, NEX Pickleball offers a solution that meets and exceeds these expectations.

Many B2B buyers in the sports retail and distribution industry struggle with the following issues:

• Finding suppliers who can deliver consistently high-performance products.

• Dealing with long production cycles and mismatched quality due to poor production techniques.

• Sourcing manufacturers who can offer customization options to meet specific branding and performance needs.

• Ensuring timely delivery and robust quality control to satisfy competitive market demands.

These common challenges often force decision-makers to compromise between cost, quality, and innovation.

A few key factors contribute to the challenges in sourcing high-quality pickleball equipment:

- Production Process Limitations: Traditional manufacturing processes may not offer the precision needed for advanced designs, leading to inconsistent paddle performance.

- Material Quality Variability: The use of inferior raw materials or inconsistent production methods reduces the durability and performance of paddles.

- Limited Customization Options: Many manufacturers do not offer customizable features such as on-demand printing, limited grip sizes, or specialized core materials.

- • Supply Chain Inefficiencies2: Delays in production and shipping can impact product launches and sales cycles adversely.

Recognizing these issues, NEX Pickleball has invested in cutting-edge production techniques and rigorous quality control to ensure that each paddle meets the highest standards.

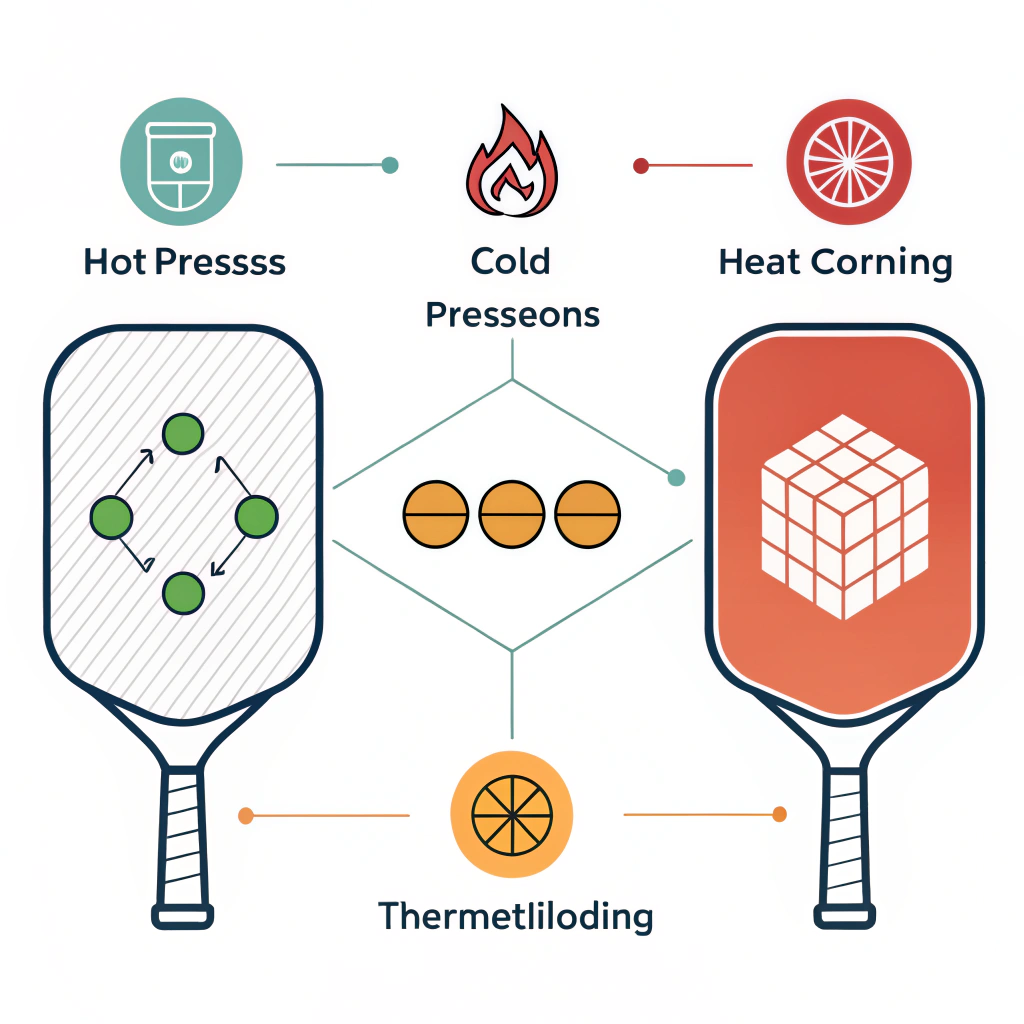

At NEX Pickleball, our competitive edge comes from three key production processes: Hot Pressing, Cold Pressing, and Thermoforming3. Each method has been optimized to create paddles that deliver exceptional performance while addressing industry challenges.

