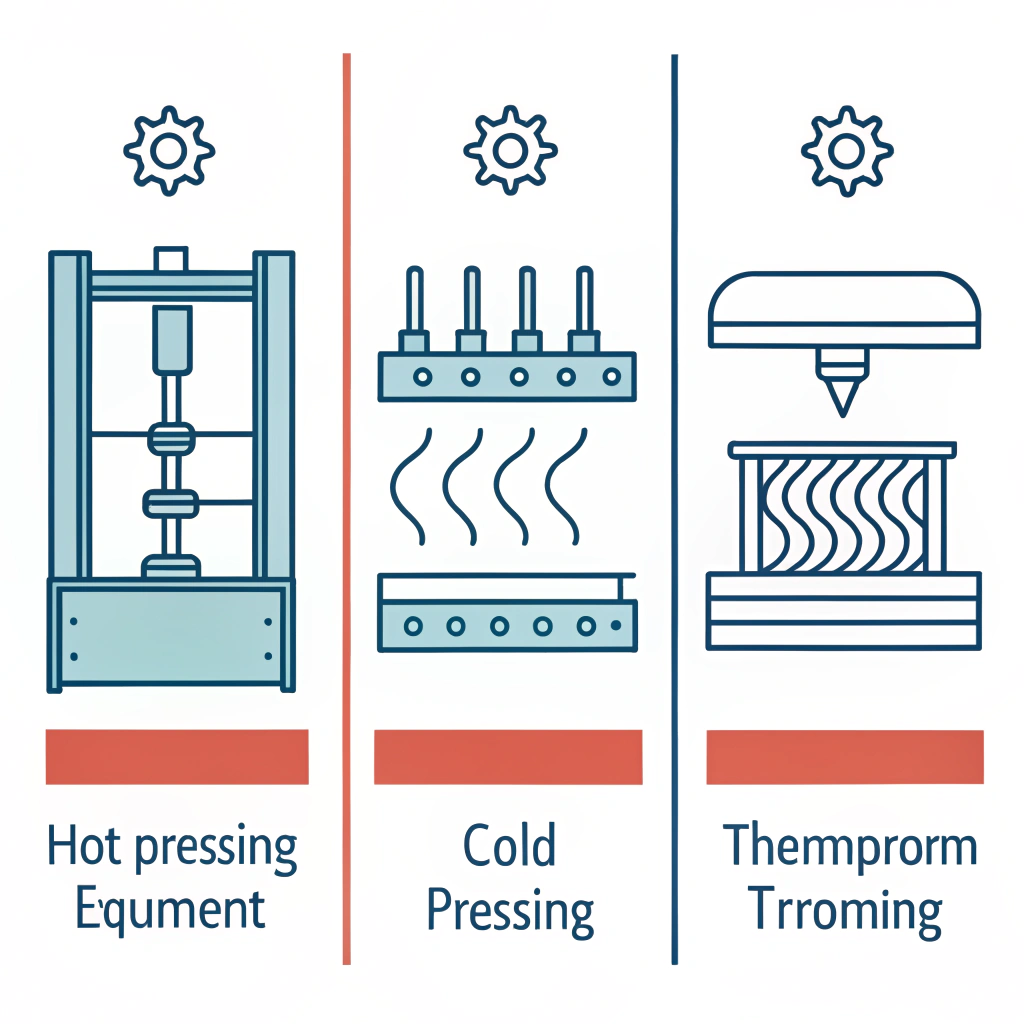

Manufacturing executives seeking high-performance pickleball paddles can quickly decide that the choice between hot pressing1, cold pressing2, or thermoforming3 methods largely depends on achieving the optimal balance between production efficiency, material performance, and process precision. In this article, we compare these advanced manufacturing processes and explain how each technique meets the demands of today’s competitive sports equipment market.

