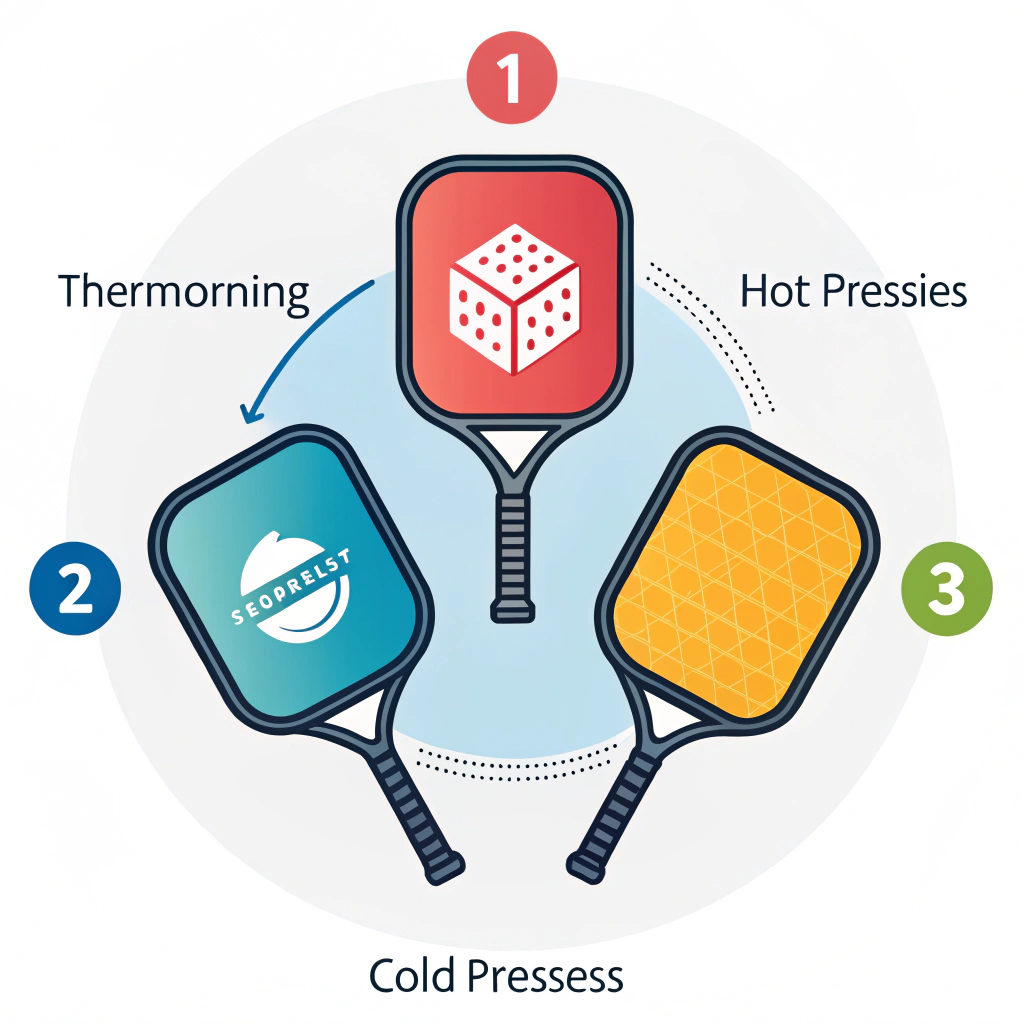

Pickleball paddle design and color trends for 2025 are set to blend vibrant aesthetics with high-performance production techniques. Advanced manufacturing methods such as thermoforming1, hot pressing2, and cold pressing3 are driving innovation and opening new avenues for design differentiation and market success.

The pickleball market is evolving rapidly, and as we approach 2025, design trends are shifting from simple aesthetics to a combination of high-performance features and striking visual appeal. B2B decision makers in the paddle manufacturing and sporting goods industry must now factor in consumer insights, advanced production techniques, and future color trends to stay competitive. In this article, we explore how strategic design innovations and cutting-edge technology can shape your next season’s product line, ensuring an edge in an increasingly competitive market.

