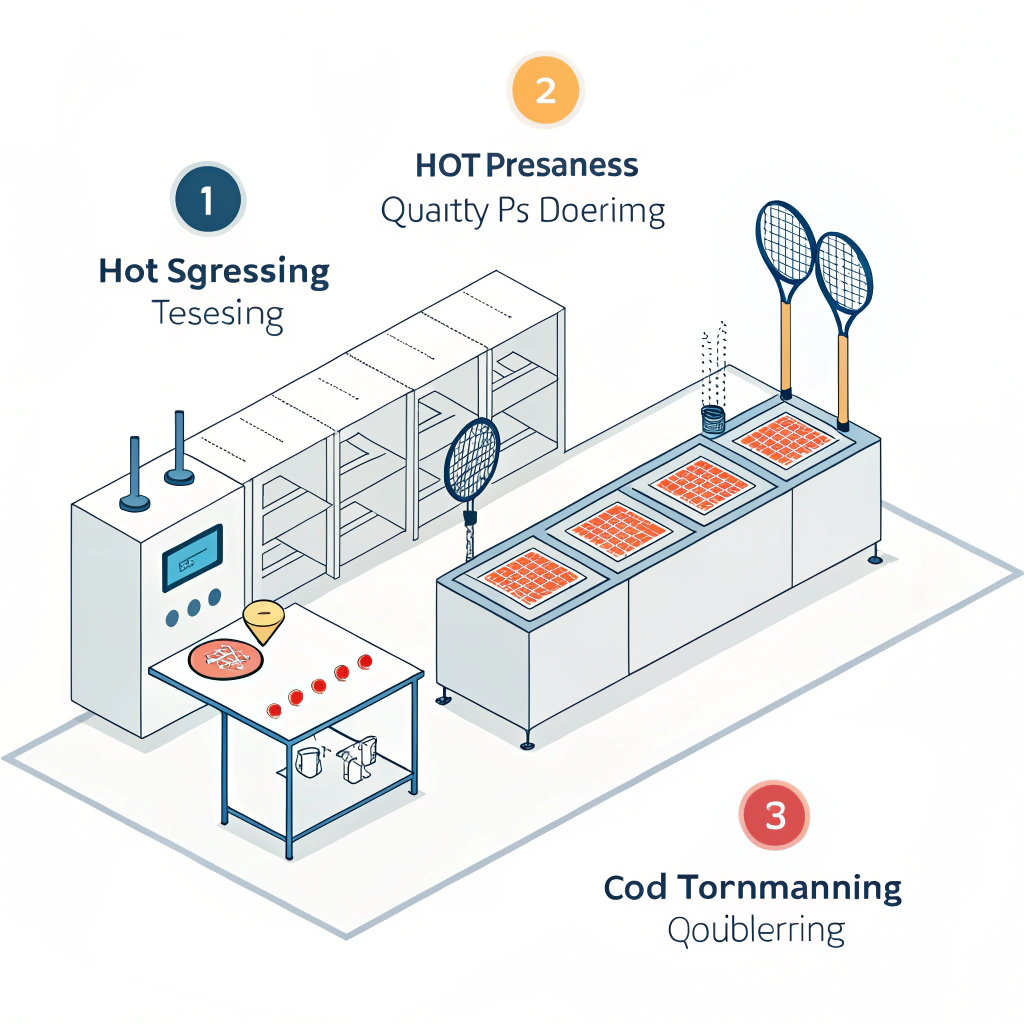

Pickleball paddle testing and quality assurance are critical for ensuring that high-performance OEM1 products meet strict durability, control, and safety standards. Rigorous production processes like hot pressing2, cold pressing, and thermoforming3, combined with advanced testing methodologies, help manufacturers guarantee superior paddle performance even under competitive conditions.

In today’s competitive sports equipment market, the integrity of your manufacturing partner is paramount. For senior procurement and product development managers, understanding the detailed testing protocols and production process variations is essential. This article dives into the testing methods and quality control standards applied in producing high-performance pickleball paddles. We will explore the nuances of advanced production processes, compare their benefits and limitations, and explain how these methods contribute to enhanced durability, impact resistance, and performance metrics.

Quality control in OEM manufacturing is not just about following standard procedures. It involves several layers of product testing, from raw material selection to final product inspection. For companies like NEX Pickleball, each paddle goes through multiple quality assurance checkpoints that include material stress tests, impact resistance evaluations, and performance trials. These protocols ensure that every paddle delivers the balanced performance players expect – combining power, control, and reliability.

Manufacturers face two main challenges:

• Ensuring overall durability and stability even under harsh playing conditions.

• Meeting the stringent quality requirements demanded by both competitive and recreational players.

