A pickleball paddle’s balance point is typically measured at the center of gravity, and fine-tuning this balance through weight distribution adjustments can significantly enhance play performance and control. In this article, we explore how to accurately measure and adjust the balance point of pickleball paddles, discuss the influence of various production methods on weight distribution, and provide actionable solutions for improving paddle performance.

Measuring and adjusting the balance point is a critical aspect of paddle design that impacts power, control, and overall playability. A well-balanced paddle enables players to achieve rapid response, reduce fatigue, and enjoy a more comfortable hitting experience. For technical product managers and quality assurance specialists, understanding these nuances is essential for refining product design and ensuring premium performance.

A pickleball paddle is more than just a sports implement; it is a finely tuned tool where every gram of weight matters. The balance point, essentially the center of gravity, dictates how the paddle behaves during play. A paddle with a forward balance (weight concentrated near the head) can generate more power, while a more evenly distributed paddle offers enhanced control and maneuverability.

- Material Composition: The choice of materials, such as carbon fiber1 (including varieties like 3K, 12K, and T300) and fiberglass, significantly affects weight distribution.

- Core Materials: Cores made from Nomex Honeycomb Core2, aluminum honeycomb, or polymer honeycomb bring different mass and compression properties to the paddle, influencing the center of gravity.

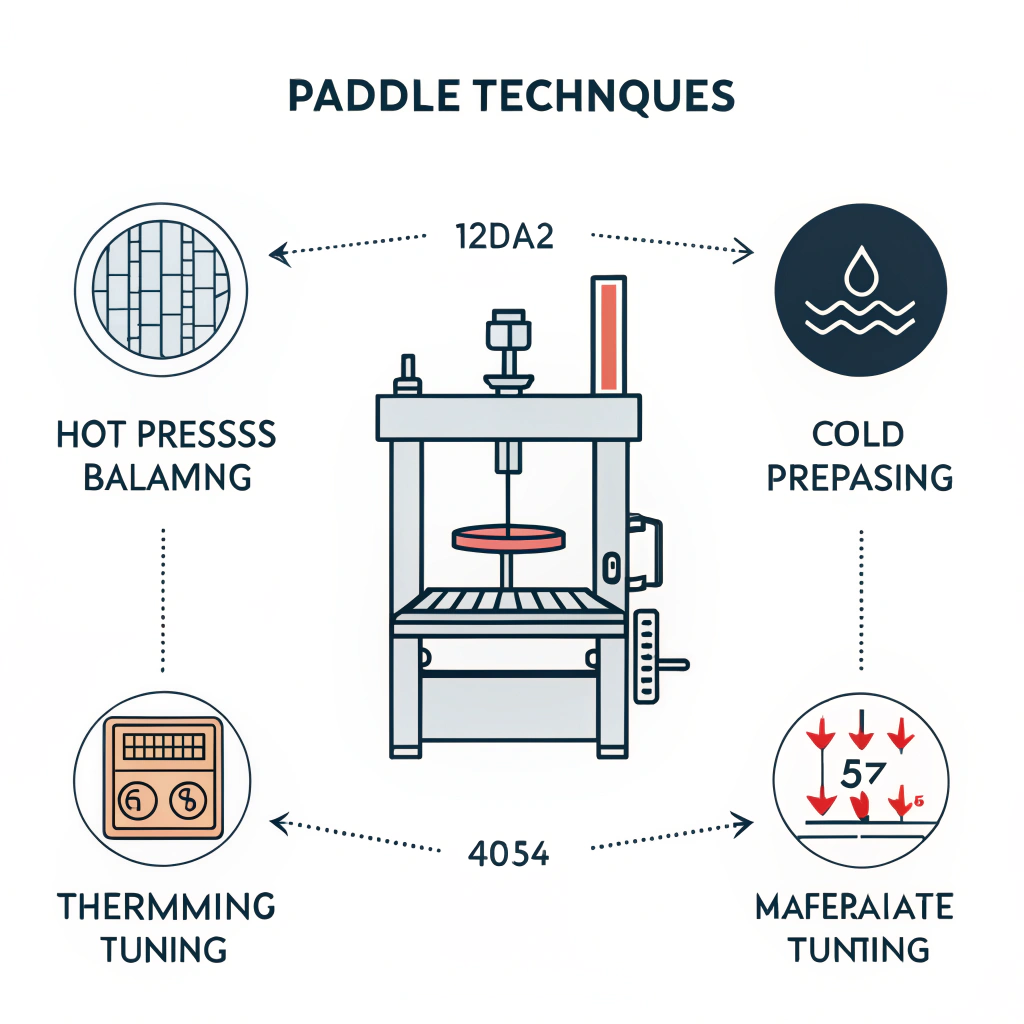

- Production Techniques: Processes such as hot pressing, cold pressing, and thermoforming can alter the density, thickness, and ultimately, the balance of the paddle.

Understanding how these factors interact is essential when setting up a manufacturing process that ensures a consistent balance point across all produced paddles.

Accurate measurement of the paddle’s balance is the foundation for any adjustment or optimization. Traditional and modern methods include:

Using a simple yet effective approach, the fulcrum method involves:

- Placing the paddle on a thin edge or cylindrical rod.

- Finding the exact point where the paddle remains horizontal.

- Marking this balance point as the center of gravity.

This method is widely used due to its simplicity and reliability.

Advanced manufacturing facilities often integrate digital scales and sensors:

- The paddle is placed on a sensor-equipped platform that can precisely calculate the center of gravity.

- Data is captured in real time, aiding in quality control and iterative design adjustments.

Modern production methods incorporate simulation:

- Using CAD software to model the paddle’s structure and material properties.

- Simulating weight distribution and balance, enabling pre-production adjustments.

Each method has its merits. The fulcrum method remains popular for its ease of implementation, whereas digital scales and simulation offer higher precision suitable for high-performance paddles.

