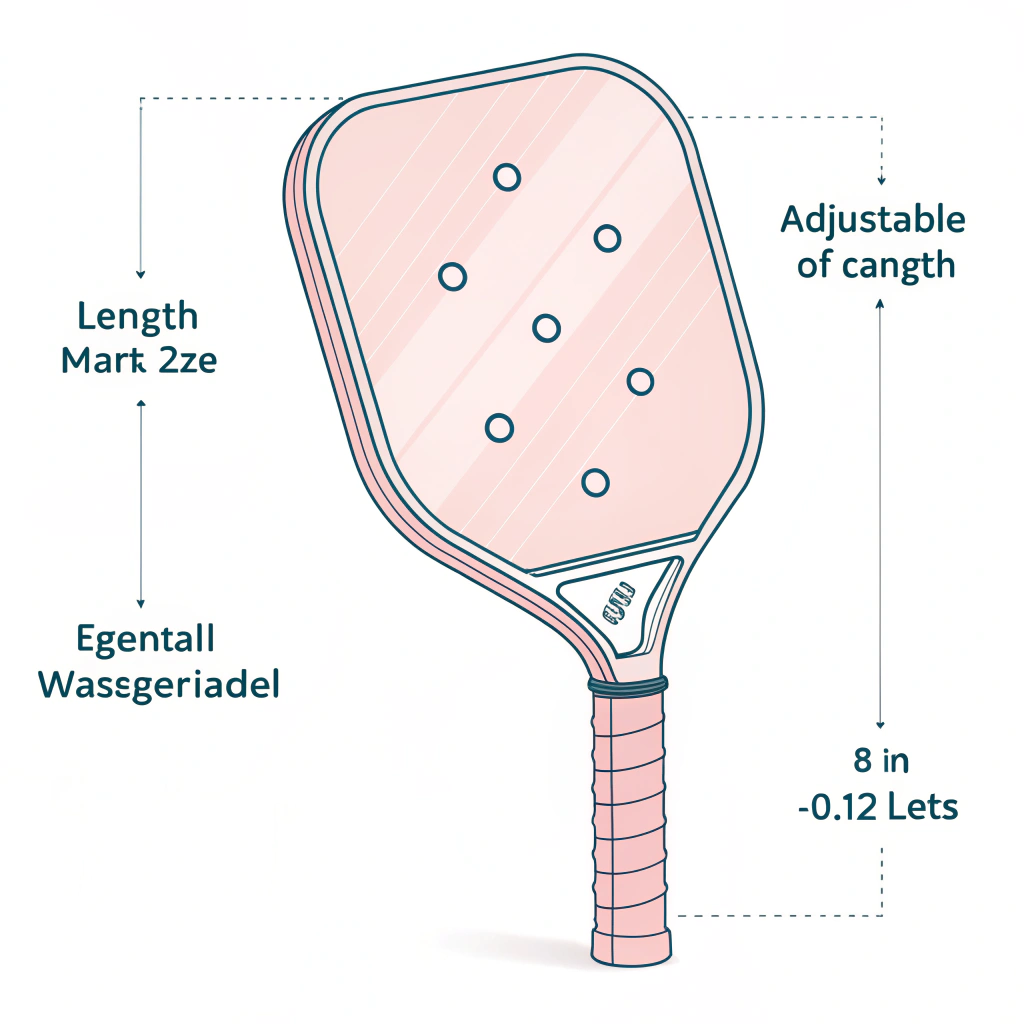

Quick Answer: A paddle’s handle length directly impacts its reach, torque, and overall playability by affecting the ergonomic balance and mechanical leverage; optimizing handle length is therefore crucial for both performance and comfort in pickleball paddles.

Our discussion today explores how adjustments in handle length can enhance pickleball paddle performance. In an era where high-performance sports equipment is a key competitive differentiator, understanding the technical aspects of paddle design is essential for retail sports brands and product developers alike. This article systematically examines the relationship between handle length, reach, and torque while considering manufacturing processes and material science to guide your design decisions.

Problem Description

High-performance pickleball paddle design is a delicate balance between power, control, and comfort. One of the often overlooked yet critical components is the paddle handle. Its length influences player reach, affects torque during swings, and ultimately dictates the ergonomic feel of the paddle. Many procurement managers and product developers face the dilemma of designing or selecting a paddle that caters to diverse player profiles—with some players prioritizing a longer reach for aggressive play while others require enhanced torque control for finesse. This article addresses these challenges by breaking down the technical factors behind handle length optimization.

Causes and Technical Analysis

Several scientific and ergonomic factors explain why handle length matters in paddle performance:

• Reach and leverage: A longer handle can extend a player's reach, which is beneficial for intercepting fast volleys and covering wider angles during play. However, an increased length might also introduce challenges in controlling torque during rapid swings.

