The quick answer: NEX Pickleball offers premium pickleball paddles built with advanced production processes and high-quality materials to ensure superior performance, durability, and customizable design options for B2B buyers seeking reliable and innovative sports equipment.

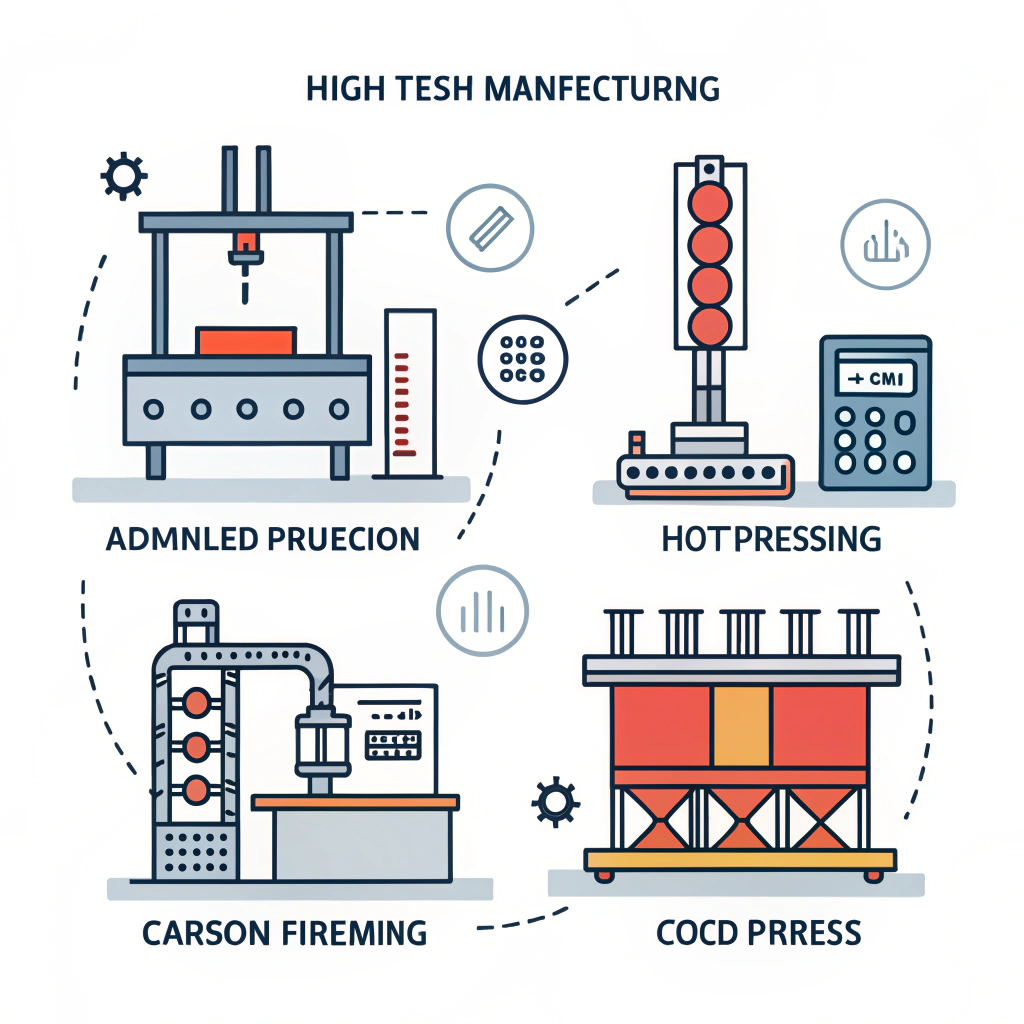

In today’s competitive sports equipment industry, procurement managers and OEM partners1 face multiple challenges when selecting pickleball paddle suppliers. They must consider factors such as manufacturing expertise, material quality, production consistency, and the ability to customize products for diverse market needs. Businesses require a supplier that not only delivers consistent quality but also supports scale, innovation, and competitive pricing. NEX Pickleball meets these demands by leveraging state-of-the-art production techniques that include hot pressing, cold pressing, and thermoforming processes2, and by offering a wide range of premium materials like carbon fiber, fiberglass, and various composites3.

