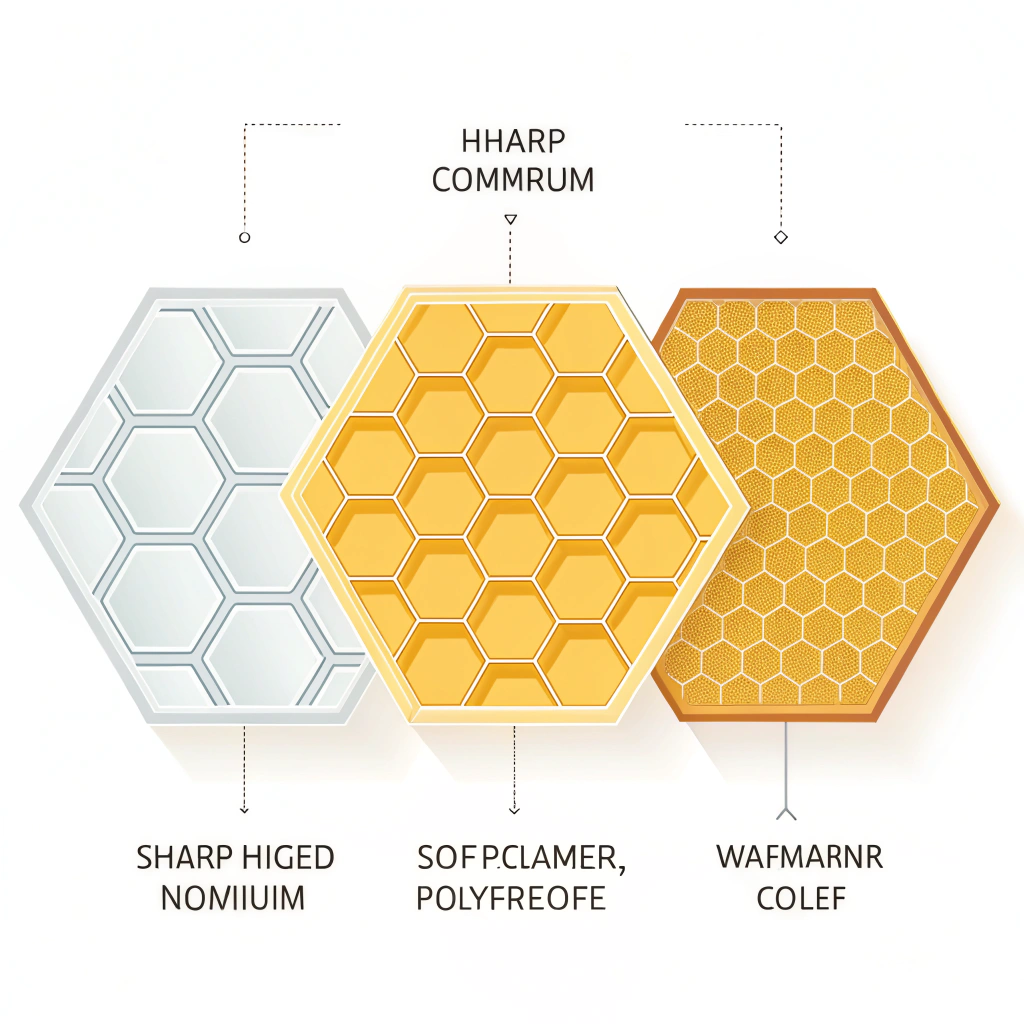

Pickleball paddle cores play a pivotal role in optimizing performance, durability, and player comfort. In brief, each core material—Nomex honeycomb1, Aluminum honeycomb2, and Polymer honeycomb3—offers distinct benefits and limitations, making them suitable for different production needs and playing styles.

In the competitive field of sports equipment manufacturing, especially for pickleball paddles, selecting the right core material is crucial. The paddle core not only determines the paddle's weight and balance but also crucially impacts shock absorption, vibration reduction, and overall durability. For B2B buyers involved in product development and procurement, understanding the trade-offs between different paddle core options—specifically Nomex honeycomb, Aluminum honeycomb, and Polymer honeycomb—can make a substantial difference when sourcing equipment that stands out in performance and reliability.