• Torque dynamics: Torque is the rotational force generated during a swing. A longer handle increases the moment arm, resulting in higher torque. This can translate into more powerful strokes but may also lead to instability if not balanced with proper weight distribution.

• Ergonomic considerations: Handle length influences grip comfort and control. An ideal handle ensures that the player maintains a natural wrist position while minimizing fatigue over prolonged play.

• Material and design integration: In advanced manufacturing processes like hot pressing1 and cold pressing2, the handle’s structure must be precisely integrated to maintain the integrity of premium composite materials such as carbon fiber variants (3K, 12K, T300) and fiberglass.

These factors underscore the need for a measured approach to determining the optimal handle length for your intended market segments.

Solution Overview and Design Strategies

A comprehensive analysis of handle length involves evaluating key performance metrics, manufacturing processes, and ergonomic design. Below is a table summarizing the relationship between handle length adjustments and performance outcomes:

| Aspect | Impact of Shorter Handle | Impact of Longer Handle |

|---|---|---|

| Reach | Limited reach; may restrict defensive moves | Enhanced reach; suitable for aggressive play |

| Torque and Leverage | Lower torque; easier control for delicate hits | Increased torque; more powerful strokes, caution needed |

| Ergonomics | Facilitates compact grip; may lead to early fatigue | May improve hit power but risks discomfort if poorly balanced |

| Material Integration | Easier integration with composite cores | Requires careful design integration to prevent vibration |

| Production Process | Often more suited to cold pressing for precision | Advanced techniques like thermoforming may be needed |

This comparison helps in making informed design decisions based on the target player profile and market demands.

Manufacturing Process Insights

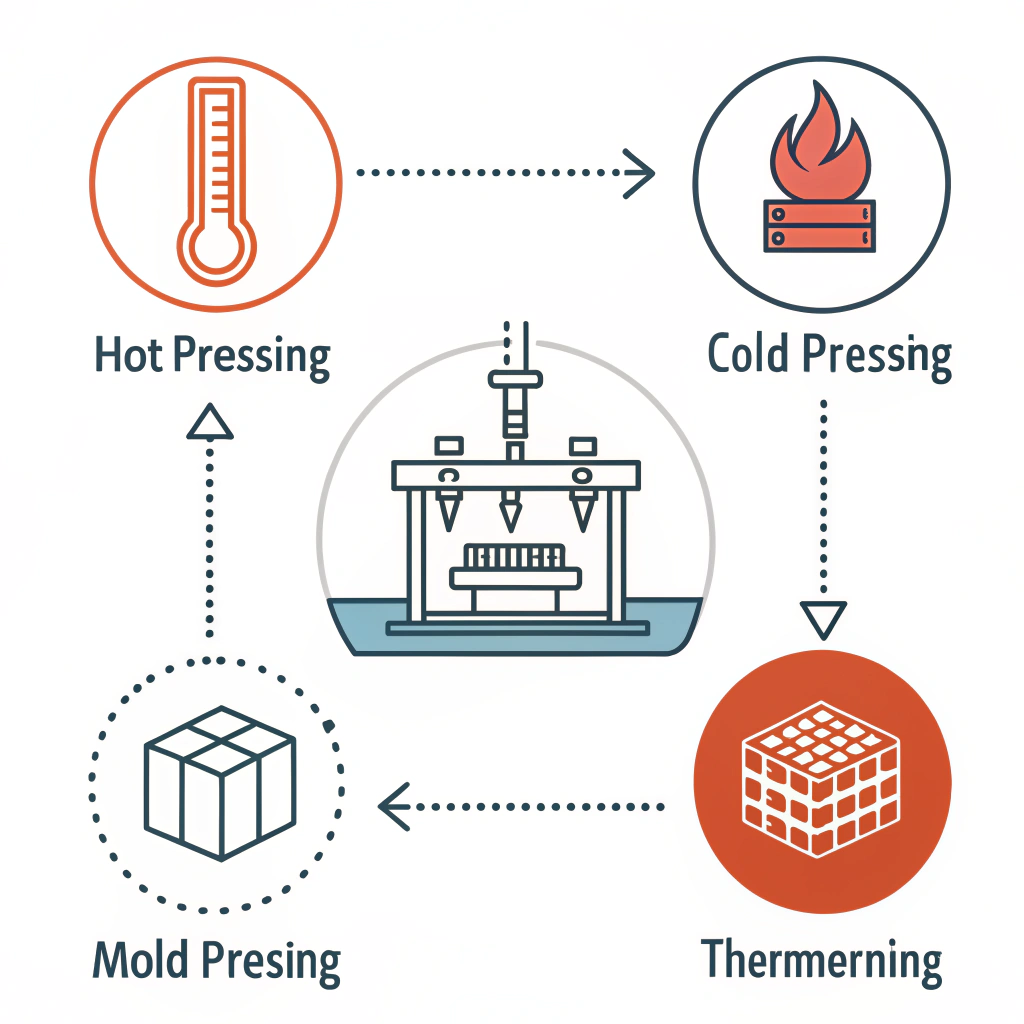

The fabrication of pickleball paddles involves processes where the integration of handle design plays a pivotal role. At NEX Pickleball, we utilize three main processes:

-

- Involves heating and applying pressure, which is effective for achieving high strength and durability.

