Recycling high-performance pickleball paddles through eco-friendly practices involves integrating advanced closed-loop systems1, material-specific recycling methodologies, and stringent regulatory compliance to reduce waste and boost production efficiency.

The manufacturing of pickleball paddles produces significant waste due to the use of multiple materials like carbon fiber, fiberglass, and various composite cores. Traditional production processes such as hot pressing, cold pressing, and thermoforming2 generate off-cuts and by-products that often end up as waste. Moreover, the complexity of recycling these composite materials is compounded by differences in structural properties.

Environmental concerns, coupled with increasing regulatory pressures and market demand for sustainable products, have driven companies to evaluate their recycling methodologies. For sustainability managers and manufacturing executives, the primary challenge lies in converting waste streams into valuable resources while maintaining the high-performance standards expected of competitive sporting goods.

Several factors contribute to the recycling challenges in pickleball paddle production:

-

Material Complexity:

- Carbon Fiber Variants: Materials such as 3K, 12K, and T300 carbon fiber3 have unique attributes. Their high strength and rigidity complicate the recycling process, as conventional methods may compromise their structural integrity.

- Composite Materials: Paddles often use blends of carbon fiber, fiberglass, and composite cores like Nomex4, aluminum, or polymer honeycombs. Each component reacts differently in recycling processes, making it hard to implement a one-size-fits-all solution.

-

Production Process Residues:

- Hot Pressing: While efficient, this method can alter material properties. Recycling remnants may no longer exhibit the same performance standards as the original raw materials.

- Cold Pressing and Thermoforming: These processes require precise control, and any deviation may render the leftover materials less suitable for high-performance reuse.

-

Economic and Regulatory Pressures:

- Implementing robust recycling processes often requires significant upfront investment. Additionally, staying compliant with environmental regulations while ensuring product performance adds another layer of complexity.

- There is a fine balance between reducing waste and maintaining production efficiency, where each misstep can lead to higher costs or suboptimal recycling outcomes.

Manufacturers can adopt several solutions to overcome these challenges, all aimed at integrating eco-friendly production with high-performance output. Below is a structured overview of strategies that can be implemented:

