High-performance pickleball paddle manufacturing relies on advanced production techniques and premium materials to deliver products that meet the rigorous demands of competitive play. In this article, we explain how our processes—ranging from hot pressing to thermoforming1—along with our selection of top-grade carbon fiber2, fiberglass3, and composite materials4, ensure quality, durability, and performance for B2B partners.

Manufacturers and distributors searching for a reliable partner in the sporting goods industry need detailed insights into production processes, material quality, and efficiency. At NEX Pickleball, we combine cutting-edge techniques with strict quality control to produce paddles that support bulk orders and custom specifications for markets worldwide. Our integrated approach encompasses three main production methods: hot pressing, cold pressing5 and thermoforming. We use a variety of premium materials—including several types of carbon fiber, fiberglass, and composite core materials—to craft paddles that cater to diverse player needs from beginners to professionals.

This article provides an in-depth look at our manufacturing processes, material selections, quality control procedures, and customization capabilities. Whether you are a B2B procurement manager or a sporting goods distributor, these insights will help you understand how our products deliver both performance and value in every paddle.

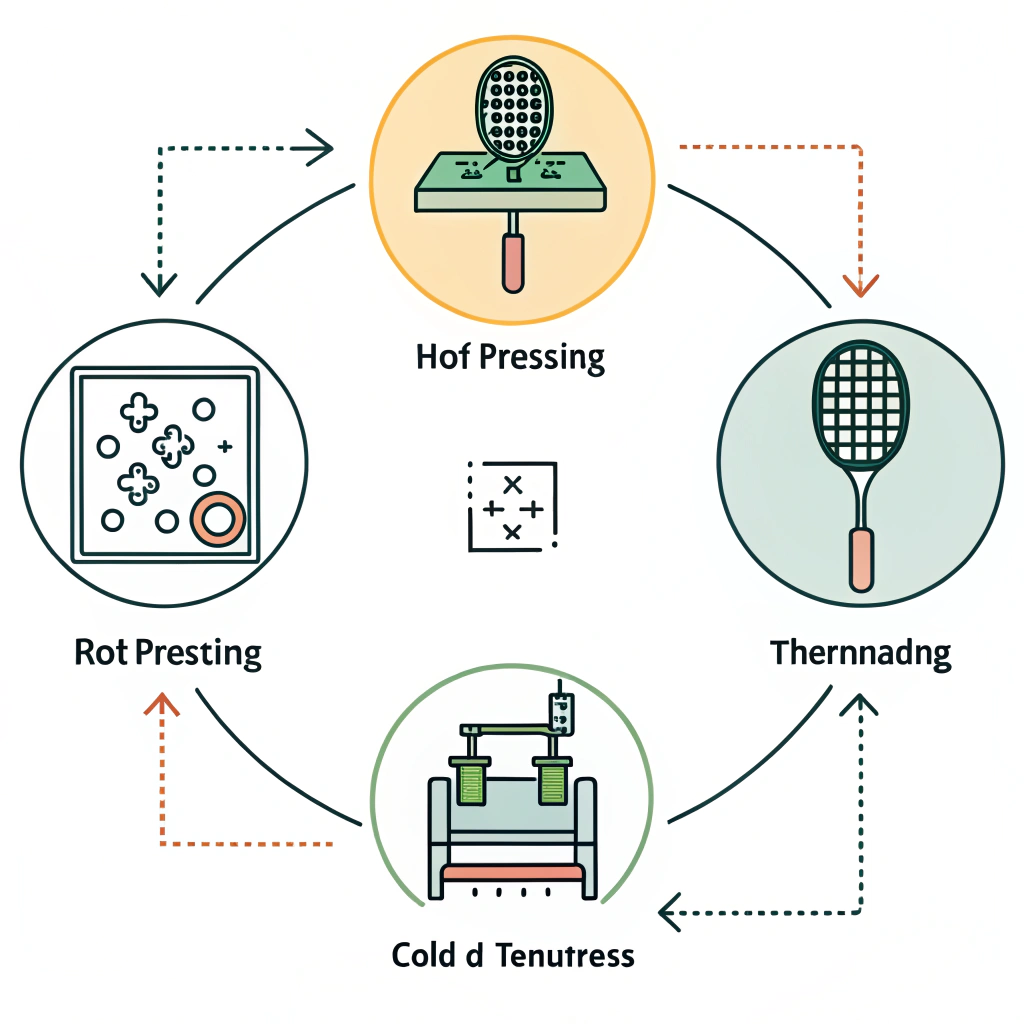

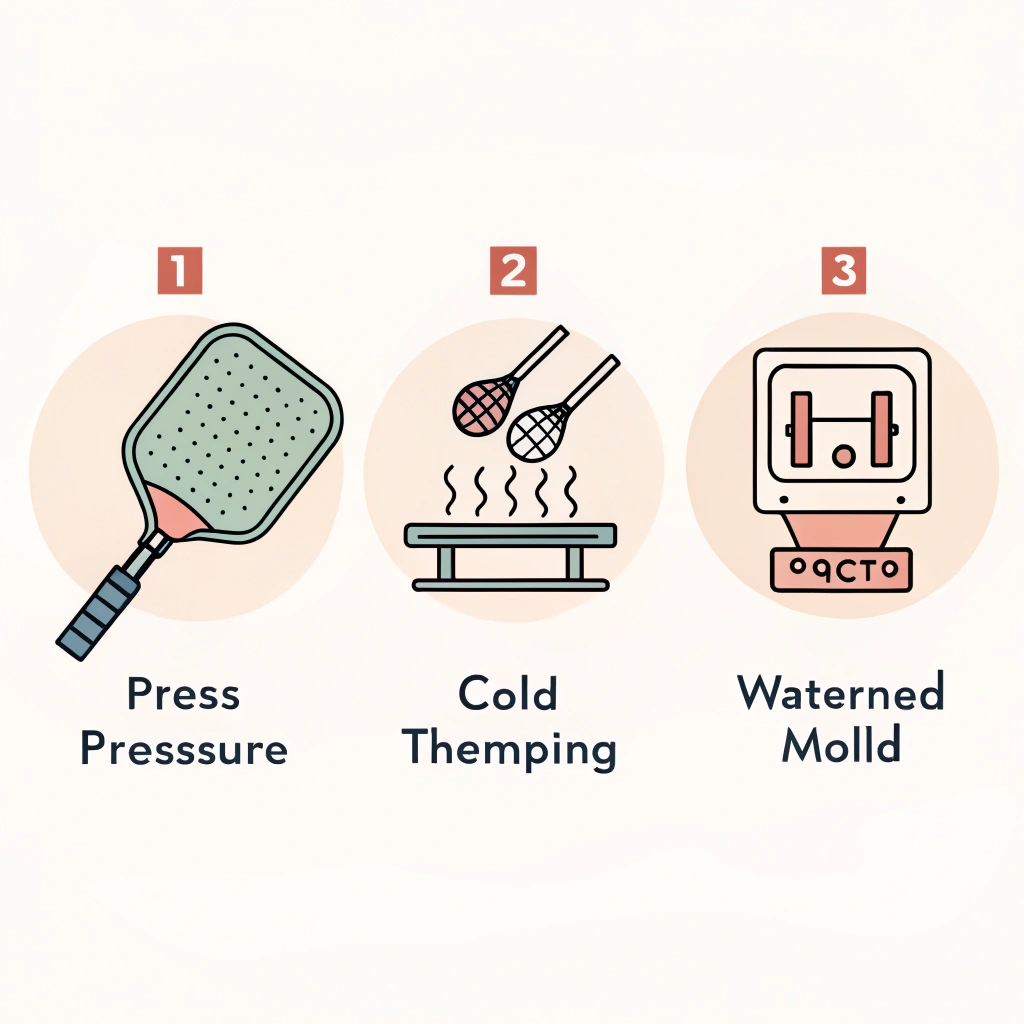

The production process is at the core of our commitment to excellence. We utilize three main manufacturing methods to produce high-performance pickleball paddles, each offering specific benefits and meeting unique design requirements.