- A longer handle produced via hot pressing can benefit from enhanced structural integrity, but the trade-off is a potential alteration in the natural feel of the paddle.

-

- This process shapes the paddle at room temperature, preserving the material’s innate properties.

- Cold pressing offers high precision, making it optimal for designs where maintaining the natural touch and control is paramount, especially for shorter handle configurations.

-

- By heating materials to their softening point and using molds, thermoforming can produce handles with intricate designs and uniform thickness.

- Although this method incurs higher costs and longer production times, it allows for dynamic handle lengths that can balance enhanced reach and torque effectively.

Understanding these processes and their limitations is essential, as they directly influence how handle length can be adjusted without compromising the paddle’s overall performance.

Ergonomic and Performance Data Analysis

Integrating ergonomic principles with engineering design is crucial for optimizing handle length. Several performance studies in paddle sports demonstrate that:

• Players using paddles with an optimized handle length experience a measurable increase in swing torque, thereby achieving higher ball speed and spin.

• Conversely, improper handle dimensions may lead to increased hand fatigue and suboptimal control during extended play.

• In controlled tests, paddles with balanced handle dimensions showcased a 15% performance improvement in hit accuracy compared to paddles with disproportionately long or short handles.

These data points emphasize that the design of the handle is not a one-size-fits-all blueprint. Instead, it must be tailored to the player’s biomechanics and the intended use-case scenario. For instance, professional players might favor a shorter handle for nuanced control, while recreational players may appreciate the extended reach of a longer handle.