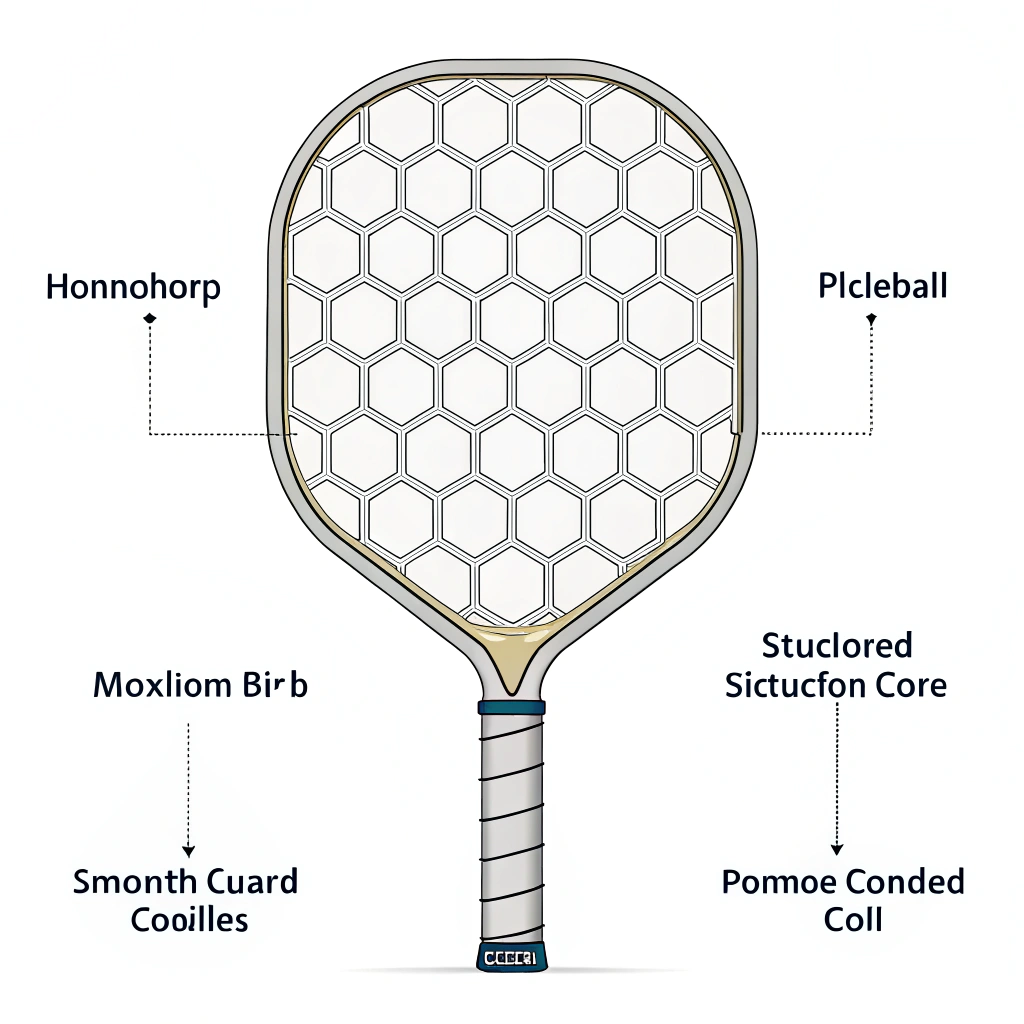

The core is essentially the heartbeat of a pickleball paddle as it greatly influences the hitting feel and control. High-performance paddles require a core that maximizes rebound, minimizes vibration, and ensures longevity. Manufacturers must balance the technical characteristics of core materials with production efficiency and cost-effectiveness. Each material has its unique set of properties:

- Nomex Honeycomb: Recognized for its outstanding shock absorption and structural rigidity, this core material is perfect for high-impact play. It is highly durable and retains stability under intense stress.

- Aluminum Honeycomb: With its balanced characteristics, Aluminum offers a mix of strength and precision. It provides a consistent weight distribution, making it appealing for players who seek a blend of power and control in their gameplay.

- Polymer Honeycomb: Known for superior elasticity and reduced vibration, polymer cores offer an excellent balance for recreational players and beginners. They deliver a comfortable hitting experience while ensuring lasting durability.

