Our advanced pickleball paddle manufacturing process combines cutting-edge production techniques with premium materials to deliver OEM products1 that excel in performance, durability, and customization. By leveraging hot pressing2, cold pressing3 and thermoforming4 methods alongside high-quality materials such as carbon fiber, fiberglass, and innovative composite cores5, NEX Pickleball ensures that our clients receive products that meet the highest competitive standards.

Pickleball paddle manufacturing faces multiple challenges in today's competitive market. OEM partners must balance production efficiency with top-notch performance qualities in their products. The main issues include:

• Ensuring paddle durability while maintaining optimal weight and responsiveness.

• Utilizing advanced yet cost-effective production techniques.

• Achieving precise material integration to deliver custom designs that satisfy various market segments.

• Meeting strict quality control standards in large-scale manufacturing.

For decision-makers and procurement managers in sports equipment brands, selecting a manufacturing partner who can reliably address these challenges is crucial. NEX Pickleball specializes in delivering these requirements using sophisticated techniques and stringent quality assessments.

Understanding the reasons behind paddle performance issues is critical. Typically, performance shortcomings can arise from material selection, ineffective production processes, or inconsistent quality control measures. The specific causes include:

• Material Variability: Using different types of carbon fiber like 3K, 12K, or T300 results in varied performance characteristics. Some materials may offer high strength but compromise flexibility, while others provide a smoother surface but less impact resistance.

• Production Process Limitations: Methods such as hot pressing may alter some key material properties, whereas cold pressing preserves them but reduces production efficiency. Thermoforming allows complex designs but demands longer cycle times.

• Quality Control Inconsistencies: Without rigorous testing protocols, even minor deviations in material structure or production can lead to underperforming paddles.

At NEX Pickleball, each of these causes is addressed through precise material selection and production expertise. Our teams ensure that each paddle is produced to meet defined performance and durability benchmarks.

