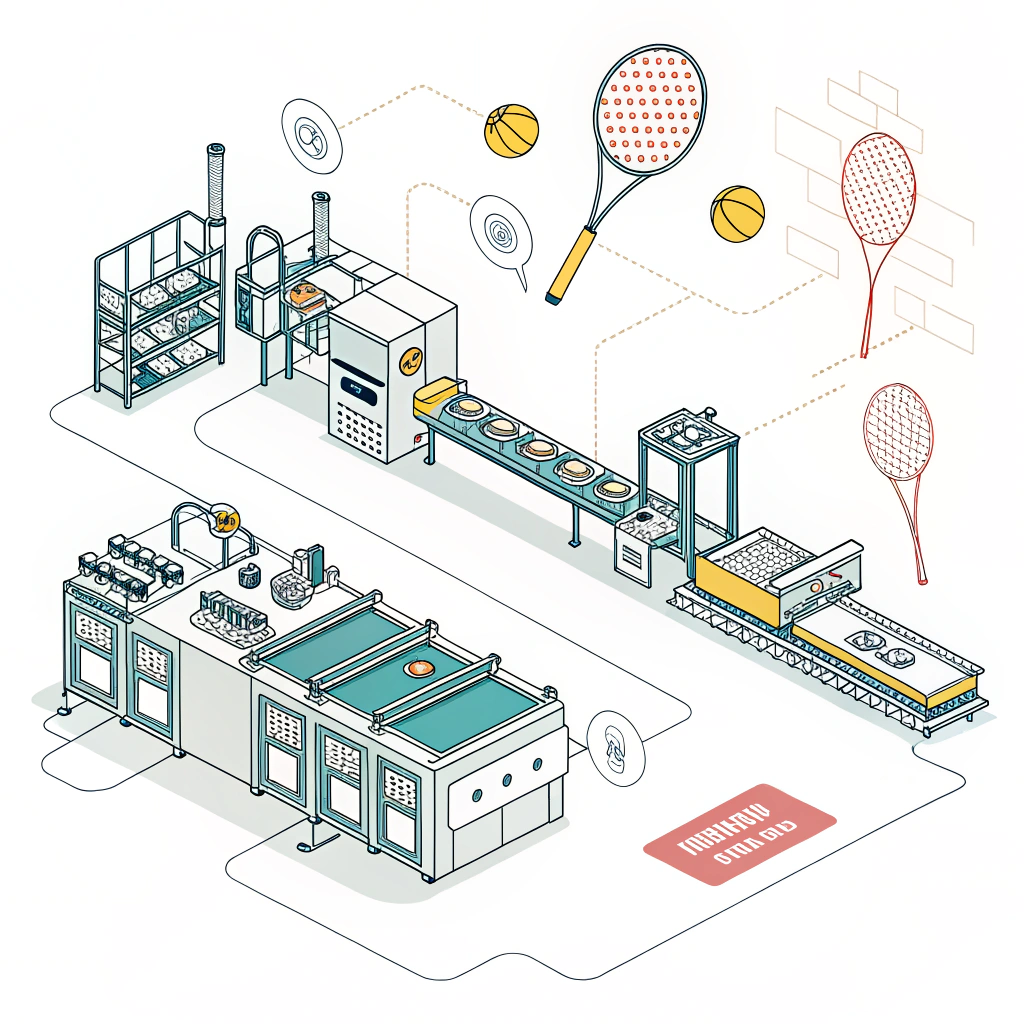

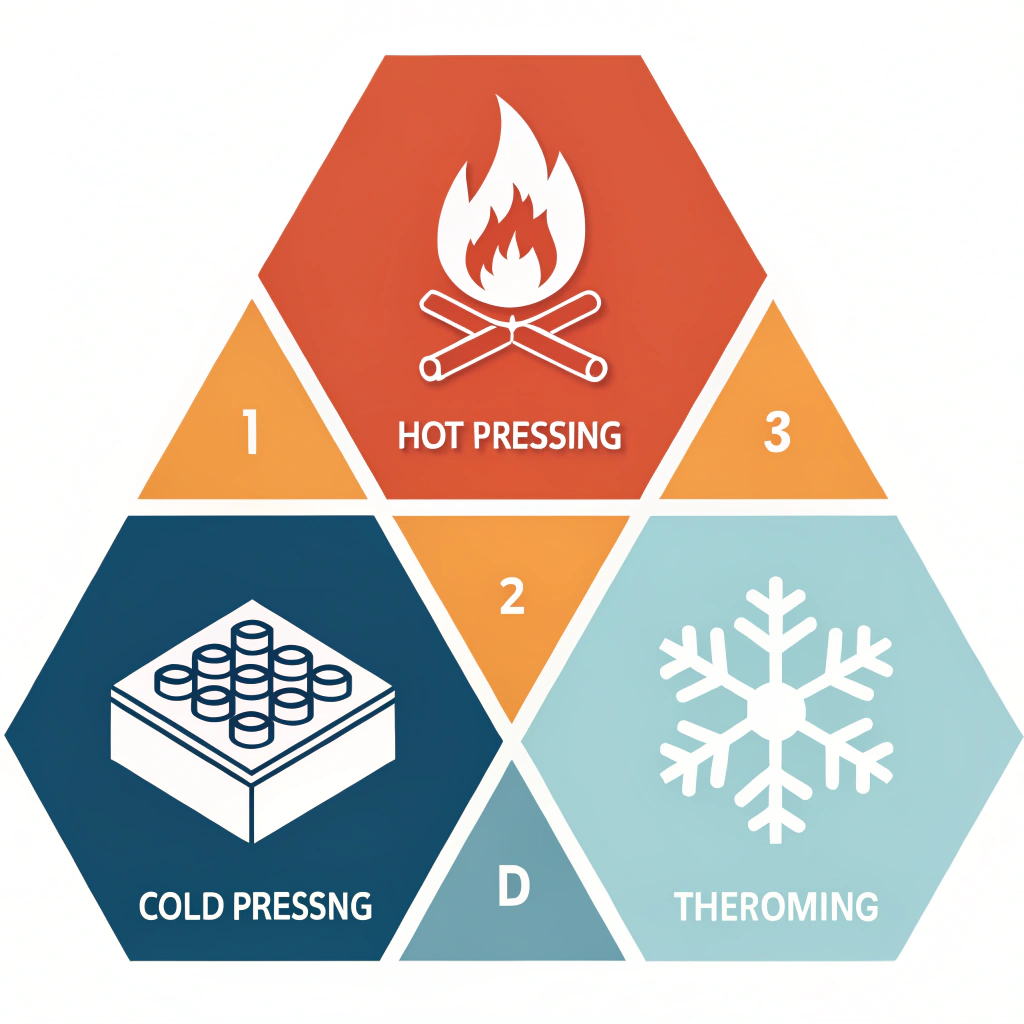

The production process of a high-performance pickleball paddle involves a series of technical decisions and manufacturing methods. This article explains how advanced processes such as hot pressing1, cold pressing2, and thermoforming3 are employed at NEX Pickleball to ensure a reliable, durable, and customizable product. By understanding these techniques and material choices, procurement managers can make informed decisions when selecting a supplier for their sports equipment needs.

In today’s competitive sports equipment market, manufacturers must balance production efficiency, material performance, and product customization. NEX Pickleball leverages advanced manufacturing processes—hot pressing, cold pressing, and thermoforming—to produce paddles that excel on every front. These methods, combined with a careful selection of premium materials like various types of carbon fiber4, fiberglass, and innovative composite cores, ensure that every paddle meets rigorous quality control standards.

Procurement managers seeking a long-term manufacturing partner must evaluate not only the production technology but also the quality control measures and customization capabilities. This article provides a comprehensive comparison of the key production processes, highlights the materials used, and outlines how these factors contribute to superior paddle performance and reliability.

Hot pressing1 is a method where materials are heated and then pressed simultaneously to form the paddle. This technique is ideal for creating strong, impact-resistant paddles that can withstand high-intensity play.

- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Produces paddles with excellent structural integrity and impact resistance.

- Well-suited for high-performance products used in competitive sports.

- Disadvantages:

- High initial investment in specialized equipment.

- The heating process can alter some material properties, potentially affecting the feel of the paddle.

Hot pressing is a preferred process when durability and strength are paramount. Its ability to produce structurally robust paddles makes it an attractive choice for sports equipment companies looking to fill large orders with consistent quality.