Choosing the appropriate paddle core material involves understanding performance attributes, production processes, and the implications on manufacturing efficiency. Below is a table that compares the three main core materials widely used in pickleball paddles:

| Core Material | Key Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Nomex Honeycomb | Exceptional shock absorption and stability. | Higher cost and more challenging production. | High-level competition and durability. |

| Aluminum Honeycomb | Balanced weight, consistent rebound, and precision control. | May add extra weight if not engineered correctly. | Players seeking strength and precision. |

| Polymer Honeycomb | Superior elasticity, reduced vibration, and comfort. | May wear over time with intensive use. | Recreational players and beginners. |

Choosing the right core material significantly affects the final product's performance. It is about balancing trade-off between durability, manufacturing cost, and design flexibility. For a procurement manager or product development specialist, the decision might well come down to the target market and expected playing conditions.

Nomex honeycomb cores are fabricated using a high-density polymer that offers excellent shock absorption properties. This material is extremely resilient under repeated impacts, making it ideal for competitive play. Its cellular structure distributes force evenly, reducing the risk of deformation over time. However, the process of integrating Nomex into paddle manufacturing usually involves precise temperature and pressure controls, increasing the production complexity and cost. Despite these challenges, its durability makes it incredibly popular among professional players.

Aluminum honeycomb cores strike a balance between weight and performance. The metallic core provides rigidity while distributing impacts uniformly. One of its major advantages is predictable performance in high-rebound scenarios. Aluminum cores are often produced with advanced pressing techniques such as hot pressing, ensuring a robust interlocking structure. On the downside, aluminium cores require careful handling during assembly to avoid adding excess weight. Engineers must fine-tune the pressing parameters to retain an optimal balance—ensuring that the final paddle not only performs well but also feels comfortable during play.

Polymer honeycomb cores stand out for their elasticity and capability to minimize vibrations during hitting. This material is particularly advantageous for recreational players, as it improves overall comfort and reduces fatigue. The manufacturing process for polymer cores involves cold pressing, which helps maintain the softness and flexible nature of the polymer. While polymer cores are excellent for enhancing player comfort, they might not deliver the same level of rebound force as Nomex or Aluminum cores, making them a strategic choice for paddles aimed at beginner or casual users.