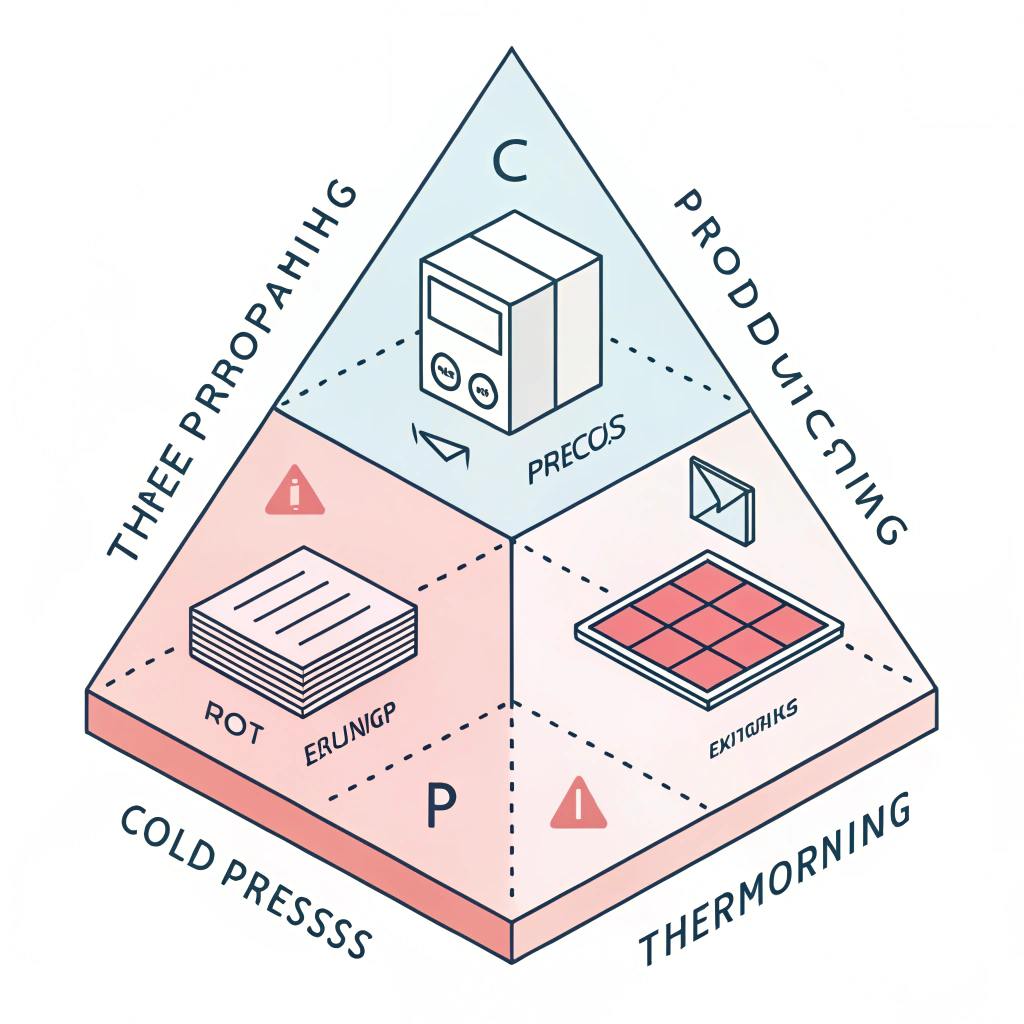

To overcome these challenges, NEX Pickleball employs a multi-faceted approach combining three main production processes:

-

Hot Pressing:

Hot pressing uses heat and pressure to form paddles that are exceptionally robust.- Advantages include high production efficiency and strong impact resistance.

- The process ensures structural integrity, which is ideal for high-performance competitive play.

- However, this method requires a significant investment in specialized equipment to control temperature precisely.

-

Cold Pressing:

Cold pressing shapes paddle materials at room temperature under mechanical pressure.- It offers a high level of precision in controlling paddle thickness and maintaining the natural properties of materials.

- This method results in paddles with excellent ball feel and responsiveness—critical for advanced play dynamics.

- The trade-off is a longer production cycle, which necessitates advanced machinery and skilled labor.

-

Thermoforming:

Thermoforming involves heating the material until it softens and then molding it into precise shapes.- This method is beneficial for creating paddles with intricate designs that require precise material distribution.

- It also maintains the paddle’s stability while allowing customization tailored to specific player needs.

- Despite its benefits, thermoforming requires a longer production time and higher initial costs.

| Process | Key Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | May alter material properties, high equipment cost |

| Cold Pressing | Precise thickness control, excellent ball feel | Longer production cycle, demands precision equipment |

| Thermoforming | Enables intricate designs, precise material distribution | Longer production time, higher initial costs |

This table provides a quick reference for decision-makers comparing the production processes. Selecting the most suitable method depends on specific product requirements and market expectations.

