High-performance pickleball paddles are best selected by carefully evaluating materials, production processes, and overall performance specifications such as durability, shock absorption, and customization options. This approach ensures that your paddle not only meets the demands of competitive sports but also aligns with cost efficiency and quality standards for B2B procurement.

High-performance paddles are built on several key factors. Primarily, a paddle’s material composition and production technique directly impact its playability and durability. For businesses looking to invest in quality equipment, understanding these technical details is crucial. NEX Pickleball leads with advanced manufacturing processes, ensuring that each paddle delivers consistent high performance for competitive play. In this article, we examine the differences in materials, production processes, and technical specifications to help you navigate your procurement decision.

Material Selection: Carbon Fiber, Fiberglass, and Composite Materials1

High-performance paddles often integrate carbon fiber materials due to their exceptional strength and lightness. Here are the types commonly used:

- 3K Carbon Fiber: Offers excellent strength and flexibility, reducing paddle vibrations. It’s known for delivering a high rebound force which is crucial for rapid ball response.

- 12K Carbon Fiber: With a higher thread density, this material provides a smoother surface, enhanced hardness, and improved durability. This makes it ideal for intense impacts during competitive play.

- T300 Carbon Fiber: Praised for its outstanding tensile strength, this high-performance fiber strikes an optimal balance between durability and weight efficiency.

These carbon fiber types ensure that players can enjoy superior control, faster rebounds, and enduring performance under pressure.

Fiberglass paddles bring a balanced approach, blending power and control. They offer a wider sweet spot and maintain excellent flexibility for improved ball handling. Specifically, E-Glass Fiberglass is recognized for its high elasticity and tensile strength, making it a reliable option for paddles focused on ball control and precision.

Recognizing that no single material can meet every performance demand, many paddles today use composite materials that combine the benefits of various fibers:

- Carbon Fiber and Fiberglass Composite: This combination embodies the strengths of both materials, providing a balance between power and control.

- Bamboo Core Composite: Bamboo cores add a lightweight advantage and high impact resistance, ensuring a clear and responsive hitting feel.

- Honeycomb Core: Known for superior shock absorption, honeycomb cores reduce vibrations and enhance overall paddle longevity. They are crafted using high-density polymers or natural pulp.

By blending these materials, manufacturers can tailor paddles for diverse playing styles, whether emphasizing power, precision, or comfort.