The procurement decision is often complicated by several key factors:

-

Material Variability: Different materials like 3K, 12K, and T300 carbon fibers, as well as fiberglass and composite blends, affect paddle performance. The challenge is to understand which material offers the best combination of power, control, and durability based on specific playing conditions.

-

Manufacturing Process Impact: Production techniques have their own advantages and constraints. Hot pressing yields high production efficiency and excellent impact resistance, but it could influence the paddle’s feel. Cold pressing maintains the material’s natural properties for greater control, whereas thermoforming enables intricate designs with precise material distribution.

-

Customization Needs: B2B buyers customarily require tailored options like specific weight distributions, grip sizes, or branding. Balancing customization while maintaining scale and quality control is a complex process.

-

Supply Reliability: Consistent supply and stringent quality control are non-negotiable requisites in B2B procurement. Manufacturers must ensure that every paddle meets performance standards before reaching the market.

NEX Pickleball transforms these challenges into opportunities by offering a streamlined, quality-focused manufacturing process. Our solution combines advanced technology with expertise in material selection to produce paddles that excel in performance and durability.

Our use of multiple production techniques allows us to tailor the paddle performance to customer needs:

| Process | Advantages | Limitations |

|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; excellent structural integrity | May alter material feel; high initial equipment investment |

| Cold Pressing | Precise control over paddle thickness and structure; preserves intrinsic material properties | Longer production cycle; requires precise pressure management |

| Thermoforming | Enables intricate designs; precise material distribution; maintains paddle stability | Longer production time; higher equipment costs |

Each process is chosen based on the desired impact on hitting feel, control, and overall paddle durability. By offering multiple techniques, NEX Pickleball ensures that every paddle is fine-tuned to meet the rigorous demands of modern pickleball players.

NEX Pickleball’s paddles are produced using a range of high-performance materials. This flexibility is essential for addressing different market segments, from recreational players to competitive professionals. Below is a brief overview of the materials we use and their benefits:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| 3K Carbon Fiber | High strength and flexibility; excellent durability and vibration reduction | Competitive paddles needing high rebound force |

| 12K Carbon Fiber | Smoother surface; greater hardness and impact resistance | Paddles requiring extreme strength and precision control |

| T300 Carbon Fiber | Exceptional tensile strength; balanced performance | Lightweight yet durable paddles for intense play |

| E-Glass Fiberglass | Superior elasticity and tensile strength | Paddles offering great ball control and a larger sweet spot |

| Composite Materials | Blend of carbon fiber and fiberglass or bamboo/honeycomb core for unique performance balance | Custom paddles balancing power and control |

By carefully selecting and combining these materials, we produce paddles with properties tuned to specific demands. For instance, a composite made from carbon fiber and fiberglass delivers both power and control—ideal for players who need to adapt to varying play styles. Furthermore, options like Nomex Honeycomb4, Aluminum Honeycomb, or Polymer Honeycomb Cores enable us to optimize shock absorption, weight distribution, and paddle responsiveness.

When evaluating a supplier for pickleball paddles, B2B buyers should keep the following in mind:

-

Customization Capabilities: Your chosen supplier must offer a range of customization options. With NEX Pickleball, companies can specify design elements such as weight, grip size, balance, and even request on-demand printing services for branding purposes. This allows your products to stand out in a competitive market.

-

Quality Control and Testing: Every paddle at NEX Pickleball undergoes rigorous testing for strength, flexibility, and impact resistance. High-quality control not only ensures the product meets performance notes but also minimizes the risk during high-volume production.

-

Technical Expertise: A supplier with multi-faceted production methods provides versatility. Understanding how different manufacturing processes affect performance is a key decision-making factor. Our detailed attention to process optimization—from hot pressing to thermoforming—ensures consistency and scalability.

-

Supply Chain Reliability: Consistent production timelines and measurable quality control are the hallmarks of a trusted supplier. NEX Pickleball has optimized its production workflow to offer timely delivery alongside competitive pricing.

-

Industry Experience: Partnering with a supplier who understands both the high-performance demands of competitive sports and the needs of recreational play positions you for long-term success. NEX Pickleball’s collaboration with major brands like JOOLA and Selkirk lends credibility to our process and product quality.

