Rapid Answer: Paddle weight optimization is a critical factor that balances performance, control, and durability in pickleball paddles. It requires combining carefully selected materials with tailored manufacturing processes to meet stringent industry standards and player expectations.

Pickleball paddle weight can make or break a player's performance on the court. In the realm of B2B sports equipment manufacturing, optimizing paddle weight is not simply a matter of reducing or increasing mass; it is a balanced engineering challenge that blends material science, design engineering, and precision production processes. In this article, we explore why paddle weight matters, how various materials and manufacturing processes impact it, and what technical decision-makers need to consider when selecting a supplier.

For procurement managers, product developers, and technical decision-makers, choosing the right paddle weight is paramount. A paddle that is too heavy can hinder a player's quick maneuvers, while one that is too light may sacrifice power and stability. Therefore, manufacturers must optimize paddle weight to enhance performance, reduce vibration, and ensure a balanced feel. Paddle weight optimization is influenced by:

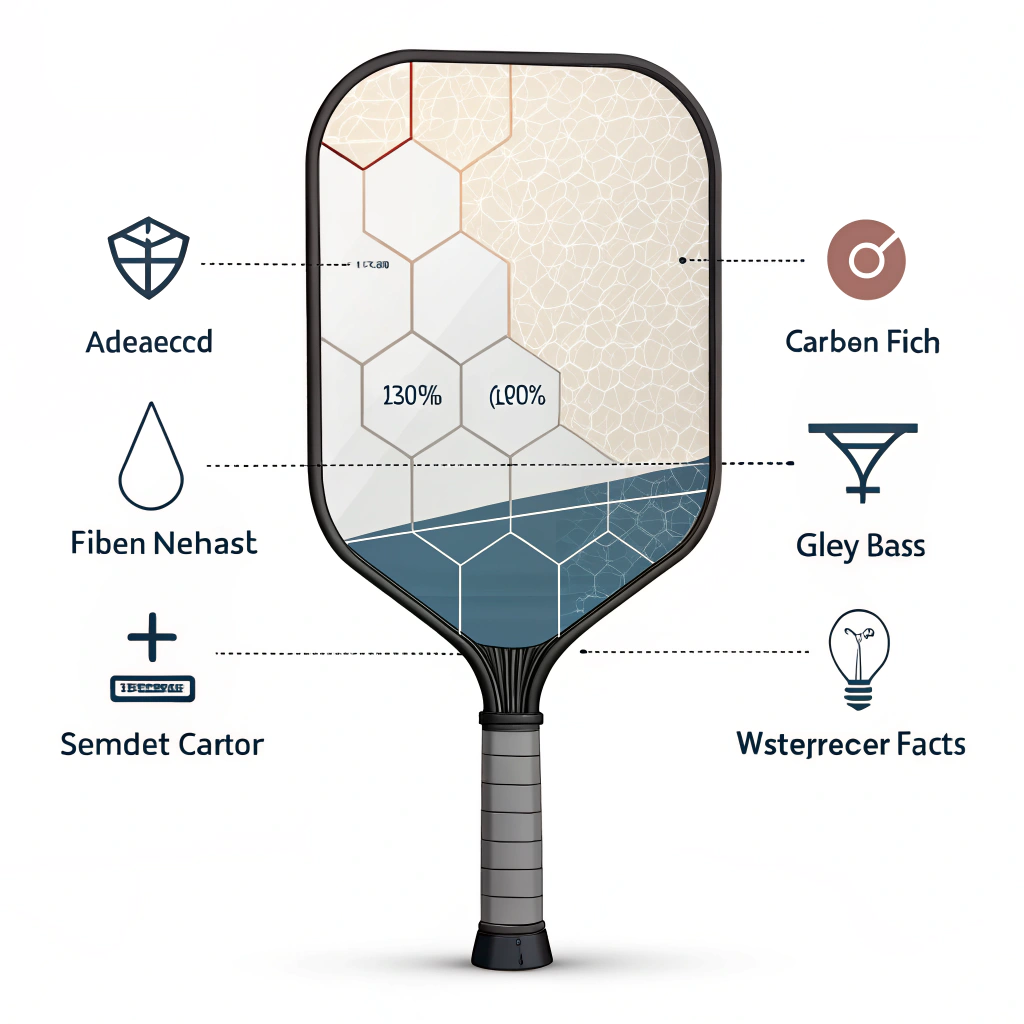

• Material selection: Choosing between carbon fiber1, fiberglass2, composites, or cores made from Nomex or polymer directly affects weight and impact absorption.