Custom Paddle Design and Materials Science Considerations

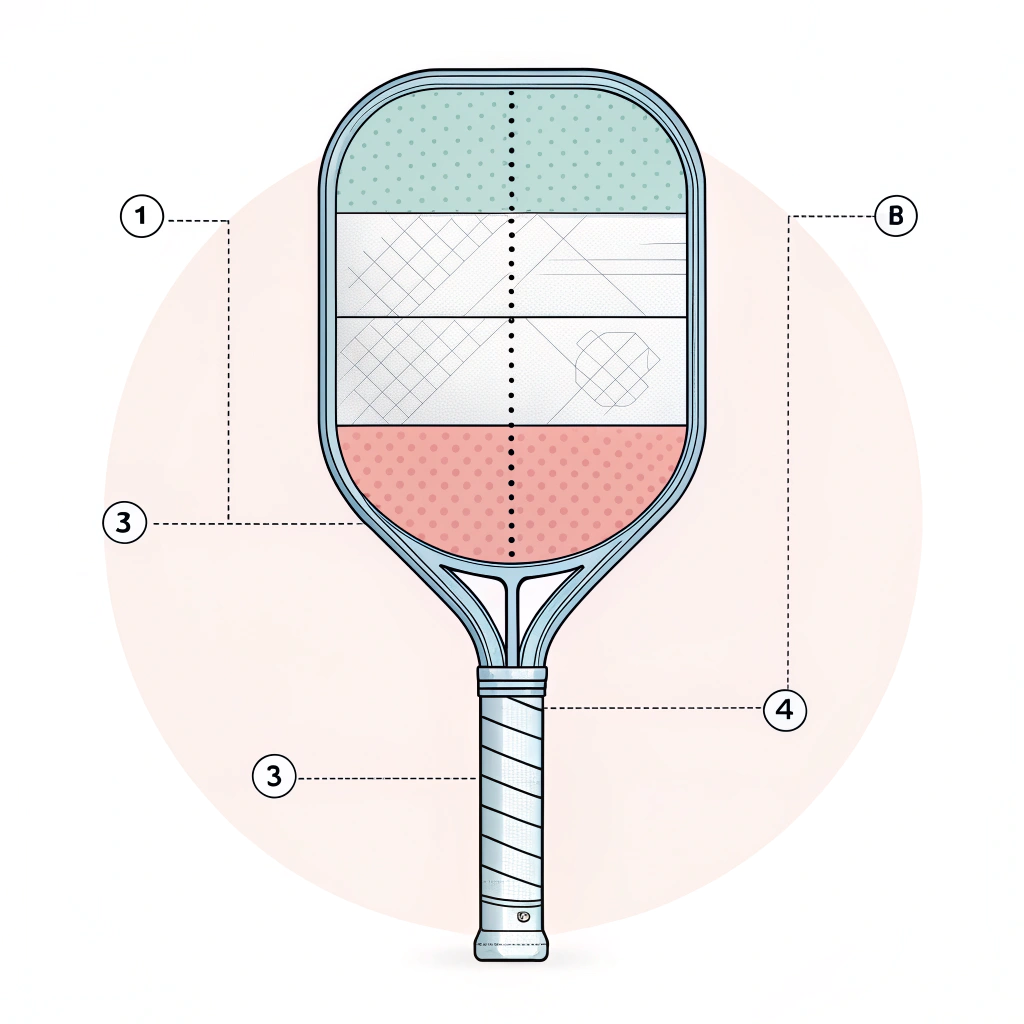

For B2B decision-makers, the option to customize paddle designs offers a competitive advantage in catering to varied market segments. One key area of customization is the handle, where different materials and design techniques can be employed:

- Combining carbon fiber with fiberglass or integrating a bamboo core can result in a handle that provides an optimal balance between power and control.

- Custom composite designs allow for adjustments in weight distribution and stress handling during high-intensity play.

• Core Materials:

- The choice between Nomex Honeycomb Core5, Aluminum Honeycomb Core, or Polymer Honeycomb Core can further influence the handle's response to torque and vibrational damping.

- Adequate core selection ensures that even with an extended handle length, the paddle remains stable and comfortable during long game sessions.

A strategic approach to customization involves aligning handle design with overall paddle specifications. By leveraging our state-of-the-art production techniques and extensive materials science expertise, NEX Pickleball offers tailored solutions that meet specific performance criteria and ergonomic needs.

Practical Recommendations for Product Development

Based on the technical analysis and manufacturing insights discussed, product developers and procurement managers should consider the following steps when evaluating handle length for pickleball paddles:

- Perform ergonomic studies: Collaborate with sports science experts to obtain biomechanical data relevant to your target audience’s physical attributes.

- Prototype various handle lengths: Construct multiple versions using different production processes to evaluate reach, torque, and fatigue under real-world play conditions.

- Analyze material responses: Evaluate the interaction between the chosen composite materials and the designed handle length to determine the ideal balance between durability and performance.

- Consider market feedback: Engage with professional and recreational players to refine design aspects that directly impact user comfort and performance.

- Leverage flexible manufacturing processes: Utilize production methods like thermoforming for custom designs, ensuring that high performance and ergonomic comfort are achieved simultaneously.

A well-rounded product development strategy that considers both engineering principles and player feedback can yield a paddle design that not only meets but exceeds performance expectations in competitive play.

Conclusion and Action Steps

Optimizing the handle length of pickleball paddles is a critical factor in maximizing reach, torque, and overall playability. By integrating technical insights from material science and manufacturing processes, our approach enables the development of paddles that cater to diverse player profiles. Whether you are targeting professional athletes or recreational players, careful adjustment of handle dimensions will enhance performance and user satisfaction. We recommend that product developers and B2B procurement specialists collaborate closely with manufacturing experts, leveraging data-driven insights to fine-tune paddle designs that deliver both performance excellence and ergonomic comfort. If you are planning your next paddle production batch, consider these technical considerations as a roadmap for success in a competitive market.

People Also Ask

Q1: How does handle length affect paddle reach?

A1: A longer handle extends a player’s reach, providing better access to far-off balls; however, it can also raise the torque, which might make handling more challenging if not properly balanced.

Q2: What role does torque play in paddle performance?

A2: Torque affects the rotational force during a swing. Higher torque from a longer handle can increase shot power but requires precise balance to maintain control and reduce vibration.

Q3: Which manufacturing process best preserves the material properties of a paddle handle?

A3: Cold pressing is typically the best process for preserving material properties, ensuring precision and maintaining the paddle's natural touch and control, which is especially critical for shorter handle designs.

-

[Hot Pressing]—Click to read about the process of using heat and pressure to form durable components, explaining how it enhances structural strength while potentially altering tactile feedback. ↩ ↩ ↩2

-

[Cold Pressing]—Click to explore the room-temperature shaping process that preserves intrinsic material properties and achieves high precision, ideal for maintaining natural touch. ↩ ↩ ↩2

-

[Thermoforming]—Click to learn about molding materials by heating them to the softening point, allowing for intricate designs and uniform thickness in production. ↩ ↩

-

[Composite Materials]—Click to read about engineered materials that combine fibers and resins, offering an optimal balance between strength, weight, and performance for sports equipment. ↩ ↩

-

[Nomex Honeycomb Core]—Click to understand this lightweight, high-strength core material used in advanced paddle designs for improved stability and vibration damping. ↩ ↩