Hot pressing involves heating materials and applying intense pressure. This process guarantees high production efficiency and creates paddles with excellent impact resistance.

• Advantages:

- High production efficiency suitable for large-scale operations.

- Enhanced structural strength and durability ideal for competitive play.

- Excellent shock-absorption properties.

• Disadvantages:

- Potential alteration of material properties that may affect paddle feel.

- High initial investment in specialized equipment.

Using cold pressing, materials are shaped at room temperature while maintaining their original properties. This technique is perfect for designs requiring precise control over paddle thickness and structural integrity.

• Advantages:

- Precise thickness and structure control, ensuring consistency.

- Maintains natural flexibility and responsiveness.

- Better overall ball feel resulting in improved performance.

• Disadvantages:

- Longer production cycles compared to hot pressing.

- Requires highly precise pressure control equipment.

Thermoforming heats the materials to a softening point and then molds them into the final shape. This process is ideal for crafting complex paddle designs with varying thickness levels.

• Advantages:

- Creates intricate designs with excellent material distribution.

- Maintains paddle stability and enhances overall performance.

- Allows integration of a variety of high-performance materials.

• Disadvantages:

- Longer production time and initially higher equipment costs.

- Best suited for premium or custom-made paddles.

The table below summarizes our three production processes:

| Production Process | Key Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency, robust structure, excellent shock absorption | Potential effect on material feel, high tooling cost |

| Cold Pressing | High precision, maintains material integrity, superior ball feel | Longer cycle times, precise equipment needed |

| Thermoforming | Intricate designs, precise material distribution, enhanced stability | Longer production time, higher initial costs |

Customization options in sports equipment are crucial for building strong brand value and meeting specific performance requirements. NEX Pickleball offers bespoke paddle options with a range of material and design choices:

Carbon Fiber4 Variants:

Our paddles incorporate several types of carbon fiber to meet diverse performance criteria:

• 3K Carbon Fiber: Provides excellent durability, flexibility, and impact resistance, ideal for high rebound force in professional games.

• 12K Carbon Fiber: Offers a smoother surface that increases field hardness and overall paddle strength, suitable for competitive play.

• T300 Carbon Fiber: Combines balanced strength and lightness, making it perfect for players who seek enhanced control without sacrificing speed.

Fiberglass Innovations:

Fiberglass is another material used for its flexibility and consistent ball control. Our E-Glass Fiberglass variant is specifically chosen for its elasticity and tensile strength.

Composite Materials:

We also offer superior Composite Materials, such as:

• Carbon Fiber and Fiberglass Composite – balancing power and control.

• Bamboo Core Composite – lightweight with exceptional durability for prolonged use.

• Honeycomb Core – reduces vibration while absorbing shocks, enhancing paddle longevity.

The core material of a paddle significantly influences its performance. NEX Pickleball provides several advanced core types:

• Nomex Honeycomb Core5: Excellent for shock absorption and stability.

• Aluminum Honeycomb Core: Maintains a balanced weight for optimal power and precision.

• Polymer Honeycomb Core: Reduces vibration and offers greater elasticity, ensuring a comfortable hitting experience.

These tailored options allow clients to customize paddles precisely to their desired performance and branding criteria. Additionally, our on-demand printing services help incorporate unique designs and logos, enhancing market differentiation for sports retailers.

In B2B relationships, reliability and consistent product quality are non-negotiable. At NEX Pickleball, every paddle undergoes rigorous quality control throughout its lifecycle:

• Raw Material Verification: We meticulously select and test raw materials such as carbon fiber and fiberglass to ensure they match high-quality standards.

• In-Process Inspections: During production, each paddle is monitored through multiple quality checkpoints. This minimizes variations and maintains consistency.