Addressing these challenges requires a combination of advanced testing methods and tailored production processes. Our discussion today will explore these facets in detail.

Pickleball paddles can be manufactured using three primary processes: hot pressing2 (see above), cold pressing, and thermoforming3. Each process affects the paddle’s characteristics in a unique way and has corresponding testing requirements.

Hot pressing involves heating materials before applying mechanical pressure. This process is widely used for producing high-strength paddles with excellent impact resistance.

-

Advantages:

• High production efficiency suitable for large-scale manufacturing.

• Enhances the structural integrity and impact resistance of the paddle.

• Results in paddles optimized for high-performance conditions. -

Disadvantages:

• Alters some material properties which may slightly affect the feel of the paddle.

• Requires significant investment in specialized equipment.

In testing, paddles produced via hot pressing are subjected to stress tests that mimic continuous high-impact forces. These evaluations ensure that material degradation is minimized and that paddle performance remains consistent over time.

Cold pressing shapes the paddle material at room temperature by applying precise mechanical pressure. This method is preferred for designs that demand ultra-precise control.

-

Advantages:

• Preserves the inherent properties of the material, offering superior control and flexibility.

• Produces paddles known for an excellent ball feel and responsive touch. -

Disadvantages:

• Extended production cycles which may lower output efficiency.

• Requires highly controlled conditions to maintain precise pressure distribution.

Paddles manufactured by cold pressing are tested for vibration reduction, consistency in thickness, and surface uniformity. These parameters are critical for ensuring an optimal hitting experience and reducing the risk of early product wear.

Thermoforming3 uses heat to soften materials before forming them into shape using molds. This process is ideal for paddles that require complex designs and precise material distribution.

-

Advantages:

• Enables the creation of paddles with intricate shapes and consistent material layouts.

• Promotes stability in paddle design by evenly distributing material thickness. -

Disadvantages:

• Longer production times and higher associated equipment costs.

For thermoformed paddles, testing methods focus on uniformity in structure and surface treatment quality. These tests ensure that the paddle’s performance is consistently high even with complex designs and that critical performance areas such as grip texture and balance are maintained.

To provide clarity on how each manufacturing process affects the final product, consider the following comparison table:

| Process | Key Advantages | Limitations | Typical Testing Focus |

|---|---|---|---|

| Hot Pressing | High impact resistance; efficient production | May alter material feel; high equipment cost | Stress tests; impact resistance; durability ratings |

| Cold Pressing | Superior control; maintains material properties | Longer production cycles; precise pressure needed | Vibration analysis; surface uniformity; ball feel tests |

| Thermoforming | Intricate design possibilities; even material distribution | Extended production time; high mold costs | Uniformity tests; balance and stability evaluations |

This table is a useful guide when comparing the cost-performance tradeoffs among these processes, especially for OEM partners looking to balance efficiency and product excellence.

Apart from production processes, the primary materials used in paddle construction significantly affect performance. Manufacturers like NEX Pickleball rely on a variety of advanced materials:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Offers excellent flexibility and durability, tested for its high rebound and vibration reduction.

- 12K Carbon Fiber: Provides a smoother surface and enhanced hardness; subjected to impact and abrasion tests.

- T300 Carbon Fiber: Known for its tensile strength and lightweight properties, often tested for balance between power and control.

-

Fiberglass:

- E-Glass Fiberglass: Offers an optimal balance between power and control with increased flexibility; tested for elasticity and tensile strength.

-

Composite Materials:

- Carbon Fiber & Fiberglass Composite: Combines the benefits of both materials leading to a balance of strength and flexibility.

- Bamboo Core Composite: Appreciated for its lightweight and impact resistance; quality assurance tests focus on long-term durability.

- Honeycomb Core: Often made from high-density polymers, it is tested primarily for its shock absorption capabilities.

-

Core Materials Testing:

- Nomex Honeycomb Core4: Stands out for its excellent shock absorption and durability, making it ideal for rigorous performance testing.

- Aluminum Honeycomb Core: Offers balanced weight and control; tested for both power and precision.

- Polymer Honeycomb Core: Known for reducing vibration and enhancing comfort; frequently evaluated for elasticity and player comfort.

Each type of material undergoes extensive testing protocols that simulate real-world conditions and ensure that each batch of paddles consistently meets industry performance standards.

To maintain a competitive edge, advanced testing methods go beyond standard mechanical tests. In our OEM production, several specific control points are implemented:

• Material Integrity Tests:

Prior to assembly, raw materials are tested for tensile strength, elasticity, and resistance to environmental factors.