By 2025, color trends will play a pivotal role in product differentiation. Consumers are no longer satisfied with plain or overly muted designs. Instead, they seek paddles that offer both a high-performance feel and a striking visual presence. Key observations include:

• Bold, saturated colors paired with contrasting graphic elements

• Use of gradients and metallic finishes to evoke both energy and sophistication

• Custom printing technology allowing companies to integrate team logos, brand identities, or even player-specific designs

These trends open new marketing opportunities. Companies can create limited editions or special collections that not only serve functional purposes but also act as statement pieces for avid players and collectors alike.

The evolution of manufacturing technology is central to realizing the new design visions. Major innovations have been made in the following areas:

Thermoforming remains a game-changer for design innovation. By heating materials to a softening point and molding them into precise shapes, manufacturers can create paddles with intricate, unibody designs that offer enhanced stability and control.

• Advantages:

– Intricate design possibilities

– Optimized weight distribution

– Enhanced impact resistance

• Limitations:

– Longer production time

– Higher upfront equipment costs

Hot pressing involves compressing materials at high temperatures to mold the paddle. This method guarantees structural integrity, making it ideal for competitive play where durability is non-negotiable.

• Advantages:

– High production efficiency

– Excellent impact resistance

– Suitable for large-scale manufacturing

• Limitations:

– Alteration of some material properties

– High capital investment in machinery

Cold pressing allows manufacturers to shape the paddle at room temperature, preserving the material’s inherent properties. This results in products with superior ball feeling and finesse, a crucial factor for players seeking precise control.

• Advantages:

– Maintains optimal material characteristics

– Superior control and responsiveness

– Customizable thickness and structure

• Limitations:

– Long production cycles

– Requires highly precise pressure controls

Below is a summary table comparing these three processes:

| Process | Key Benefit | Main Limitation | Ideal For |

|---|---|---|---|

| Thermoforming | Intricate design & stability | Longer production times | High-end, custom-made paddles |

| Hot Pressing | Strength & durability | Material property alterations | Mass production for competitive play |

| Cold Pressing | Precision control & responsiveness | Extended production cycles | Paddles requiring high ball feel control |

These processes enable designers to achieve a harmonious balance between aesthetics and performance. Manufacturers like NEX Pickleball leverage these techniques to create paddles that not only perform at the highest levels but also captivate consumers with their innovative designs.

The selection of materials has a profound impact on both paddle performance and visual appeal. Today’s paddles are crafted from advanced materials that include several variants of carbon fiber4, fiberglass, and composite combinations. Here’s how these materials influence design:

-

3K Carbon Fiber

– Offers excellent strength and flexibility.

– Ideal for paddles requiring high rebound force.

– Enhances durability while reducing vibration. -

12K Carbon Fiber

– Provides a smoother surface with superior hardness.

– Perfect for competitive play due to enhanced impact resistance. -

T300 Carbon Fiber

– Known for high tensile strength.

– Balances strength with lightweight characteristics for improved handling.

Each type of carbon fiber brings unique qualities to the paddle, allowing for innovation in surface treatment and graphic detailing. A well-designed paddle can take advantage of these properties by incorporating accent colors that complement the carbon fiber’s natural hue or by adding printed patterns that enhance the product’s visual appeal.

Composite materials, such as the combination of carbon fiber with fiberglass, offer an excellent balance between power and control. Additionally, the use of organic elements like bamboo core composites is increasingly popular because they provide a lightweight structure with a unique visual texture.

• Bamboo Core Composite:

– Provides an eco-friendly alternative

– Enhances paddle aesthetics with natural patterns

– Offers high impact resistance

• Honeycomb Core:

– Made from high-density polymer or pulp

– Superior shock absorption and durability

– Reduces vibration effectively during play

By integrating these advanced materials, manufacturers can offer paddles that are not only functionally superior but also visually distinctive. The emerging trend is all about creating products that consumers immediately recognize as innovative and performance-oriented.

Recent market trends indicate that consumers are increasingly influenced by both performance metrics and the visual design of sports equipment. For instance, players at both recreational and competitive levels are searching for paddles that match their personal style while also providing a competitive edge. The latest trends in graphic design—such as the integration of fluid shapes, geometric patterns, and vibrant color schemes—are a response to these shifting demands.

Incorporating unique design elements not only improves the paddle's visual appeal but also reinforces brand identity at the point of sale. For B2B clients, these factors are crucial, as they directly affect consumer purchasing decisions and the overall market positioning of the products.