Cold pressing2 operates at room temperature, using mechanical pressure to shape the paddle without significant heat-induced alterations. This process is crucial when maintaining the inherent properties of the raw materials is important for performance.

- Advantages:

- Precise control over paddle thickness and structure.

- Retains the natural characteristics of the material, ensuring better ball feel and control.

- Provides a consistent, ergonomic design ideal for both recreational and competitive play.

- Disadvantages:

- Longer production cycles reduce overall efficiency.

- Requires high-accuracy pressure monitoring and quality equipment.

For procurement managers, cold pressing offers the benefit of precision and superior control over final product characteristics. This meticulous approach is particularly valuable when the playing experience, such as feel and responsiveness, plays an essential role in product differentiation.

Thermoforming3 involves heating materials to a softening point and then molding them using custom-built molds. This method is particularly effective for creating paddles with intricate designs and consistent material distribution.

- Advantages:

- Allows for the creation of complex, customized paddle shapes.

- Provides excellent stability by ensuring even material distribution.

- Supports a variety of high-performance materials, enhancing product versatility.

- Disadvantages:

- Higher equipment and maintenance costs.

- Longer production times compared to both hot and cold pressing.

Thermoforming is highly suited for premium product lines or custom paddle orders where design intricacies and material distribution are crucial for the end-user performance. The ability to offer customization drives added value for businesses and specialty sports retailers looking for unique product offerings.

The following table summarizes the core aspects of each manufacturing process:

| Process | Advantages | Disadvantages | Best Used For |

|---|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance; robust product | High investment costs; potential material alteration | Large-scale production, competitive play paddles |

| Cold Pressing | Superior control over thickness; retains material properties; enhanced ball feel | Longer production cycles; requires precise pressure control | Custom design with high focus on playability |

| Thermoforming | Allows intricate design; ensures material stability; versatile material usage | Longer production time; higher equipment costs | Premium products and custom orders |

This detailed comparison provides a clear picture for procurement managers who need to balance quality, cost, and customization. With each method offering distinct benefits, the choice depends on specific production requirements and market positioning.

Apart from production processes, the selection of materials plays a crucial role in defining the performance and durability of pickleball paddles. At NEX Pickleball, the thoughtful use of materials such as carbon fiber4, fiberglass, and specialized composite cores ensures that every paddle is built to excel.

Different types of carbon fiber are used to target varying performance needs:

- 3K Carbon Fiber: Known for its flexibility and high rebound force. Its strong and durable nature minimizes vibration, making it suitable for players who demand dynamic play.

- 12K Carbon Fiber: Provides a smoother surface and greater hardness due to a higher thread density, ideal for competitive play requiring extreme strength.

- T300 Carbon Fiber: Balances strength and weight to produce paddles that are both robust and lightweight, suitable across different skill levels.

The careful selection and combination of carbon fiber types allow NEX Pickleball to offer paddles that cater to various performance needs, from casual play to high-stakes competition.

Fiberglass and Composite Materials5

Fiberglass paddles are recognized for their enhanced ball control and wider sweet spots. Materials like E-Glass Fiberglass provide excellent elasticity combined with high tensile strength, ensuring that each paddle offers a pleasant feel and optimal control.

Composite Materials5 such as:

- Carbon Fiber and Fiberglass Composite: This amalgamation achieves a balance between strength and flexibility, ideal for players who require both power and precision.

- Bamboo Core Composite: Lightweight and highly impact-resistant, providing excellent durability and a clear hitting sensation.

- Honeycomb Core (Nomex, Aluminum, and Polymer Options): These cores optimize weight distribution, shock absorption, and vibration damping, thereby enhancing paddle longevity.

Using composite materials addresses the demands of both performance and durability, offering a versatile solution that meets the diverse needs of players and manufacturers alike.

For B2B procurement, ensuring consistent quality control and the ability to customize products for specific markets is essential. NEX Pickleball employs rigorous testing protocols across all steps of the production process. Each paddle undergoes extensive assessments for strength, hardness, elasticity, and response time to ensure it meets predefined performance criteria.

- Material Testing: Every raw material, whether carbon fiber, fiberglass, or composite material, is tested to ensure it meets durability standards.

- Process Validation: Continuous monitoring is done during hot pressing, cold pressing, and thermoforming to secure consistency in every batch.