• Process Control Monitoring:

During methods like hot pressing and cold pressing, sensors track temperature, pressure, and timing to ensure each paddle maintains consistency. Any deviation is flagged for further review.

• End-Product Inspection:

Every paddle is subjected to impact tests, vibration analysis, and balance assessments to ensure that performance metrics meet or exceed industry benchmarks.

• Long-Term Durability Trials:

Selected products undergo accelerated life-cycle testing. This simulates months of play over a short period to confirm the paddle will not degrade prematurely.

These quality control measures are documented in detailed production reports, which are crucial for providing transparency to our B2B partners. This rigor not only builds trust but also supports the OEM’s claim of delivering products that stand up to the demands of professional play.

When evaluating potential OEM partners, it is essential to understand the underlying testing methodologies and their impact on final product quality. Here are several crucial considerations:

-

Test Data Transparency:

Reliable OEMs share detailed test results for each production batch. Look for documented stress tests, vibration analysis data, and long-term durability assessments. -

Adaptability of Manufacturing Processes:

A partner who can customize production processes (e.g., adjusting hot pressing parameters or fine-tuning thermoforming molds) shows the ability to optimize products for specific market needs. -

Material Versatility:

The range of materials (from high-grade carbon fiber5 to innovative composite cores) available in production ensures that a manufacturer can cater to diverse market segments – from recreational players to competitive athletes. -

Certifications and Standards:

Ensure that the OEM adheres to recognized international standards, especially in terms of environmental compliance and quality assurance. Certifications in manufacturing and testing processes are a key indicator of reliability. -

Scalability and Lead Times:

Meeting both market demand and quality benchmarks at scale is challenging. Assess whether the OEM can maintain testing rigor and quality control during high-volume production runs without compromising performance levels.

For procurement managers assessing OEM partnerships, here are actionable recommendations based on our comprehensive review:

• Conduct a detailed review of the OEM's quality control documentation and test reports.

• Request sample products and data from stress tests that simulate competitive play scenarios.

• Evaluate the flexibility of the OEM in adjusting production processes to meet specific product performance requirements.

• Consider the material spectrum offered and confirm that each type has undergone rigorous, standardized testing.

• Look for third-party certifications or industry endorsements that verify the robustness of testing protocols and manufacturing precision.

By following these steps, you can ensure that the OEM you select will provide paddles that consistently deliver superior performance and durability—factors which are essential for maintaining competitive advantage in your product line.

High-performance pickleball paddle production requires an intricate balance of advanced production methods and rigorous testing protocols. Understanding these manufacturing processes—hot pressing, cold pressing, and thermoforming—and the associated quality control measures is critical for ensuring that each paddle meets the exacting standards required for both competitive and recreational play. For B2B procurement managers, these insights provide the foundation to make informed decisions about OEM partnerships, securing a reliable source for products that combine innovative material science with proven manufacturing excellence.

By partnering with a manufacturer that demonstrates transparency in testing and a commitment to top-tier quality control, you empower your product development pipeline with reliability, consistency, and superior performance.

People Also Ask

-

How is the durability of pickleball paddles evaluated during production?

Manufacturers use a combination of stress tests, impact resistance evaluations, and long-term durability trials to simulate real-world play conditions and ensure paddles maintain their performance over time. -

What are the differences in quality control between hot pressing and cold pressing methods?

Hot pressing typically emphasizes high impact resistance and efficient production, while cold pressing is focused on preserving material properties for superior ball feel and precision. Each has distinct testing protocols to assess structural integrity and performance consistency. -

How does thermoforming contribute to paddle performance?

Thermoforming allows for intricate design and precise material distribution, resulting in uniform balance and stability. Quality control tests for thermoformed paddles focus on uniformity and structural consistency to ensure high-performance play.

-

OEM: Click to read an article explaining the role and importance of Original Equipment Manufacturers in streamlining production, ensuring quality standards, and fostering strategic partnerships in B2B operations. Back to OEM ↩

-

hot pressing: Click to understand how the hot pressing process works, its advantages in boosting material strength, and its impact on production efficiency in high-performance manufacturing. Back to hot pressing ↩ ↩2

-

thermoforming: Click to explore the thermoforming process, highlighting its role in crafting complex shapes and ensuring consistent material distribution for optimal product performance. Back to thermoforming ↩ ↩2 ↩3

-

Nomex Honeycomb Core: Click to discover the benefits of Nomex Honeycomb Core in shock absorption and durability testing, and its critical role in meeting stringent industry standards. Back to Nomex Honeycomb Core ↩

-

high-grade carbon fiber: Click to learn about high-grade carbon fiber, its properties, and why it is pivotal in enhancing product durability and performance in advanced manufacturing. Back to high-grade carbon fiber ↩