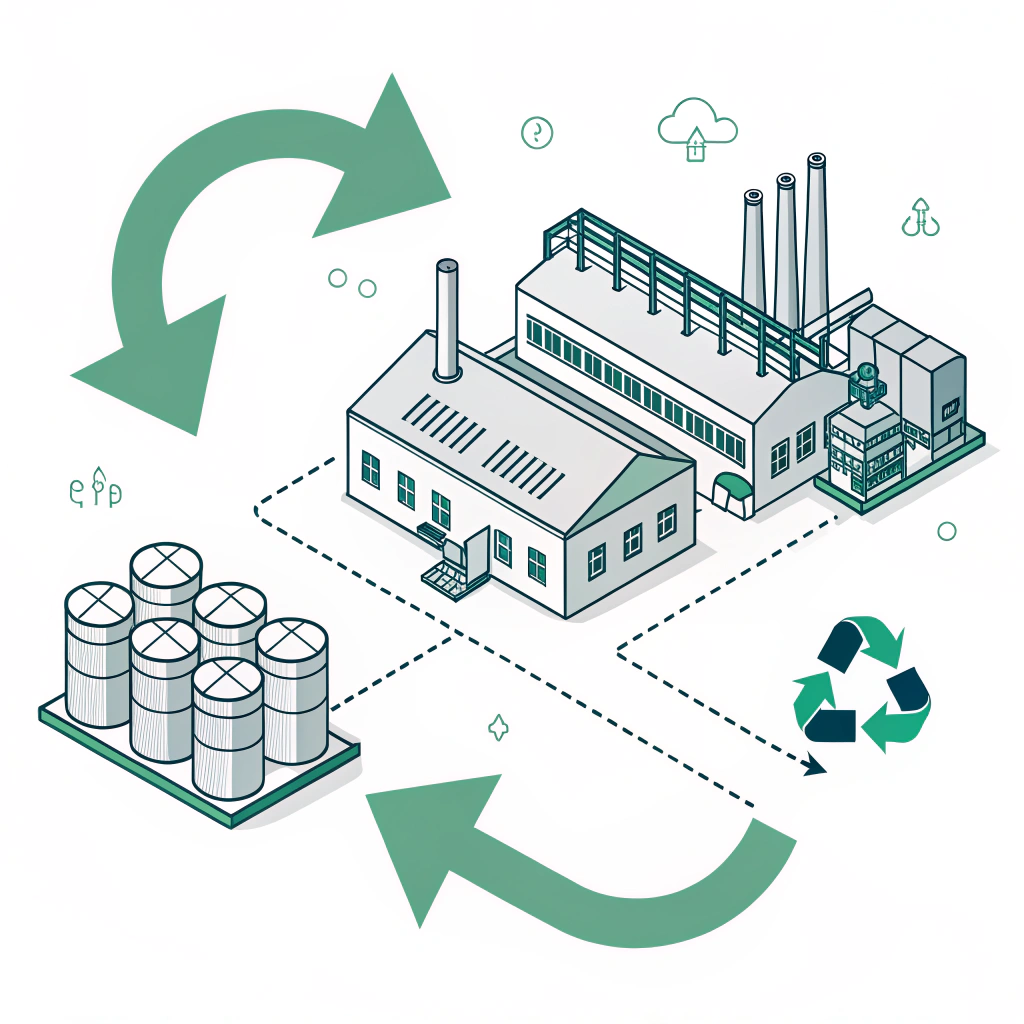

Manufacturers may need to adjust their existing processes to incorporate waste recovery and recycling systems effectively. For instance, upgrading from traditional hot pressing methods to systems that allow for better recovery of material properties can help create a closed-loop manufacturing system.

A closed-loop recycling system1 ensures that waste materials are routinely fed back into the production process. This not only mitigates environmental impact but also reduces raw material costs. For example, reclaimed carbon fiber can be processed and reused in non-critical components or new paddle designs.

Each primary material used in paddle production calls for specialized recycling techniques:

| Material Type | Recycling Strategy | Benefits | Considerations |

|---|---|---|---|

| Carbon Fiber (3K, 12K, T300) | Mechanical recycling and controlled pyrolysis processes5 | Retains high strength and durability; reduces waste | Requires advanced technology and careful quality control |

| Fiberglass | Thermal recycling to reclaim fiber properties | Offers balance between control and recyclability | May require additional treatments to recover quality |

| Composite Materials | Separation technologies to reclaim individual material components | Enables reuse of both carbon fiber and fiberglass in new formulations | Complex and cost-intensive; often needs customized solutions |

| Core Materials (Nomex, aluminum, polymer) | Chemical or mechanical recovery methods, depending on material | Improves sustainability by repurposing internal structures | Process efficiency varies with material type |