• Manufacturing processes: Techniques such as hot pressing3, cold pressing4, and thermoforming5 have varying impacts on material density and overall weight distribution.

• Design engineering: Ergonomic shapes, grip designs, and surface textures must be carefully engineered to harmonize weight distribution.

The challenge lies in ensuring that each paddle offers high-performance characteristics, such as improved responsiveness, enhanced ball control, and long-lasting durability.

Several technical factors contribute to paddle weight optimization:

Different materials are selected based on their strength, elasticity, and weight:

- Carbon Fiber:

- 3K Carbon Fiber provides strength and flexibility, ensuring excellent rebound capabilities.

- 12K Carbon Fiber offers a smoother surface and greater hardness, ideal for competitive play due to its superior impact resistance.

- T300 Carbon Fiber strikes a balance between tensile strength and light weight.

- Fiberglass:

- E-Glass Fiberglass provides a balance of flexibility and an expansive sweet spot, beneficial for ball control.

- Composite Materials:

- Combinations like Carbon Fiber and Fiberglass or Bamboo Core Composite blend benefits to achieve power and control.

- Core Materials:

- Nomex Honeycomb offers stability and shock absorption, while Polymer Honeycomb improves elasticity and reduces vibration.

These materials influence not only weight but also the overall performance and durability of a paddle.