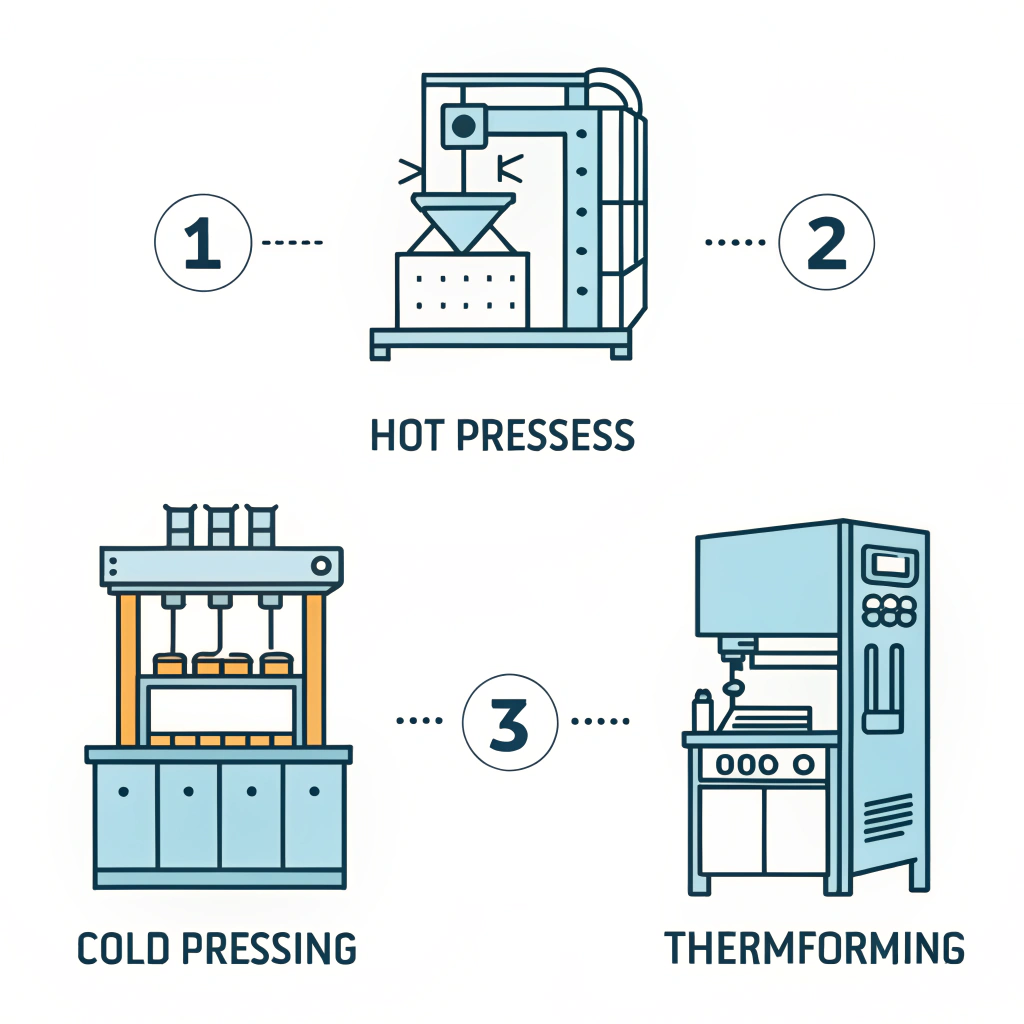

Production Processes: Hot Pressing2, Cold Pressing3, and Thermoforming4

The production process plays a critical role in ensuring that high-performance paddles meet rigorous quality standards. NEX Pickleball employs advanced techniques to harness the full potential of each material.

Hot pressing involves heating and then applying pressure to materials, resulting in a paddle with unmatched durability and structural integrity.

- Advantages:

- High production efficiency makes it excellent for large-scale manufacturing.

- Produces paddles with robust impact resistance.

- Ensures a consistent structural bond across the paddle.

- Disadvantages:

- High initial equipment investment.

- Potential slight alteration of material properties which may affect the paddle’s feel.

Cold pressing is a precision method that shapes paddle materials at room temperature, preserving the original properties of the materials.

- Advantages:

- Offers precise control regarding paddle thickness and structure.

- Maintains material integrity, resulting in improved control and flexibility.

- Enhances the natural ball feel during play.

- Disadvantages:

- Longer production cycles compared to hot pressing.

- Requires high-quality, precise pressure equipment for consistent results.

Thermoforming is used for paddles that demand intricate designs and precise material distribution. The method involves heating materials to a pliable state before molding them into the desired shape.

- Advantages:

- Allows for complex shapes and detailed material layouts.

- Enhances paddle stability and overall performance by even distribution of materials.

- Ideal for premium or custom-made products.

- Disadvantages:

- Longer production times and higher equipment costs.

- Best suited for specialized batches rather than high-volume orders.

The table below summarizes the advantages and disadvantages of each production process:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency, robust impact resistance, consistent structure | High equipment investment, potential material alteration |

| Cold Pressing | Precise control over thickness, maintains material integrity, superior ball feel | Longer production cycles, requires precise equipment |

| Thermoforming | Complex designs, precise material distribution, enhanced stability | Higher costs, longer production time |

The core material is central to a pickleball paddle's performance. It determines the paddle's hardness, vibration damping, and overall playability. Common core materials include:

- Nomex Honeycomb Core5: Offers excellent shock absorption and durability, ideal for players demanding long-lasting stability.

- Aluminum Honeycomb Core: Provides balanced weight distribution which supports both power and control.

- Polymer Honeycomb Core: Known for superior elasticity and reduced vibration, offering comfort during prolonged gameplay.

In addition to core materials, ergonomic design such as grip sizes and surface treatment are significant. Customization options allow retailers or sports organizations to select personalized paddles that suit different hand sizes and playing styles. This level of customization not only improves user experience but also enables branding opportunities for teams and events.