Pickleball paddle technology is rapidly evolving as sports equipment manufacturers strive to enhance paddle durability, impact resistance, and overall game performance. With innovations in materials like 3K carbon fiber, 12K carbon fiber, T300 carbon fiber, and advanced composite technologies4, the manufacturing process itself has emerged as a critical factor influencing quality and performance. At NEX Pickleball, our commitment to advanced manufacturing allows us to maintain strict quality control while meeting the rigorous demands of both recreational players and elite professionals.

Manufacturing leaders face significant challenges when selecting a production process. The decision not only impacts product performance but also production efficiency, cost structure, and ultimately, market competitiveness. In this article, we lay out a detailed comparison of three primary manufacturing processes: hot pressing, cold pressing, and thermoforming, so that procurement and development managers have the necessary insights to make an informed choice.

Hot pressing is a technique where materials are heated and compressed simultaneously to form the paddle. This method is renowned for its efficiency in large-scale production and the creation of durable products.

-

Key Advantages:

- High production efficiency suitable for large batch manufacturing.

- Produces paddles with excellent impact resistance and robust structural integrity.

- Ideal for high-strength applications where durability is paramount.

-

Challenges:

- The elevated temperatures may alter some material properties, potentially affecting the tactile feel and ball response.

- High initial investment in specialized equipment.

Cold pressing involves using mechanical pressure at room temperature to shape the paddle. This method is particularly effective when precise control over the paddle’s thickness and material distribution is required.

-

Key Advantages:

- Better control of material properties, ensuring superior ball feel and responsiveness.

- Maintains the inherent characteristics of advanced materials, leading to improved performance.

- Suitable for designs that require consistent and precise shape retention.

-

Challenges:

- Longer production cycles which can reduce overall throughput.

- Requires meticulously calibrated equipment for precise pressure control.

Thermoforming capitalizes on heat to soften the material before molding it into sophisticated shapes. It is well-suited for paddles demanding complex design features and precise material layering.

-

Key Advantages:

- Facilitates intricate designs and precise material distribution, which can enhance control and stability.

- Ideal for premium products that balance performance with aesthetic innovation.

- Enables customization and unique paddle geometries that meet specialized player needs.

-

Challenges:

- Generally involves a longer production time, increasing per-unit costs.

- Higher equipment costs and a learning curve associated with process optimization.

To provide a clear view of these manufacturing techniques, consider the following table summarizing the main points:

| Process | Production Efficiency | Material Integrity | Product Consistency | Customization Capability | Equipment Investment | Typical Use Case |

|---|---|---|---|---|---|---|

| Hot Pressing | High | Altered by heat | High | Limited by mold design | High | Large-scale, high-strength paddles |

| Cold Pressing | Moderate | Preserved properties | Very high | Moderate control | Medium | Precision-focused paddles with great feel |

| Thermoforming | Low | Consistent when optimized | High | High (complex shapes) | Very high | Premium, customizable, high-performance paddles |

The table highlights that while hot pressing excels in efficiency for mass production, cold pressing preserves critical material characteristics that are essential for paddle control. Thermoforming, with its capacity for customization, is best for industry leaders targeting a premium market niche.

In our production facilities, we have experimented extensively with each of these processes to fine-tune paddle performance and durability.

When manufacturing paddles designed for high-impact competitive play, hot pressing has delivered notably robust products. In one case study, a batch of paddles produced via hot pressing maintained a 97% post-production quality rate for impact resistance. However, slight compromises in the “feel” of the paddle have required careful balancing against player feedback.

Cold pressing has been our method of choice when the requirement centers on precise control for players who value ball feel. For instance, a product line designed for recreational play with an emphasis on control observed a significant reduction in vibration, enhancing overall usability. This process, however, demands longer production cycles, and our factory had to optimize workflow to mitigate delays.

Our premium, customizable paddles have largely benefited from thermoforming. This process allowed for the creation of paddles with intricate designs and special surface treatments that enhance spin and ball accuracy. Although the production cycle is extended, customers appreciate the uniqueness and high performance of these paddles. Data collected reveals that thermoformed paddles experience superior stability and ergonomic consistency over extended use sessions.