Manufacturers who invest in advanced production techniques stand out in the crowded market. For example, the use of thermoforming technology allows for more bespoke paddle designs with higher precision and aesthetic appeal. Meanwhile, methods like cold pressing deliver products that excel in ball control and overall performance. These innovations allow companies to cater to niche segments by offering customized products that meet specific athletic needs and aesthetic preferences.

From a strategic standpoint, incorporating the latest manufacturing technologies is crucial. Decision-makers should consider:

- Upgrading equipment to support advanced techniques such as thermoforming and cold pressing.

- Investing in R&D to explore new materials and composites that align with evolving color trends and graphic designs.

- Offering customizable paddle options to differentiate their product lines in a saturated market.

- Engaging in partnerships with leading designers to continually refresh product aesthetics and maintain competitive differentiation.

These steps can help businesses not only capture emerging market opportunities but also build long-term brand loyalty among end users.

To effectively harness these trends and technology advancements, consider the following steps:

-

Invest in Research:

Stay updated with the latest consumer trends and manufacturing technologies. Consider hosting focus groups or market surveys to gauge color and design preferences. -

Upgrade Production Capabilities:

Evaluate your current manufacturing processes. Investing in advanced equipment for thermoforming, hot pressing, or cold pressing could increase both efficiency and design flexibility. -

Enhance Material Innovation:

Explore hybrid material options such as carbon fiber/fiberglass composites to create products with balanced performance characteristics. This approach can help target both amateur and professional segments. -

Diversify Customization Options:

Offering on-demand printing or custom design services can allow sports teams and brands to create paddles that reflect their unique identities. This move not only meets consumer demand but also opens up higher-margin opportunities. -

Build Strong Partnerships:

Collaborate with experienced design agencies and material experts. Strategic partnerships can lead to innovations that set your product line apart from the competition. -

Leverage Digital Marketing:

Use visually-driven digital campaigns to showcase innovative designs and advanced technology. Highlighting the unique production processes and customization options can capture the interest of both retailers and end users.

By taking these proactive steps, B2B decision makers can not only better respond to market shifts but also guide their product development processes toward future-proof designs that meet both aesthetic and performance demands.

The journey towards innovative pickleball paddle design in 2025 is an exciting blend of advanced manufacturing, material innovation, and trend-driven aesthetics. As consumer expectations evolve, so must the strategies of manufacturers and B2B partners. Adopting technologies like thermoforming, hot pressing, and cold pressing along with a strong focus on vibrant color schemes and custom graphics can help brands stand out in a competitive market.

Ultimately, the future of paddle design is not just about creating a visually striking product but also about enhancing player performance and comfort. With the right investment in research, technology, and design partnerships, companies can position themselves as leaders in the industry—delivering products that resonate with both style-savvy consumers and performance-driven athletes.

Prioritizing these trends and making strategic manufacturing enhancements today will pave the way for long-term success. As you plan your next product launch, consider how these design and technological innovations can form the core of your brand’s competitive strategy in 2025 and beyond.

• What is the best pickleball paddle for 2025?

Based on current trends, the best pickleball paddles for 2025 are those that blend innovative graphic designs and vibrant color trends with superior manufacturing techniques such as thermoforming, hot pressing, and cold pressing. These paddles often feature advanced composite materials, providing a balance between power, control, and durability.

• What is the latest technology in pickleball paddles?

The latest technology in pickleball paddles includes the use of thermoforming processes and advanced composite materials like carbon fiber variants combined with fiberglass and honeycomb cores. This technology enhances paddle stability, impact resistance, and overall performance, resulting in products that deliver a superior playing experience while also offering unique design aesthetics.

-

Thermoforming: Click to learn how the process of heating materials to a pliable state enables manufacturers to create complex, precision-molded designs that enhance product aesthetics and performance. ↩ ↩

-

Hot pressing: Click to discover how compressing materials at high temperatures improves structural integrity and durability, particularly for large-scale production. ↩ ↩

-

Cold pressing: Click to understand how room-temperature molding preserves material properties, delivering superior ball control and finesse in paddle design. ↩ ↩

-

Carbon fiber: Click to explore the various types of carbon fiber, their unique properties, and how they contribute to lightweight and high-strength sports equipment. ↩ ↩