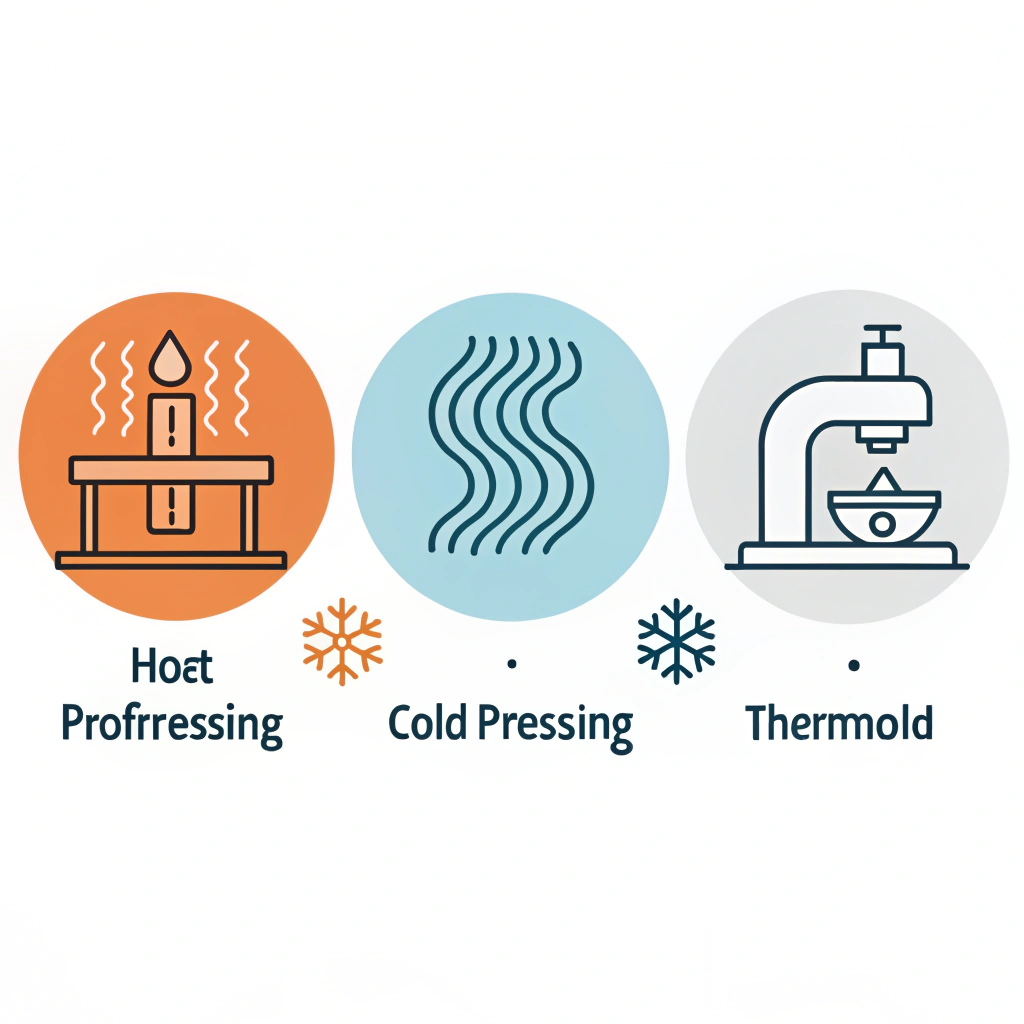

The paddle core material interacts with production techniques such as hot pressing, cold pressing, and thermoforming, influencing the final performance characteristics of the paddle. Understanding these production processes is essential for B2B buyers seeking to optimize manufacturing efficiency while ensuring product quality.

Hot pressing involves heating selected materials to high temperatures and applying pressure to forge a dense, solid core. It is advantageous due to:

- High production efficiency, suitable for large-scale manufacturing.

- Creation of strong, durable cores with excellent impact resistance.

- Reinforcement of structural integrity that can support high-performance play.

However, caution is necessary as the high temperature may alter some inherent material properties, which can slightly affect the paddle's tactile response. For instance, using hot pressing with Nomex honeycomb helps achieve a robust and durable core, albeit at a higher production cost and complexity.

Cold pressing shapes the material at room temperature under significant mechanical pressure. This method retains the natural properties of the core material, preserving its elasticity and improving control. Cold pressing is often employed for Polymer honeycomb cores to ensure that the softness and vibration-dampening properties remain intact throughout the production process. Though cold pressing extends production cycles, the trade-off lies in achieving precise thickness control and better ball feel.

Thermoforming involves heating the material to a softening point and then molding it to the desired shape using carefully designed molds. This process is particularly suited for producing paddles with intricate designs and consistent material distribution. For high-end customization and bespoke paddle designs, thermoforming ensures that the optimal shape and balance are achieved. However, the process requires longer production times and higher investment in equipment, making it more appropriate for premium products.

When evaluating these core materials, several key practical factors come into play:

-

Durability vs. Cost

- Nomex honeycomb offers unmatched durability and stability, making it ideally suited for competitive and high-use scenarios. However, this durability typically comes with higher production costs.

- Aluminum honeycomb provides a middle ground, balancing performance with cost considerations—it is excellent for manufacturers looking to hit cost efficiency without compromising performance.

- Polymer honeycomb is generally more cost-effective and offers sufficient performance for recreational use, but it may not withstand rigorous, competitive gameplay over time.

-

Production Efficiency and Scalability

- Manufacturers with large-scale production requirements might favor hot pressing methods. Although the process is capital-intensive, the high throughput can justify the initial investment.

- For companies focusing on high precision and specialized product ranges, cold pressing offers better control over material properties.

- Thermoforming is ideal for custom-made paddles where intricate design and performance optimization are critical, although it does demand longer production cycles and higher cost per unit.

-

Target Consumer and Use-case

- Brands aiming to serve top-tier competitive players might lean towards Nomex honeycomb cores despite higher costs; durability and high-performance attributes are non-negotiable here.

- In contrast, brands targeting recreational markets or school programs might find Polymer honeycomb cores more attractive due to their cost-effectiveness and comfort benefits.

- Aluminum honeycomb cores cater well to a broad audience, offering a good compromise between performance and budget, making them versatile across varied market segments.