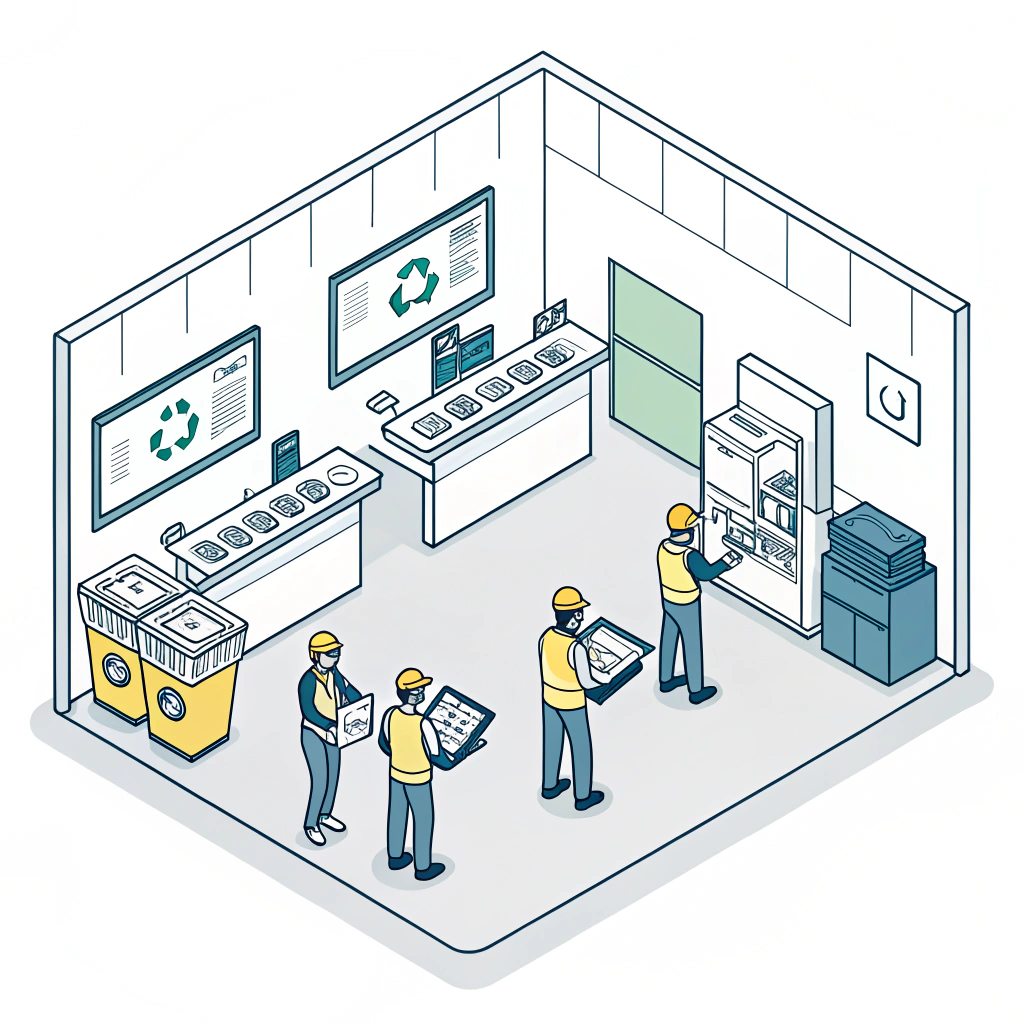

Begin with a comprehensive audit of the waste generated during every production stage. Identify the types and quantities of waste—whether they stem from off-cuts during pressing or surplus composite materials. This assessment provides a clear picture of the environmental impact and areas for process improvement.

Identify which technologies can be retrofitted into the current production line. For example, integrating a thermal recycling system for fiberglass or a mechanical recovery system for carbon fiber can enhance overall material reuse. Collaboration with technology providers and equipment manufacturers is crucial during this phase.

Implement closed-loop systems that automatically route recycling waste back into production. This requires comprehensive process mapping, ensuring that reclaimed materials meet the required performance standards. Regular testing and quality analysis are vital to guarantee that recycled materials deliver consistent performance without compromising the paddle’s integrity.

Manufacturers need to align their recycling methods with local and international environmental standards. This involves:

- Regular Audits: Periodically revisiting recycling processes to ensure compliance.

- Certifications: Engaging third-party auditors to certify recycled materials.

- Documentation: Keeping detailed records of waste management, recycling flows, and energy consumption data.

Sustainable manufacturing is not solely about technology; it also depends on skilled personnel. Train staff to monitor new recycling processes and maintain high standards in quality control. This training should include:

- Familiarization with new recycling technologies.

- Best practices in waste auditing.

- Troubleshooting potential recycling inefficiencies.

Engage with research institutions, environmental agencies, and industry consortia to innovate and refine recycling techniques. Cooperation can lead to breakthrough solutions and shared resources, reducing the financial and technical burdens on individual manufacturers.