For B2B procurement managers, quality control is a critical factor. At NEX Pickleball, each paddle undergoes rigorous testing to ensure consistency in performance metrics such as rebound effect, shock absorption, and overall durability. Our combination of advanced production techniques and comprehensive quality checks, such as vibration tests and weight distribution analysis, ensures that every paddle meets high-performance benchmarks.

Customization options are crucial for meeting diverse market needs. From specifying paddle weight and balance to choosing the exact mixture of carbon fiber and fiberglass, manufacturers enable clients to tailor products to their unique requirements. Such flexibility is particularly valuable in meeting the demands of professional players or distributing brands that need distinctive equipment.

Many sports equipment distributors have reaped significant benefits by choosing paddles manufactured through these advanced processes. For example, a major distributor in North America reported a 20% increase in customer satisfaction after switching to paddles made with T300 carbon fiber and a polymer honeycomb core. The enhanced shock absorption led to fewer product returns and improved player performance on the court.

Another case involved a European retailer who opted for a cold pressing process to ensure that the paddle preserved a natural ball feel. This adjustment resulted in higher repeat orders as players preferred the paddle’s responsiveness and control. Such case studies provide tangible evidence that detailed attention to material composition and production methods directly translates into better market performance.

- Conduct a Needs Analysis: Evaluate what characteristics are most important for your target market. Are players looking for maximum power, superior control, or enhanced durability?

- Review Production Techniques: Understand the benefits and limitations of hot pressing, cold pressing, and thermoforming to align production methods with product expectations.

- Customize Specifics: Consider options for customizations, such as grip size, weight balance, and material hybrids, which can differentiate your products in a competitive market.

- Examine Core Material Choices: Evaluate how different core materials like Nomex, aluminum, or polymer honeycomb can impact performance in terms of shock absorption and durability.

- Quality Assurance Checks: Ensure that your manufacturing partner employs rigorous testing methods to deliver consistent product quality.

By thoroughly assessing these factors, you can confidently select high-performance paddles that satisfy market standards and your business objectives.

In summary, selecting the right pickleball paddle involves more than just considering superficial features. A deep dive into material choices like carbon fiber variants, fiberglass, and composite materials, combined with an understanding of advanced production techniques such as hot pressing, cold pressing, and thermoforming, is essential. Coupled with strategic quality control and customization options, these factors ensure that your product will meet the high-performance needs of competitive players.

For B2B procurement managers, this comprehensive understanding allows you to make well-informed decisions and partner with manufacturers like NEX Pickleball who are committed to technical excellence and reliability. Ultimately, these steps will not only enhance customer satisfaction but also boost your market position in the sports equipment industry.

How do I know which pickleball paddle to buy?

When looking for a pickleball paddle, assess critical factors including weight, grip size, materials used (such as different types of carbon fiber or fiberglass), the paddle’s shape, and its core material. Evaluate how each feature aligns with the playing style and skill level of your target audience.

Do more expensive pickleball paddles make a difference?

Higher-end paddles often incorporate advanced materials like high-grade carbon fiber and specially engineered cores. These paddles provide improved control, power, and reduced vibrations, leading to a better overall performance on the court. However, the highest price doesn’t always guarantee the best fit for every player's needs.

Do you want 16mm or 13mm pickleball paddle?

The choice between a 16mm and a 13mm paddle primarily depends on the player's strategy. A 13mm paddle may favor outright power and quicker shots, while a 16mm paddle typically offers better control and a more measured response, ideal for players who value precision and a softer ball feel.

-

Composite Materials: Read this article to understand how composite materials blend multiple fibers to optimize performance, offering benefits like enhanced durability, weight efficiency, and customization potential. ↩ ↩

-

Hot Pressing: Click here to explore how the hot pressing process improves production efficiency and structural integrity, while also considering its equipment investment and material property effects. ↩ ↩ ↩2

-

Cold Pressing: Discover more about cold pressing to learn how this method preserves material integrity for optimal control and natural ball feel during play. ↩ ↩ ↩2

-

Thermoforming: Learn about thermoforming and its advantages in achieving complex designs and precise material distribution for premium, custom-made products. ↩ ↩ ↩2

-

Honeycomb Core: Explore the benefits of honeycomb core technology, including superior shock absorption, vibration reduction, and impact resistance that contribute to paddle longevity. ↩ ↩