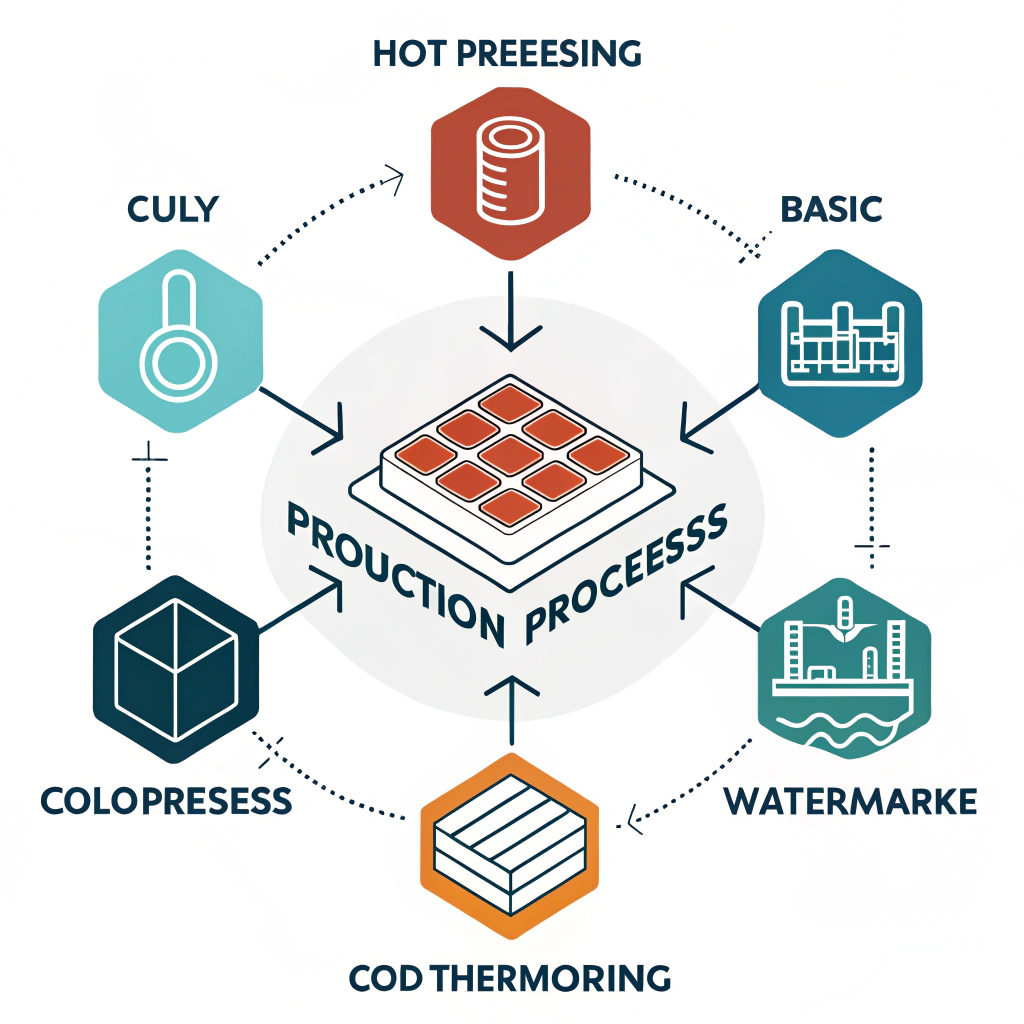

The manufacturing process plays a pivotal role:

- Hot Pressing:

- Increases production efficiency and forms a strong paddle structure but can alter material properties that may affect the paddle’s feel.

- Cold Pressing:

- Ensures better material integrity and precise thickness control, ideal for players needing refined ball feel.

- Thermoforming:

- Allows for complex shapes and precise distribution of materials, albeit with longer production times and higher costs.

Differences in these processes affect the final paddle weight and performance characteristics, which may influence a company’s manufacturing strategy.

For technical decision-makers, understanding trade-offs is essential. The table below outlines key aspects of the production processes used by leading sports equipment manufacturers like NEX Pickleball:

| Production Process | Advantages | Disadvantages | Impact on Weight & Performance |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structure, excellent impact resistance | Potential alteration of material properties, high equipment cost | Produces durable paddles; minor trade-offs in feel may occur |

| Cold Pressing | Superior control over thickness, preserves material integrity, excellent ball responsiveness | Longer production cycles, requires precise pressure control | Ideal for precision-weight control and maintaining natural material properties |

| Thermoforming | Enables intricate designs and precise material distribution, maintains paddle stability | Higher production time, greater equipment investment | Best for premium, custom-design paddles that require specific weight distributions |

Another crucial area of focus is the selection of core materials, which directly affect weight and vibration absorption:

| Core Material Type | Characteristics | Best Use Case |

|---|---|---|

| Nomex Honeycomb Core | Excellent shock absorption, durable polymer build | Competitive play requiring long-lasting durability |

| Aluminum Honeycomb Core | Balanced weight for optimal power and control | Players needing a mix of precision and strength |

| Polymer Honeycomb Core | Enhanced elasticity, reduced vibration | Recreational play and for players seeking comfort |

By offering a range of materials from 3K, 12K, T300 carbon fiber to various composite and core options, manufacturers can tailor paddles for a wide variety of player profiles and performance expectations.

Paddle weight not only affects swing speed and control but also interacts with human biomechanics. A paddle’s weight distribution and balance have substantial implications for:

- Agility: A lighter paddle allows quicker movements and rapid responses. However, if the weight is not optimized, players may struggle with power during swings.

- Energy Transfer: Proper weight ensures maximum energy is transferred during ball contact, leading to improved power without added fatigue.

- Vibration Reduction: An optimized weight distribution helps reduce vibration, resulting in less strain on the player’s arm.

Adopting a data-driven approach can guide procurement managers in identifying the right balance between materials and processes that suit both recreational and competitive play.