Our proven track record in manufacturing top-tier paddles is supported by both industry data and client case studies. For example, our collaboration with leading sports brands ensures that our paddles have consistently delivered exceptional performance on the court. Analyzing customer feedback and on-field performance data, we continuously refine our production processes and materials. These metrics not only validate the quality of our paddles but also demonstrate that our approach to combining hot pressing, cold pressing, and thermoforming is both innovative and effective.

A simplified view of our production process performance is shown below:

| Performance Metric | Measurement Criteria | Outcome with NEX Pickleball |

|---|---|---|

| Impact Resistance | Ability to withstand high impact hits | High durability across all production methods |

| Customization Accuracy | Degree of fulfillment of custom specs | Consistent delivery of custom requests |

| Production Efficiency | Time taken to manufacture per unit | Optimized cycle times with quality checks |

| Material Integrity | Testing of material endurance | Superior longevity and play performance |

Our systematic approach in evaluating these performance metrics enables us to serve B2B clients with confidence and unmatched quality.

To maximize your investment in high-performance pickleball paddles, consider the following recommendations when selecting a supplier:

-

Evaluate Material Options Thoroughly: Ensure the materials used align with the competitive nature of your target market. For intense play, a combination of 12K carbon fiber and a polymer honeycomb core can be engineered to deliver precision and durability.

-

Prioritize Process Versatility: A supplier with diverse manufacturing techniques can better cater to custom paddle designs and variations in product performance. Understand the trade-offs between hot pressing, cold pressing, and thermoforming techniques, and discuss these in detail with your supplier.

-

Request Sample Testing Data: Look into the performance metrics provided by the supplier. Data on impact resistance, production efficiency, and customization accuracy can provide insightful benchmarks for your procurement decision.

-

Discuss Supply Chain Flexibility: During the purchasing conversation, ensure that the supplier can provide consistent lead times and quality even under high-volume orders. This is crucial for maintaining market competitiveness.

-

Focus on Long-Term Partnership: Engage with a supplier who is not only focused on using advanced production methods and premium materials but also on innovation and continuous improvement. A supplier that evolves with emerging trends and technologies will be a valuable strategic partner.

NEX Pickleball has established itself as a leader in the production of high-performance pickleball paddles by addressing the critical pain points for B2B buyers. Through advanced manufacturing processes such as hot pressing, cold pressing, and thermoforming, combined with a robust material selection ranging from various carbon fibers to composite cores, we provide a comprehensive solution that balances performance, durability, and customization.

Our deep understanding of both consumer needs and production challenges positions us as trusted OEM partners in the sports equipment industry. Whether you are looking for paddles that deliver superior power and control or need customization options tailored to your brand, our commitment to quality control and innovation ensures that the products you receive will meet and exceed your expectations.

To achieve the best results for your business and secure a reliable partnership in the competitive pickleball equipment market, consider engaging with NEX Pickleball as your strategic supplier. We are dedicated to helping you drive performance, innovation, and market success with every paddle delivered.

-

Which brand has the best pickleball paddles?

While many brands offer high-performing paddles, the quality of calf pickup depends primarily on material composition and production techniques. Manufacturers like NEX Pickleball emphasize using advanced production processes and premium materials to ensure durability, precision, and customizable options. -

Is there really a difference between pickleball paddles?

Yes, the differences in pickleball paddles are largely due to the materials used and the manufacturing process. Higher-quality paddles often use advanced materials such as various grades of carbon fiber and specialized cores, while production methods such as hot pressing, cold pressing, or thermoforming significantly influence the paddle’s performance, control, and durability.

-

OEM partners: Read more to understand the role of Original Equipment Manufacturer (OEM) partners in integrating specialized components into larger products and how they drive strategic supplier relationships in B2B markets. ↩ ↩

-

Thermoforming processes: Click here to explore how thermoforming works, its benefits in manufacturing complex shapes, and why it is a preferred method for high-performance sporting equipment. ↩ ↩

-

Composites: Learn about composite materials, including their properties and advantages, to see how combining different fibers can enhance performance and durability in sports equipment. ↩ ↩

-

Nomex Honeycomb: Discover the innovative use of Nomex Honeycomb in manufacturing, its role in improving shock absorption and weight distribution, and its application in premium product designs. ↩ ↩