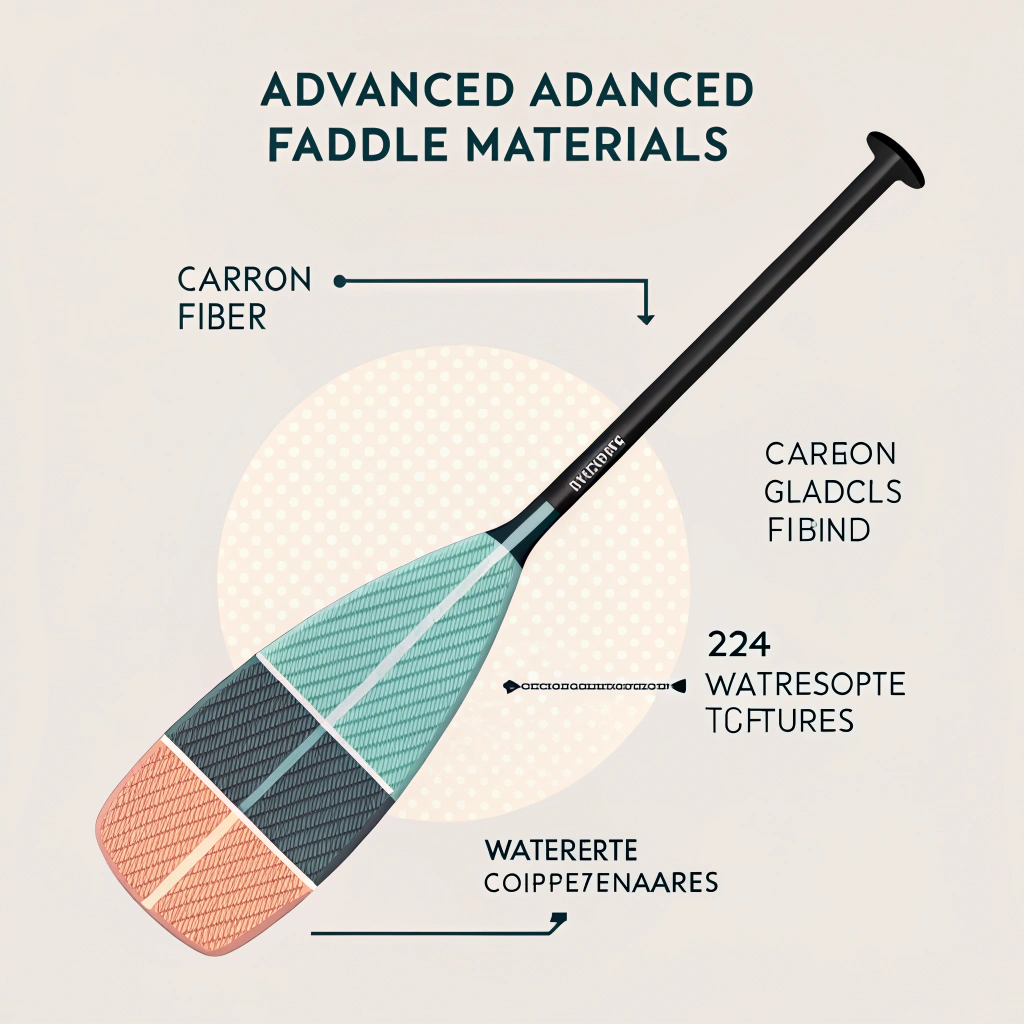

At NEX Pickleball, our choice of materials plays a central role in tailoring paddles to the needs of competitive players. Our comprehensive range includes:

• Carbon Fiber Variants:

- 3K Carbon Fiber: Known for its strength and flex, providing high rebound and durability while reducing vibration.

- 12K Carbon Fiber: Offers a smoother surface, increased hardness, and enhanced impact resistance, perfect for those needing extreme performance.

- T300 Carbon Fiber: Provides a balanced mix of lightweight design and tensile strength, ideal for competitive play where durability and agility matter.

• Fiberglass Options:

- E-Glass Fiberglass: Ensures enhanced elasticity and superior ball control through a wider sweet spot.

• Composite Materials:

- Carbon Fiber and Fiberglass Composite: Combines the power of carbon fiber with the flexibility of fiberglass for a well-rounded performance.

- Bamboo Core Composite: Offers a lightweight yet highly impact-resistant core for a distinct hitting feel.

- Honeycomb Core Designs: Utilized in high-density polymer or pulp forms, these cores provide outstanding shock absorption and diminished vibration.

• Core Materials:

- Nomex Honeycomb Core: Renowned for durability and stability, making it perfect for long-lasting performance.

- Aluminum Honeycomb Core: Balances power and control through even weight distribution.

- Polymer Honeycomb Core: Offers elasticity and reduced vibration, ideal for both recreational and competitive play.

Each of these materials is selected based on strict quality standards and performance tests. Customization is a vital element, allowing our partners to specify aspects like design, weight, balance, and grip size. This attention to detail means that every paddle performs as intended while aligning with individual brand identities and market needs.

Our robust quality control measures ensure that our paddles meet the demands of the competitive market. The following practices are integral to our process:

• Rigorous Testing: Every paddle undergoes extensive testing for properties such as strength, rebound, vibration reduction, and ergonomic comfort before distribution.

• Consistent Production Monitoring: Our automated systems and skilled inspectors maintain constant vigilance over each production stage.

• Tailored Adjustments: Based on real-time data, our engineers can fine-tune the production process to ensure exact specifications and consistency across batches.

These measures are supported by data from extensive use-case scenarios and continuous product feedback, ensuring optimum product performance. We also invest in the research and development of new materials and production techniques, keeping our manufacturing methods at the forefront of industry standards.