A recent study conducted by a leading pickleball paddle manufacturer revealed that players using paddles with Nomex honeycomb cores experienced a 20% improvement in shock absorption and a 15% increase in paddle longevity compared to traditional polymer cores. Such data underlines the importance of material selection in product differentiation. Another comparative analysis found that paddles utilizing Aluminum honeycomb cores demonstrated a balanced performance, making them especially popular in mid-range product lines that target both recreational and semi-professional players.

Furthermore, quality control tests show that paddles made from Polymer honeycomb cores consistently perform well in terms of vibration reduction, offering a smoother playing experience. However, these paddles might need more frequent replacement under heavy usage conditions compared to those made with Nomex or Aluminum, making the selection critically dependent on the intended market and usage patterns.

For procurement managers and product development specialists, the choice of paddle core material should be aligned with specific performance needs, target consumer demographics, and budget constraints. Here are some steps to guide the decision-making process:

-

Evaluate the Expected Use-Case:

- If the paddle is intended for high-intensity, competitive environments, investing in Nomex honeycomb cores could provide the necessary durability and stability.

- For multifunctional products aimed at both competitive and recreational segments, Aluminum honeycomb cores offer a balanced performance.

- When targeting entry-level or casual players, Polymer honeycomb cores deliver comfort and cost efficiency, though with lower durability.

-

Assess Production Capabilities:

- Confirm that your manufacturing process can handle the specific nuances of each core material. Ensure that high-precision equipment is available if opting for a cold pressing methodology, or that you are prepared for the longer cycle times associated with thermoforming.

-

Consider Cost vs. Performance Trade-offs:

- Evaluate the overall cost implications, including raw materials, labor, and production time. An optimal solution might require a balance between performance characteristics and cost-effectiveness to meet market expectations.

-

Conduct Pilot Testing:

- Before scaling production, consider running pilot tests with each core type to gather empirical data on durability, performance, and customer satisfaction. Such tests can provide valuable insights into potential improvements and material performance in real-world scenarios.

In the dynamic market of pickleball equipment manufacturing, the choice of paddle core material can significantly influence product performance and brand reputation. By understanding the inherent advantages and limitations of Nomex honeycomb, Aluminum honeycomb, and Polymer honeycomb cores, B2B buyers can tailor their production strategies to meet the specific demands of their target markets. Coupled with a detailed analysis of production techniques such as hot pressing, cold pressing, and thermoforming, these material comparisons provide a concrete foundation for informed decision-making.

For companies striving to enhance their product offerings, balancing durability, performance, and cost is key. Leveraging advanced production techniques alongside precise material selection will ultimately lead to products that not only meet but exceed customer expectations. Act now by testing different core options, reviewing production methodologies, and aligning your sourcing decisions with market needs.

Q: What are the main advantages of using a Nomex honeycomb core in pickleball paddles?

A: Nomex honeycomb cores offer superior shock absorption, excellent durability, and enhanced structural stability, making them ideal for high-impact competitive play.

Q: How does an Aluminum honeycomb core compare with other paddle cores?

A: Aluminum honeycomb cores provide a balanced blend of strength and control, offering consistent rebound performance and precise weight distribution, suitable for a broad range of players.

Q: Why might a manufacturer choose a Polymer honeycomb core for their pickleball paddles?

A: Polymer honeycomb cores are chosen for their elasticity and vibration reduction capabilities, delivering enhanced comfort and a cost-effective solution ideal for recreational players.

-

Nomex honeycomb: Read the article to understand its high shock absorption and structural integrity, as well as the specialized manufacturing requirements that make it ideal for competitive sports equipment. ↩ ↩ ↩2

-

Aluminum honeycomb: Read the article to learn how aluminum honeycomb achieves a balance of strength and weight efficiency, making it a popular choice for precision-engineered sports products. ↩ ↩ ↩2

-

Polymer honeycomb: Read the article to explore how polymer honeycomb offers vibration reduction and cost benefits, particularly suited for recreational sports equipment applications. ↩ ↩ ↩2

-

Hot pressing: Read the article to gain insights into how the hot pressing process creates a high-density, durable core, and why it’s critical for large-scale production in sports equipment manufacturing. ↩ ↩

-

Thermoforming: Read the article to understand how thermoforming is used to mold materials into precise shapes, ensuring optimal material distribution and performance in custom sports products. ↩ ↩