Implementing these recycling practices provides multiple benefits to manufacturers:

- Environmental Impact Reduction: An effective closed-loop system significantly lowers the overall carbon footprint and minimizes waste.

- Cost Efficiency: Recycling initiatives can reduce raw material purchasing costs and decrease waste disposal fees.

- Product Differentiation: Companies that adopt sustainable practices can market their products as eco-friendly, gaining a competitive edge in markets where consumers are increasingly conscious about the sustainability of sporting equipment.

- Regulatory Compliance: Staying ahead of environmental regulations not only avoids potential fines but also enhances the company's reputation in the global marketplace.

- Innovation and Market Leadership: By investing in advanced recycling technologies, manufacturers position themselves as industry innovators, paving the way for future improvements in production efficiency and product quality.

Consider a manufacturing facility that recently integrated a closed-loop system focused on carbon fiber paddle recycling. The process involved the following steps:

- Waste Assessment: The facility identified that nearly 15% of production waste consisted of unusable carbon fiber segments.

- Technological Upgrade: They installed a mechanical recycling unit capable of processing off-cuts and recycling them into a composite filler material.

- Quality Control: Recycled materials underwent rigorous testing to ensure they met the performance criteria needed for athletic performance.

- Cost Savings: Within one year, the factory observed a 10% reduction in raw material costs and a significant cutback in waste disposal expenditures.

- Regulatory Alignment: The system was certified by an independent environmental agency, ensuring compliance and boosting stakeholder confidence.

This case highlights the direct correlation between sustainable practices and operational efficiency, proving that an eco-friendly approach can bolster both profitability and environmental stewardship.

Sustainable recycling in pickleball paddle production is not a one-time project but a continuous improvement process that aligns environmental goals with production performance. Manufacturers must:

- Conduct in-depth audits of their waste streams.

- Invest wisely in appropriate recycling technologies.

- Develop and maintain closed-loop systems.

- Train staff to adapt to new processes.

- Collaborate with industry peers for continuous innovation.

Embracing these practices not only reduces environmental impact and regulatory risks but also strengthens the overall business case in B2B markets. For manufacturing executives and sustainability managers, this comprehensive approach offers a pathway to enhance both production efficiency and brand reputation in the competitive world of high-performance sporting goods.

-

What are the key strategies for recycling high-performance pickleball paddles?

Answer: Key strategies include implementing closed-loop recycling systems, re-engineering production processes to optimize material recovery, and integrating specialized recycling technologies for different materials such as carbon fiber, fiberglass, and composite cores. These strategies help reduce waste and ensure that recycled materials meet performance standards. -

How does closed-loop recycling benefit manufacturers?

Answer: Closed-loop recycling benefits manufacturers by reducing raw material costs, lowering the environmental impact through waste minimization, and enhancing compliance with environmental regulations. This approach also supports product differentiation by positioning the company as a leader in sustainability. -

What are the best practices for sustainable production of pickleball paddles?

Answer: Best practices include conducting comprehensive waste audits, investing in modern recycling technologies, training staff for quality control, developing partnerships for innovation, and ensuring strict regulatory compliance. These practices lead to improved production efficiency and market competitiveness while promoting environmental stewardship.

-

closed-loop systems: Click to read an in-depth overview of how closed-loop systems recycle production waste back into manufacturing processes, thereby enhancing sustainability and reducing raw material costs. ↩ ↩ ↩2

-

thermoforming: Click to explore the thermoforming process—a manufacturing technique that shapes materials using heat, offering insights into its advantages and challenges in industrial production. ↩ ↩

-

T300 carbon fiber: Click to learn about T300 carbon fiber, including its properties, applications, and why its specific variant presents unique recycling challenges. ↩ ↩

-

Nomex: Click to understand Nomex, a high-performance material used in composite cores, detailing its benefits in structural applications and recycling complexities. ↩ ↩

-

controlled pyrolysis processes: Click to read about controlled pyrolysis processes, a method used to break down composite materials in recycling, preserving material integrity while reducing waste. ↩ ↩