NEX Pickleball’s expertise lies in its advanced production techniques and rigorous quality control. As a contract manufacturer for renowned brands like Joola and Selkirk, NEX Pickleball leverages high-precision equipment and state-of-the-art manufacturing methods to ensure consistent quality. Key considerations include:

-

Consistency in Material Application:

Ensuring that the properties of carbon fiber1, fiberglass2, and composite materials are uniformly applied across each paddle minimizes variations in weight and balance. -

Precision in Production:

Techniques such as cold pressing allow for a meticulous control of paddle thickness and material distribution. This precision minimizes deviations that might impact overall performance. -

Customizability:

Offering on-demand print services and customizable options enables players and organizations to specify design, weight, balance, and grip size based on their specific requirements. Flexibility in manufacturing is an asset for market differentiation. -

Rigorous Testing:

Each paddle undergoes thorough testing to verify standards related to impact resistance, vibration absorption, and ergonomic comfort. This inspires confidence in both the product quality and subsequent customer performance.

With these processes, manufacturers can achieve the dual goal of optimizing paddle weight and ensuring robust overall performance standards.

For those in the process of selecting a manufacturing partner or upgrading product specifications, focus on the following steps:

-

Evaluate Material Specifications:

Compare the performance benefits of different materials such as 3K carbon fiber versus fiberglass. Consider the specific demands of your target market—be it agility for recreational players or durability for competitive play. -

Assess Production Processes:

Determine whether high-speed production (hot pressing3) or precision quality (cold pressing4 or thermoforming5) aligns best with your manufacturing priorities and budget constraints. -

Consider Customization Capabilities:

Opt for suppliers that offer customizable paddle options with flexible weight distribution, as this allows you to rapidly respond to changing market trends and customer needs. -

Review Quality Control Protocols:

Look for manufacturers who implement rigorous testing procedures. Transparent quality control processes reduce risk and improve customer satisfaction. -

Leverage Industry Standards:

Stay updated on industry benchmarks and performance metrics. Aligning your product design with established standards can help ensure market competitiveness.

By following these recommendations, you not only enhance product performance but also build a robust supply chain that supports long-term growth and innovation.

In summary, paddle weight optimization is a multifaceted challenge that demands careful control over material selection, production processes, and design engineering. For B2B stakeholders in the sports equipment manufacturing industry, understanding these technical intricacies is key to delivering paddles that meet both competitive performance standards and consumer expectations. By analyzing the trade-offs between different materials like carbon fiber and fiberglass and leveraging advanced production techniques such as hot pressing, cold pressing, and thermoforming, companies can significantly improve paddle performance while maintaining efficient manufacturing processes.

As you navigate your next investment decision, consider partnering with a supplier known for its commitment to quality, precise manufacturing, and innovative design. Let our expertise help you elevate your product offerings, ensuring that every paddle hits the mark on performance and durability.

People Also Ask

Q1: How does paddle weight affect performance?

A1: Paddle weight directly impacts a player’s agility, power, and control; optimizing weight improves swing speed, energy transfer, and reduces vibration.

Q2: What are the advantages of different manufacturing processes in paddle production?

A2: Hot pressing offers rapid production and impact resistance, cold pressing ensures precise control and optimal material integrity, and thermoforming allows for intricate design and precise weight distribution.

Q3: How do manufacturers choose between carbon fiber and fiberglass for pickleball paddles?

A3: The decision depends on the desired balance of strength, flexibility, and durability; carbon fiber, available in variants like 3K, 12K, and T300, offers superior power and control, while fiberglass delivers enhanced flexibility and a wider sweet spot.

-

carbon fiber: Read this article to understand advanced composite materials, their manufacturing benefits, and how they enhance sports equipment performance. ↩ ↩ ↩2

-

fiberglass: Learn about fiberglass properties and applications in manufacturing for improved durability and flexibility in equipment. ↩ ↩ ↩2

-

hot pressing: Explore the hot pressing process to see how it enhances production efficiency while affecting material properties in sports manufacturing. ↩ ↩ ↩2

-

cold pressing: Discover insights into cold pressing techniques that preserve material integrity and allow for finer control over product attributes. ↩ ↩ ↩2

-

thermoforming: Understand thermoforming methods and how precise material distribution and complex shapes are achieved in high-end product design. ↩ ↩ ↩2