Hot pressing involves heating the paddle materials and applying pressure to form a robust structure. This method ensures high production efficiency and consistent quality across large batches.

-

Advantages:

- High production throughput for large-scale orders.

- Produces strong paddles with excellent impact resistance.

- Maintains structural integrity for high-performance play.

-

Disadvantages:

- High initial equipment investment.

- Material properties can be altered slightly by heat.

In cold pressing5, mechanical pressure is applied at room temperature, preserving the intrinsic qualities of the materials. This approach is essential for paddles needing precise control over thickness and structure.

-

Advantages:

- Maintains the material’s natural properties.

- Offers unparalleled control over paddle design.

- Provides a superior ball feel and responsiveness.

-

Disadvantages:

- Longer production cycles compared to hot pressing.

- Requires sophisticated pressure control for consistency.

Thermoforming1 heats materials to a soft state and then molds them. This process is ideal for producing paddles with complex shapes and optimal material distribution.

-

Advantages:

- Enables intricate design possibilities.

- Enhances paddle stability by preserving material distribution.

- Suitable for premium or custom-made products.

-

Disadvantages:

- Longer production time.

- Higher equipment and operational costs.

Below is a table summarizing the benefits and limitations of each process:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, excellent structural integrity. | High equipment cost, potential alteration of material properties. |

| Cold Pressing | Preserves material properties, precise control, excellent ball feel. | Longer cycle times, requires high-quality pressure control. |

| Thermoforming | Intricate design, even material distribution, enhanced stability. | Extended production times, higher operating costs. |

The choice of materials is as crucial as the process in producing paddles that meet the performance demands of competitive pickleball. At NEX Pickleball, we select materials with care to ensure each paddle delivers power, control, vibration reduction, and longevity.

Carbon fiber technology2 is a cornerstone of high-performance paddle design. We offer multiple types, each with unique properties:

-

3K Carbon Fiber:

Ideal for paddles that require a high rebound force, this fiber provides excellent durability and reduces unwanted vibration during fast-paced rallies. -

12K Carbon Fiber:

With a higher thread density, 12K offers a smoother surface and increased hardness, making it perfect for competitive play that demands extreme strength and impact resistance. -

T300 Carbon Fiber:

Known for its outstanding tensile strength, T300 strikes a balance between strength and lightweight design, delivering a responsive paddle for high-level competitive play.

Fiberglass paddles3 are crafted to offer a blend of power and control with a wider sweet spot and superb durability. We employ E-Glass fiberglass, which is known for its elasticity and tensile strength, contributing to a superior feel and precise control when striking the ball.

We take advantage of composite materials4 for added benefits:

-

Carbon Fiber & Fiberglass Composite:

This combination capitalizes on the strengths of both materials, resulting in a paddle that balances light weight and excellent rigidity. -

Bamboo Core Composite:

Bamboo cores are highly impact-resistant and provide a unique, clear hitting feel, ensuring long-lasting paddle performance. -

Honeycomb Core:

Constructed with high-density polymer or pulp, honeycomb cores offer exceptional shock absorption, reducing vibration and enhancing durability.

Additionally, our selection of core materials—such as Nomex Honeycomb, Aluminum Honeycomb, and Polymer Honeycomb—allows us to fine-tune paddle characteristics to meet specific play styles. For B2B customers needing precise performance statements, these materials ensure that every paddle is not only lightweight but also robust enough for extended play.