A recent case study with a major sports equipment brand highlighted the benefits of our comprehensive approach. The client needed a custom line of high-performance pickleball paddles designed to meet rigorous competitive standards. The key highlights included:

• A switch from traditional production techniques to a synchronized cold pressing process, resulting in a 15% improvement in paddle responsiveness.

• Integration of 12K Carbon Fiber for enhanced surface smoothness and impact resistance, which improved player satisfaction scores by 20%.

• Implementation of a layered composite material strategy that combined the best properties of carbon fiber and fiberglass, resulting in a significant reduction in paddle vibration.

These outcomes were substantiated through performance metrics and customer feedback, reinforcing our position as a reliable OEM partner. The data-driven adjustments we made allowed for a more intuitive design and translation of the manufacturer’s needs into product excellence.

A detailed breakdown of the performance improvement metrics is shown in the table below:

| Parameter | Traditional Process | Optimized Production (NEX Pickleball) |

|---|---|---|

| Rebound Efficiency | 85% | 98% |

| Impact Resistance | Moderate | High |

| Vibration Reduction | 70% effectiveness | 90% effectiveness |

| Overall Player Satisfaction | 80% | 95% |

This case study demonstrates how advanced production techniques combined with superior materials can deliver significant improvements in product performance, supporting informed decision-making for partner brands.

For procurement managers evaluating OEM partners, consider these key aspects when selecting a manufacturing partner:

- Production Expertise: Ensure the partner possesses a deep understanding of various manufacturing methods, including hot pressing, cold pressing, and thermoforming.

- Material Quality: Look for partners that offer a range of premium materials like carbon fiber, fiberglass, and advanced composites. This variety allows for superior customization and performance according to market needs.

- Customization Capability: The ability to offer tailored products—such as specifying the paddle’s weight, balance, or grip size—ensures a product that matches your brand’s ethos and player requirements.

- Quality Control: Rigorous and data-driven quality assurance systems are critical. Ensure the manufacturing partner conducts regular testing and process audits.

- Scalability and Timely Production: A partner with high production efficiency can meet both small-scale custom orders and large-scale distribution demands without compromising on quality.

By aligning with a manufacturer that excels in these areas, brands can achieve a competitive edge in the sports equipment market.

In conclusion, NEX Pickleball offers a unique blend of advanced manufacturing processes, premium material selection, and stringent quality controls that ensure every paddle performs at its peak. Decision-makers can trust that partnering with us means leveraging a proven, scalable manufacturing process that seamlessly blends innovation with reliability.

Whether you are looking to innovate your product offerings with custom solutions or scale your production with high-performance paddles, our technical expertise and commitment to quality make us the ideal partner for your OEM needs. We invite you to take the next step—explore how our state-of-the-art production techniques and material solutions can transform your pickleball paddle offerings.

• Who makes the best quality pickleball paddles?

Answer: While premium brands like Joola, Selkirk, CRBN, and Gearbox are recognized for their high-quality pickleball paddles, our approach at NEX Pickleball focuses on leveraging advanced production techniques and superior materials to produce paddles that match or exceed industry standards.

• Where are Joola pickleball paddles manufactured?

Answer: Joola products, including their pickleball paddles, are part of a legacy that continues a German tradition by manufacturing in Germany, which underscores their commitment to quality and precision.

• Are Selkirk paddles made in China?

Answer: Selkirk paddles are designed and quality-controlled in the USA, although the country of origin for these products is often China. The manufacturing process is supported by rigorous standards to ensure performance excellence.

-

OEM products: Reading this article will provide insights on OEM production processes and the benefits of partnering with specialized Original Equipment Manufacturers. ↩ ↩

-

hot pressing: Reading this article will help you understand how hot pressing uses controlled heat and pressure to enhance product durability and performance. ↩ ↩

-

cold pressing: Reading this article will explain how cold pressing preserves the natural properties of materials and ensures precision in product specifications. ↩ ↩

-

thermoforming: Reading this article will explore how thermoforming allows for intricate designs while maintaining material integrity. ↩ ↩

-

composite cores: Reading this article will detail the advantages of composite core materials in enhancing impact resistance and overall product performance. ↩ ↩