• Final Performance Testing: Post-manufacturing tests assess durability, flexibility, and ball response, ensuring every paddle lives up to its promised performance.

This robust quality assurance process reduces defects and enables predictable production outcomes, vital for businesses looking to build trust and deliver consistent quality to their end customers.

Choosing NEX Pickleball as your manufacturing partner offers several tangible benefits:

• Enhanced Product Performance: Our advanced production techniques guarantee paddles with superior strength, control, and durability.

• Customization and Flexibility: With a wide range of materials and production choices, we adapt to your unique branding and performance needs.

• Competitive Pricing: Our efficient manufacturing processes and economies of scale help keep costs competitive, supporting your margin goals.

• Timely Production and Delivery: We understand market timing and ensure that product delivery schedules are met without compromising on quality.

• Long-Term Partnership: Focus on innovation and reliability builds a foundation for a lasting business relationship, ensuring you remain competitive in the fast-paced sports equipment market.

A strong partnership with a manufacturer like NEX Pickleball means that as trends and consumer demands evolve, you benefit from ongoing research, development, and improved production processes.

For procurement managers and business developers evaluating suppliers, consider these actionable steps when partnering with a manufacturer:

-

Evaluate the Production Technique:

– Understand the differences between hot pressing, cold pressing, and thermoforming.

– Ask for detailed production process documentation and quality control procedures. -

Assess Material Quality and Customization:

– Ensure the manufacturer offers premium materials like various types of carbon fiber or composite cores.

– Look for customization capabilities, such as on-demand printing, to align with your brand’s identity. -

Confirm Supply Chain Reliability:

– Request samples and conduct onsite visits if possible.

– Verify production capacity and the manufacturer’s track record for timely delivery. -

Performance Data and Case Studies:

– Seek references and performance data from similar B2B partnerships.

– Compare production efficiency and defect rates with industry benchmarks. -

Consider Long-Term Partnerships:

– A supplier’s commitment to innovation and continuous improvement is critical.

– Think beyond short-term transactions and look for partners invested in your long-term growth.

Following these recommendations will help ensure a well-informed decision that enhances both product quality and market competitiveness.

In a crowded marketplace, strategic partnerships with reliable manufacturers are essential. NEX Pickleball stands out by offering advanced production technologies, superior material choices, and robust quality control measures. Our commitment to innovation, customization, and operational excellence enables us to deliver pick-up paddles that meet the high standards of competitive performance.

For procurement managers and B2B professionals seeking a dependable manufacturing partner, NEX Pickleball provides not just products, but a pathway to enhanced business growth and customer satisfaction.

Taking steps now to partner with a manufacturer that demonstrates excellence in both production and performance will ultimately secure a competitive edge in the sports equipment market.

Q: Which company makes the best pickleball paddles?

A: While several well-known brands are recognized for high-performance paddles—such as those from JOOLA and Paddletek—NEX Pickleball distinguishes itself by combining advanced production techniques with superior material quality, ensuring exceptional performance for competitive play.

Q: Who manufactures pickleballs?

A: Several companies produce pickleballs, with ONIX Pickleball being one prominent example. However, NEX Pickleball specializes in high-performance paddle manufacturing, offering products that complement leading pickleball accessories and equipment.

Q: Are all pickleball paddles made in China?

A: No, not all pickleball paddles are made in China. While many high-performance paddles, including those from NEX Pickleball, are manufactured in China under strict quality controls, other companies like Paddletek and Engage manufacture their products in the USA, sometimes sourcing materials locally for added consistency.

-

Quality Control: Reading this article provides insights into the systems and processes that ensure product consistency and excellence throughout the manufacturing cycle. ↩ ↩

-

Supply Chain Inefficiencies: Reading this article discusses common challenges in supply chain management, such as production delays and shipping issues, and provides strategies to mitigate these risks. ↩ ↩

-

Thermoforming: Reading this article helps you understand how materials are heated and molded into complex shapes, enhancing design flexibility and performance in sports equipment. ↩ ↩

-

Carbon Fiber: Reading this article offers a detailed explanation of carbon fiber properties, its applications in high-performance products, and the benefits it brings to paddle manufacturing. ↩ ↩

-

Honeycomb Core: Reading this article explains the structure and advantages of honeycomb core technology, including improved shock absorption and stability for enhanced paddle performance. ↩ ↩