Once the balance point is measured accurately, the next step is to adjust it to achieve optimal performance. Below is a detailed solution-oriented approach, including possible adjustments and critical considerations.

-

Identify the Target Balance

Determine the desired balance point based on the intended play style:- Competitive players might favor a paddle with a forward bias to maximize power.

- Recreational players may require a balanced paddle that enhances control and comfort.

-

Analyze Material Distribution

Figure out how different materials contribute to weight:- Carbon Fiber and Fiberglass Composites: Offer strength with lightweight performance. Adjust the ratio to modify weight distribution.

- Core Adjustments: Substituting a Nomex Honeycomb Core with an aluminum honeycomb core can shift the balance point closer to the head or handle as needed.

-

Optimize Production Techniques

Different manufacturing processes contribute uniquely:- Hot Pressing3: Offers high production efficiency and strong paddle structures but might alter the material feel.

- Cold Pressing4: Improves precision in thickness and structure while preserving material properties.

- Thermoforming5: Aids in creating intricate designs that can evenly distribute materials.

-

Iterative Testing and Validation

After making adjustments, test the paddle:- Use the fulcrum method or digital scales to re-assess the balance.

- Implement feedback from player testing to refine further.

| Production Process | Impact on Weight Distribution | Pros | Cons |

|---|---|---|---|

| Hot Pressing | Slight material property changes; strong impact resistance; can lead to a forward balance | High efficiency; strong, durable paddles | May alter the natural feel of materials |

| Cold Pressing | Preserves material properties; allows for fine-tuning | Precise control over structure; excellent ball feel | Longer production cycles; requires high-precision equipment |

| Thermoforming | Superior design flexibility; intricate material distribution | Allows for complex paddle designs; maintains stability | Longer production time; higher equipment cost |

By considering the above table, decision-makers can select the production method that best aligns with the balance performance objectives.

- 3K Carbon Fiber: Flexible and strong, ideal for paddles that need high rebound force.

- 12K Carbon Fiber: Provides a smoother surface and increased hardness, making it perfect for competitive play.

- T300 Carbon Fiber: Balances strength and lightness, resulting in an evenly distributed paddle suitable for versatile play.

- E-Glass Fiberglass: Delivers excellent elasticity and control.

- Composite Options: Combining carbon fiber and fiberglass can yield a paddle that balances both power and control. Similarly, using a bamboo core composite or honeycomb core provides unique weight profiles that can be adjusted to tailor balance.

Core materials play a pivotal role in dictating the paddle's feel:

- Nomex Honeycomb Core2: Provides robust shock absorption, offering long-term durability.