- Final Product Inspection: Finished products undergo a series of tests, including vibration reduction, shock absorption, and ergonomic analysis.

By following these strict quality control measures, manufacturers can reduce defect rates and ensure that every paddle delivers consistent performance.

Customization options, such as design variations, weight adjustments, grip size changes, and even on-demand printing services, are critical when catering to a diverse market. This level of flexibility allows companies to adapt quickly to market trends or specific customer needs without compromising on quality.

- On-Demand Printing: Businesses can request custom branding on paddles to enhance team identity or promote retail strategies.

- Custom Paddle Configurations: Options include adjustments in balance, size, and even surface texture for improved grip performance and control.

These customization capabilities not only satisfy the end-users but also strengthen the business relationships between manufacturers and procurement managers by delivering tailor-made solutions that meet evolving market demands.

When selecting a manufacturing partner, procurement managers should also consider factors such as production capacity, delivery timelines, and cost-effectiveness. NEX Pickleball is well-equipped to handle large-scale orders by maintaining high production standards, robust logistics, and competitive pricing, thus ensuring timely delivery without compromising on product quality.

- Production Capacity: Leveraging advanced methods and automation allows for high-volume manufacturing with consistent quality.

- Timely Delivery: Streamlined logistics ensure that orders are processed and shipped within the required timelines, an essential factor for B2B relationships.

- Competitive Pricing: Efficient production processes and economies of scale contribute to cost-effective manufacturing, offering substantial value during bulk orders.

These factors make NEX Pickleball a reliable partner, capable of meeting both the performance and logistical demands of the modern sports equipment market.

In summary, the manufacturing processes of hot pressing, cold pressing, and thermoforming each offer unique advantages that can be strategically applied depending on production needs, cost factors, and desired product performance. NEX Pickleball’s expertise in combining these processes with top-tier raw materials such as carbon fiber, fiberglass, and advanced composite cores provides a robust framework for delivering high-performance pickleball paddles.

For procurement managers, selecting a partner with such technical prowess and a commitment to quality control is crucial. The detailed methods and customization capabilities described in this article should serve as a guide in the evaluation and comparison of potential manufacturing partners. When quality, reliability, and customizability are non-negotiable, NEX Pickleball stands out as a supplier ready to meet the challenges of a dynamic and rapidly expanding market.

The next steps involve:

• Evaluating your product requirements against the production processes described.

• Considering customization options that align with your brand identity.

• Contacting technical representatives to discuss further details on production capacity and delivery timelines.

By carefully examining these factors, procurement managers can make well-informed decisions that ensure both immediate and long-term success in the sports equipment market.

-

What company makes the best pickleball paddles?

Leading brands like JOOLA and Selkirk are frequently mentioned, but the best choice depends on specific performance needs such as power, control, and design preferences. Manufacturers like NEX Pickleball, the OEM for JOOLA and Selkirk, focus on advanced manufacturing techniques to deliver high-performance paddles tailored for competitive play. -

How many pickleball paddle factories are there?

The market has seen significant growth; recent figures indicate that the number of manufacturers has surged from around 50 to nearly 900 in a few years. This reflects an expanding, highly competitive landscape that emphasizes quality and innovation in paddle production. -

What brand is better, Selkirk or Joola?

Both brands offer exceptional performance with distinct strengths. Selkirk typically emphasizes durability and advanced materials, while JOOLA is known for ergonomic design and aerodynamics. The choice largely depends on whether you prioritize power and control or speed and spin.

-

hot pressing: Click to learn about the benefits of hot pressing in manufacturing, including how heat and pressure are used to produce durable, high-impact sports equipment. ↩ ↩2

-

cold pressing: Click to explore cold pressing technology, which preserves material integrity and provides precision in shaping products for improved performance. ↩ ↩2

-

thermoforming: Click to understand thermoforming, a process that enables intricate design and customization by molding materials at controlled temperatures. ↩ ↩2

-

carbon fiber: Click for an in-depth look at carbon fiber, its unique properties, and its applications in high-performance sporting equipment and engineering. ↩ ↩2

-

Composite Materials: Click to discover how composite materials combine different elements to achieve optimized strength, durability, and versatility in product manufacturing. ↩ ↩2