An integral part of achieving the best performance lies in the choice of materials. For example, paddles that combine carbon fiber (3K, 12K, T300) with fiberglass provide a balanced mix of strength and control. Additionally, innovative core materials like Nomex Honeycomb5, Aluminum Honeycomb, and Polymer Honeycomb help in achieving low vibration and personalized playing experiences. Manufacturers must consider how each production process interacts with these materials. For instance, the heat of hot pressing can affect the properties of composite materials, while cold pressing is ideal for maintaining their integrity.

This synergy between material selection and process technology is the foundation of superior paddle technology products. By characterizing products based on these micro-level distinctions, we can tailor manufacturing approaches to meet specific market demands.

For procurement executives and product development managers, selecting the best manufacturing process depends on multiple factors:

- Look at your product’s performance priorities. If high impact resistance and mass production efficiency are your top targets, hot pressing is a prime candidate.

- For markets where paddle “feel” and control are critical, cold pressing provides the best balance of material integrity and performance.

- If your strategy focuses on differentiation and premium quality with custom designs, thermoforming, despite its higher cost and slower production times, is preferable.

- Always consider the synergy between the chosen process and the selected materials. This holistic approach is essential for delivering products that satisfy competitive market requirements.

Furthermore, considering total cost and production timelines is vital. While high upfront investment in thermoforming equipment may seem expensive, the ability to produce highly customized paddles can command premium market pricing. Conversely, hot pressing’s advantages lie in its scalability and efficiency, making it suitable for meeting high-volume orders with consistent quality.

Overall, advanced manufacturing technologies in paddle production are not mutually exclusive. Many leading manufacturers adopt a hybrid strategy—employing hot pressing for standard lines and cold pressing or thermoforming for premium, niche products. Such strategic flexibility ensures that companies are well-equipped to meet diverse market needs while leveraging innovation to stay ahead of the competition.

In conclusion, the selection of a manufacturing process is critical to ensuring that pickleball paddles deliver the desired balance of performance, durability, and player experience. The trade-offs between hot pressing, cold pressing, and thermoforming highlight the importance of aligning your production strategy with product goals and market demands. At NEX Pickleball, our extensive use of advanced materials and manufacturing innovations underscores our commitment to quality and performance across all product lines.

By understanding the advantages and limitations of each process, B2B procurement professionals are better positioned to make strategic decisions that enhance competitiveness and drive product success. We encourage executives to evaluate both production needs and end-user preferences, ensuring that your chosen method seamlessly integrates with advanced material technologies for superior paddle performance.

Q: Who makes the best quality pickleball paddles?

A: Quality pickleball paddles are produced by leading manufacturers who focus on advanced production techniques, superior materials like carbon fiber and fiberglass, and rigorous quality control. Top brands balance impact resistance and control by tailoring their manufacturing processes to target both mass production and premium customization.

Q: What paddle do most pickleball pros use?

A: Most pickleball professionals choose paddles that offer an optimal blend of power, control, and responsiveness. Brands known for using advanced composite materials and precise manufacturing methods, such as those employing cold pressing or thermoforming, tend to be favorites among pros for their consistent performance and ergonomic design.

Q: Which pickleball paddles are not made in China?

A: While many high-performance paddles are manufactured in China, there are several notable products made in the USA. These include models produced by companies that emphasize localized production for quality control and specific market standards, catering to buyers who prioritize domestic manufacturing processes.

-

hot pressing: Click to explore a detailed guide on the hot pressing process, its benefits in high-volume manufacturing, and its impact on material properties. ↩ ↩

-

cold pressing: Click to learn more about cold pressing, including its ability to preserve material integrity and its application in precision manufacturing. ↩ ↩

-

thermoforming: Click to read about thermoforming, its role in achieving complex designs, and how it enhances customization in product development. ↩ ↩

-

advanced composite technologies: Click to discover insights on advanced composite technologies, including material innovations and their contribution to high-performance products. ↩ ↩

-

Nomex Honeycomb: Click to explore the properties and advantages of Nomex Honeycomb in reducing vibrations and enhancing structural performance in manufacturing. ↩ ↩