For procurement managers and distributors, the ability to customize products to meet local market preferences is paramount. At NEX Pickleball, we offer extensive customization options:

-

Design Flexibility:

Clients can specify design aspects such as paddle shape, weight distribution, and grip size. Our advanced manufacturing techniques enable adaptability without compromising product quality. -

Material Selection:

Depending on performance requirements, customers can choose between various carbon fiber types, fiberglass, and composite blends. This flexibility is particularly useful when targeting different player demographics. -

Production Scalability:

With a production capacity that meets demands for minimum orders such as MOQ 100 pcs, we ensure timely delivery and consistent quality across all batches. Our streamlined processes and rigorous quality testing enable us to offer competitive pricing without sacrificing performance. -

Quality Assurance:

Every paddle undergoes thorough testing for strength, flexibility, balance, and durability. This ongoing commitment to quality ensures that our products not only meet industry standards but often exceed them, reinforcing our reputation as a trusted supplier in the sporting goods market.

Our quality control system is built into every phase of production:

- Material Inspection:

Every batch of carbon fiber, fiberglass, and composite material is rigorously tested before production begins. - Process Monitoring:

Each manufacturing process—whether hot pressing, cold pressing, or thermoforming—is closely monitored to ensure adherence to precise specifications. - Final Product Testing:

Finished paddles are subjected to performance, durability, and safety tests to certify their compliance with high-quality standards.

In today's competitive B2B landscape, efficiency and reliability are crucial. Our production processes are designed to support large volume orders while maintaining affordability and consistent quality. The benefits for wholesale purchasing include:

-

Scalable Production:

Our advanced manufacturing methods allow us to increase production without a drop in quality, making it possible to meet the demands of bulk orders. -

Cost Efficiency:

The integration of automated production techniques and effective quality control has helped us reduce wastage and costs. This efficiency enables us to offer competitive pricing while ensuring product excellence. -

Reliable Delivery:

With an established supply chain and logistics network, we ensure that orders, whether small or large, are delivered promptly, supporting client operations without disruption. -

Flexible Production Models:

We accommodate custom orders and provide technical support through every step of the buying process, ensuring that the final product meets the precise needs of distributors and retailers alike.

For procurement managers, these aspects are critical in making informed purchasing decisions. Our reliable production capacity and consistent quality control throughout the manufacturing process offer the assurance that every order will perform in the field as expected.

To sum up, our manufacturing approach is built on technical precision, premium materials, and robust quality control. At NEX Pickleball, we understand that B2B procurement decisions hinge on the balance of quality, cost, and customization flexibility. By employing advanced production processes such as hot pressing, cold pressing, and thermoforming, and by offering a diverse palette of materials including carbon fiber, fiberglass, and innovative composites, we provide paddles that are engineered for both performance and longevity.

Key takeaways include:

- A clear understanding of production processes and their respective benefits and limitations.

- Detailed insights into the various premium materials used, ensuring that the final product meets the rigorous demands of high-performance sports.

- A robust quality control framework that guarantees every paddle is built to last.

- Customization options that cater to diverse market requirements and adaptable production models that support scalable and cost-effective manufacturing.

For B2B procurement managers looking for a trusted manufacturing partner in the sports equipment industry, partnering with NEX Pickleball offers the confidence of superior performance, efficient production, and exceptional value. We invite you to contact us for detailed quotations, technical discussions, or to arrange a product trial. Embrace the advantage of high-performance pickleball paddles that meet both the sport's competitive demands and the business's supply chain needs.

What is the best pickleball paddle manufacturer?

NEX Pickleball is among the top pickleball paddle manufacturers, offering high-performance products crafted using advanced production techniques and premium materials such as carbon fiber and fiberglass. Our strict quality control and customization options ensure that every paddle meets the rigorous standards required for competitive play, making us a reliable partner for B2B procurement.

-

Thermoforming: Click to read about the thermoforming process and its role in creating complex shapes and optimized material distribution. ↩ ↩2

-

Carbon fiber technology: Click to learn more about the properties, manufacturing process, and applications of carbon fiber in advanced sporting goods. ↩ ↩2

-

Fiberglass paddles: Click to explore the benefits of fiberglass, including its elasticity and durability in sports equipment. ↩ ↩2

-

Composite materials: Click to understand how composite materials combine different fibers for improved performance and design flexibility. ↩ ↩2

-

Cold pressing: Click to discover how cold pressing preserves material integrity and contributes to precise paddle design. ↩ ↩2