- Aluminum Honeycomb Core: Balances power and precision but may add weight towards the paddle's central region.

- Polymer Honeycomb Core: Enhances elasticity, resulting in reduced vibrations and increased comfort.

Changing the core material allows for a shift in the center of gravity with minimal adjustments to the paddle’s overall dimensions.

Different production techniques provide varied opportunities for balance tuning:

- Fine-tune the pressing temperature and duration to control the material compression.

- Adjust the layer stacking sequence for consistency in weight distribution.

- This method is ideal for large-scale production where uniformity is key.

- Utilize precision molds to achieve the desired shape and thickness.

- Gradually adjust the pressure and duration to maintain the desired material properties.

- This is beneficial when slight changes in structure significantly impact the paddle’s feel and balance.

- Customize mold shapes to create a paddle with a designed focal balance.

- Integrate temperature-controlled processes to ensure uniform softening and material distribution.

- Suited for premium products or custom paddle orders where balance tuning is critical.

To maintain consistent quality and optimal performance, manufacturers should implement rigorous quality control standards:

- Consistent Testing: Integrate regular balance measurement tests on production lines using both manual (fulcrum) and digital methods.

- Data-Driven Adjustments: Record balance point measurements for each production batch and use this data to calibrate machinery and adjust material input accordingly.

- Iterative Prototyping: Utilize CAD simulations alongside physical testing to continuously refine paddle designs before mass production.

- Feedback Loop: Ensure that feedback from players and in-field tests feeds back into the production process for continuous improvement.

These quality control practices help minimize discrepancies in balance across paddles and ensure every unit meets the desired performance standards.

For technical product managers, quality assurance specialists, and procurement officers evaluating pickleball paddles, the key to success lies in understanding how to precisely measure and adjust the balance point. By leveraging a combination of measurement methods, material adjustments, and production technique optimizations, manufacturers can create paddles that deliver both power and control, tailored to the demands of competitive play.

In summary:

- Begin with accurate balance measurement using either the fulcrum method, digital scales, or simulation.

- Adjust material composition and core selection to fine-tune the center of gravity.

- Optimize production processes (hot pressing, cold pressing, thermoforming) to achieve the desired weight distribution.

- Implement rigorous quality control and continuous feedback integration to sustain product excellence.

For businesses seeking to refine their product offerings, partnering with an experienced manufacturer like NEX Pickleball ensures access to advanced production techniques, consistent quality, and reliable performance tuning. These steps will arm you with the technical insights necessary to make data-backed procurement decisions and elevate your product portfolio in a competitive market.

People Also Ask

Q1: How do you accurately measure the balance point of a pickleball paddle?

A1: The most common method is the fulcrum method, where the paddle is balanced on a thin edge to locate its center of gravity. Digital scales and CAD simulations can further enhance precision.

Q2: What production methods can influence the weight distribution in a paddle?

A2: Production techniques such as hot pressing, cold pressing, and thermoforming significantly affect weight distribution by altering material density and structure.

Q3: How do core materials impact the balance and performance of a pickleball paddle?

A3: Core materials like Nomex, aluminum, and polymer honeycomb each contribute different weight and shock absorption properties, allowing manufacturers to adjust the paddle’s balance for optimal power and control.

-

Carbon Fiber: Click to explore an in-depth explanation of carbon fiber’s properties, including its types (3K, 12K, T300), benefits in weight reduction, and impact on the strength and performance of high-performance sports equipment. ↩ ↩

-

Nomex Honeycomb Core: Click to read about the technical attributes of Nomex honeycomb cores, such as shock absorption, durability, and how they influence the overall balance and playability of sporting equipment. ↩ ↩ ↩2

-

Hot Pressing: Click for detailed information on hot pressing, a manufacturing process that enhances production efficiency, material bonding, and strength while affecting the balance of composite products. ↩ ↩

-

Cold Pressing: Click to learn about cold pressing, a precision manufacturing technique that retains material properties and allows for fine adjustments in thickness and weight distribution of composite products. ↩ ↩

-

Thermoforming: Click to discover how thermoforming enables custom designs and intricate material distributions, allowing manufacturers to optimize product balance and achieve high-quality finishes in production. ↩ ↩